Industrial Fans Impeller Welding Machines: Precision in Airflow Engineering

Industrial fans play a pivotal role in diverse sectors, relying on efficient impellers. Explore the technical marvels of impeller welding machines shaping the future of airflow engineering.

Understanding Industrial Fans and Impellers:

Industrial fans, omnipresent in manufacturing, ventilation, and HVAC systems, owe their efficiency to well-crafted impellers. These blades, essential components, demand precision in construction to optimize airflow and energy efficiency.

The Significance of Welding in Impeller Manufacturing:

Welding, a cornerstone in impeller fabrication, warrants attention. Crafting robust, aerodynamically efficient impellers involves overcoming unique welding challenges. This blog delves into the intricate world of welding machines tailored for impeller production.

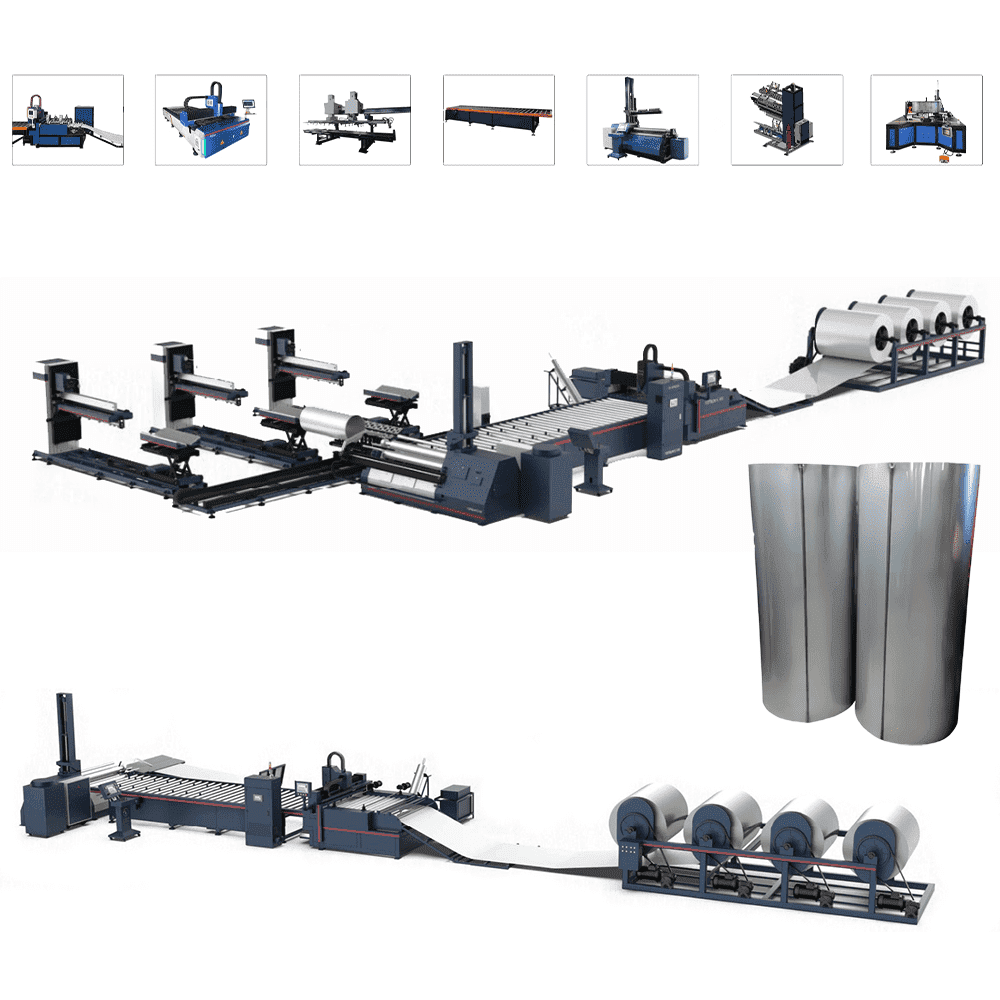

Altron’s Industrial fan impeller welding machine for manufacturing high efficiency impellers. cameras and laser scanning to Auto welding.

Manual Welding Techniques:

Manual welding plays a pivotal role in crafting impellers, ensuring meticulous precision in joining components for optimized airflow. This blog delves into the intricacies of manual welding techniques specifically tailored for impeller manufacturing.

In impeller production, manual welding stands as a cornerstone method, demanding skilled craftsmanship to meticulously fuse components. The hands-on approach allows for intricate control over the welding process, ensuring the creation of durable, high-performance impellers.

