How Does the Shape of Metal Spinning Tool Affect the Spinning Process?

Metal spinning, a craft dating back centuries, has witnessed a modern resurgence owing to its versatility and efficiency in shaping various metals into intricate forms. At the heart of this ancient art lies a crucial component: the metal spinning tool. This article delves into the intricacies of metal spinning rollers, the selection process for different materials, the nuances of shape and angle, and the significance of material selection in crafting these indispensable tools.

Understanding Metal Spinning Rollers: The Workhorses of the Craft

Metal spinning rollers, also known as spinning tools or chucks, serve as the primary instruments in the metal spinning process. These tools enable artisans to transform flat metal discs or blanks into seamless, symmetrical shapes by rotating them at high speeds while applying pressure. The rollers come in various sizes and designs, each tailored to accommodate different project requirements and metal types.

Types of Metal Spinning Rollers

Conventional Rollers: Traditional metal spinning rollers feature a cylindrical design, offering stability and precision during the spinning process. They are ideal for crafting symmetrical shapes such as bowls, domes, and cylindrical vessels.

Profiled Rollers: Profiled rollers, characterized by their customized shapes and contours, cater to the production of complex forms with intricate details. These rollers allow artisans to create diverse designs ranging from decorative ornaments to functional components with precision and finesse.

Combination Rollers: Combination rollers incorporate elements of both conventional and profiled designs, providing versatility in shaping a wide array of metal objects. These rollers offer flexibility and efficiency, making them a popular choice for craftsmen seeking adaptability in their projects.

Selection Metal Spinning Tools for Different Materials: Precision meets Versatility

The selection of metal spinning tools plays a pivotal role in achieving optimal results across various materials. Each metal possesses unique properties that influence the spinning process, requiring careful consideration when choosing the appropriate tools for the job.

Tool Material Compatibility

Steel Rollers: Steel rollers exhibit exceptional durability and heat resistance, making them well-suited for spinning ferrous metals such as stainless steel and aluminum. Their robust construction ensures longevity and reliability, even in demanding industrial applications.

Carbide Tipped Rollers: Carbide tipped rollers offer superior wear resistance and cutting performance, rendering them ideal for spinning abrasive materials like titanium and inconel. These rollers maintain sharpness and precision over prolonged use, enhancing productivity and efficiency in high-volume production settings.

Ceramic Rollers: Ceramic rollers, renowned for their non-conductive and non-magnetic properties, excel in spinning non-ferrous metals such as copper, brass, and bronze. Their smooth surface finish minimizes friction and prevents surface blemishes, resulting in pristine metalwork with minimal post-processing requirements.

Material-Specific Considerations

Thickness: The thickness of the metal blank influences the selection of spinning tools, with thicker materials requiring sturdier rollers to withstand the applied forces without deformation or failure.

Ductility: The ductility of the metal dictates the optimal spinning speed and pressure settings, guiding the choice of rollers to ensure consistent forming without material defects or cracking.

Surface Finish: Metals with high surface finish requirements necessitate precision-engineered rollers with smooth contact surfaces to prevent marring or scratching during the spinning process.

Exploring the Shape and Angle of Metal Spinning Tools: Precision Engineering in Motion

The shape and angle of metal spinning tools play a crucial role in determining the final outcome of the spun metal piece. From achieving specific geometries to enhancing formability and surface finish, these design aspects are meticulously calibrated to meet the diverse needs of artisans and industries alike.

Geometry of Spinning Tools

Radius: The radius of the spinning tool influences the curvature of the spun metal, with larger radii yielding gentler curves and smaller radii producing sharper bends. Artisans can select rollers with varying radii to achieve desired design aesthetics and structural integrity in their creations.

Taper Angle: The taper angle of the spinning tool determines the draft or inclination of the spun metal, facilitating smooth material flow and release during the forming process. Adjustable taper angles offer flexibility in shaping complex geometries and transitioning between different sections of the workpiece seamlessly.

Enhancing Formability and Surface Finish

Relief Grooves: Relief grooves, strategically machined into the spinning tool surface, optimize material flow and reduce frictional forces during the spinning process. These grooves prevent metal buildup and distortion, ensuring consistent forming and superior surface finish in the final product.

Polished Finish: Finely polished spinning tools minimize surface imperfections and frictional losses, resulting in smoother metalwork with enhanced luster and aesthetic appeal. Advanced surface treatments and coatings further enhance tool longevity and performance, enhancing productivity and reducing maintenance requirements.

