Edited by: Engineer Joby

Edited by: Engineer Joby

Metal Spinning And Flanging For Industrial Fans

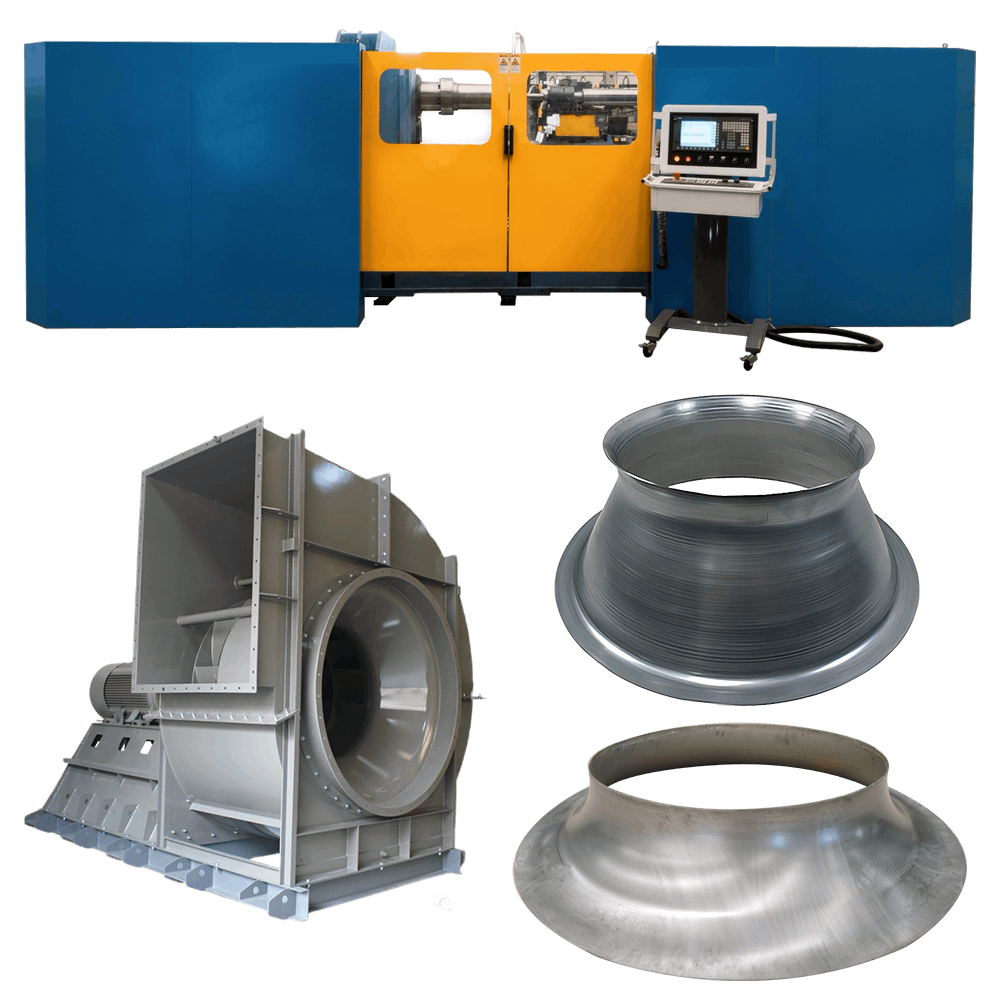

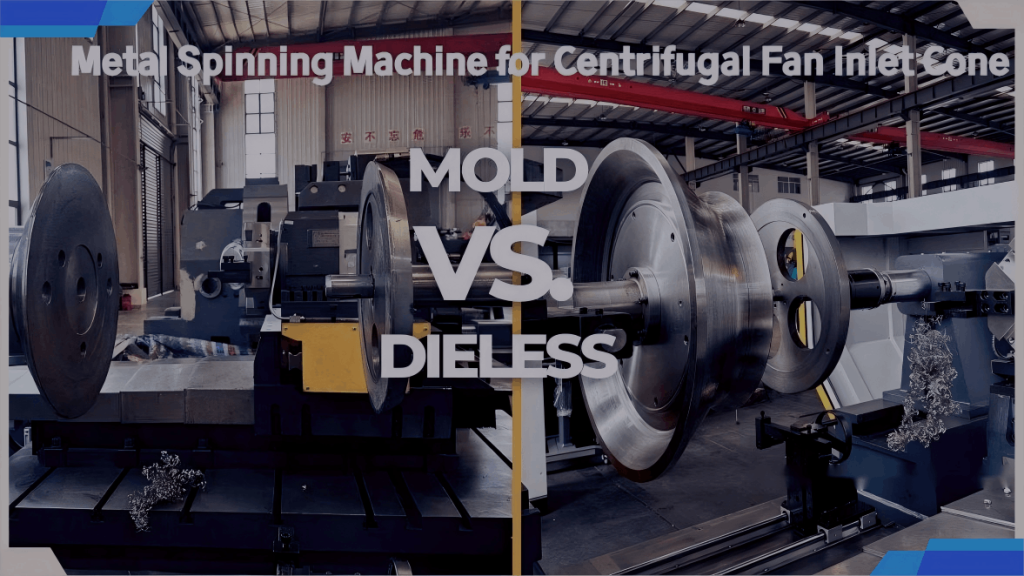

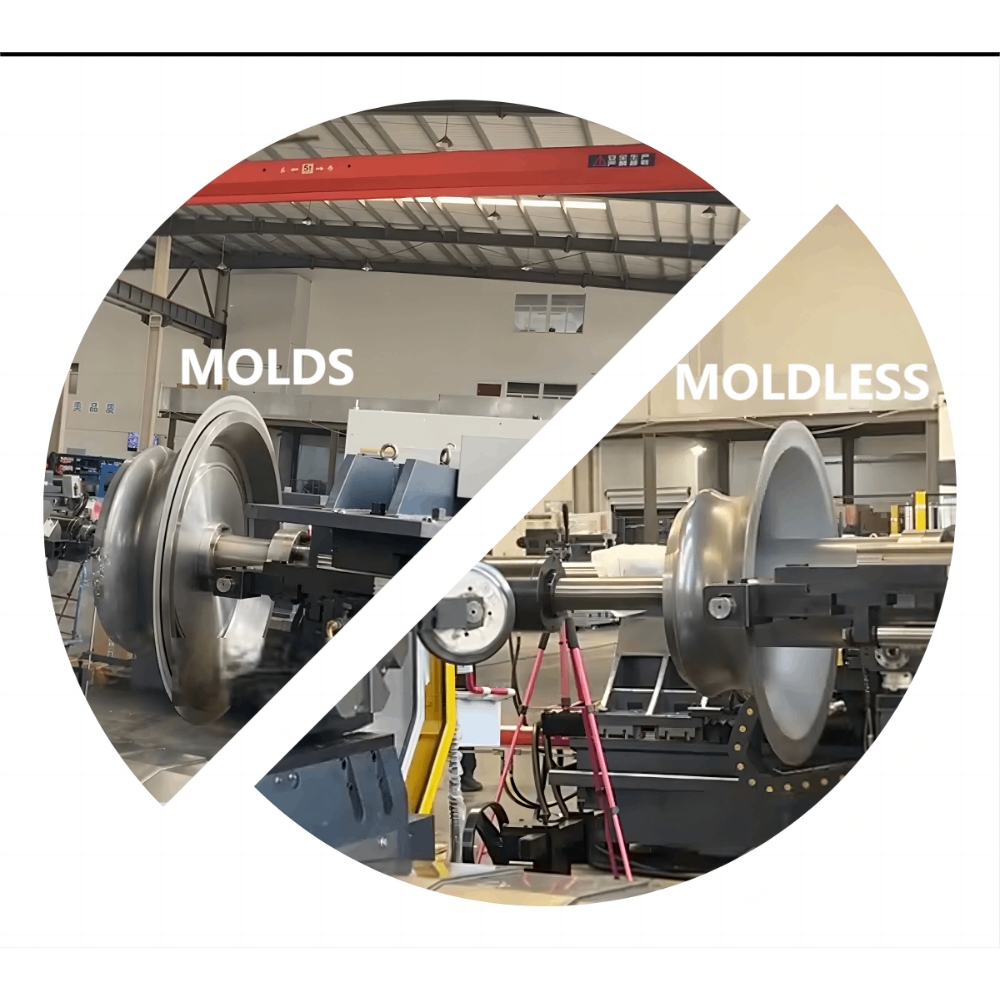

The case of Metal Spinning Machine for Centrifugal Fan Inlet Cone is mainly divided into traditional die spinning and moldless spinning. Whether dieless spinning is used depends on the single-side angle of the air inlet cone and the thickness of the material!

Conditions for choosing moldless spinning to process the air inlet cone

