Industrial Fan Manufacturers Training with Axial Flow Fan Production Line In Spain From Altron

Comprehensive Insight into Axial Flow Fan Production Lines

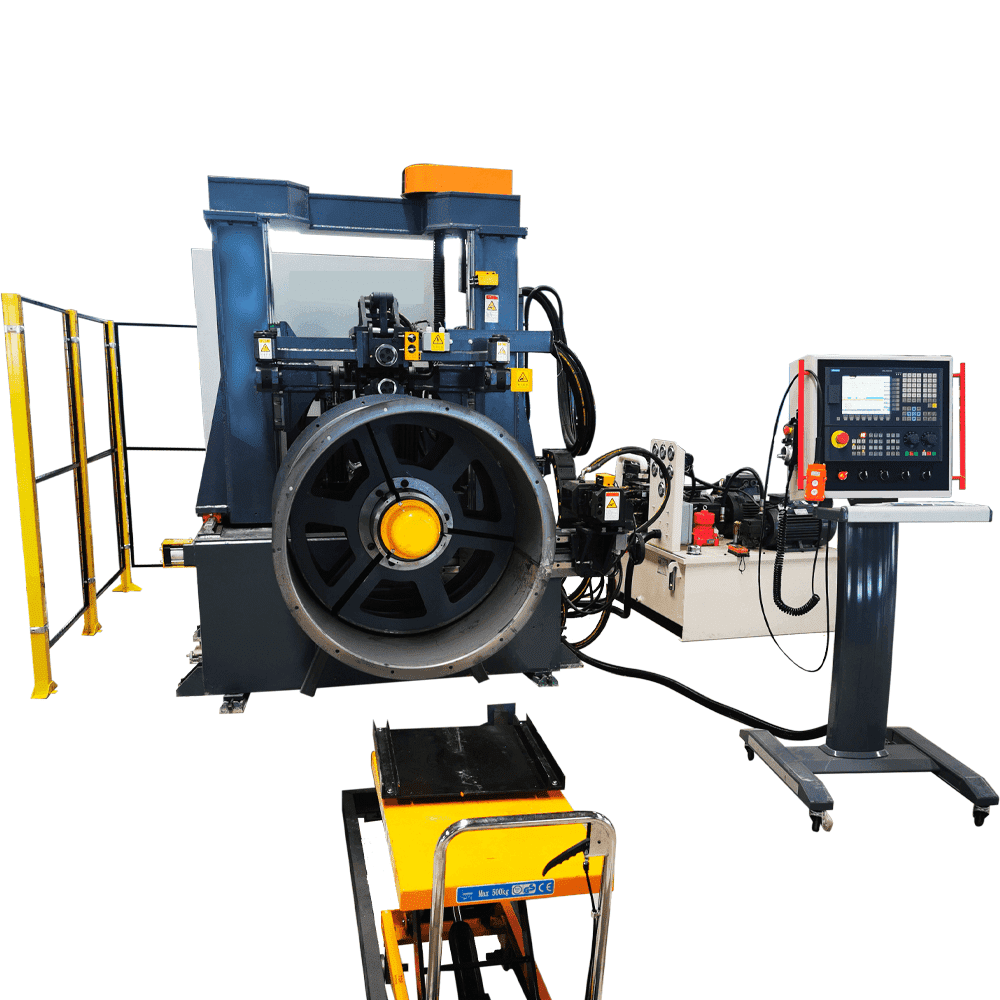

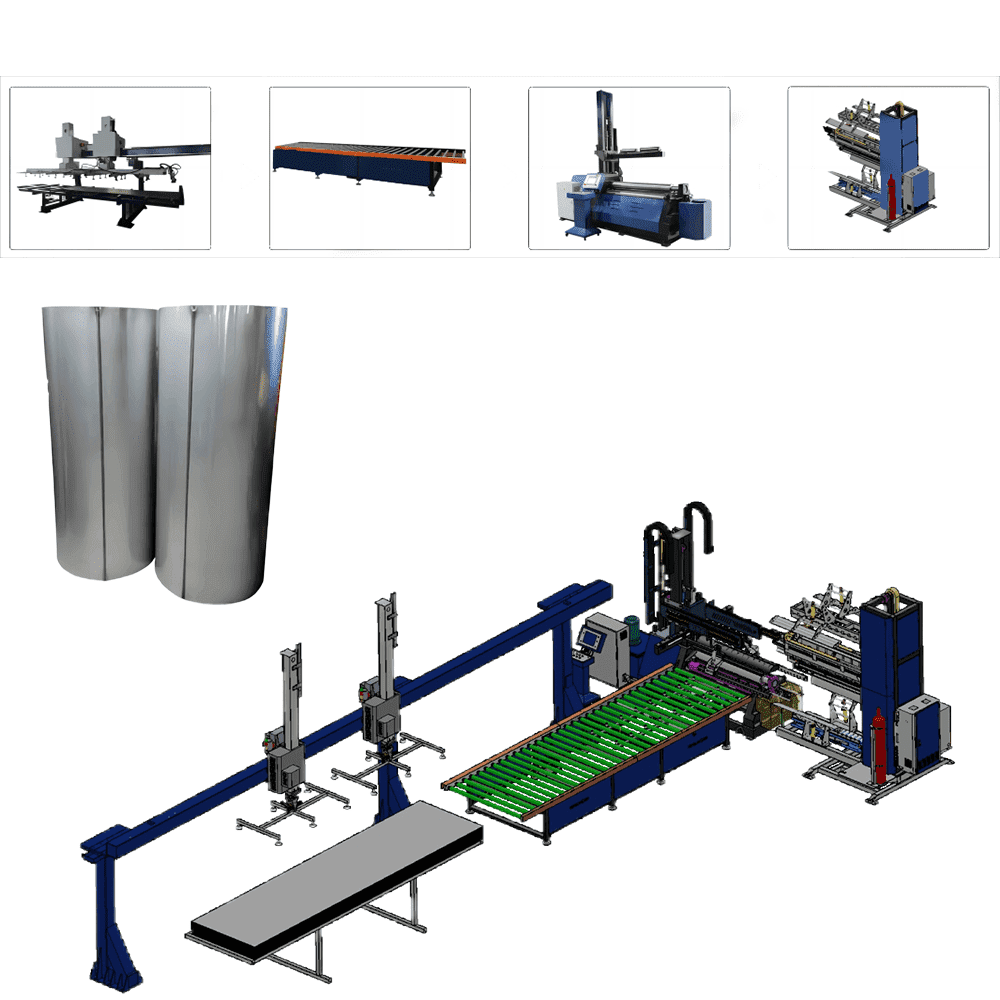

The Industrial Fan Manufacturers Training , Axial Fan Production Line:CNC Rolling Machine, Automatic Straight Seam Welding Machine, CNC Flanging Machine.

Altron recently conducted an intensive training program in Spain, focusing on the operational Axial flow Industal Fan production line training. This specialized initiative aimed to equip industrial fan manufacturers with advanced techniques encompassing rolling, welding, flanging, and punching, essential for optimizing production processes and ensuring top-notch quality.

The utilization of production lines in manufacturing axial flow fans requires a nuanced understanding of various techniques and processes. Altron’s training program was meticulously structured to delve into the core aspects of these production lines, offering a comprehensive insight into the intricate operations involved.

Rolling Techniques:

Precision in Fan Component Formation

One of the fundamental elements covered in the training revolved around rolling techniques integral to shaping fan components. Participants were immersed in detailed sessions, unraveling the complexities involved in selecting materials, executing precise rolling methodologies, and evaluating their impact on the overall performance of axial flow fans.

