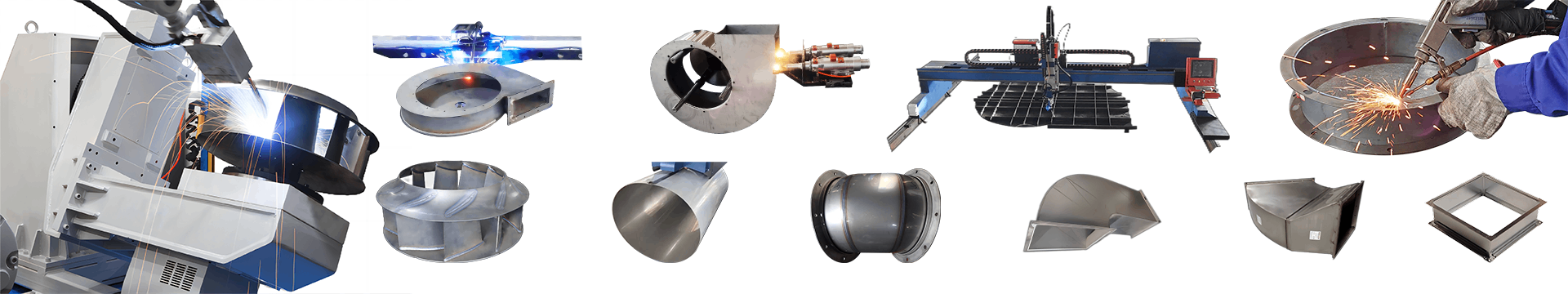

Are You Aware of the Latest Advancements in Industrial Fans Impeller Welding Technology?”

Industrial Fans Impeller Welding has emerged as a pivotal technology in the realm of industrial manufacturing. As industries continually evolve, so does the need for more efficient and advanced welding techniques. ALTRON, a leading Industrial Fans impeller welding machine manufacturer, is at the forefront of these innovations. This blog delves into the latest advancements in Industrial Fans Impeller Welding technology, shedding light on its growing significance and the transformative trends shaping the industry.

Reducing Downtime: A Crucial Role of Industrial Fans Impeller Welding

1.1 Downtime Challenges in Industrial Settings

Downtime in industrial settings can be a costly affair, impacting productivity and, consequently, the bottom line. Industrial Fans Impeller Welding plays a pivotal role in mitigating this challenge. ALTRON’s welding machines are designed with efficiency in mind, facilitating quicker and more precise welding processes. By minimizing the time required for impeller welding, industries can significantly reduce downtime, ensuring continuous operations and optimizing overall productivity.

1.2 ALTRON’s Contribution to Downtime Reduction

ALTRON’s commitment to cutting-edge technology is evident in its Industrial Fans Impeller Welding machines. These machines are engineered to streamline the welding process, incorporating features that expedite setup, execution, and inspection. The result is a substantial reduction in downtime, allowing industries to meet tight production schedules and enhance overall operational efficiency.

The Essential Needs of Industrial Fans Impeller Welding

2.1 Precision and Durability

In the world of industrial fans, precision and durability are non-negotiable. Industrial Fans Impeller Welding meets these needs head-on, ensuring that each weld is executed with meticulous precision. ALTRON’s cutting-edge welding machines are designed to deliver welds that not only withstand the harsh industrial environment but also contribute to the overall efficiency of the system.

2.2 Efficiency and Cost-Effectiveness

Efficiency and cost-effectiveness go hand in hand in any industrial process. With Industrial Fans Impeller Welding, manufacturers can achieve both. The latest advancements in technology have paved the way for faster welding processes, minimizing downtime and maximizing production output. ALTRON’s commitment to innovation ensures that their welding machines not only improve efficiency but also offer a cost-effective solution for industries seeking to enhance their bottom line.