Material Selection of Metal Spinning Tools: Engineering Excellence Meets Craftsmanship

The material selection process for metal spinning tools is a critical aspect of ensuring durability, precision, and performance in the spinning process. From conventional steel alloys to advanced ceramics and composites, the choice of materials encompasses a diverse range of properties and applications, catering to the evolving needs of modern metalworking industries.

Factors Influencing Material Selection

Wear Resistance: Metal spinning tools subjected to high-speed rotation and contact with abrasive metals require exceptional wear resistance to maintain sharpness and dimensional accuracy over time. Hardened steel alloys and carbide inserts offer superior wear resistance, prolonging tool life and minimizing downtime in production environments.

Thermal Stability: The thermal stability of spinning tools is paramount in withstanding the intense heat generated during the spinning process, especially when working with high-temperature alloys and exotic metals. Heat-resistant materials such as ceramic composites and refractory metals ensure reliable performance and dimensional stability under extreme operating conditions.

Compatibility: The compatibility of spinning tool materials with specific metal types influences process efficiency, surface finish, and overall quality of spun components. Material-specific coatings and surface treatments further enhance tool performance and mitigate adverse effects such as galling, adhesion, and chemical reactions between dissimilar materials.

Crafting Precision: Processing Metal Spinning Rollers

Metal spinning rollers, the cornerstone of the metal spinning process, undergo a series of intricate manufacturing steps to achieve the precision and durability required for shaping various metals. From raw material selection to final finishing, each stage in the production process contributes to the performance and longevity of the spinning tool.

Raw Material Selection

High-Quality Alloys: Metal spinning rollers are typically crafted from high-strength steel alloys or advanced composite materials selected for their exceptional mechanical properties and wear resistance. These materials undergo rigorous testing and quality control measures to ensure consistency and reliability in the finished product.

Customized Specifications: Depending on the application and performance requirements, metal spinning tool manufacturers tailor the material composition and properties to meet specific customer needs, whether it be enhanced heat resistance, corrosion resistance, or surface finish.

Precision Machining

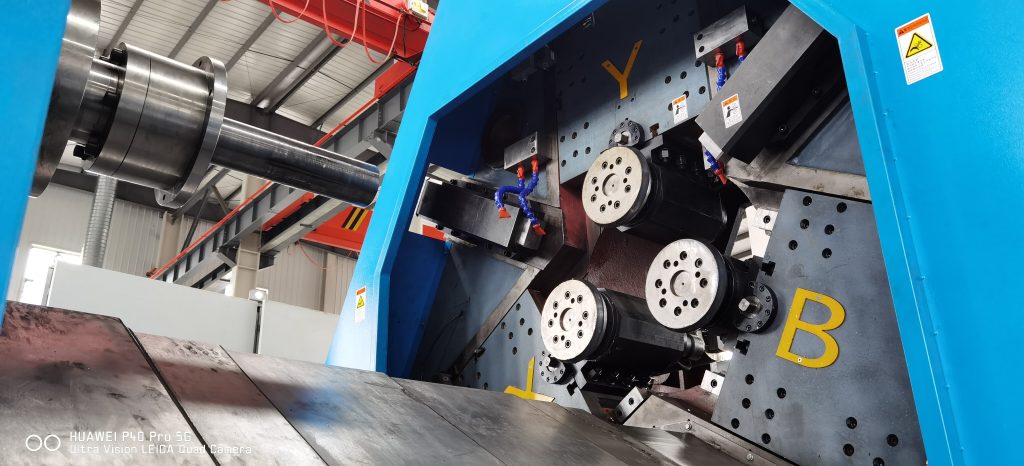

CNC Machining: Computer Numerical Control (CNC) machining plays a crucial role in shaping metal spinning rollers with unparalleled accuracy and repeatability. Advanced CNC milling and turning processes enable manufacturers to create complex geometries, profiles, and surface finishes with micron-level precision, ensuring optimal performance in demanding spinning applications.

