Mastering Metal: Exploring ALTRON CNC Metal Spinning and Expanding Process

Mastering Metal: Exploring ALTRON CNC Metal Spinning and Expanding Process

In the realm of precision metalworking, the ALTRON CNC Metal Spinning and Expanding Process stands tall as a beacon of excellence. This innovative technique revolutionizes the fabrication of metallic components, offering unmatched precision and efficiency. Let’s delve into the intricacies of this process and uncover its transformative potential.

Understanding Metal Spinning

Metal spinning, also known as spin forming or spinning, is a metalworking process wherein a disc or tube of metal is rotated at high speeds and formed into axially symmetric parts. This technique is widely employed in various industries, including aerospace, automotive, and manufacturing.

Traditional vs. CNC Metal Spinning

Traditional metal spinning involves manual manipulation of the workpiece by skilled craftsmen. While effective, this method is labor-intensive and limited in precision. In contrast, CNC (Computer Numerical Control) metal spinning leverages automated machinery guided by computer programs to achieve unparalleled accuracy and consistency.

The ALTRON Advantage

ALTRON, a pioneering force in precision engineering, has perfected the art of CNC metal spinning. Their cutting-edge technology and meticulous craftsmanship converge to deliver superior results, setting new standards in the industry.

Key Components of ALTRON CNC Metal Spinning

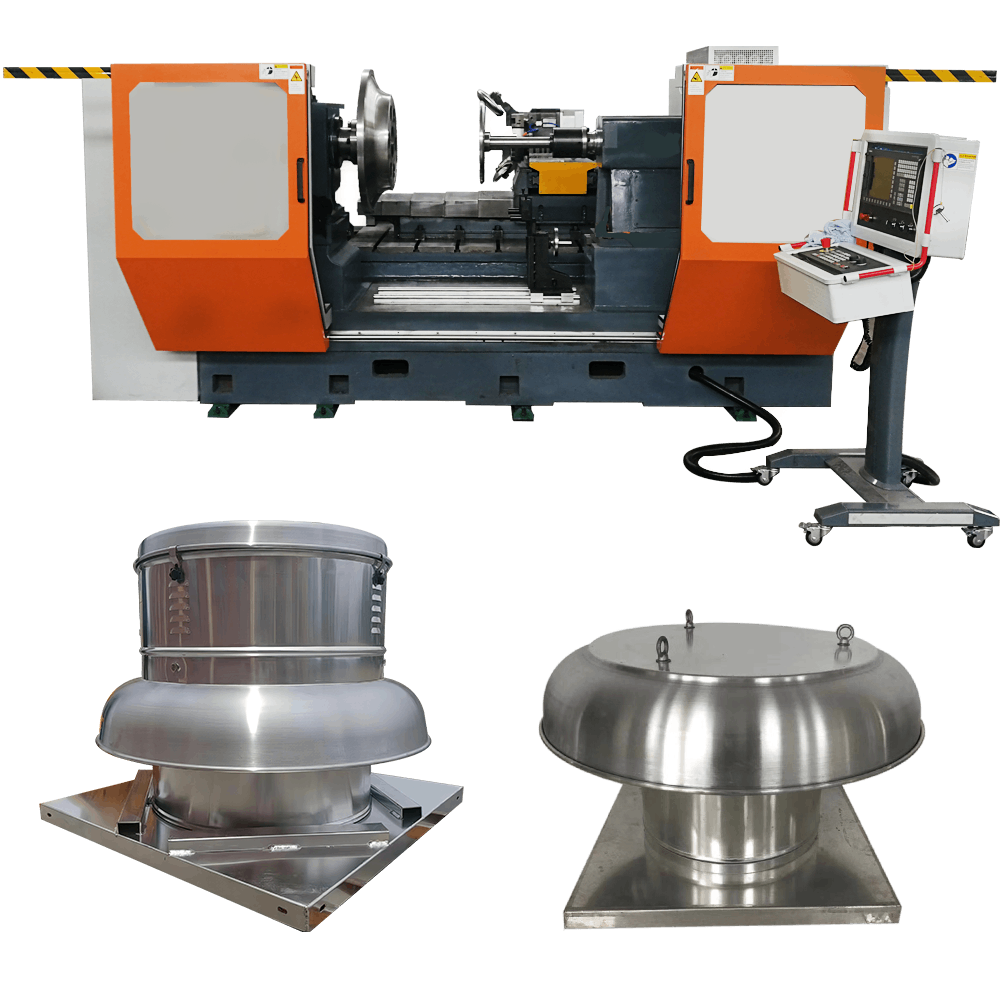

Precision Machinery:

ALTRON’s state-of-the-art CNC spinning machines are engineered to exacting specifications, enabling precise control over the metal forming process. These machines boast advanced features such as variable speed control, multi-axis manipulation, and real-time monitoring.