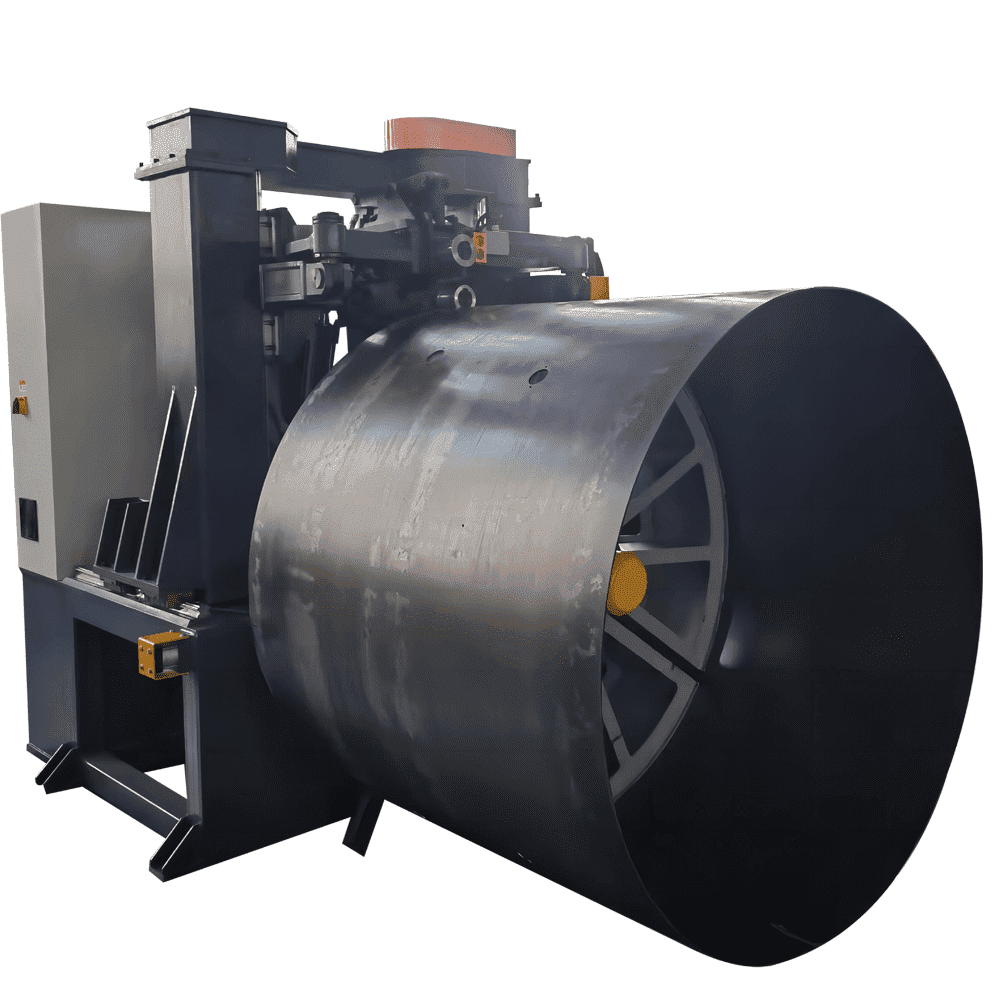

The metal rolling process is integral in the production of industrial axial flow fans, shaping crucial components to ensure optimal performance. This technique involves manipulating metal sheets to create cylindrical parts essential for fan assembly.

Initially, the process begins with flat metal sheets, typically aluminum, steel, or alloys, chosen for their durability and compatibility with fan manufacturing requirements. These sheets undergo precision cutting to achieve the desired dimensions, ensuring they align with the specific fan component being produced.

The metal rolling process employs specialized machinery called rolling mills. These mills feature rollers that exert pressure on the metal sheet, gradually altering its shape. The primary objective is to transform the flat sheet into cylindrical forms that constitute essential elements of axial flow fans, such as fan blades or housing components.

As the metal sheet passes through the rolling mill, the rollers exert controlled pressure, progressively curving the sheet. This gradual deformation ensures a uniform curvature, crucial for maintaining structural integrity and ensuring consistency in the final product. The rollers’ configuration and adjustments determine the diameter and thickness of the rolled metal, shaping it precisely according to design specifications.

Precision and accuracy are paramount in the metal rolling process. Operators monitor and regulate the pressure, speed, and alignment of the rollers to achieve the desired curvature without compromising the metal’s integrity. Factors like material thickness, ductility, and the desired curvature radius influence the rolling parameters, demanding a meticulous approach for each fan component.

Furthermore, the rolling process may involve multiple passes through the rolling mill to achieve the precise dimensions and curvature required for axial flow fan components. Each pass refines the shape, incrementally adjusting the metal until it conforms to the specified measurements.

Quality checks are conducted throughout the process to ensure the integrity and accuracy of the rolled metal. Inspections ascertain the uniformity, smoothness, and dimensional accuracy of the cylindrical components, addressing any imperfections to meet stringent industry standards.

