The Art and Science of Volute Welding Machines in Industrial Fan Manufacturing

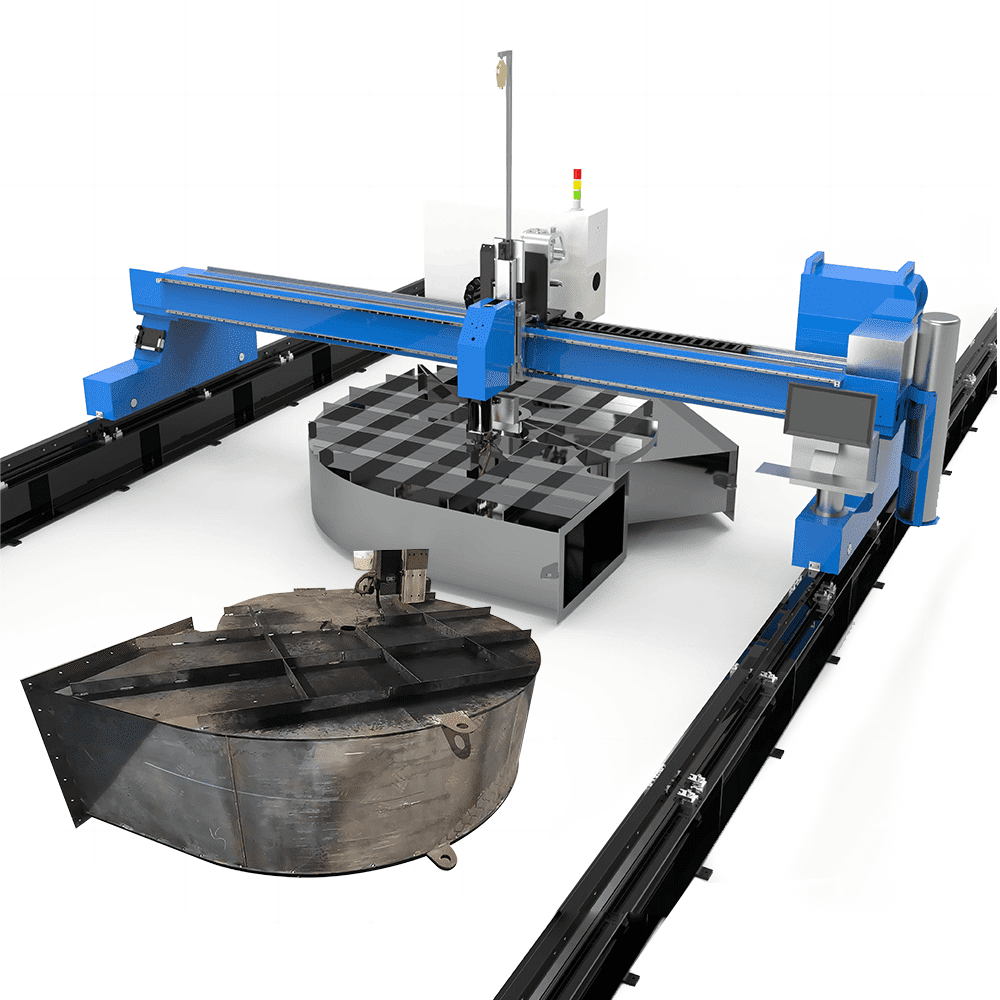

In the vast realm of industrial fan production, the significance of Industry Fans Volute welding machines cannot be overstated. These specialized machines play a pivotal role in crafting the intricate volutes – the spiral-shaped casings that define the aerodynamics and efficiency of industrial fans.