Tooling Expertise:

Central to the success of CNC metal spinning is the design and fabrication of specialized tooling. ALTRON’s team of engineers and toolmakers possess unrivaled expertise in developing custom tooling solutions tailored to each unique application. This meticulous attention to detail ensures optimal performance and flawless execution.

Material Selection:

The choice of material plays a critical role in metal spinning. ALTRON works with a wide range of metals, including aluminum, stainless steel, copper, and titanium, meticulously selecting the appropriate material based on factors such as strength, ductility, and thermal conductivity.

The CNC Metal Spinning Process

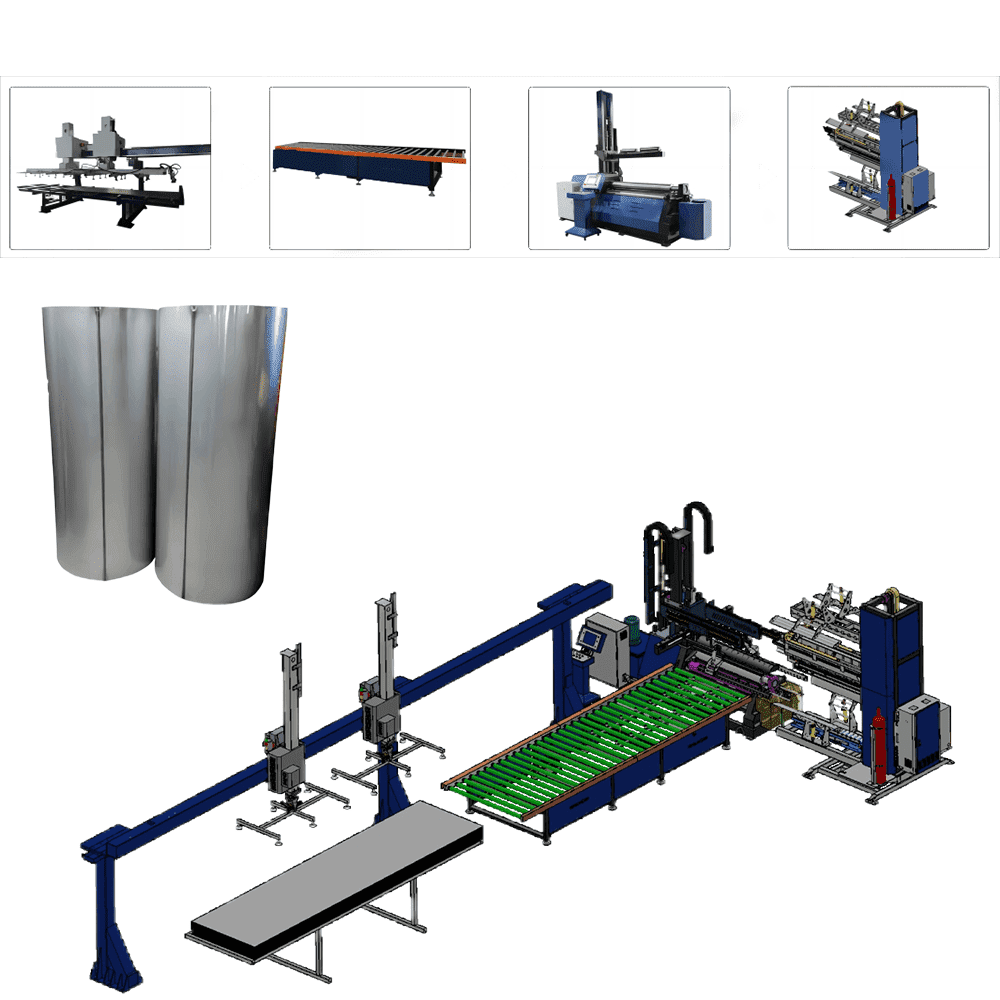

Preparation:

The process begins with meticulous preparation, including material selection, tooling design, and programming of the CNC spinning machine. ALTRON’s engineers collaborate closely with clients to understand their specific requirements and tailor the process accordingly.