The metal rolling process stands as a fundamental stage in the production of industrial axial flow fans, showcasing the meticulous manipulation of metal sheets to create precisely shaped components essential for efficient and reliable fan systems. This technique exemplifies the precision and expertise required in manufacturing high-performance industrial equipment.

CNC rolling process:

According to the unfolded size of the industrial axial flow fan casing, load and unload the material on the laser cutting machine, and cut the required motor bracket mounting holes and inspection windows at the same time. In the case of larger windows, the non-cutting process can be used, so that It prevents damage to the machine’s rollers and molds during the rolling and flanging process, and is also safer.

Put the metal plate into a CNC rounding machine with set parameters. The plate will be formed by four rollers according to the set program, and the metal plate will be bent into a round shape with a specific diameter.

Welding Mastery: Ensuring Structural Integrity

The training placed significant emphasis on welding methodologies specifically tailored to axial flow fan manufacturing. Attendees gained in-depth knowledge about the diverse welding methods, their applicability, strengths, and potential challenges. Understanding these aspects is crucial in ensuring the structural integrity and longevity of fan components.

The metal rolling process is pivotal in crafting essential components of industrial axial flow fans, involving the manipulation of metal sheets into precise cylindrical shapes. This technique is fundamental in shaping fan blades, housings, and other critical elements vital for optimal fan performance.

At the outset, flat metal sheets, often aluminum, steel, or specialized alloys, are chosen for their durability and compatibility with fan manufacturing requirements. These sheets undergo meticulous cutting to attain precise dimensions, ensuring alignment with the specific fan components to be fabricated.

The metal rolling process is facilitated by specialized machinery known as rolling mills. These mills feature rollers that apply controlled pressure on the metal sheet, gradually altering its form. The primary goal is to transform the initially flat sheet into cylindrical shapes, integral to the construction of axial flow fans.

As the metal sheet advances through the rolling mill, the rollers exert carefully regulated pressure, progressively curving the sheet. This gradual deformation ensures uniformity in curvature, preserving structural integrity and ensuring consistency in the final components. The roller configurations and adjustments dictate the diameter and thickness of the rolled metal, precisely adhering to design specifications.

Precision and accuracy are paramount in the metal rolling process. Operators meticulously monitor and regulate the pressure, speed, and alignment of the rollers to achieve the desired curvature without compromising the metal’s integrity. Factors such as material thickness, ductility, and the desired curvature radius significantly influence the rolling parameters, demanding a methodical approach for each fan component.

Moreover, the metal rolling process may involve multiple passes through the rolling mill to achieve the precise dimensions and curvature required for axial flow fan components. Each pass refines the shape, incrementally adjusting the metal until it conforms precisely to the specified measurements.

Throughout the process, stringent quality checks are conducted to ensure the integrity and accuracy of the rolled metal. Inspections scrutinize the uniformity, smoothness, and dimensional accuracy of the cylindrical components, addressing any imperfections to comply with rigorous industry standards.

The metal rolling process stands as an indispensable stage in the production of industrial axial flow fans, showcasing the intricate manipulation of metal sheets to create precisely shaped components essential for the efficiency and reliability of fan systems. This technique underscores the precision and expertise required in manufacturing high-performance industrial equipment.

