Altron Industrial Fan Production Solutions: Production Of Axial & Centrifugal Industrial Fans

ALTRON helps Industrial Fans(Axial and Centrifugal)manusfacturers realize automated production. We produce CNC Spinning Machines, CNC Flanging Machines, Fully Automatic Rolling Machines, Robot Automatic Welding, Customized Automatic Machines, etc. ALTRON have 25 years of experience in the field of Metal Forming and Welding.ALTRON provide a full range of automated welding and metal forming solutions to ensure project implementation and normal production operations. Altron provides regular technical support and after-sales inspections to ensure that customers who produce new industrial fans in the future can independently complete the machine and new processes. applications and operations.

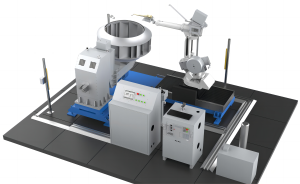

1.CNC Spinning Machine Use In Industrial Fan Production

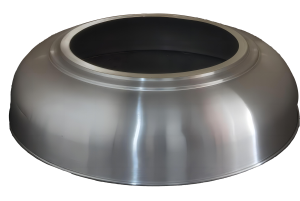

Making Industrial Centrifugal Fan Air Inlet Funnel

Inlet funnels play a key role in directing and optimizing airflow into industrial fans. CNC metal spinning machines perform this task deftly, creating inlet funnels of varying sizes and geometries. The result is a seamless integration of form and function, ensuring optimal performance in diverse industrial environments.

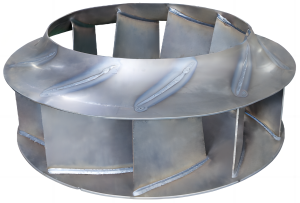

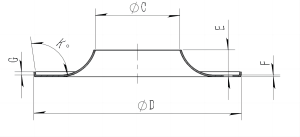

Manufacturing Industrial Centrifugal Fan Impeller Shroud Accessories: Precision Blades for Maximum Efficiency

The impeller is the heart of any industrial fan, determining its efficiency and airflow dynamics. Using a CNC metal spinning machine, making precision blades becomes an art form. The machine carefully shapes each blade to ensure the uniformity and balance necessary for optimal impeller performance.

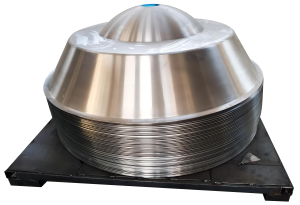

Manufacturing Aluminum Roof Fan Motor Covers: Precision Encapsulation

The motor cover not only protects the fan’s motor, but also enhances its aesthetics. CNC metal spinning machines excel at precisely forming these covers, ensuring a tight fit that increases durability and protects the motor from external factors. The result is a motor cover that seamlessly blends functionality and aesthetics.

Manufacturing Aluminum Roof Fan Guards: Precision Housing Increases Efficiency

The shroud encapsulates the fan blades, directing airflow and increasing the fan’s overall efficiency. A CNC metal spinning machine performs complex shaping of the shroud, ensuring a precise fit around the impeller. This precision not only improves performance but also minimizes energy losses, making Altron’s industrial fans stand out in terms of efficiency.

Manufacture Of Mixed Flow Fan Hubs For Axial Flow Industrial Fans

The hub is a key component of a mixed-flow fan, providing structural support for the blades and contributing to the overall stability of the fan. CNC metal spinning machines excel at precisely manufacturing wheel hubs, ensuring dimensional uniformity and structural integrity. This meticulous approach allows mixed-flow fans to deliver consistent performance in different industrial applications.