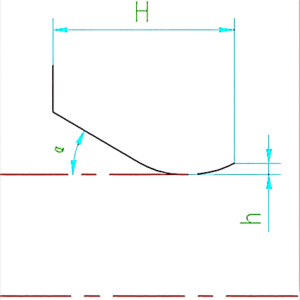

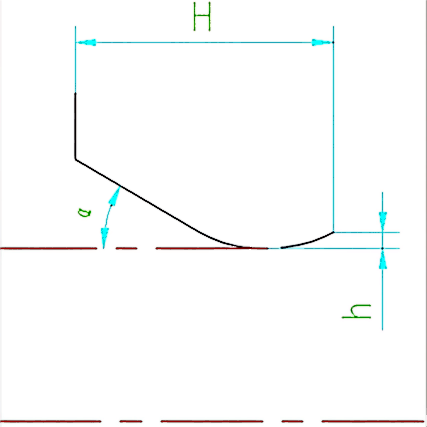

Requirements for the shape and size of the air inlet cone:

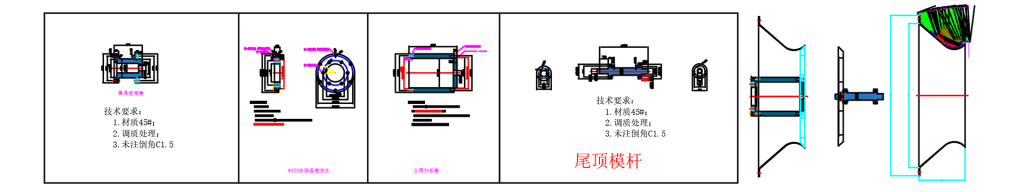

|

|

Inlet Cone Size Data Diagram Height: 350≤H ≤450mm, Remarks: H is the total height, h is the depth of the mouth, α is the angle of the slope! If the above shape and size requirements are met, the moldles metal spinning process can be selected |

Requirements for the material thickness of the air inlet cone before spinning:

- Refer to the different diameters of the air inlet cone of the centrifugal fan;

- Refer to the height of the air inlet cone spinning of the centrifugal fan;

- Mainly to ensure that the material has sufficient strength to support the forming of the air inlet cone during the plastic deformation process of metal spinning!

- The material thickness is too thin, wrinkles, cracks, and unstable processing;

- Selecting the wrong materials will increase the manufacturing cost and assembly difficulty of the process fan!