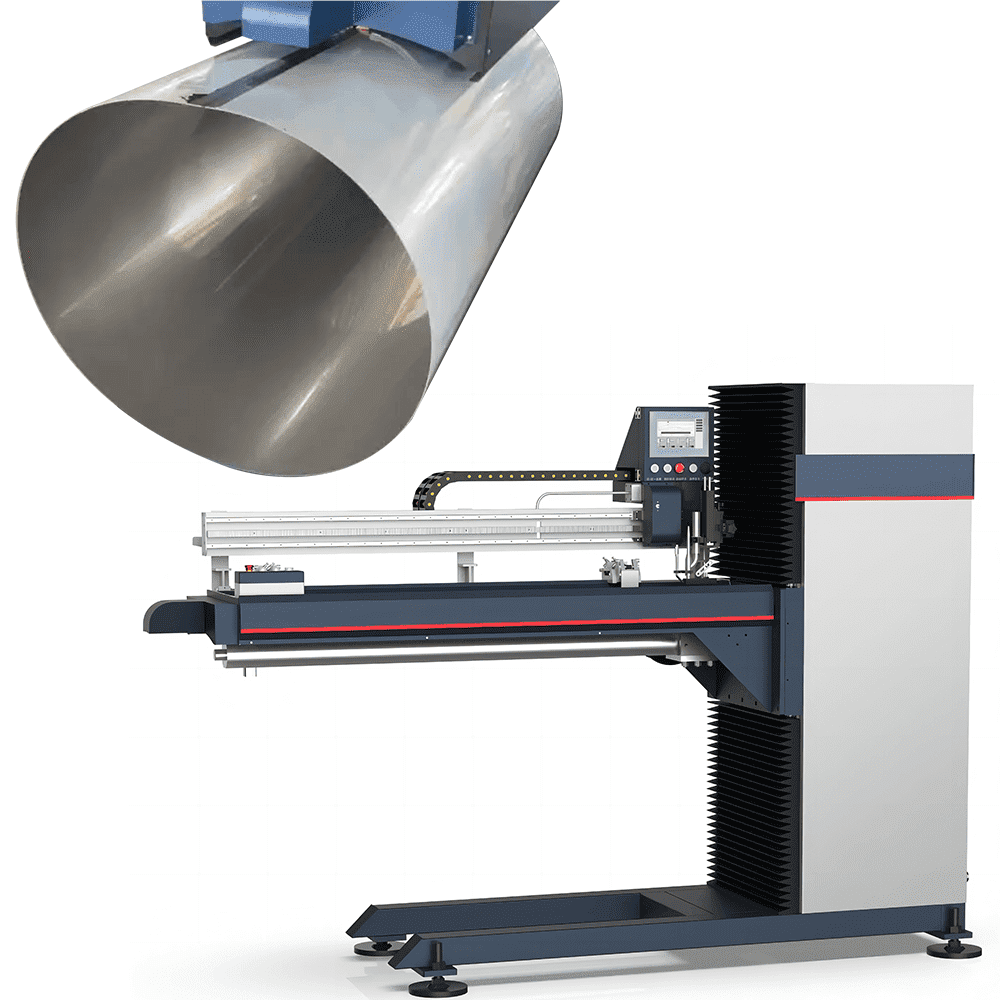

Welding process:

Different welding machines are selected according to different metal sheets:

Carbon steel: argon arc welding (GIT) gas shielded welding (MIG)

Galvanized sheet: Argon arc welding (GIT)

Stainless steel: argon arc welding (GIT)

Aluminum: laser welding argon arc welding (GIT)

Depending on the selection of different welding machines, the welding structure on the automatic welding machine will be different. The actual production needs must be referred to for details.

As mentioned above, we have talked about completing the rounding on the CNC rounding machine. Next, we use an automatic welding machine to complete the welding of the cylinder to ensure that the welding water penetrates the plate, thereby ensuring the welding strength and no cracking during the flanging process of the next process.

Flanging Proficiency:

Precision and Dimensional Accuracy

Flanging, a critical stage in fan assembly, received dedicated attention during the training sessions. Professionals were guided through the intricate techniques and precision required in flanging processes, highlighting the paramount importance of dimensional accuracy and material compatibility in achieving optimal results.

Flanging technology is pivotal in the production of industrial axial flow fans, playing a crucial role in shaping and assembling fan components with precision and structural integrity.

Primarily, flanging involves the process of forming edges on metal components, typically fan housings or structural elements, to create a flange. This flange serves various purposes, including providing reinforcement, facilitating connections, and ensuring compatibility with other fan parts.

The initial phase of flanging begins with carefully prepared metal sheets, usually aluminum, steel, or alloys suitable for fan construction. These sheets are meticulously cut to specific dimensions before entering the flanging process.

The flanging technique utilizes specialized machinery, such as flanging presses or machines equipped with flanging dies. These machines are designed to manipulate the metal sheet, precisely forming the desired flanges according to precise measurements and design specifications.

Operators meticulously position the metal sheets within the flanging machines, ensuring precise alignment and accuracy in the formation process. The machines apply controlled pressure to shape the edges of the metal, creating flanges with defined dimensions and shapes.

The process involves bending or folding the edges of the metal sheet, resulting in the creation of flanges that are integral to the structural integrity and assembly of axial flow fans. The formed flanges often feature specific angles, widths, and shapes tailored to seamlessly integrate with other fan components during assembly.