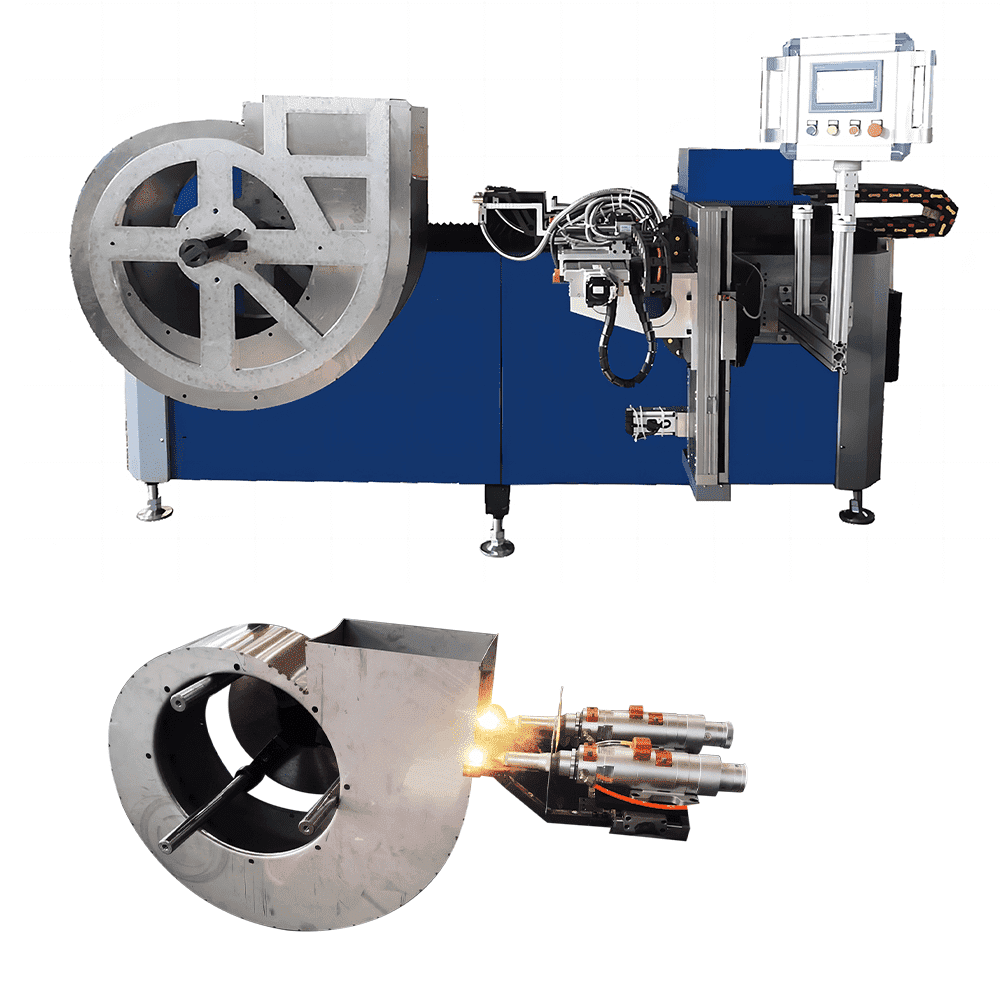

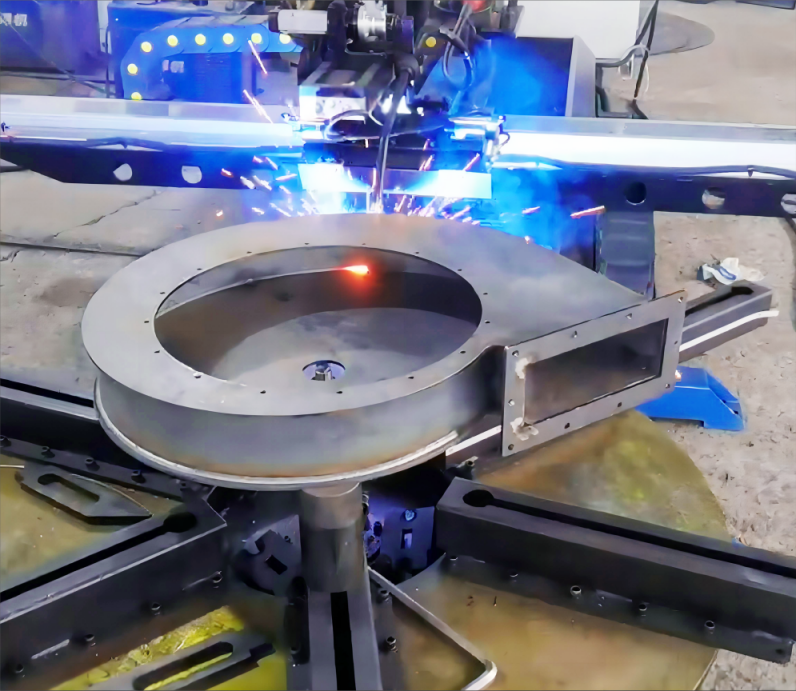

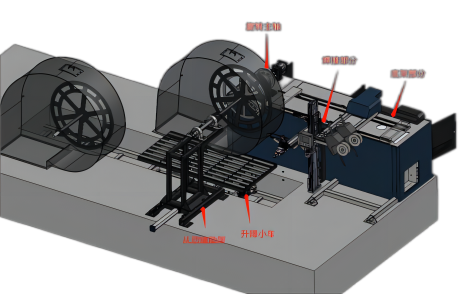

Especially for the welding of industrial centrifugal fan casings, we have specially developed a single-gun visual and double-gun profiling synchronous automatic welding machine for industrial fan housing, which has solved the problem of welding quality and welding workers’ safety for hundreds of industrial fan manufacturers. question.

1. Understanding Industry Fans Volute welding machines

1.1 Definition and Function

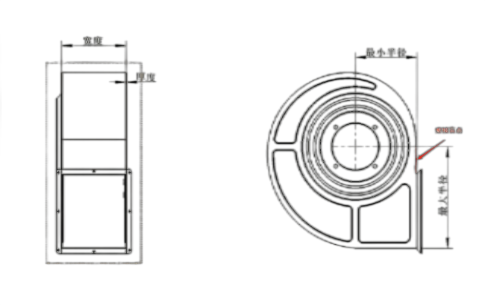

Volute welding machines are automated devices designed for the precise welding of volutes onto fan casings. The volute, a crucial component in fan design, influences airflow, pressure, and overall efficiency.

