What Are the Energy Efficiency Benefits of Upgrading to Modern Industrial Inline Duct Fans?

In the fast-paced world of industrial manufacturing, precision and efficiency are paramount. Industrial inline duct fan factories, such as those supplied by ALTRON AUTO, face unique challenges in meeting the demands of their customers while maintaining high-quality standards. Custom machine solutions play a pivotal role in addressing these challenges by optimizing manufacturing processes and meeting specific factory requirements.

The Importance of Custom Machines in Optimizing Manufacturing Processes

1.1 Precision Engineering for Enhanced Performance

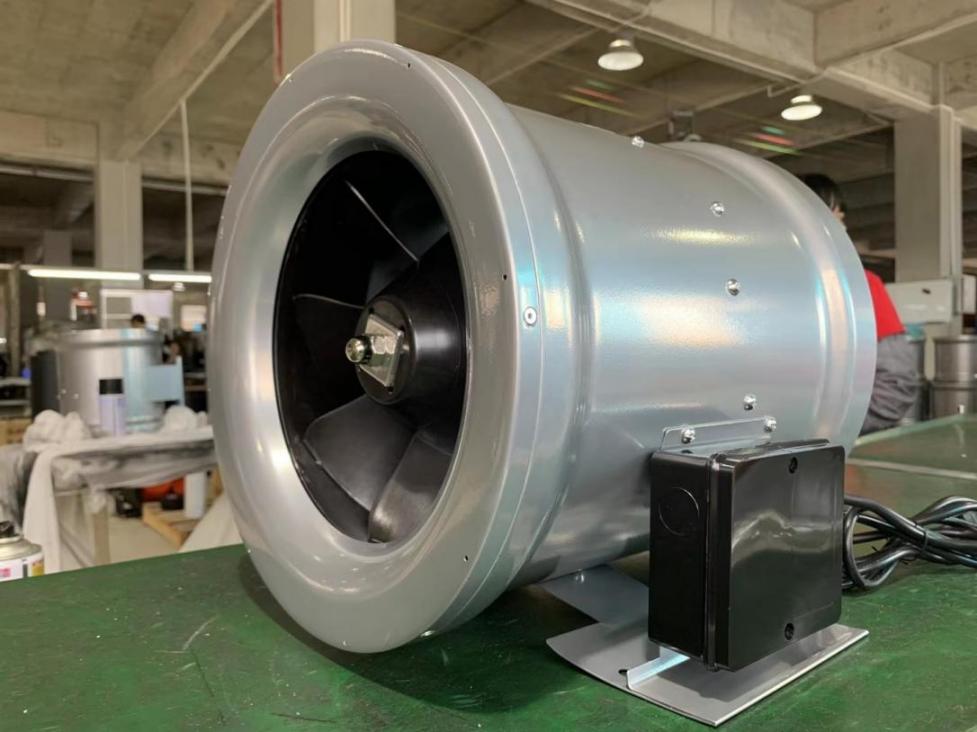

In the realm of industrial inline duct fan manufacturing, precision is non-negotiable. Custom machine solutions allow factories to achieve the exacting standards required for these vital components of ventilation systems. From blade fabrication to motor assembly, every step in the manufacturing process demands meticulous attention to detail, which custom machines are uniquely equipped to deliver.

1.2 Meeting Varied Production Needs

No two factories are alike, and neither are their production requirements. Custom machine solutions provide the flexibility needed to adapt to diverse production needs, whether it’s scaling up to meet increased demand or accommodating unique customization requests from customers. ALTRON AUTO understands the importance of versatility in manufacturing, and their custom solutions are designed with adaptability in mind.

Common Challenges in Industrial Inline Duct Fan Manufacturing

2.1 Precision Requirements

Industrial inline duct fans must meet strict performance specifications to ensure optimal airflow and efficiency. Achieving such precision in manufacturing poses a significant challenge, especially when dealing with intricate components and tight tolerances. Custom machine solutions offer the precision machining capabilities necessary to meet these exacting standards consistently.

2.2 Production Speed and Efficiency

In a competitive market, speed matters. Factories must strive to increase production rates without sacrificing quality. However, traditional manufacturing methods often struggle to keep pace with growing demand. Custom machine solutions leverage advanced automation and streamlined processes to enhance production speed and efficiency, enabling factories to meet tight deadlines and stay ahead of the competition.