Latest Trends in Industrial Fans Impeller Welding

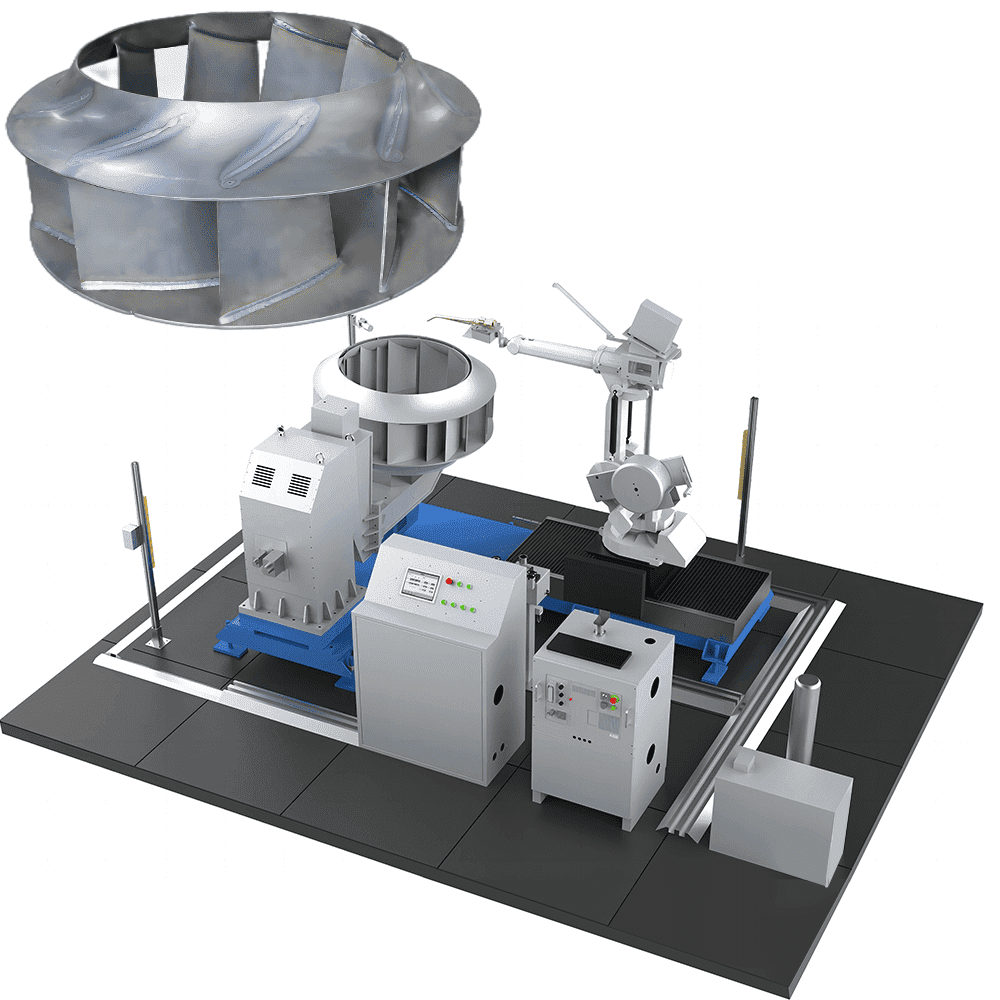

3.1 Automation and Robotics Integration

One of the prominent trends in Industrial Fans Impeller Welding is the integration of automation and robotics. ALTRON has spearheaded this trend by developing welding machines that leverage robotic technology to enhance precision and speed. Automated welding processes not only reduce manual labor but also contribute to a consistent and high-quality weld every time.

3.2 Smart Welding Technologies

The era of smart manufacturing has ushered in smart welding technologies for Industrial Fans Impeller Welding. ALTRON’s machines come equipped with advanced sensors and monitoring systems that provide real-time data during the welding process. This not only ensures the quality of each weld but also enables predictive maintenance, reducing the risk of unexpected breakdowns.

