Metal Spinning Machines: Driving Innovation in Engineering

Metal spinning, a fascinating manufacturing technique, has been at the heart of innovation in the engineering field. This process involves the transformation of flat metal discs or sheets into intricate, three-dimensional shapes. At its core, metal spinning is about precision, creativity, and versatility.

a. Metal Spinning Machines: Definition of Metal Spinning

Metal spinning, also known as spin forming or spin turning, is a metalworking process that forms sheet metal into a rotational symmetrical part. It uses a combination of axial force and simultaneous rotation to achieve precise shapes, making it a crucial part of modern manufacturing.

b. Metal Spinning Machines: Importance of Metal Spinning in Manufacturing

Metal spinning plays a vital role in various industries, such as automotive and home decor. Its ability to create complex and lightweight components with minimal material waste makes it indispensable for modern manufacturing.

c. Metal Spinning Machines: Purpose of Metal Spinning Machines

Metal spinning machines are designed to automate and streamline the metal spinning process. They enable manufacturers to achieve higher precision, consistency, and efficiency in shaping metal parts. ALTRON, a leading metal spinning machine manufacturer, has been at the forefront of this innovative technology.

Types of Metal Spinning Machines

Metal spinning machines come in two primary types: manual and CNC (Computer Numerical Control). Let’s delve into these machines to understand their descriptions, operations, advantages, and applications.

a. Manual Metal Spinning Machines

- Description and Operation

It are operated by skilled craftsmen who use their expertise to shape metal. These machines consist of a spinning lathe and a set of forming tools. The operator manually feeds the metal sheet onto the spinning lathe and shapes it using hand tools while the lathe rotates.

- Applications

Manual metal spinning machines are ideal for producing small quantities of intricate and customized parts. They are often used in industries requiring unique designs and low production volumes, such as custom lighting fixtures and artistic metalwork.

b. CNC Metal Spinning Machines

- Description and Operation

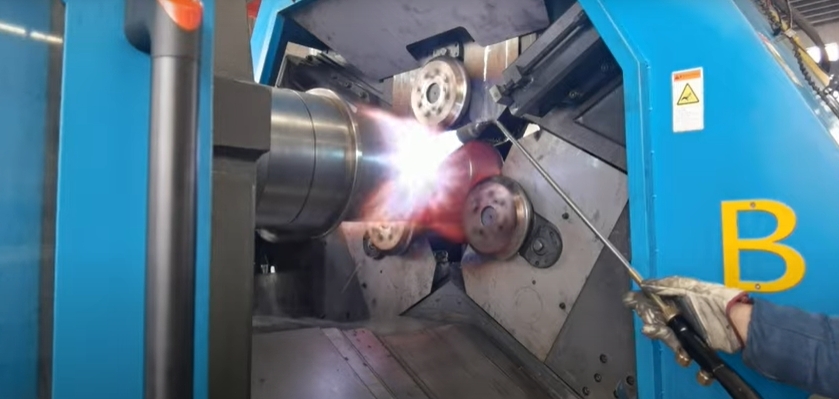

It is automated and highly precise. They are controlled by computer programs that dictate the spinning process. These machines feature a chuck or mandrel to hold the metal, forming tools that are precisely guided by the CNC system, and a drive mechanism for rotation.

- Advantages Over Manual Machines

CNC metal spinning machines offer several advantages over manual ones. They provide unparalleled precision and repeatability, making them suitable for high-volume production. CNC control allows for complex and uniform shapes, reduced setup times, and minimal operator intervention.

- Applications

CNC metal spinning machines are essential in industries demanding large quantities of uniform components, such as the automotive sector. They are used to produce parts like engine housings, satellite dishes, and reflectors.

Advantages and Limitations of Metal Spinning Machines

It is revolutionizing engineering with their unique set of advantages and overcoming challenges. ALTRON, a prominent manufacturer of metal spinning machines, plays a pivotal role in enabling these advancements.

a. Advantages of Metal Spinning Machines

- Cost-Effective Production

One of the standout advantages of it is its cost-effectiveness. Unlike traditional manufacturing methods that involve extensive tooling and setup costs, metal spinning offers a more economical approach. ALTRON’s machines, for instance, optimize material usage, reduce production time, and minimize tooling expenses. This cost efficiency makes it an attractive choice for industries seeking to streamline their production processes.