Various manual welding techniques are employed, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas), each offering unique advantages in impeller fabrication. This post details the nuances of these techniques, emphasizing their role in achieving weld quality, strength, and consistency essential for efficient airflow.

Precision and expertise are paramount in manual welding for impellers. Welders navigate challenges such as heat distortion and material compatibility to craft seamless joints, ensuring optimal impeller functionality.

Automated Machine Welding:

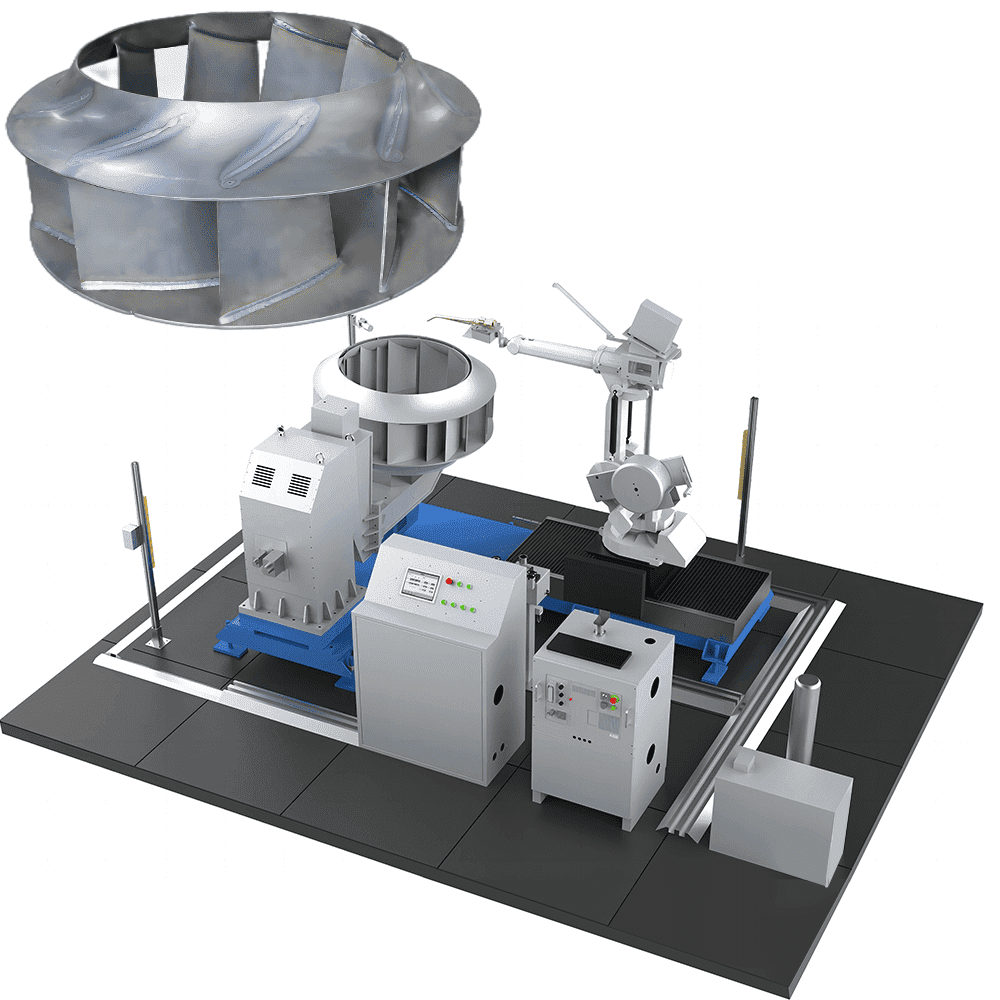

In impeller production, automated machine welding stands as a beacon of precision, leveraging advanced technology to streamline processes. This blog explores the prowess of automated welding machines tailored for impeller manufacturing.

Automated machine welding has redefined impeller fabrication by introducing efficiency and consistency in welding processes. These machines, equipped with sophisticated robotic arms and precise control systems, ensure uniform welds on complex impeller components.

