How To Improve Industry Fan Welding Quality

Reduce manual welding and improve automated welding processes; use welding solutions with AI visual guidance, without the need for teaching programming to control welding! Choose the appropriate welding process and type of welding machine for the corresponding welding materials! Do a good job of surface cleaning of materials and ensure the consistency of welding accessories can improve the welding quality of industrial fans!

What are the basic ways to improve welding quality?

Always keep the workpiece clean:

Clean the oil stains and dust, iron slag and other impurities on the welding surface to make the welding water more permeable, prevent bubbles and hardening during welding, and effectively improve the strength of the weld.

Find a good welding platform:

Choose a suitable positioner or a plane positioning work platform according to different welding structures!

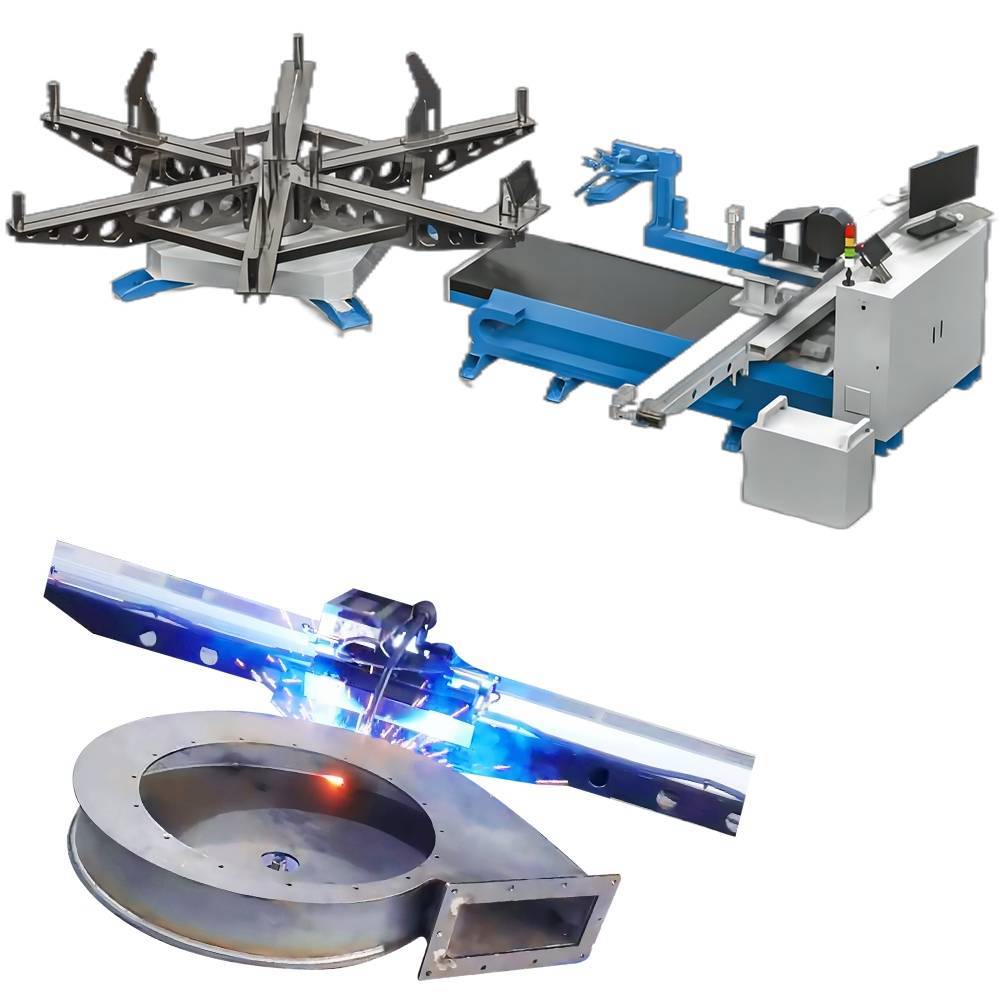

For example, for automatic welding of impellers, a 2-axis positioner must be used as an auxiliary to cooperate with a 6-axis manipulator to adjust to the appropriate welding posture and angle.