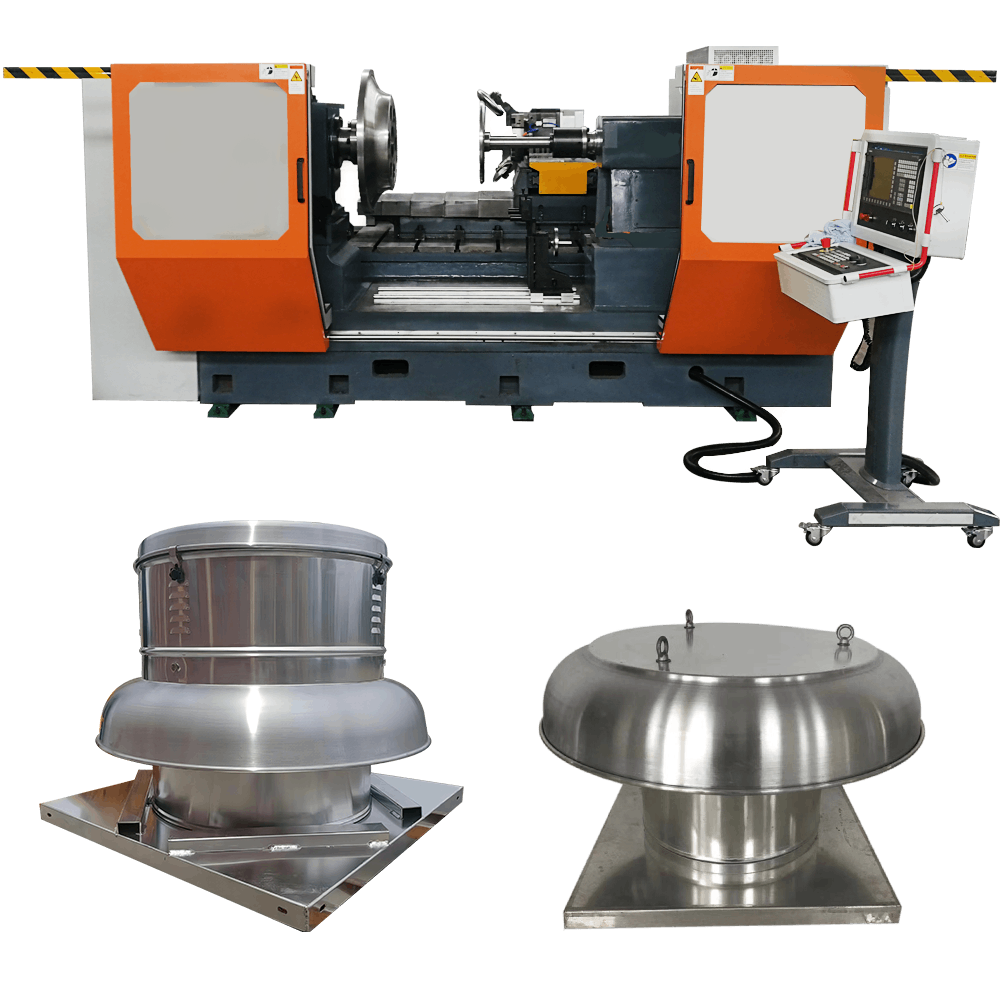

How to use metal spinning machine to process air inlet cone for industrial centrifugal fan

- How to use metal spinning machine to process the air inlet cone of industrial centrifugal fan

- Design the mold according to the air inlet cone, traditional solid mold or moldless mold process;

- Choose a CNC metal spinning machine with suitable diameter;

- Choose spinning tools, roller diameter, shape and R value;