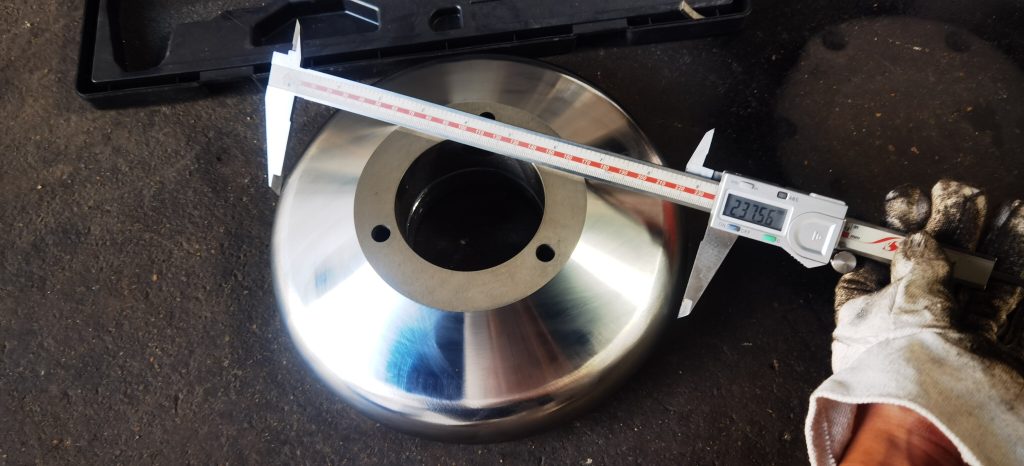

Tolerance Control: Tight tolerance control is paramount in the machining of metal spinning rollers to maintain dimensional accuracy and concentricity essential for seamless spinning operations. State-of-the-art metrology equipment and quality assurance protocols verify compliance with stringent specifications, guaranteeing consistent results in production environments.

Surface Treatment and Coating

Surface Finish Optimization: Surface treatment techniques such as polishing, grinding, and honing enhance the surface finish of metal spinning rollers, reducing friction and minimizing material adhesion during the spinning process. Mirror-like surface finishes promote smooth metal flow and improve the quality of spun components, particularly in applications requiring high aesthetic standards.

Protective Coatings: Protective coatings and surface treatments such as hard chrome plating, ceramic coatings, and PVD coatings enhance the wear resistance and durability of metal spinning rollers, prolonging tool life and minimizing maintenance requirements in harsh operating environments.

Precision in Practice: Installation of Metal Spinning Tools in the Machine

The installation of metal spinning tools in spinning machines is a critical step that directly impacts the quality and efficiency of the spinning process. Proper setup and alignment ensure optimal performance, safety, and longevity of both the tools and the machine, minimizing downtime and maximizing productivity.

Alignment and Balancing

Precision Alignment: Accurate alignment of metal spinning tools within the spinning machine is essential for achieving uniform wall thickness, concentricity, and dimensional accuracy in spun components. Laser alignment systems and precision measuring instruments enable operators to align spinning tools with sub-micron precision, mitigating runout and vibration-induced defects during spinning.

Dynamic Balancing: Dynamic balancing of metal spinning rollers minimizes vibration and oscillation during operation, improving surface finish and dimensional stability in spun components. Advanced balancing equipment and techniques ensure optimal weight distribution and rotational symmetry, enhancing tool performance and extending tool life in high-speed spinning applications.

Tool Clamping and Fixturing

Secure Clamping: Proper clamping and fixturing of metal spinning tools within the spinning machine prevent tool slippage, deflection, and chatter during the spinning process. Robust clamping mechanisms and hydraulic fixtures exert uniform pressure on the tool interface, maximizing rigidity and stability while minimizing distortion and tool wear.

Quick Change Systems: Quick change tooling systems facilitate rapid setup and changeover of metal spinning tools, reducing downtime and increasing production flexibility in multi-product manufacturing environments. Tool presetting stations and automated tool changers streamline the setup process, allowing operators to optimize machine utilization and throughput.

Safety Considerations

Operator Training: Comprehensive training programs educate machine operators on proper handling, installation, and maintenance of metal spinning tools, promoting safe and efficient operation of spinning machines. Emphasis on ergonomic practices and personal protective equipment (PPE) ensures operator safety and reduces the risk of accidents and injuries in the workplace.

Machine Guarding: Well-designed machine guarding and safety interlocks protect operators from hazards such as rotating machinery, flying debris, and high-pressure fluids associated with metal spinning operations. Compliance with industry standards and regulations ensures a safe working environment and minimizes the likelihood of accidents and liabilities.

Striving for Perfection: Perfect Metal Spinning Tools and Perfect Spinning Procedures

The pursuit of perfection in metal spinning encompasses not only the quality and performance of spinning tools but also the precision and efficiency of spinning procedures. From material selection and tool design to process optimization and quality control, every aspect of the metal spinning workflow is meticulously calibrated to achieve flawless results.

Perfect Metal Spinning Tools

Optimal Geometry: The geometry of metal spinning tools, including the radius, taper angle, and relief features, is carefully optimized to promote uniform material flow, minimize tool wear, and maximize dimensional accuracy in spun components. Iterative design and simulation techniques refine tool profiles and configurations to achieve optimal performance across a range of materials and applications.