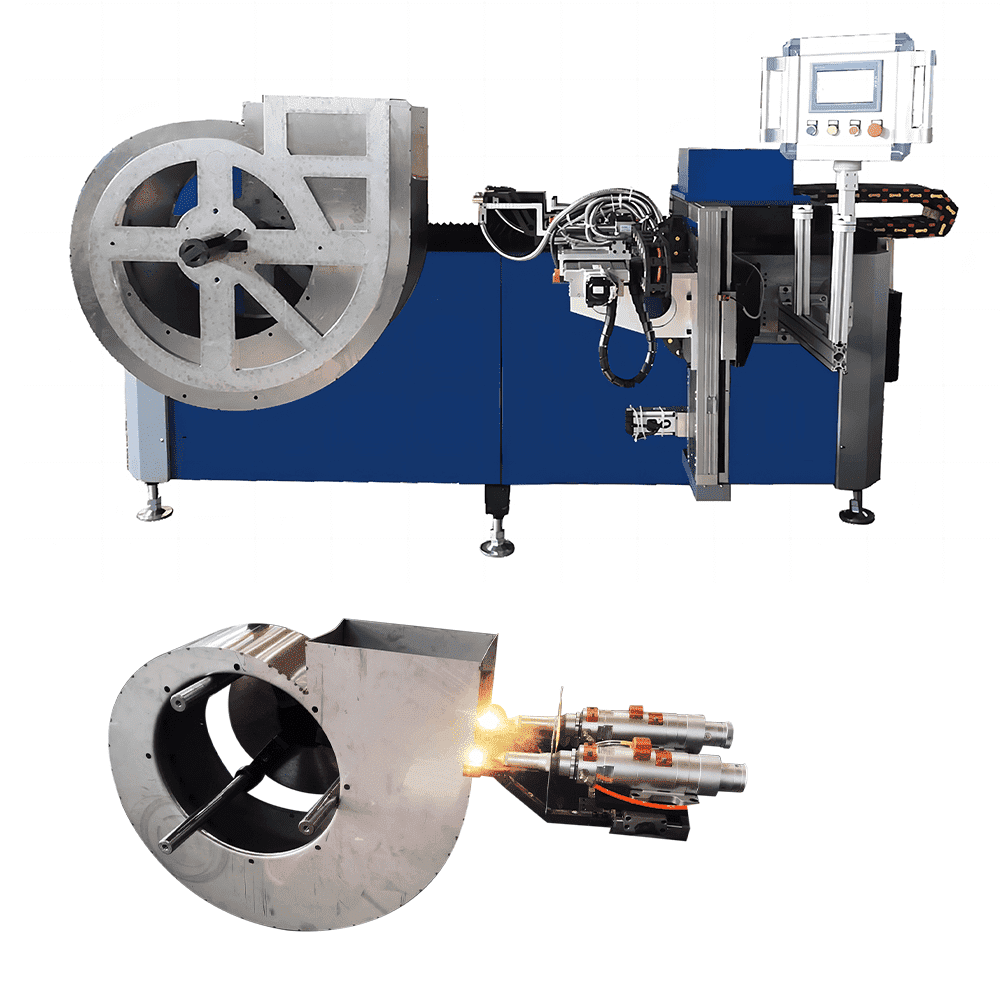

When welding centrifugal fan housing, only a single-axis rotary positioner and a cross coordinate manipulator are required to achieve a suitable welding posture.

Choose the right gas:

Traditional metal welding processes include laser welding, argon arc welding, and gas shielded welding! Different gas protection and auxiliary are needed in the welding process. It is conducive to improving welding quality and welding efficiency.

Set reasonable welding parameters and speed:

When welding different metal materials and thicknesses, welding machines with different processes need to adjust the welding power, voltage, speed of the automatic wire feeder, moving speed of the welding gun and other related parameters.

Listen and observe the changes in the welding process:

During the test welding process, it is necessary to judge whether the welding process is normal by sound. The welding sounds of different welding machines are different. Engineers with rich welding experience can judge the welding results by the welding sound;

When encountering uncertainty, you need to wear goggles or welding masks to observe the forming effect of the weld; by adjusting parameters, the best welding effect can be achieved.

Matching auxiliary equipment:

In the field of automated welding, many complex equipment will be used, such as laser ranging, industrial cameras, welding gun cleaning, multi-axis positioner, etc. Traditional automatic welding equipment requires a lot of trial teaching and programming work in the early stage of welding! Altron’s automated welding solution uses AI algorithms and industrial-grade cameras to make automated welding simpler and more efficient.

Protective measures, pay attention to the strong light generated by the arc:

It is usually necessary to pay attention to avoid observing the welding torch without wearing a protective welding mask during the welding test. The operating platform and welding parts of the machine are marked with eye-catching attention signs to ensure safe operation.