- Design Flexibility

Metal spinning machines provide unparalleled design flexibility. They can shape metal into complex, custom, and precision-engineered components. ALTRON’s commitment to innovation ensures that its machines can adapt to various design requirements, allowing engineers to explore new possibilities in product development. Whether it’s producing intricate lighting fixtures or intricate aerospace components, metal spinning offers a canvas for creativity.

- Minimal Material Wastage

Sustainability is a key concern in modern manufacturing. Metal spinning excels in this aspect by minimizing material wastage. Unlike subtractive manufacturing processes like milling or drilling, where substantial material is removed, metal spinning works with the existing material, reducing scrap and conserving resources. ALTRON’s machines are designed to optimize material usage further, aligning with the growing demand for eco-friendly manufacturing practices.

b. Limitations and Challenges

- Material Thickness and Size Constraints

While metal spinning is versatile, it does have limitations when it comes to material thickness and size. Extremely thick or large materials may not be suitable for the process due to the immense forces involved. However, ALTRON continually innovates to expand these boundaries, developing machines capable of handling larger and thicker materials. As technology advances, these constraints are gradually becoming less restrictive.

- Skilled Labor Requirement

Operating metal spinning machines effectively requires skilled operators who possess a deep understanding of the process. The intricacies of tool selection, speed control, and material manipulation demand a level of expertise. ALTRON supports the industry by offering training programs and resources to help bridge the skills gap. They understand that a well-trained workforce is essential for harnessing the full potential of their machines.

Metal Spinning Machines: Safety Considerations

Safety is paramount when working with metal spinning machines. ALTRON takes safety seriously and equips its machines with state-of-the-art safety features. These features include emergency stop mechanisms, safety interlocks, and protective enclosures to safeguard operators from potential hazards.

Additionally, operators working with metal spinning machines must adhere to strict safety precautions. These precautions include wearing appropriate personal protective equipment (PPE), maintaining a clean and organized workspace, and undergoing proper training in machine operation and emergency procedures.

Metal Spinning Machines: Maintenance and Care

To ensure the longevity and optimal performance of metal spinning machines, regular maintenance is essential. ALTRON provides comprehensive guidance on maintenance tasks, including lubrication, inspection, and calibration. Routine maintenance helps prevent breakdowns and ensures consistent, high-quality production.

In case of issues, ALTRON’s support extends to troubleshooting common problems. Their technical expertise and responsive customer service help minimize downtime and keep production running smoothly.

Future Trends in Metal Spinning Machines

As technology continues to evolve, so do metal spinning machines. ALTRON anticipates and contributes to future trends in this field.

a. Metal Spinning Machines: Automation and Industry 4.0 Integration

Automation is a key trend in metal spinning, with the integration of robotics and computerized systems. ALTRON’s machines are compatible with Industry 4.0 principles, allowing for remote monitoring, predictive maintenance, and data-driven decision-making. This not only enhances efficiency but also positions metal spinning at the forefront of smart manufacturing.

b. Metal Spinning Machines: Materials and Technology Advancements

Innovation in materials and technology is reshaping the capabilities of metal spinning. Advanced alloys, composites, and nanomaterials are expanding the range of applications. ALTRON’s commitment to research and development ensures that their machines stay ahead of the curve, ready to handle new materials and emerging technologies.

Conclusion

In conclusion, metal spinning machines, led by manufacturers like ALTRON, are driving innovation in engineering. Their advantages in cost-effectiveness, design flexibility, and sustainability are transforming manufacturing processes. While limitations exist, ongoing technological advancements and a focus on safety and maintenance ensure that metal spinning remains a cornerstone of modern engineering.

Stay tuned for more insights into the world of metal spinning and its profound impact on various industries.