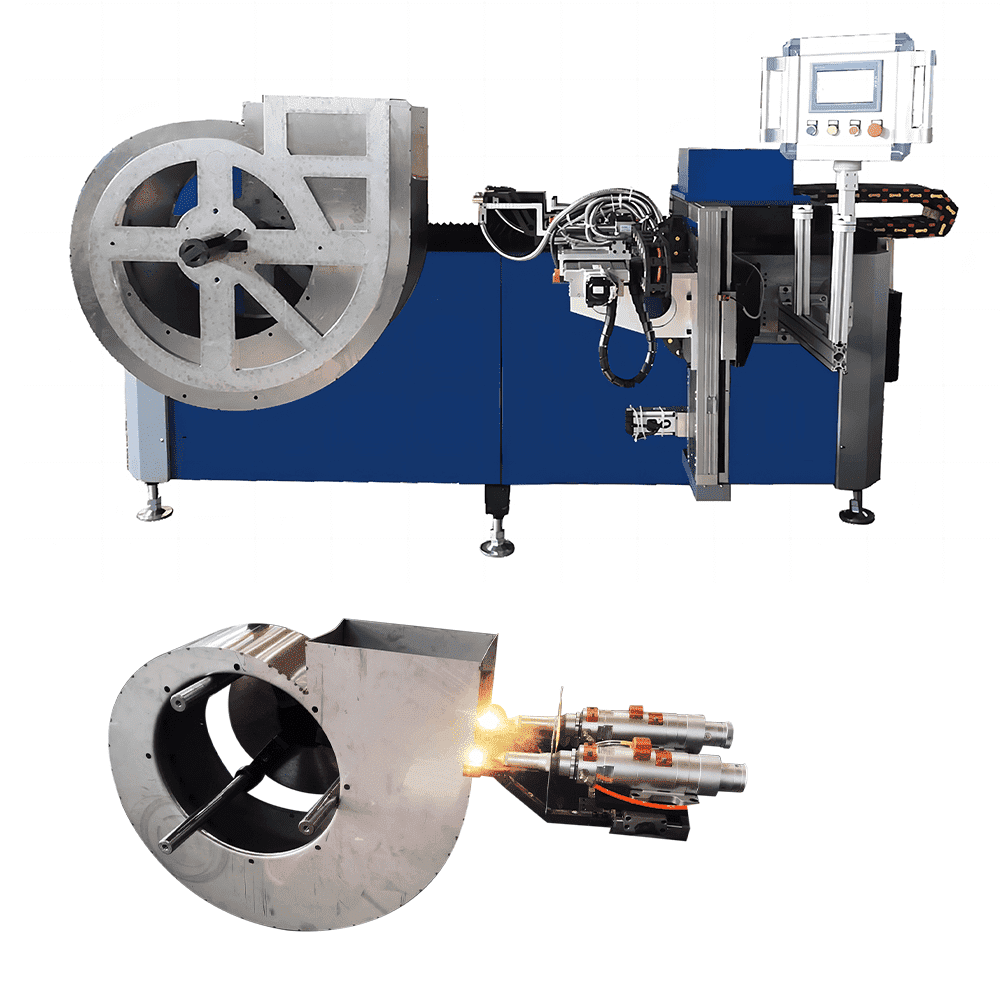

Various techniques, such as laser welding and robotic MIG welding, dominate the realm of automated impeller welding. Their ability to handle intricate designs and maintain superior weld quality enhances the structural integrity of impellers.

The utilization of automated welding machines minimizes human error, optimizes production times, and guarantees uniformity in impeller construction. This results in durable, high-performance impellers essential for efficient airflow systems.

Types of Impeller Welding Machines:

Various welding techniques are employed in impeller manufacturing, each with distinct advantages. From TIG and MIG welding to laser and friction stir welding, this section elucidates the nuances of these methods and their suitability for impeller construction.

Advancements in Impeller Welding Technology:

Technological strides in welding machines transform impeller production. Automation and robotics, coupled with advancements in materials and design software, contribute to heightened precision. Discover the transformative impact of cutting-edge technologies on impeller welding.

Quality Control and Inspection in Impeller Welding:

The integrity of welded impellers is non-negotiable. This section scrutinizes the critical role of quality control and inspection methods. From non-destructive testing to ensuring weld durability, maintaining high standards is paramount for optimal impeller performance.

Applications and Industries Utilizing Impeller Welding Machines:

Impeller welding machines find applications across diverse industries. HVAC systems, aerospace, automotive—each sector demands specialized impellers. This segment examines how welding machines cater to the unique requirements of these industries.

Challenges and Future Trends:

While impeller welding machines have revolutionized production, challenges persist. Heat distortion, material compatibility—this section addresses hurdles and looks ahead to anticipated future trends in impeller welding technology. What innovations will shape the trajectory of these crucial machines?

Industrial Fans Impeller Welding Conclusion:

In the complex realm of industrial fan manufacturing, impeller welding machines emerge as unsung heroes. This blog underscores their role in ensuring efficiency, durability, and optimal performance in diverse sectors reliant on precise airflow engineering.

In a Nutshell:

Navigating the intricate landscape of impeller welding machines unveils the art and science of crafting components pivotal to industrial fan functionality. From traditional methods to cutting-edge technologies, the journey is one of continuous innovation, ensuring a breath of fresh air in various industries.