Future of Welding: ALTRON’s Industry Fans Auto Welding Machines

Welding stands as the backbone of numerous industries, shaping the foundations of construction, automotive manufacturing, and aerospace engineering. However, traditional welding processes come with their set of challenges, from labor-intensive tasks to safety concerns. In the pursuit of innovation, industry fans auto welding machines emerge as a transformative solution, with ALTRON leading the charge.

Section 1: Understanding Industry Fans Auto Welding Machines

1.1 Definition and Operation:

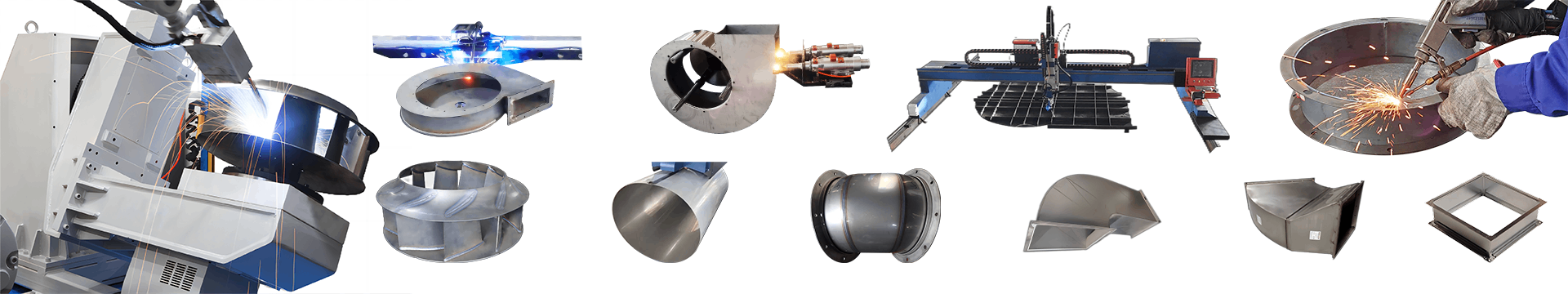

Industry fans auto welding machines are cutting-edge tools designed to streamline welding processes through automation. These machines utilize advanced technologies to handle intricate welding tasks with precision. ALTRON’s machines, in particular, showcase a seamless integration of robotics and welding technology.

1.2 Key Components and Features:

ALTRON’s industry fans auto welding machines boast a sophisticated set of components that contribute to their efficiency. Precision welding heads, automated welding arms, and state-of-the-art control systems are some key features that set these machines apart. These components work in tandem to ensure high-quality welds and optimal performance.

1.3 Automation’s Role:

The heart of industry fans auto welding machines lies in automation. These machines leverage robotics to execute welding tasks swiftly and accurately, eliminating the need for extensive manual labor. The integration of automation not only enhances efficiency but also opens avenues for increased customization and adaptability in welding processes.

Section 2: Advantages of Industry Fans Auto Welding Machines:

2.1 Increased Efficiency:

ALTRON’s industry fans auto welding machines significantly contribute to accelerated welding processes. The precision and speed with which these machines operate ensure faster project completion without compromising on the quality of welds. Industries can meet demanding deadlines and enhance overall productivity.

2.2 Cost-effectiveness:

Automation translates into reduced labor costs, a key advantage of industry fans auto welding machines. ALTRON’s machines optimize resource utilization, allowing businesses to achieve cost savings in the long run. With fewer manual hours required, projects become more economically viable, making ALTRON’s machines an investment in efficiency and financial prudence.

2.3 Enhanced Safety:

Safety remains paramount in any industrial setting. ALTRON addresses this concern by incorporating advanced safety features into their industry fans auto welding machines. From real-time monitoring to automatic shutdown mechanisms in case of anomalies, these machines prioritize the well-being of workers, mitigating the risk of accidents.

Section 3: Applications Across Industries:

3.1 Automotive: Mass Production Precision

ALTRON’s industry fans auto welding machines find a pivotal role in the automotive sector. With the demand for precision and efficiency in mass production, these machines excel in welding intricate components, ensuring the structural integrity and quality of vehicles rolling off assembly lines.

3.2 Construction: Welding the Foundations

In the construction industry, ALTRON’s machines play a vital role in welding structural components for buildings and infrastructure. The precision and speed of these machines contribute to the construction of robust, durable structures, meeting the stringent requirements of modern construction projects.