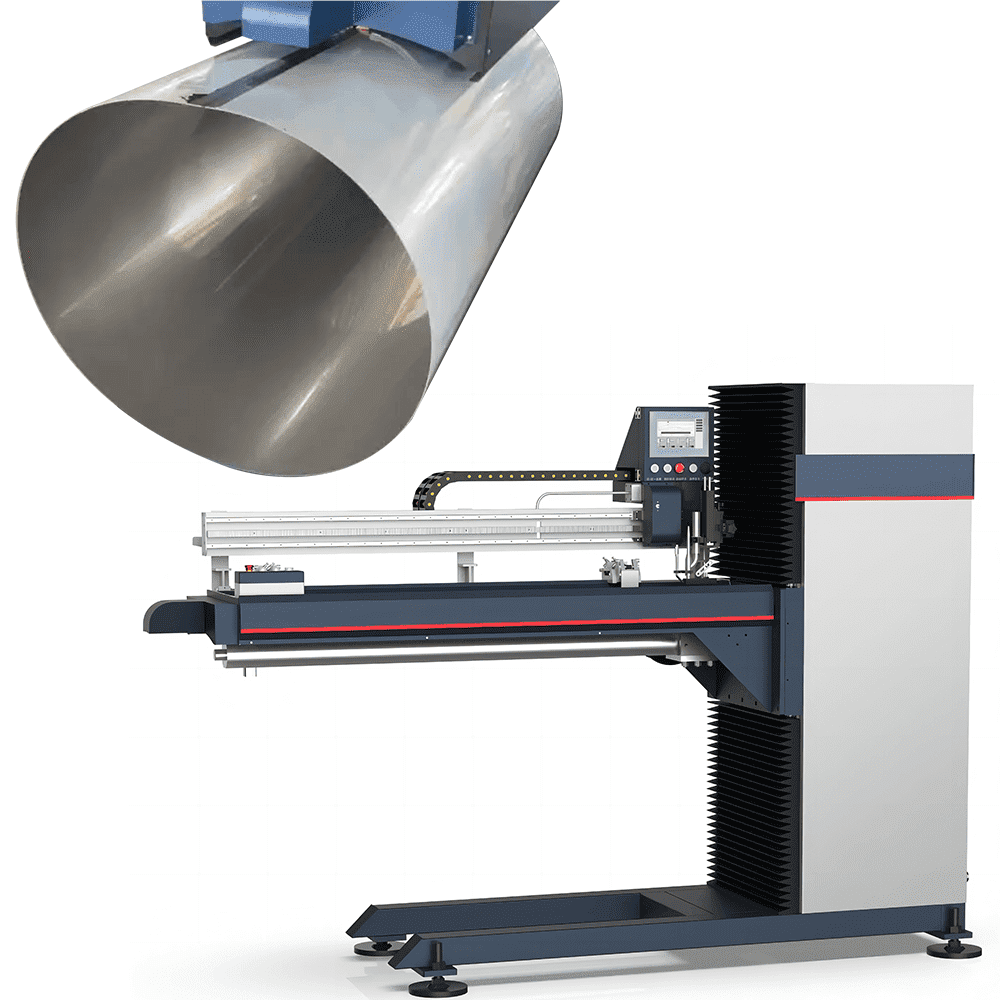

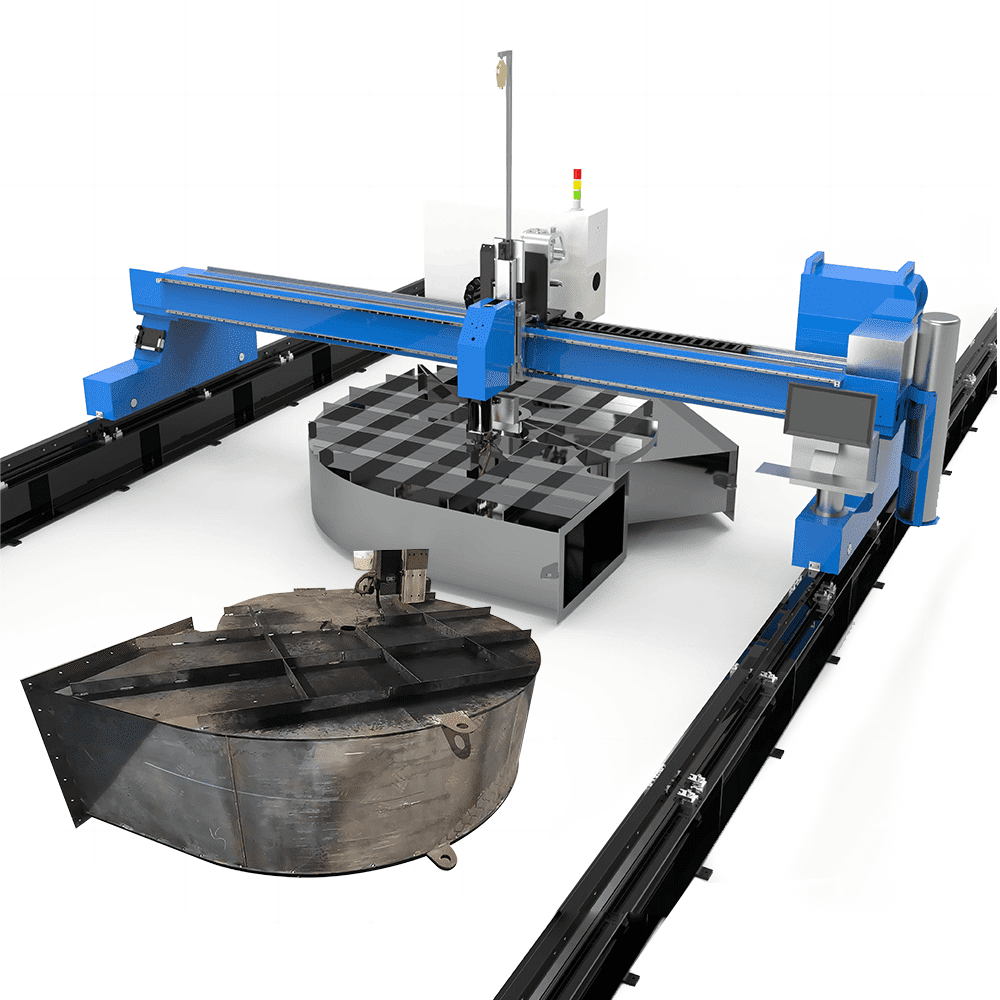

Overview of ALTRON’s Fully Automatic Welding Machine:

ALTRON’s fan volute fully automatic welding machine represents a paradigm shift in the welding technology landscape. The machine is designed to handle the welding of stainless steel and carbon steel industrial fan volutes, where maintaining a high level of consistency is crucial.

4.1 Gas Shielded Welding & Argon Arc Welding:

The utilization of gas-shielded welding and argon arc welding techniques enhances the overall welding quality. These methods provide a clean and controlled environment, reducing the chances of impurities compromising the weld integrity. ALTRON’s commitment to excellence is evident in its choice of welding techniques.

4.2 Vision Al Corrects Welding Trajectory:

One of the standout features of ALTRON’s technology is the integration of Vision Al, an artificial intelligence system that corrects welding trajectories. In large-diameter applications, maintaining consistency during spot welding and splicing assembly can be challenging for manual labor. Vision Al eliminates the need for a complicated and high-precision positioning device by automatically correcting the weld trajectory.

The Unique ALTRON Technology:

ALTRON’s unique Al technology simplifies the automation problem associated with difficult manual positioning. By employing the industrial fan volute automatic welding equipment, the company ensures a hassle-free welding process that saves time and resources.

5.1 Scanning and Identification Process:

Before the welding process begins, the machine employs an industrial camera and ranging laser to scan and identify the welding position of the industrial fan volute. This pre-welding analysis is crucial for determining the optimal trajectory for seamless welding.

5.2 Automatic Trajectory Calculation:

Once the welding position is identified, ALTRON’s Al technology automatically calculates the best trajectory for the welding gun. This eliminates the need for manual adjustments and ensures a precise and consistent weld. The automated system allows individuals to focus on multiple operations simultaneously, enhancing overall efficiency.