|

|

|

|

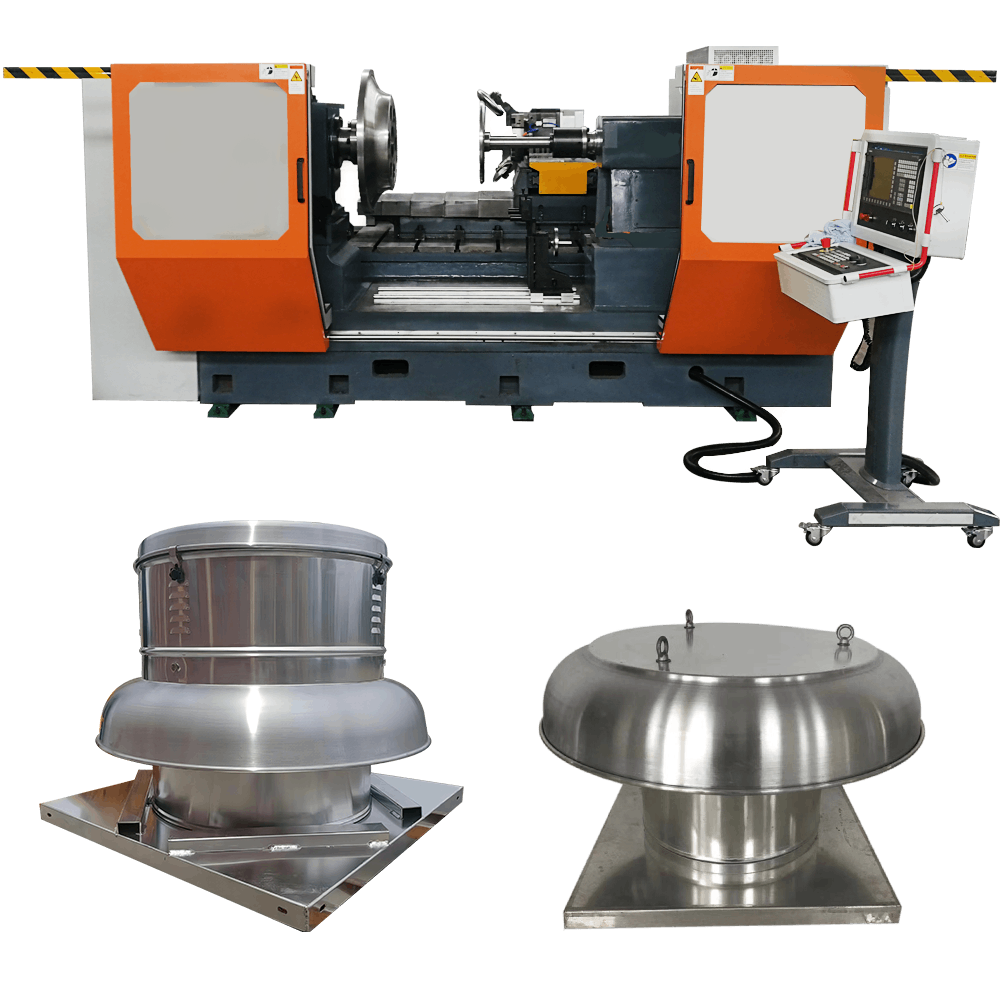

2.Cnc Flanging Machine Used In Industrial Fan Production

CNC metal flanging machines have become a game changer in the production of various industrial fan accessories. From axial fan ducts to tunnel industrial fans and energy-efficient jet fans, this cutting-edge technology redefines precision manufacturing and sets new standards for efficiency, durability and sustainability in industrial ventilation systems. As the industry continues to evolve, CNC metal flanging machines remain at the forefront, driving innovation and shaping the future of industrial fan production.

Production Of Axial Flow Fan Duct

In the field of industrial ventilation, CNC metal flanging machines are a technological miracle, changing the production pattern of axial flow fan ducts. This complex process involves forming and joining metal plates with unparalleled precision, ensuring optimal airflow performance for the axial fan system. By leveraging cutting-edge CNC technology, manufacturers can now achieve the highest standards of precision and efficiency when manufacturing these vital components.