Flanging technology extends beyond merely shaping edges; it ensures the uniformity, strength, and compatibility of flanges with other parts of the fan. This precision is crucial in maintaining the overall efficiency and performance of the axial flow fan system.

Quality checks are conducted throughout the flanging process to verify the accuracy, dimensions, and consistency of the formed flanges. Inspections aim to detect any deviations or imperfections, ensuring compliance with stringent industry standards.

In essence, flanging technology stands as a fundamental aspect of manufacturing industrial axial flow fans, showcasing the meticulous shaping and assembly of components to create fan structures that meet exacting specifications. This technique underscores the precision and expertise essential in crafting high-quality and efficient industrial fan systems.

Flanging process:

According to different production needs, you can choose CNC flanging machine: PLC flanging machine; the main difference between these two machines is the intelligent operation. The CNC flanging machine can automatically process arc flanges through programs, while the PLC Flanging machine Flanging wheels with different arc data need to be manufactured.

Put the welded cylinder into the CNC flanging machine. Set the program in the machine, and the machine will automatically complete flanging and CNC punching. When processing the other side flange, you need to manually rotate the cylinder to In the other direction, repeat the procedure.

Punching Techniques:

Enhancing Manufacturing Efficiency

An essential facet covered in the program was the incorporation of punching techniques within production lines. Participants were acquainted with the intricacies of precise punching methods, understanding their role in streamlining manufacturing processes and enhancing overall efficiency in fan component creation.

The punching process is a fundamental step in crafting components for industrial axial flow fans, employing specialized techniques to create precise perforations and shapes essential for fan performance.

Initially, the process begins with carefully selected metal sheets, often aluminum, steel, or alloys, chosen for their durability and suitability for fan construction. These sheets undergo precise cutting to attain specific dimensions, aligning them with the intended fan components.

The punching process utilizes specialized machinery equipped with dies designed to create perforations, holes, or intricate shapes in the metal sheets. These machines, such as punching presses, operate with precision to execute the desired patterns according to the fan design specifications.

Operators meticulously position the metal sheets within the punching machines, ensuring accurate alignment and adherence to the intended perforation locations. The machines apply controlled force to the metal, creating perforations or shapes with defined dimensions and configurations.

The punched holes or shapes play a critical role in the functionality and efficiency of axial flow fans. These perforations serve purposes such as facilitating airflow, mounting fan components, or contributing to structural integrity.

The punching process requires a high level of precision to ensure uniformity and accuracy in the perforations created. Operators closely monitor the process to prevent deviations or irregularities that could impact the fan’s performance.

Furthermore, the punching process might involve multiple operations to create various perforation sizes or shapes as per the fan design requirements. Each punch operation is meticulously executed to maintain consistency and precision across all fabricated components.

Quality checks are integral throughout the punching process to verify the accuracy, consistency, and integrity of the created perforations or shapes. Inspections aim to identify any deviations or imperfections, ensuring compliance with stringent industry standards.

In summary, the punching process stands as a vital phase in manufacturing industrial axial flow fans, demonstrating the meticulous creation of perforations and shapes essential for optimal fan performance. This technique underscores the precision and expertise necessary in crafting high-quality and efficient industrial fan systems.

Punching process:

If it needs to be beautiful, the weld needs to be between the two flange holes. You can manually align the weld with the punching mechanism before punching and indexing, and the program will automatically index it according to the number of holes.

Hands-On Training for Practical Mastery

An integral component of the training involved hands-on learning through workshops and simulated production line setups. This practical exposure empowered participants to apply theoretical knowledge in real-time scenarios, refining their skills under expert guidance. Such immersive experiences fostered a deeper comprehension of the manufacturing processes, enabling attendees to optimize techniques for enhanced efficiency.

Empowering Spanish Industrial Fan Manufacturers

Altron’s commitment to advancing technical expertise within the industrial fan manufacturing sector was evident throughout the training program. Armed with newfound knowledge, refined skills, and a deeper understanding of axial flow fan production line operations, professionals emerged ready to elevate production standards, innovate with confidence, and contribute significantly to the evolution of the industry in Spain.

Altron provides production lines or stand-alone semi-automatic production lines for industrial fans, including: CNC spinning, CNC flanging, CNC rolling, automatic welding, robot vision impeller welding, gantry welding and other different processes to provide comprehensive services to industrial fan manufacturers.