1.2 Core Components

1.2.1 Welding Head

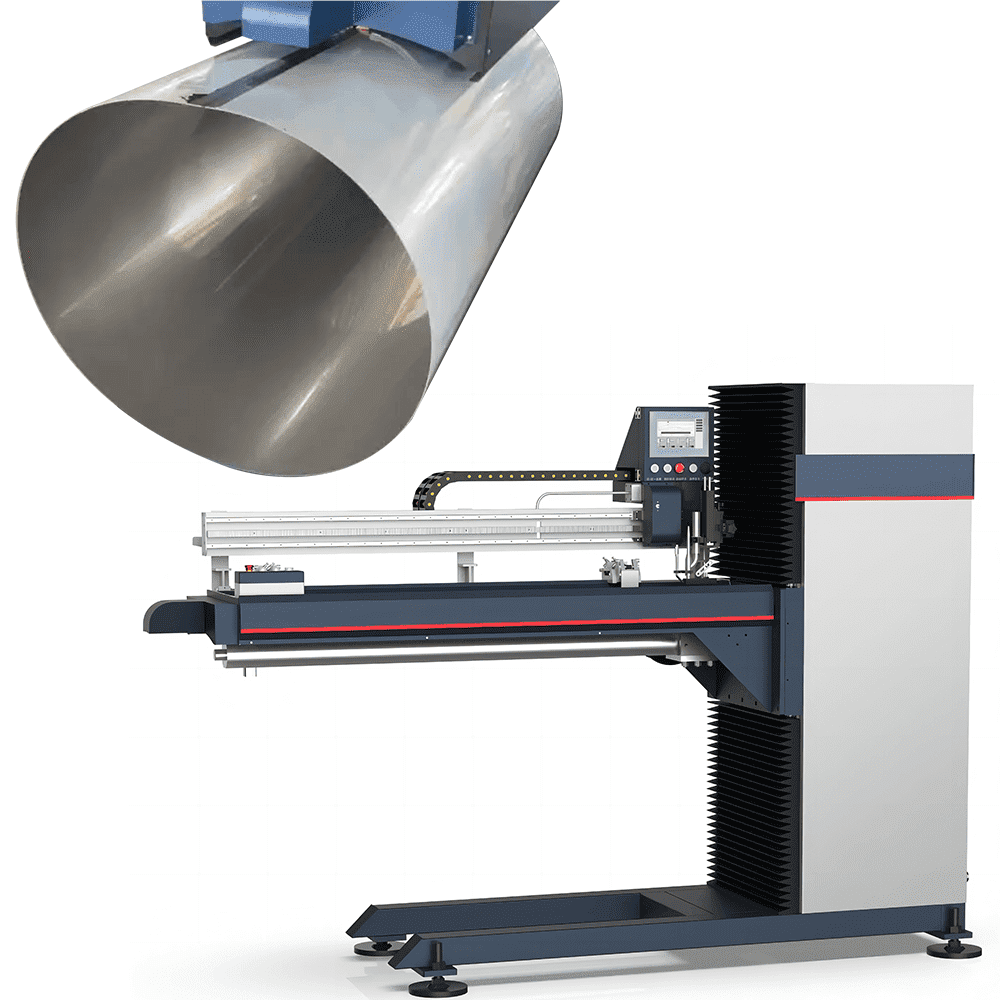

At the heart of the volute welding machine is the welding head, a sophisticated mechanism equipped with high-precision sensors and actuators. This component ensures accurate alignment and consistent weld quality.

1.2.2 Power Source

Powering the welding process is a robust energy source, often utilizing advanced technologies such as laser welding or high-frequency welding. These methods ensure a fusion of materials that is both durable and efficient.

1.3 Types of Volute Welding Machines

1.3.1 Resistance Spot Welding Machines

Commonly used in the manufacturing of smaller fans, resistance spot welding machines utilize electrical resistance to create localized heat for welding. This method offers high-speed production with minimal material distortion.

1.3.2 Laser Welding Machines

In the realm of precision, laser welding machines take the lead. Employing a focused laser beam, these machines provide unparalleled accuracy, making them ideal for intricate volute designs and high-end applications.

2. Advantages of Industry Fans Volute welding machines

2.1 Enhanced Precision

One of the primary advantages of Industry Fans Volute welding machines is their ability to achieve a level of precision that surpasses manual welding methods. The automated nature of these machines ensures consistency in weld quality, contributing to the overall reliability of industrial fans.

2.2 Increased Efficiency

The automated processes of volute welding machines significantly reduce production time compared to manual welding. This increased efficiency not only translates to cost savings but also allows manufacturers to meet growing demand without compromising on quality.

2.3 Versatility in Design

The versatility offered by volute welding machines allows manufacturers to experiment with intricate and complex volute designs. This flexibility opens doors to innovation in fan engineering, enabling the production of fans tailored to specific industrial needs.

3. Challenges in Industry Fans Volute welding machines

3.1 Material Compatibility

Selecting the right materials for Industry Fans Volute welding machines is crucial. Manufacturers must consider factors such as material conductivity, heat resistance, and weldability to ensure the durability and longevity of the final product.

3.2 Design Complexity

While volute welding machines offer versatility in design, the complexity of some designs can pose challenges. Achieving precision in intricate patterns requires advanced programming and meticulous calibration of welding parameters.

4. Case Studies: Industry Applications

4.1 Aerospace Industry

In the aerospace sector, where efficiency and reliability are paramount, volute welding machines find extensive application. These machines contribute to the production of high-performance fans used in aircraft cooling systems.

4.2 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on industrial fans with precisely welded volutes. The seamless integration of volute welding machines ensures optimal performance and energy efficiency in HVAC applications.