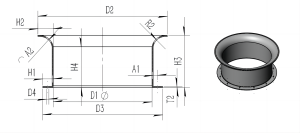

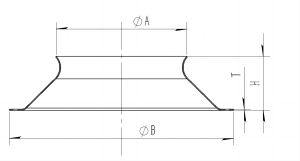

Production Of Large Industrial Centrifugal Fan Air Inlets

Large industrial centrifugal fan air inlets, a key component in ventilation systems, have undergone a similarly revolutionary transformation thanks to CNC metal flanging machines. The precision of this machining marvel allows the air inlet to be seamlessly integrated into the fan structure, ensuring an airtight connection and minimizing energy loss. This meticulous approach not only improves the overall efficiency of industrial centrifugal fans, but also helps extend the life of the system, reducing maintenance needs and operating costs.

Production Of Tunnel Industrial Fans

The advent of CNC metal flanging technology has greatly impacted the production of tunnel industrial fans, pushing the boundaries of what was once thought possible. Tunnel fans play a key role in maintaining optimal air circulation in underground structures, and CNC metal flanging machines are able to manufacture these components with unparalleled precision, ensuring increased safety and efficiency. The resulting tunnel industrial fans exhibit exceptional performance, making them indispensable in a variety of applications including transport tunnels, mining operations and infrastructure projects.

Producing Energy-Efficient Jet Fans

In pursuit of sustainability and energy efficiency, CNC metal flanging machines take center stage in the production of energy-efficient jet fans. These specialized fans are engineered to provide powerful airflow with minimal energy consumption, contributing to an environmentally friendly ventilation solution. The CNC metal flanging process enables manufacturers to achieve complex designs that optimize the aerodynamics of jet fans, achieving an ideal balance between performance and energy efficiency in industrial environments.