2.3 Quality Control

Maintaining consistent quality throughout the manufacturing process is essential to uphold the reputation of the brand. However, ensuring quality control can be challenging, particularly in high-volume production environments. Custom machine solutions integrate quality control measures directly into the manufacturing process, minimizing defects and ensuring that every inline duct fan meets stringent quality standards before leaving the factory floor.

2.4 Customization Demands

Customers today expect more than off-the-shelf solutions; they seek products tailored to their specific needs and preferences. Industrial inline duct fan factories must be able to accommodate varying customization demands while maintaining efficient production processes. Custom machine solutions enable factories to offer a wide range of customization options without compromising on quality or efficiency, enhancing customer satisfaction and loyalty.

Benefits of Custom Machine Solutions for Industrial Inline Duct Fan Manufacturing

3.1 Increased Efficiency

Custom machine solutions are designed to streamline manufacturing processes, reduce waste, and optimize workflow. By automating repetitive tasks and minimizing human error, these solutions can significantly increase production efficiency, allowing factories to produce more inline duct fans in less time and at a lower cost per unit.

3.2 Improved Product Quality

Precision engineering and strict quality control measures inherent in custom machine solutions result in superior product quality. Consistency in manufacturing ensures that every inline duct fan meets or exceeds performance standards, enhancing reliability and longevity. Customers can trust that ALTRON AUTO’s inline duct fans will deliver consistent airflow and performance in any application.

3.3 Reduced Downtime

Equipment breakdowns and maintenance downtime can disrupt production schedules and incur significant costs. Custom machine solutions are designed for reliability and durability, minimizing the risk of unplanned downtime. Additionally, proactive maintenance schedules and remote monitoring capabilities help identify potential issues before they escalate, further reducing the likelihood of disruptions in production.

3.4 Flexibility in Production

Custom machine solutions offer the flexibility needed to adapt to changing market demands and customer preferences. Whether it’s adjusting production volumes, changing product specifications, or accommodating last-minute design changes, these solutions empower factories to respond quickly and efficiently to evolving needs, maintaining a competitive edge in the market.

Design and Development of Custom Machines for Industrial Inline Duct Fan Factories

4.1 Understanding Factory Requirements

The design and development process for custom machines begin with a comprehensive understanding of the factory’s requirements and production goals. ALTRON AUTO works closely with each customer to assess their unique needs, taking into account factors such as production volume, product specifications, and available floor space.

4.2 Integration with Existing Systems

Custom machine solutions must seamlessly integrate with existing production systems to maximize efficiency and minimize disruption. ALTRON AUTO’s engineering team collaborates closely with factory personnel to ensure compatibility with existing equipment and workflows, minimizing downtime during installation and implementation.

4.3 Scalability for Future Growth

As factories expand and production volumes increase, custom machine solutions must be scalable to accommodate growing demand. ALTRON AUTO designs its solutions with scalability in mind, allowing factories to easily upgrade or expand their production capabilities as needed, without the need for costly equipment replacements or redesigns.

4.4 Safety Considerations

Safety is paramount in any manufacturing environment, and custom machine solutions are no exception. ALTRON AUTO prioritizes safety in the design and development of its custom machines, incorporating features such as interlocking safety guards, emergency stop buttons, and ergonomic controls to protect workers and minimize the risk of accidents.