The Transformative Power of Industrial Fans Impeller Welding

6.1 Improved Airflow Dynamics

Industrial Fans Impeller Welding plays a pivotal role in shaping the airflow dynamics within industrial settings. By ensuring precise and secure welds on fan impellers, the technology contributes to optimal airflow. This, in turn, enhances the overall efficiency of ventilation and cooling systems, a critical factor in various industrial processes.

6.2 Enhanced Safety Standards

Safety is paramount in any industrial environment, and Industrial Fans Impeller Welding directly impacts safety standards. ALTRON’s welding machines are designed to meet and exceed industry safety regulations, ensuring that the welding process is not only efficient but also safe for operators and the surrounding environment.

Small Changes, Big Improvements: The ALTRON Advantage

7.1 Precision in Welding Techniques

The phrase “small changes” takes center stage when considering the precision achieved through Industrial Fans Impeller Welding. ALTRON’s machines excel in executing precise welds on fan impellers, ensuring each weld meets stringent quality standards. These seemingly small improvements in welding precision have a cascading effect on the overall performance of industrial fans, translating into enhanced efficiency and durability.

7.2 Efficiency Gains from Improved Welding Techniques

ALTRON’s Industrial Fans Impeller Welding techniques go beyond traditional methods, introducing advancements that might seem small but result in substantial improvements. By optimizing the welding process, industries benefit from increased energy efficiency, reduced material wastage, and extended equipment lifespan. These seemingly minor adjustments, when compounded, lead to significant improvements in the overall efficiency of industrial fan systems.

Choosing the Right Technique: Industrial Fans Impeller Welding by ALTRON

ALTRON’s Industrial Fans Impeller Welding Technology represents a groundbreaking advancement in the welding industry. By integrating gas-shielded welding, argon arc welding, and Vision Al technology, ALTRON has successfully addressed the challenges associated with large-diameter welding applications. The fully automatic welding equipment not only streamlines the welding process but also ensures a high level of consistency and precision. As industries continue to evolve, ALTRON stands at the forefront, revolutionizing the way we approach Industrial Fans Impeller Welding.