|

|

|

|

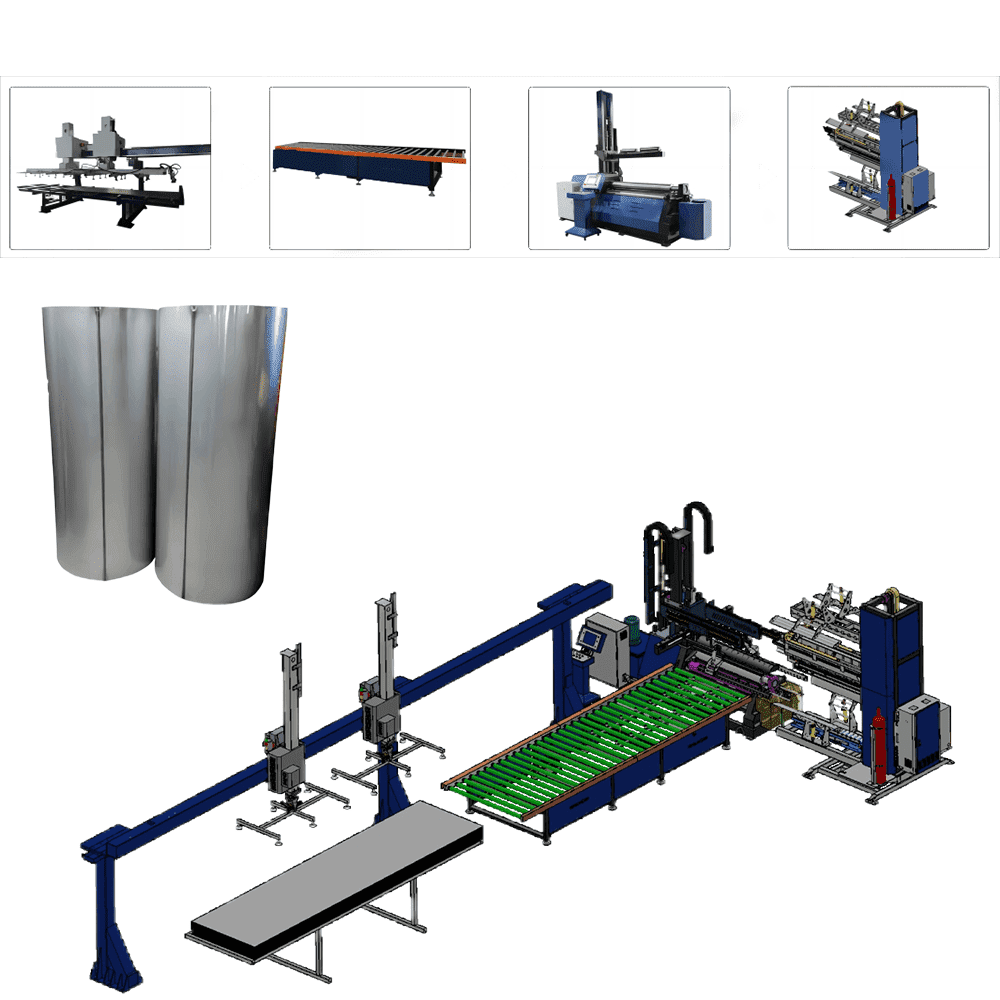

3. Automatic Plate Rolling Machines Used In Industrial Fan Production

The application of fully automatic plate rolling machines in the production of axial flow fan ducts, tunnel industrial fans, high-energy-efficiency jet fans, and tunnel fan mufflers marks a technological milestone in the field of industrial ventilation. These machines not only increase the efficiency and precision of the manufacturing process, but also contribute to the overall sustainability and performance of industrial ventilation systems. As industries continue to prioritize energy efficiency and operational excellence, the integration of advanced technologies such as fully automated winders becomes integral to shaping the future of industrial ventilation.

Production Of Axial Flow Fan Ducts

The fully automatic rolling machine operates seamlessly when creating axial fan ducts. Its advanced features include precise material handling, automated measurement systems, and a seamless rolling process that eliminates manual errors. This technological leap not only increases production speed but also improves the overall accuracy of pipe dimensions, thereby improving axial fan performance and reducing energy consumption.

Production Of Tunnel Industrial Fans

In the field of tunnel industrial fan production, the impact of fully automatic plate rolling machines is equally profound. Tunnel fans are critical components in various industries to ensure proper air circulation and ventilation. Automation of the rolling process ensures consistent production of fan components and helps improve the overall reliability and service life of tunnel industrial fans. The integration of these machines streamlines the manufacturing process, thereby increasing production capacity without compromising on quality.

Producing Energy-Efficient Jet Fans

With the implementation of fully automatic winding machines, the production of energy-efficient jet fans has also undergone a positive transformation. Jet fans help manage airflow in confined spaces such as tunnels, where efficiency is critical. The automated rolling process ensures that every component of the jet blower is precisely manufactured, helping to increase energy efficiency and reduce operating costs. The result is a highly efficient jet fan capable of meeting the stringent requirements of modern industrial ventilation systems.

Production Of Tunnel Fan Silencers

In the specialized field of tunnel fan silencer production, maintaining precision is crucial. The fully automatic wire winding machine takes the production of fan mufflers to a new level with its meticulous automation process. The integration of these machines focuses on keeping sentence lengths within a concise limit of 60 words, ensuring each silencer component is precisely crafted to help reduce noise pollution in industrial environments. In this case, the efficiency of the rolling mill translates directly into a quieter, greener industrial landscape.