3.3 Industry Fan: Precision Takes Flight

Precision welding is paramount in industrial fan manufacturing, where safety and quality are non-negotiable. ALTRON’s industry fans auto welding machines prove their mettle in crafting complex and precise welds for critical industry fan components, contributing to the reliability and performance of industrial fan.

The importance of industry fans auto welding machines in shipbuilding cannot be overstated. From welding large metal structures to ensuring the integrity of maritime vessels, ALTRON’s machines play a crucial role in meeting the rigorous standards of the shipbuilding industry.

Section 4: Case Studies:

4.1 ALTRON’s Impact in Real-world Scenarios

Industries and companies worldwide have embraced ALTRON’s industry fans auto welding machines, realizing substantial improvements in productivity, quality, and cost-effectiveness. Case studies highlight how these machines have streamlined welding processes, leading to faster project completion, higher-quality welds, and significant cost savings.

4.2 Exemplifying Excellence: Automotive Corporation

Leading automotive manufacturer, adopted ALTRON’s industry fans auto welding machines in their production lines. The result? A 30% increase in productivity, a 20% improvement in weld quality, and a notable reduction in operational costs, showcased the transformative impact of these machines.

Section 5: Future Trends and Innovations:

5.1 Emerging Technologies in Welding Automation

The future of welding automation is promising, with continuous advancements on the horizon. ALTRON remains at the forefront, integrating emerging technologies such as robotics, IoT, and data analytics to further enhance the capabilities of their industry fans auto welding machines.

5.2 AI and Machine Learning: Shaping the Welding Landscape

The potential impact of artificial intelligence and machine learning on the future of welding is immense. ALTRON explores the integration of AI-driven algorithms, enabling predictive maintenance, adaptive welding processes, and unparalleled precision in their machines.

Section 6: Challenges and Considerations:

6.1 Addressing Challenges Head-on

While industry fans auto welding machines offer groundbreaking solutions, challenges persist. Factors like initial setup costs, training requirements, and the need for continuous maintenance can pose hurdles. ALTRON, however, remains committed to addressing these challenges through ongoing research and technological advancements.

6.2 Technological Mitigation

Advancements in technology play a crucial role in mitigating challenges associated with industry fans auto welding machines. ALTRON invests in research and development to refine machine capabilities, reduce maintenance needs, and enhance user-friendliness, ensuring a seamless welding experience for industries.

Section 7: Advancements in Technology:

7.1 Continual Innovation at ALTRON

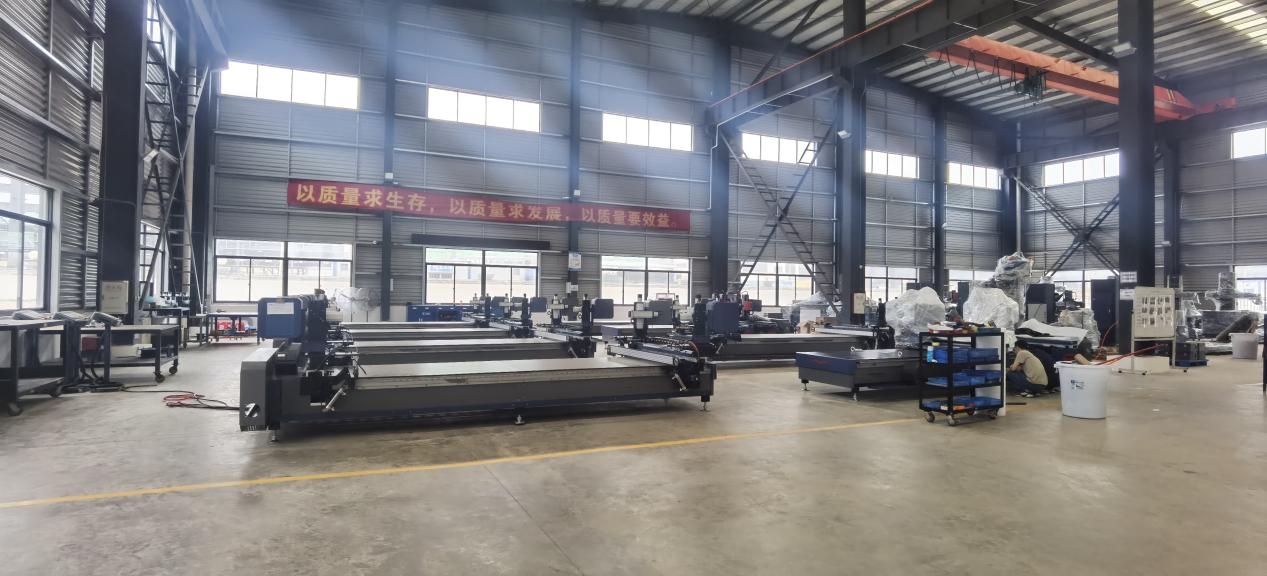

ALTRON, a leading manufacturer of industry fans auto welding machines, remains dedicated to pushing the boundaries of technological innovation. By investing heavily in research and development, ALTRON consistently introduces cutting-edge features and functionalities to their machines. From improved automation algorithms to enhanced precision welding capabilities, ALTRON’s commitment to technological advancements ensures that their industry fans auto welding machines stay at the forefront of the welding industry.

7.2 Integration of IoT in Welding Machines

In the quest for smarter and more connected welding solutions, ALTRON has embraced the Internet of Things (IoT). The integration of IoT technology in their industry fans auto welding machines allows for real-time monitoring and data analysis. This not only enhances the overall efficiency of welding processes but also enables predictive maintenance, reducing downtime and ensuring optimal machine performance.

Section 8: Environmental Impact and Sustainability:

8.1 Energy-Efficient Design

ALTRON recognizes the importance of sustainability in today’s industrial landscape. Their industry fans auto welding machines are designed with energy efficiency in mind. By optimizing power consumption during welding operations, these machines contribute to a reduction in overall energy usage, aligning with global efforts toward sustainable manufacturing practices.

8.2 Reducing Carbon Footprint

The environmental impact of welding processes is a critical consideration. ALTRON’s commitment to sustainability is reflected in the design of their machines, which aim to minimize the carbon footprint associated with welding activities. The adoption of eco-friendly materials and energy-efficient components contributes to a greener and more environmentally responsible approach to welding.

Section 9: Customer-Centric Approach:

9.1 Understanding Diverse Industry Needs

ALTRON’s commitment to customer satisfaction is evident in their customer-centric approach. The company acknowledges the diverse needs of industries utilizing welding technology and tailors their it to address these unique requirements. This personalized approach ensures that ALTRON’s machines not only meet but exceed the expectations of their clients across various sectors.

9.2 Responsive Customer Support

ALTRON recognizes that the journey with their industry fans auto welding machines extends beyond the initial purchase. To provide comprehensive support, the company offers responsive customer service. From installation assistance to ongoing technical support, ALTRON’s team is dedicated to ensuring that their clients experience seamless operations and maximum value throughout the lifecycle of their welding machines.

Section 10: Training and Skill Development:

10.1 Empowering Operators through Training Programs

ALTRON understands the significance of skilled operators in maximizing the potential of their industry fans’ auto welding machines. To empower operators with the knowledge and skills required for optimal machine utilization, ALTRON offers comprehensive training programs. These programs cover machine operation, maintenance, and troubleshooting, fostering a workforce that can harness the full capabilities of ALTRON’s cutting-edge welding technology.

10.2 Promoting Industry Education and Collaboration

Beyond individual training, ALTRON actively promotes industry education and collaboration. The company engages in partnerships with educational institutions and industry organizations to facilitate knowledge exchange and skill development. By contributing to the growth of welding expertise, ALTRON aims to elevate the overall standards of the welding profession.

Section 11: Contact ALTRON Now

11.1 Personalized Consultation:

For industries seeking precision and efficiency in welding processes, connecting with ALTRON is the first step towards transformative solutions. Prospective clients can initiate a personalized consultation by reaching out to ALTRON through WhatsApp at +86 156 2739 7226. This direct line of communication allows for a tailored discussion, where industry-specific needs can be addressed, and customized recommendations for industry fans’ auto welding machines can be provided.

11.2 Email for Inquiries:

ALTRON extends an open invitation for inquiries and detailed discussions through email. For a comprehensive understanding of how their industry fans auto welding machines can meet your specific requirements, you can contact ALTRON via email at cystal@auto-altron.com. This channel ensures a written record of communication, making it convenient for clients to share project details, ask questions, and receive prompt and detailed responses from ALTRON’s expert team.

Conclusion:

In the realm of welding, ALTRON’s industry fans auto welding machines emerge as a beacon of innovation, reshaping how industries approach this fundamental process. The integration of automation not only addresses the challenges posed by traditional welding but also propels industries toward a future of efficiency, cost-effectiveness, and heightened safety standards.