Superior Materials: The choice of materials for metal spinning tools is driven by considerations of wear resistance, thermal stability, and compatibility with specific metal types. Advanced alloys, coatings, and surface treatments enhance tool longevity and performance, ensuring reliable operation and consistent quality in high-volume production environments.

Rigorous Testing: Metal spinning tools undergo rigorous testing and validation procedures to verify compliance with performance specifications and industry standards. Finite element analysis (FEA), mechanical testing, and field trials assess tool durability, dimensional accuracy, and surface finish under simulated operating conditions, providing confidence in tool performance and reliability in real-world applications.

Perfect Spinning Procedures

Process Optimization: Spinning procedures are continuously optimized through data-driven analysis, experimentation, and feedback loops to improve efficiency, productivity, and quality in metal spinning operations. Advanced process monitoring and control systems enable real-time adjustments to spinning parameters such as speed, pressure, and lubrication, optimizing material flow and minimizing defects in spun components.

Quality Assurance: Stringent quality assurance protocols ensure consistency and reliability in metal spinning processes, from initial material inspection to final product verification. In-process inspection techniques such as laser scanning, coordinate measuring, and non-destructive testing verifies dimensional accuracy, surface finish, and material integrity, guaranteeing compliance with customer specifications and industry standards.

Continuous Improvement: A culture of continuous improvement fosters innovation and excellence in metal spinning operations, driving advancements in technology, materials, and techniques to push the boundaries of what is possible. Cross-functional collaboration, knowledge sharing, and employee training initiatives empower teams to identify and implement best practices, driving efficiency gains, and quality improvements throughout the organization.

Revolutionizing Metal Spinning: The Role of CNC Metal Spinning Solutions

CNC metal spinning solutions represent a paradigm shift in the metalworking industry, combining the precision of computer-controlled machining with the versatility of traditional spinning techniques. From complex geometries to high-volume production, CNC spinning machines offer unparalleled flexibility, efficiency, and quality in metal forming applications.

Advanced Automation

CNC spinning machines feature programmable control systems that automate toolpath generation, speed adjustment, and material handling, reducing setup time and maximizing productivity in metal spinning operations. Operators can create custom spinning programs using intuitive software interfaces, enabling rapid prototyping, iterative design refinement, and seamless integration with CAD/CAM workflows. Real-time monitoring and diagnostics provide insights into machine performance, allowing for proactive maintenance and optimization of spinning processes.

Versatile Machining Capabilities

Multi-Axis Machining: CNC spinning machines offer multi-axis machining capabilities, enabling complex shapes and contours to be formed with precision and repeatability. With simultaneous control over spinning, feeding, and tool movement, operators can produce intricate geometries, tapered profiles, and asymmetric features previously unattainable with conventional spinning methods.

Adaptive Tooling: Adaptive tooling systems on CNC spinning machines dynamically adjust tool geometry, pressure, and feed rates based on real-time feedback from sensors and actuators. This adaptive control optimizes material flow, minimizes tool wear, and maximizes process stability, resulting in superior surface finish and dimensional accuracy in spun components.

Scalable Production Solutions

Batch Processing: CNC spinning machines support batch processing of multiple workpieces in a single setup, streamlining production and reducing cycle times for high-volume manufacturing applications. Automated tool changers and workpiece handling systems facilitate uninterrupted operation, allowing for continuous production with minimal operator intervention.

Flexible Workholding: Modular workholding systems on CNC spinning machines accommodate a wide range of workpiece sizes, shapes, and materials, providing flexibility and versatility in production setups. Quick-change collets, chucks, and mandrels enable rapid reconfiguration of machine tooling, facilitating efficient changeovers and setup optimization for diverse manufacturing requirements.

Conclusion—Crafting Excellence with ALTRON: A Testament to Innovation and Expertise

As a leading provider of metal spinning tools and services, ALTRON stands at the forefront of innovation and engineering excellence in the metalworking industry. With a diverse portfolio of precision-engineered rollers, cutting-edge materials, and customized solutions, ALTRON empowers artisans and manufacturers to unleash their creativity and realize their vision with unparalleled precision and efficiency.

From aerospace components and automotive parts to architectural features and artistic masterpieces, ALTRON’s metal spinning tools embody the perfect synergy of craftsmanship, technology, and performance. With a commitment to quality, reliability, and customer satisfaction, ALTRON continues to redefine the boundaries of metalworking excellence, shaping the future of the industry one revolution at a time.