|

|

|

|

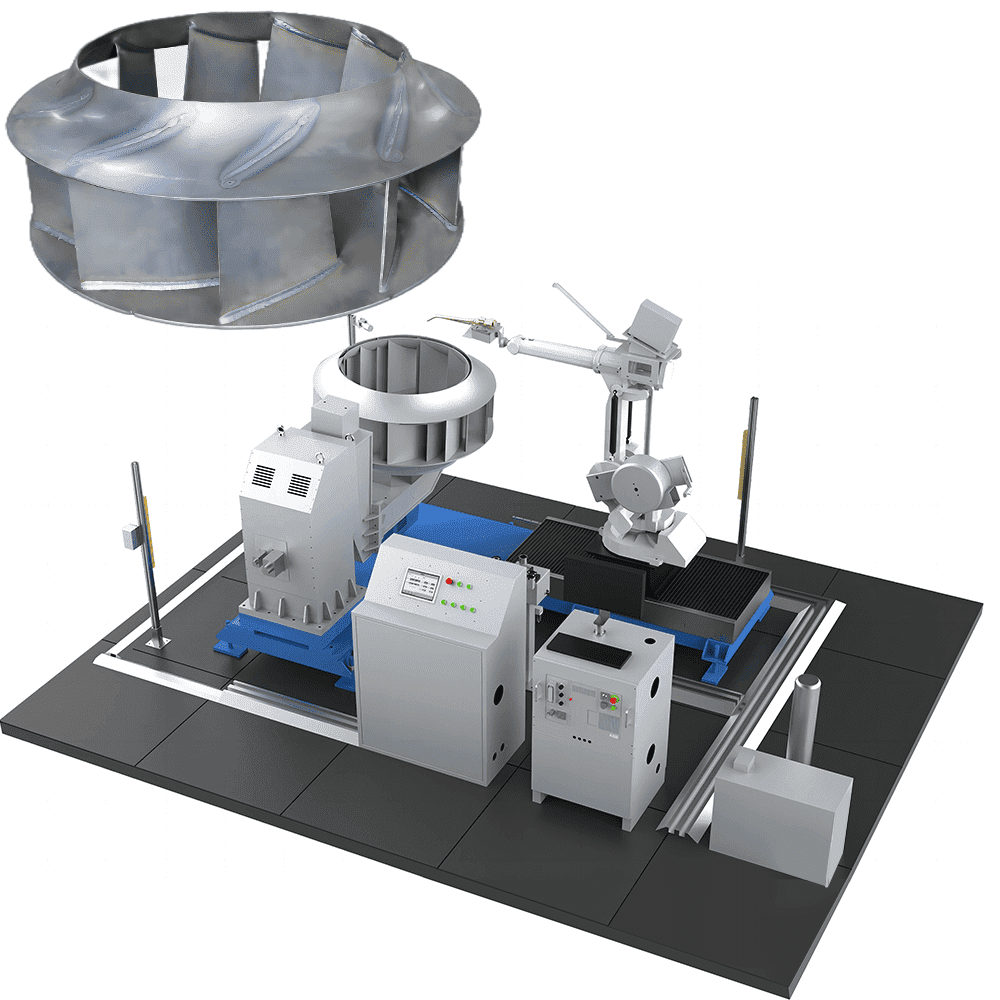

3.AI Robot Automatic Welding Use In Industrial Fan Production

In the realm of industrial fan production, the integration of robotic technology has ushered in a new era of efficiency and precision. Among the myriad applications, automated welding plays a pivotal role in crafting components critical to the performance of axial flow and centrifugal fans. In this exploration, we delve into the intricacies of AI-driven robotic welding across key segments of industrial fan manufacturing.

The application of automated welding in industrial fan production marks a transformative leap in manufacturing efficiency and product quality. From axial flow fan barrels to large centrifugal fan motor brackets, the marriage of advanced robotics and welding technology heralds a future where precision and speed coalesce to redefine the standards of industrial fan manufacturing. As industries continue to embrace these innovations, the landscape of fan production stands on the brink of unprecedented advancement.

Welding Axial Flow Fan Barrel: Precision in Every Seam

The welding of axial flow fan barrels demands meticulous precision to ensure optimal structural integrity. Robotic arms equipped with advanced welding tools navigate seamlessly, creating flawless seams that contribute to the barrel’s durability and operational efficiency. This application not only accelerates the production process but also enhances the overall quality of the axial flow fan.