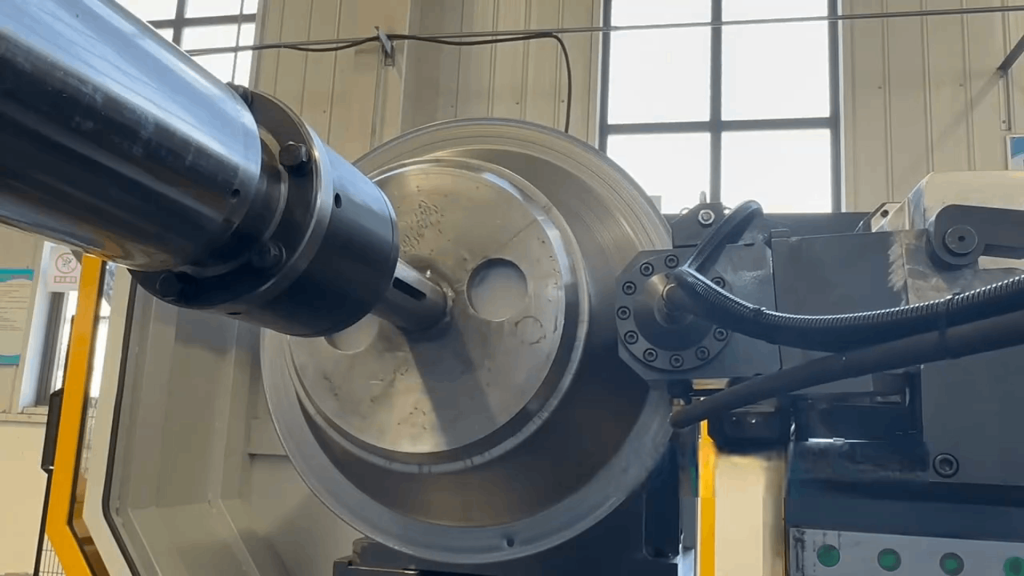

- Install the mold and spinning tools on the CNC spinning machine;

- Operate the CNC metal spinning machine to find the mold coordinates, start drawing the spinning trajectory, and ask Altron’s CNC metal spinning software to automatically export the metal spinning program!

- The CNC spinning machine opens the corresponding program and simulates it! Observe whether the coordinates of the spinning trajectory are consistent with the computer trajectory;

- Adjust the diameter position of the hydraulic reverse roller and the mold and the height to the end face of the mold, depending on the shape and height of the product! The main function is to spin the flange side flatness of the air inlet cone!

- Install the cutter on the turret. After spinning, the bottom must be cut off to remove the air inlet cone;

Moldless metal spinning for air inlet funnel,

How to adjust and solve the dimensional accuracy of the spinning air inlet cone!

Check the diameter and height of the centrifugal fan;

Adjust the spinning profile to make the angle of the air inlet meet the requirements of the drawing!

Adjusting the raw material diameter before spinning can solve the size tolerance of the outer edge diameter! Usually the outer edge diameter is not turned!

How to process the flange hole position of the air inlet cone?

The punching of the flange can be done by using a punching mechanism on a CNC spinning machine or by laser cutting, or by using an automatic indexing punching machine!

Moldless Metal Spinning Processing Video

Trends in metal spinning for centrifugal fan inlet cones

In recent years, more and more industrial fan manufacturers will choose to develop new industrial fans and highlight the advantages of other industrial fans in the market! Thereby continuously optimizing and improving the energy efficiency of the fan!

The energy efficiency, air volume and air pressure of a high-quality industrial centrifugal fan are optimized and adjusted by the designer on the core impeller and the air inlet cone of the housing to achieve the best data!

CNC metal spinning can complete the processing and production of impeller shrouds and air inlet cones at the lowest manufacturing cost and the shortest manufacturing cycle!

The mold cost is about 10% of deep drawing, especially the moldless spinning solution, which can almost ignore the mold cost!

The trend of metal CNC spinning in the field of industrial fan manufacturing is rising, eliminating the original traditional hydraulic profiling machinery! Complex operation, poor consistency and other problems!

Altron Manufactures And Provides Forming and Welding Solutions For:

- CNC Metal Spinning Machine,

- Multi-Roller Flow Forming Machine,

- Neck Spinning Machine,

- Internal Spinning Machine,

- Hub Spinning Machine,

- CNC Flanging Machine,

- Welding Robot, Rolling Machine,

- Seam Welding,

- Axial Flow Fan Production Line,

- Centrifugal Fan Impeller Welding,

- Centrifugal Fan Housing Welding,

- Air Duct Production Line,

- Spiral Duct Production Line,

- Rectangular Duct Production Line,

- Impeller Forming Production Line,

- Customized Industrial Fan Impeller,

- Laser Cutting Production Line,

- Laser Welding Solution, ect…