6 Common Welding Problems

Avoiding common welding errors that reduce welding quality and efficiency

Such as insufficient air pressure, poor material matching, and neglecting preventive maintenance can reduce costs and increase productivity.

- 1. Poor connection or cable

- 2. Improper air pressure or flow

- 3. Poor material matching

- 4. Too much anti-splash agent

- 5. Ignore preventive maintenance

- 6. Improper machine settings

Advantages of automated machine welding:

- No need for polishing and grinding

- Beautiful welds, high quality

- High production efficiency, no need for high-tech welders,

- Laser vision scanning welds, automatic correction of weld positions,

- Flexible welding process, solving welding deformation,

- Intelligent production, enhancing the corporate image of manufacturers

Core welding parts of industrial centrifugal fans:

Impeller welding

| Welding method: |

centrifugal Impeller Welding video

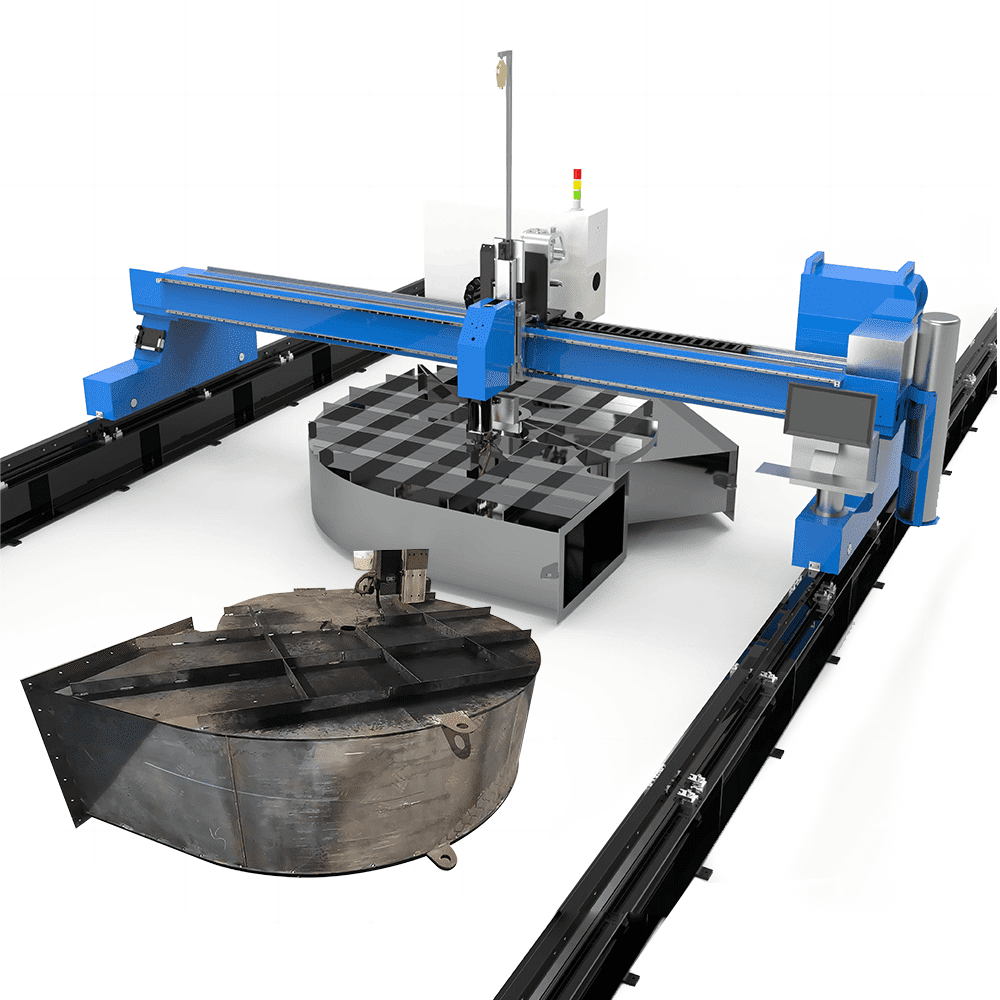

Housing welding

| Welding method: |

|

centrifugal housing Welding video

Inlent /outlet Ducts welding:

Support customized welding machines,

It mainly appears in the design of special industrial fans; or the traditional molding process cannot be processed and manufactured and must be welded to achieve the designed shell shape; or it is a test match and a small number of orders to reduce mold development costs.