Loading and Fixturing:

The raw material, typically a flat sheet or tube, is securely loaded onto the CNC spinning machine. Precision fixturing ensures proper alignment and stability during the spinning process, minimizing deviations and optimizing accuracy.

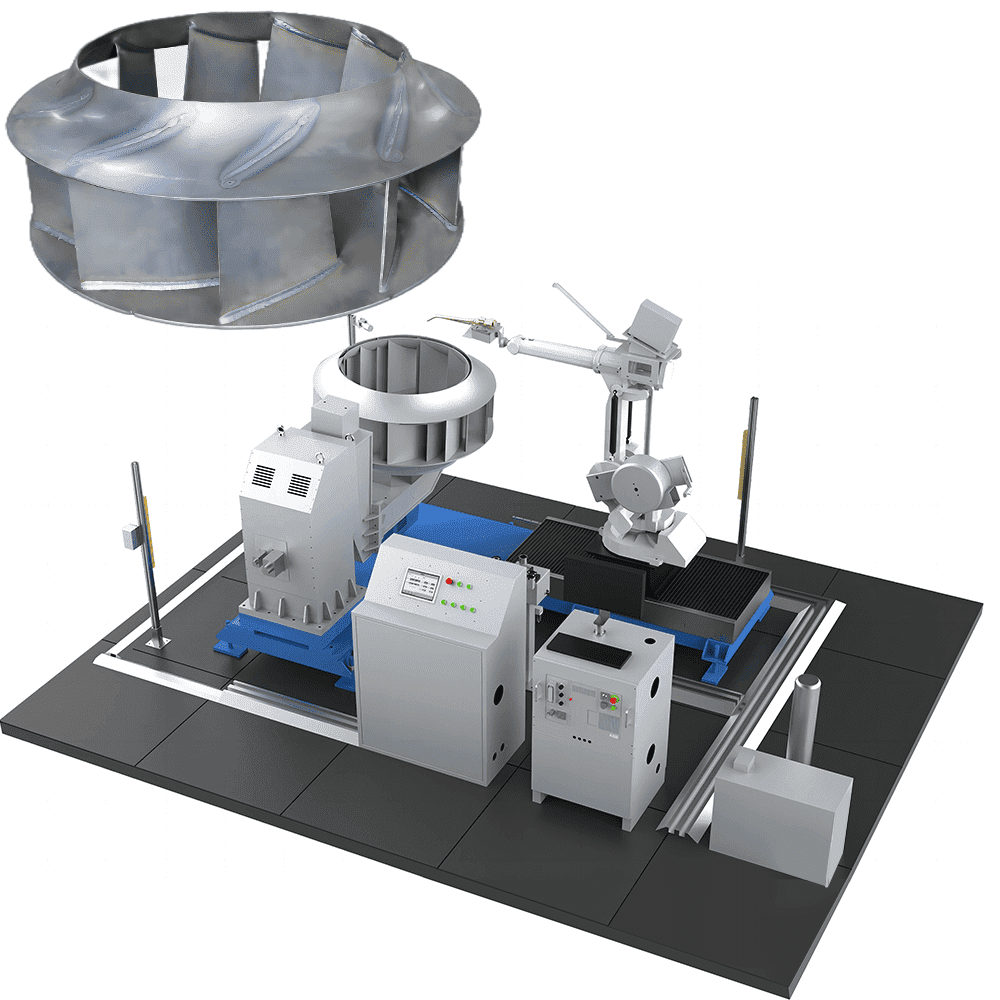

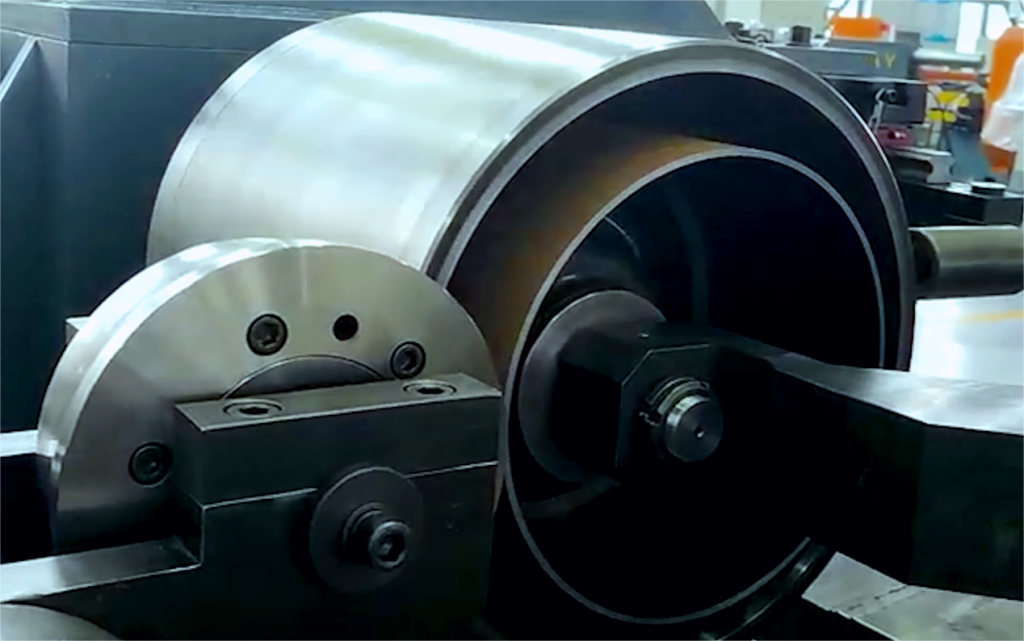

Forming:

As the spinning machine rotates the workpiece at high speeds, specialized forming tools gradually shape the metal against a mandrel or mold. The CNC control system precisely manipulates the position and speed of the tools, allowing for intricate geometries and smooth contours.

Monitoring and Quality Control:

Throughout the spinning process, sensors and monitoring systems continuously track key parameters such as temperature, pressure, and dimensional accuracy. Any deviations or anomalies are promptly detected and corrected, ensuring uncompromising quality and consistency.

Finishing Touches:

Upon completion of the spinning process, the formed component undergoes secondary operations such as trimming, machining, and surface treatment as required. ALTRON’s meticulous attention to detail ensures that every part meets the highest standards of quality and craftsmanship.

Applications of ALTRON CNC Metal Spinning

ALTRON’s CNC metal spinning capabilities find applications across a diverse range of industries and sectors, including:

Aerospace:

From engine components to satellite housings, precision is paramount in aerospace applications. ALTRON’s CNC metal spinning process delivers lightweight, high-strength parts with exceptional dimensional accuracy and surface finish, meeting the stringent demands of the aerospace industry.

Automotive:

In the automotive sector, ALTRON’s CNC metal spinning process is employed in the fabrication of exhaust systems, fuel tanks, and decorative trim components. The ability to produce complex shapes and contours with tight tolerances makes it ideal for automotive applications where aesthetics and performance are equally important.