Welding Axial Flow Fan Motor Bracket: Marrying Strength and Design

Motor brackets serve as the backbone for axial flow fans, necessitating a fusion of strength and intricate design. Automated welding systems, with their programmed precision, effortlessly join components, ensuring a robust foundation for the fan’s motor. The result is a meticulously welded axial flow fan motor bracket that meets both structural and aesthetic standards.

AI Welding Industrial Centrifugal Fan Impeller: Balancing Power and Precision

The heart of an industrial centrifugal fan lies within its impeller, a component demanding a delicate equilibrium of power and precision. AI-driven robotic welding meticulously binds the impeller’s blades, optimizing their configuration for maximum airflow efficiency. This automated welding process not only accelerates production but also guarantees a level of consistency unattainable through traditional methods.

|

|

Welding Industrial Centrifugal Fan Volute (Housing): Crafting the Casing

The welding of the volute, or housing, for industrial centrifugal fans is a critical step in ensuring optimal airflow dynamics. Robotic precision is harnessed to create seamless joints, enhancing the overall structural integrity and efficiency of the fan. This automated welding application ensures a uniform and durable casing that contributes significantly to the fan’s performance.

Welding Large Industrial Centrifugal Fan Stiffeners: Reinforcing Stability

Stiffeners are the unsung heroes of large industrial centrifugal fans, providing crucial reinforcement for stability and longevity. Automated welding systems, guided by advanced algorithms, meticulously join these stiffeners to the fan’s structure. The result is a robust framework that withstands the rigors of industrial applications, ensuring prolonged and reliable operation.

Welding Industrial Centrifugal Fan Motor Brackets: Securing the Powerhouse

The welding of motor brackets for industrial centrifugal fans demands precision to secure the powerhouse within. Robotic arms, programmed for accuracy, seamlessly weld these brackets, providing a stable foundation for the fan’s motor. This automated welding application ensures the seamless integration of the motor, contributing to the overall efficiency and reliability of the centrifugal fan.

ALTRON Industrial Fan Automation Production Solution Conclusion

In the fields of industrial axial flow, centrifugal, tunnel, ventilation, fire protection and other industrial fans, Altron is an innovative engineer who provides comprehensive solutions for the production of high-performance industrial fans.

Altron produces core accessories and equipment for industrial axial flow fans and centrifugal industrial fans:

CNC metal spinning machine processing:

Impeller shroud & air inlet of industrial centrifugal fan,

Industrial axial flow fan shroud,

Axial flow fan impeller boss (hub),

Aluminum roof fan guard,

duct fan housing froming,

CNC flanging machining processing:

Impeller shroud & air inlet of large stainless steel industrial centrifugal fan,

Industrial fan flange for industrial centrifugal & axial fans,

Axial flow fan duct flanging & punching,

Tunnel & jet fan flanging or expansion,

High strength marine axial flow fan flanging & punching,

Fully automatic axial flow fan duct production line:

Laser cutting of industrial axial flow fans,

Fully automatic rolling of industrial axial flow fan cylinders,

Straight seam welding of industrial axial flow fan cylinder,

CNC or PLC flange machined the flange edge and punched holes of the air duct,

AI robot automatic welding equipment:

Impeller welding of industrial centrifugal fans (medium and low pressure) (robot + AI)

Automatic welding of housing for industrial centrifugal fans (multi-axis machinery + AI)

Welding of side plates and reinforcement ribs of industrial centrifugal fan volute housing (gantry welding machine)

Customer customized solution machine,etc.

Customize forming & welding machines and manufacture special machines according to customer requirements.

ALTRON helps industrial fan manufacturers realize industrial standards for automation and semi-automation. It is the perfect turnkey project for industrial fan manufacturing factories and the best supplier choice. ALTRON takes technical services as its core.