Case Studies: Successful Implementation of Custom Machines

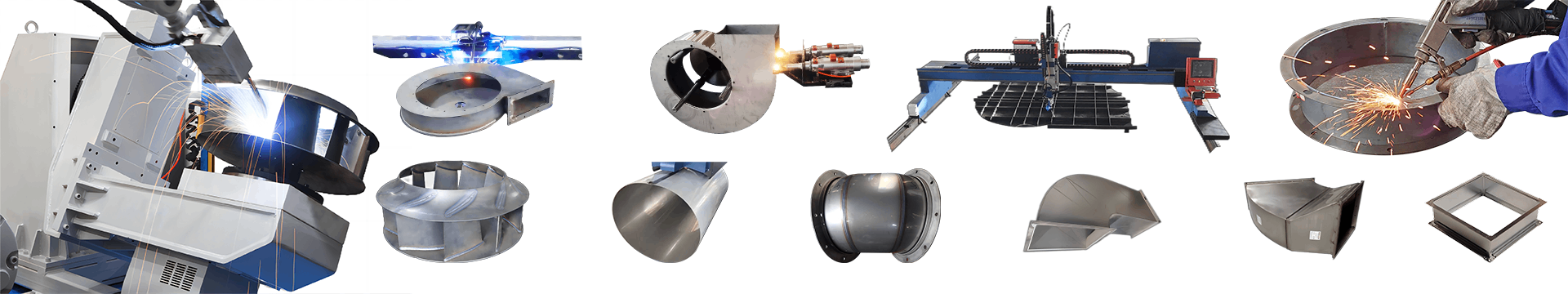

5.1 Precision Blade Cutting Machine

One notable case study involves the implementation of a precision blade-cutting machine at an industrial inline duct fan factory supplied by ALTRON AUTO. Before the introduction of this custom machine solution, the factory faced significant challenges in achieving uniform blade dimensions, resulting in inconsistencies in fan performance. The custom machine solution addressed this issue by automating the blade-cutting process with high precision, ensuring consistent dimensions, and improving airflow efficiency. As a result, the factory experienced a significant reduction in product defects and increased customer satisfaction.

5.2 Automated Assembly Line

Another successful case study involves the implementation of an automated assembly line for industrial inline duct fan motors. Prior to the introduction of this custom machine solution, the factory struggled with labor-intensive manual assembly processes, leading to production bottlenecks and quality control issues. The automated assembly line streamlined the production process by integrating robotics and advanced automation technologies, significantly reducing assembly time and minimizing errors. This resulted in improved productivity, reduced manufacturing costs, and enhanced product quality.

Cost Considerations and Return on Investment (ROI) of Custom Machine Solutions

6.1 Factors Influencing Costs

When considering the financial aspects of investing in custom machine solutions for industrial inline duct fan manufacturing, several factors must be taken into account. These include the design complexity of the custom machines, the materials used in their construction, labor costs associated with implementation and maintenance, and ongoing operational expenses. Additionally, factors such as the level of automation and integration with existing systems can influence upfront investment costs.

6.2 Analyzing Potential ROI

Despite the initial investment required, custom machine solutions offer significant long-term benefits and a favorable return on investment (ROI). By increasing production efficiency, reducing labor costs, and minimizing product defects, these solutions contribute to overall cost savings and improved profitability for industrial inline duct fan factories. Furthermore, the enhanced quality and consistency of the manufactured products result in increased customer satisfaction and loyalty, further contributing to the ROI of custom machine solutions.

Technological Innovations in Custom Machine Solutions

7.1 Integration of Machine Learning

One of the recent technological advancements in custom machine solutions is the integration of machine learning algorithms. These algorithms analyze data collected from sensors and production processes to optimize machine performance, detect anomalies, and predict maintenance needs. In the context of industrial inline duct fan manufacturing, machine learning can help identify patterns in airflow dynamics, optimize blade designs, and improve energy efficiency.

7.2 Robotics and Automation

The integration of robotics and automation technologies in custom machine solutions has revolutionized industrial manufacturing processes. Robots are increasingly being used for tasks such as material handling, assembly, and quality inspection, allowing for faster production rates, improved accuracy, and reduced labor costs. In industrial inline duct fan factories, robotics can be utilized for tasks such as blade fabrication, motor assembly, and packaging, enhancing overall efficiency and productivity.

Future Outlook: Evolving Trends in Custom Machine Solutions

8.1 Advancements in Automation and AI-driven Optimization

Looking ahead, advancements in automation and AI-driven optimization are expected to continue shaping the future of custom machine solutions for industrial inline duct fan factories. AI algorithms will become increasingly sophisticated, enabling predictive maintenance capabilities, real-time production optimization, and adaptive manufacturing processes. Automation technologies will continue to evolve, with robots becoming more agile, versatile, and collaborative, further enhancing production capabilities.

8.2 Sustainable Manufacturing Practices

In response to growing environmental concerns, sustainable manufacturing practices will play an increasingly important role in the development of custom machine solutions. Manufacturers will prioritize energy efficiency, waste reduction, and resource conservation in the design and operation of custom machines. This includes the use of renewable materials, recycling initiatives, and the adoption of eco-friendly production processes. ALTRON AUTO is committed to incorporating sustainable practices into its custom machine solutions, helping industrial inline duct fan factories minimize their environmental footprint while maximizing operational efficiency.

Conclusion

Custom machine solutions are indispensable assets for industrial inline duct fan factories seeking to optimize their manufacturing processes and meet the demands of a competitive market. ALTRON AUTO’s commitment to innovation and excellence ensures that its custom solutions deliver unmatched performance, efficiency, and reliability, helping factories achieve their production goals and exceed customer expectations. With ALTRON AUTO as their partner, industrial inline duct fan factories can confidently navigate the challenges of modern manufacturing and thrive in an ever-evolving industry landscape.