Lighting and Architecture:

The architectural and lighting industries leverage ALTRON’s CNC metal spinning expertise to create custom fixtures, reflectors, and decorative elements. The process enables the production of seamless, uniform shapes with precise optical characteristics, enhancing both functionality and aesthetics.

Medical Devices:

In the medical field, ALTRON’s CNC metal spinning process is used to manufacture components for diagnostic equipment, surgical instruments, and prosthetic devices. The biocompatibility of materials such as titanium and stainless steel, combined with the process’s precision and reliability, makes it well-suited for medical applications demanding uncompromising quality and performance.

Advantages of ALTRON CNC Metal Spinning

Precision:

ALTRON’s CNC metal spinning process offers unmatched precision, with the ability to achieve tight tolerances and complex geometries with ease.

Efficiency:

By automating the metal spinning process, ALTRON enhances efficiency and productivity, reducing lead times and minimizing waste.

Versatility:

With the flexibility to work with a wide range of materials and geometries, ALTRON’s CNC metal spinning process caters to diverse applications across industries.

Cost-Effectiveness:

Despite its advanced technology and capabilities, ALTRON’s CNC metal spinning process remains cost-effective, offering exceptional value for clients seeking superior metal components.

Conclusion

In conclusion, the ALTRON CNC Metal Spinning and Expanding Process represents a pinnacle of precision engineering and innovation. With its advanced technology, meticulous craftsmanship, and unrivaled expertise, ALTRON continues to redefine the possibilities of metalworking, delivering superior results across industries.