5. Future Trends in Industry Fans Housing Welding Technology

5.1 Integration of Artificial Intelligence

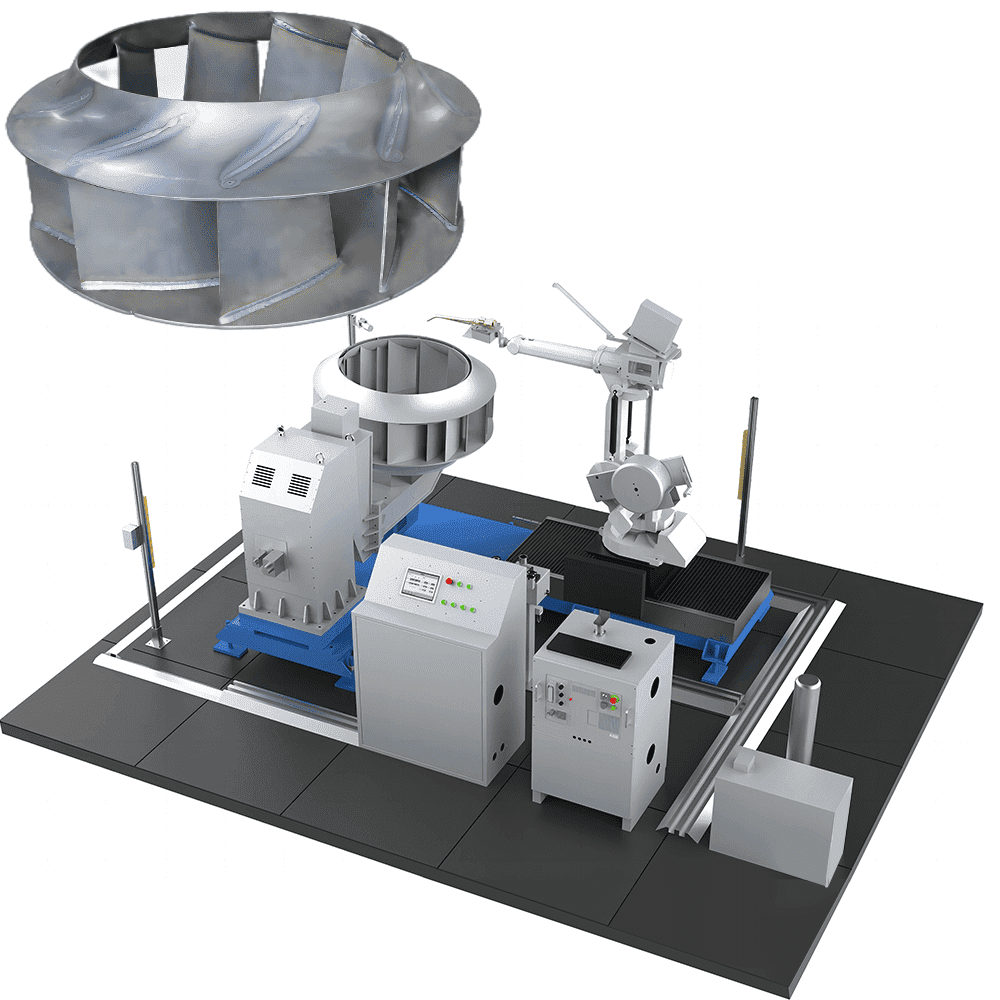

The next frontier in Industry Fans housing welding machines lies in the integration of artificial intelligence (AI). Smart machines equipped with machine learning algorithms can adapt to variations in materials and designs, further enhancing precision and efficiency.

5.2 Industry 4.0 Integration

As industries embrace the principles of Industry 4.0, volute welding machines are expected to become integral components of smart manufacturing processes. Integration with data analytics and connectivity features will enable real-time monitoring and optimization

Conclusion

In the dynamic landscape of industrial fan manufacturing, the role of volute welding machines is irreplaceable. From enhancing precision and efficiency to enabling innovative designs, these machines have become indispensable in shaping the future of industrial fan technology. As technology continues to evolve, so too will the capabilities of housing welding machines, driving advancements in fan performance and contributing to the overall efficiency of industrial processes.