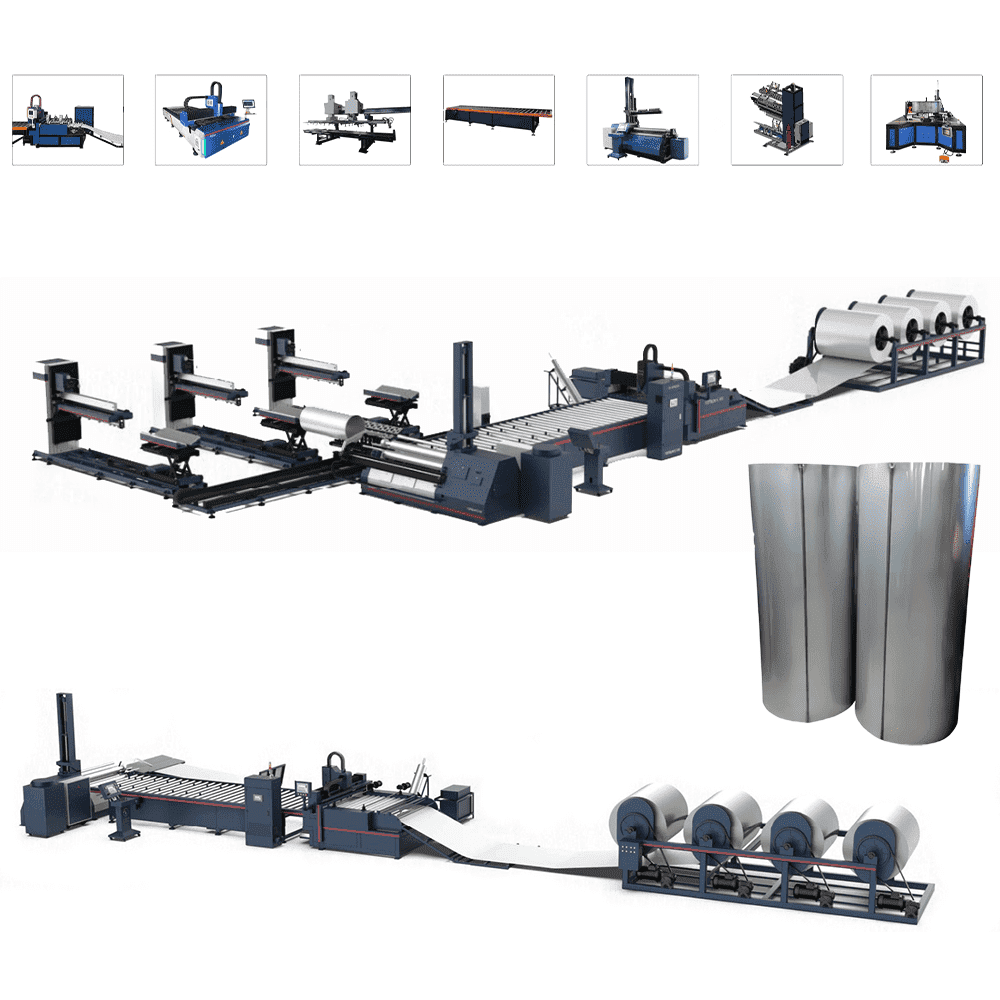

Welding method: This type of parts welding usually uses circumferential seam or longitudinal seam welding. Circumferential seam welding can use the machine for centrifugal fan shell welding; longitudinal seam welding can use seam welding machine or robot welding, and the final welding process is formulated according to the actual situation.

Core welding part of industrial axial fan case:

Axial fan‘s Impeller

| Welding method: |

|

Axial fan‘s ducts

| Welding method: |

Axial fan‘s ducts rolling & welding video

Axial fan‘s Motor bracket

Welding method: Through the positioning tooling, the bracket and the wind tube are fixed by manual spot welding, and the robot completes the full welding automatic welding inside.

Axial fan motor bracket welding video:

Summary of Improving Welding Quality

The rapid development of society is inseparable from the replacement of high labor costs with industrial automation machinery, while ensuring quality and efficiency! As the current number of highly skilled welders is gradually decreasing, automated welding is an inevitable trend in the future!

For related automated welding solutions, please contact Altron, we will quickly provide you with a complete metal welding forming solution. More Ai auto weliding viedo