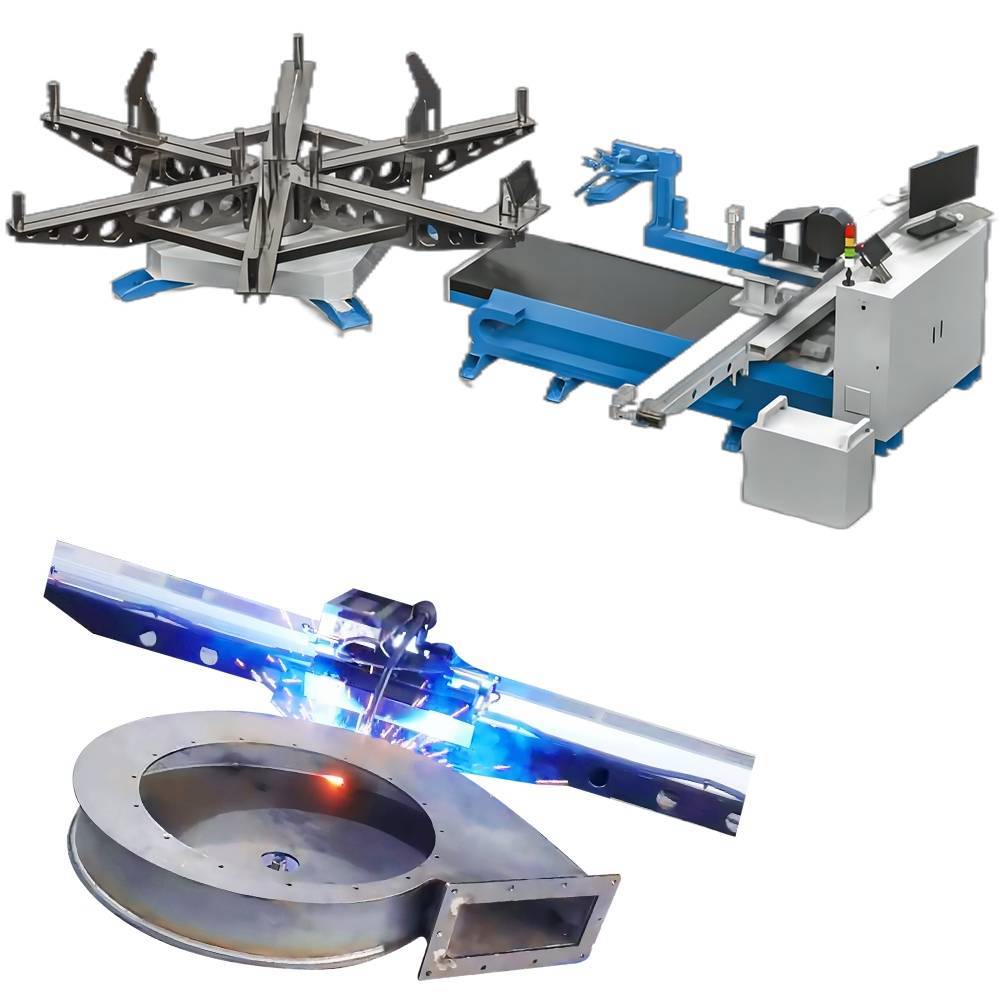

8.1 Diverse Welding Techniques for Varied Industries

Industrial Fans Impeller Welding is not a one-size-fits-all solution, and ALTRON recognizes the diverse needs of different industries. The manufacturer offers a range of welding techniques tailored to specific industrial requirements. Whether it’s arc welding, resistance welding, or laser welding, ALTRON provides solutions that align with the unique demands of each industry, ensuring optimal performance and longevity of fan systems.

8.2 Customized Solutions for Industry-Specific Needs

Understanding that each industry has its own set of challenges, ALTRON’s Industrial Fans Impeller Welding techniques are designed for customization. Industries can choose the welding technique that best suits their specific applications, be it for aerospace, automotive, or general manufacturing. This tailored approach ensures that the welding process seamlessly integrates into existing workflows, maximizing efficiency without compromising on quality.

Your One-Stop Solution for Industrial Fans Impeller Welding

When it comes to Industrial Fans impeller welding, ALTRON stands out as a one-stop solution for businesses seeking excellence in manufacturing. Here’s why you should consider ALTRON for your welding needs:

9.1 Comprehensive Product Range

ALTRON boasts a diverse range of Industrial Fans impeller welding machines, catering to various sizes and specifications. Whether you’re a small-scale manufacturer or an industrial giant, ALTRON has the right solution for you. Their product range is designed to meet the evolving needs of the industry, ensuring that you stay ahead of the curve.

9.2 Unparalleled Quality and Durability

ALTRON takes pride in delivering welding machines that not only meet industry standards but exceed them. The impellers produced using ALTRON’s technology exhibit unparalleled quality and durability. Investing in ALTRON’s welding solutions is an investment in the long-term reliability of your industrial fans.

9.3 Global Reach and Support

ALTRON has a global presence, making its welding solutions accessible to manufacturers worldwide. With a commitment to customer satisfaction, ALTRON provides comprehensive support services. Whether you need assistance with installation, training, or maintenance, ALTRON’s team is ready to ensure that you get the most out of your welding machines.

How to Acquire ALTRON’s Industrial Fans Impeller Welding Machines

Acquiring ALTRON’s state-of-the-art welding machines is a straightforward process. To initiate the purchase of your one-stop solution for Industrial Fans impeller welding, you can contact ALTRON through the following channels:

Altron WhatsApp: +8615627397226

E-mail: info@auto-altron.com

ALTRON’s responsive customer service team will guide you through the selection process, ensuring that you choose the welding machine that aligns with your production goals and requirements.

Conclusion

The latest advancements in Industrial Fans Impeller Welding technology are reshaping the landscape of industrial manufacturing. ALTRON’s commitment to innovation positions them as a key player in providing cutting-edge solutions for the evolving needs of industries worldwide. As the demand for precision, efficiency, and cost-effectiveness continues to rise, Industrial Fans Impeller Welding stands as a testament to the transformative power of technology in the industrial sector.