Altron Story

Atron’s engineers will use the core technology to bring actual production value to customers. Creating benefits for customers is the common concept of every Altron employee!

Complete each project responsibly, deliver complete and perfect machines and production lines to customers, and solve technical problems and practical problems encountered in production!

Leave no problems and hidden dangers behind, make predictions about possible situations as early as possible, and solve most of the difficulties and risk assessments of the project before sales!

Altron Story :Service In Customer Factories

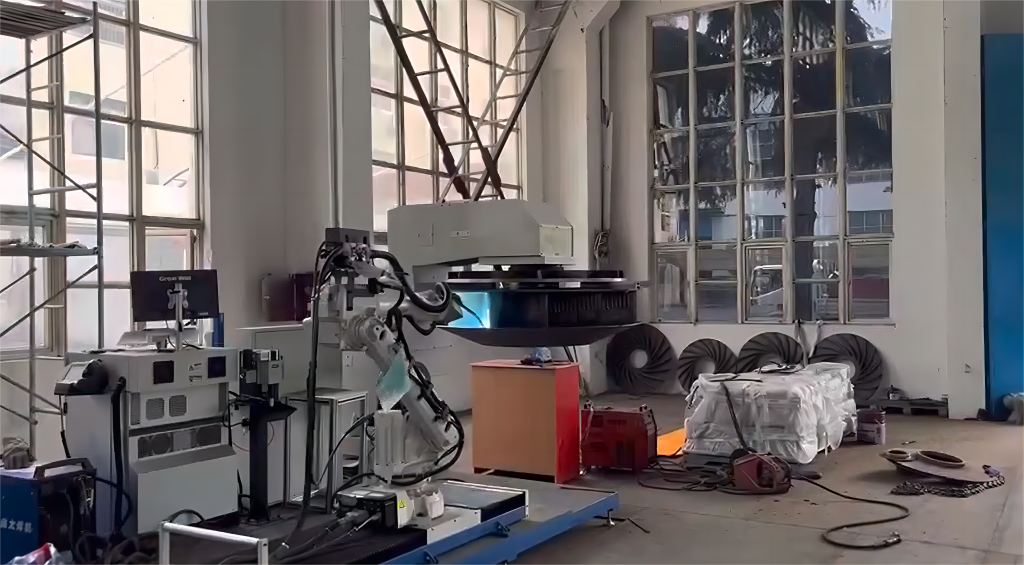

Our engineers debug the impeller automatic welding robot in South Korea–Welding Machine For Centrifugal Blower Impeller

We debug CNC spinning machines and CNC flanging machines at Nantong Datong Baofu Fan Co., Ltd.-CNC Flanging Machine ACFB-3012

We debug the CNC spinning machine and impeller automatic welding robot at Jiangsu Hengkang Mechanical and Electrical Co., Ltd.

–Single Wheel CNC Spinning Machine AC1600 & Welding Machine For Centrifugal Blower Impeller

We debugged several completed production lines at the Infinair factory.

We are debugging several impeller automatic welding robots at Shanghai Yingda Factory.–Welding Machine For Centrifugal Blower Impeller

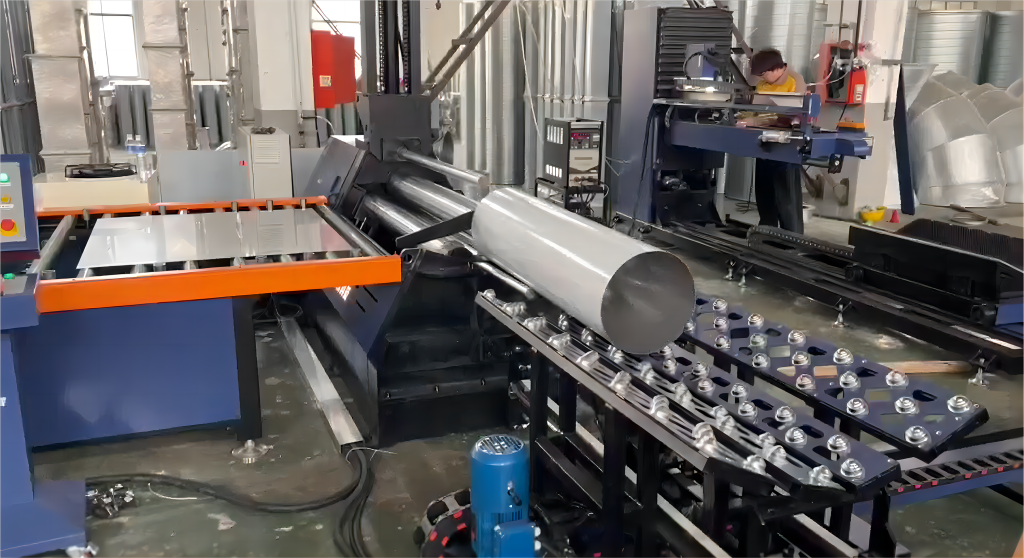

We are debugging the centrifugal fan production line at Foshan Delitai Machinery Factory.–Rounding & Welding Auto Production Line For Industrial Exhaust Fan Cylinder Pipe

We are debugging the centrifugal fan production line at the Anhui Yiniu Tong factory.-Air Duct Automatic Rolling Production Line

ALTRON industrial fan production line services

We are debugging CNC spinning machines in Atticbreeze factory.–Single Wheel CNC Spinning Machine AC1600

We debug CNC flanging machines, automatic rounding machines and automatic longitudinal seam welding machines in CASALS factory.–CNC Flanging Machine ACFB-1605 Seam welding machine CNC rolling machine

ALTRON CNC FLANGING SERVICES

Automatic welding and commissioning of impeller in Nantong Halifax factory-Welding Machine For Centrifugal Blower Impeller

Our engineers are in the automatic welding and debugging of the impeller in the АЭРДИН factory in Russia

–Single Wheel CNC Spinning Machine AC1600 &CNC Flanging Machine ACFB-1605

Our engineers are in the automatic welding and debugging of the impeller in Guangdong Xinfeng factory.-Welding Machine For Centrifugal Blower Impeller

Our engineers in Guangdong Detong factory multi automatic welding equipment-Fully Automatic Welding Machine For Fan Volute &

Zhejiang Haobo Machinery has 18 machines, including 11 CNC spinning machines, 2 CNC flanging machines, 2 PLC custom flanging machines, 2 CNC internal spinning machines, 1 impeller robot automatic welding machine.

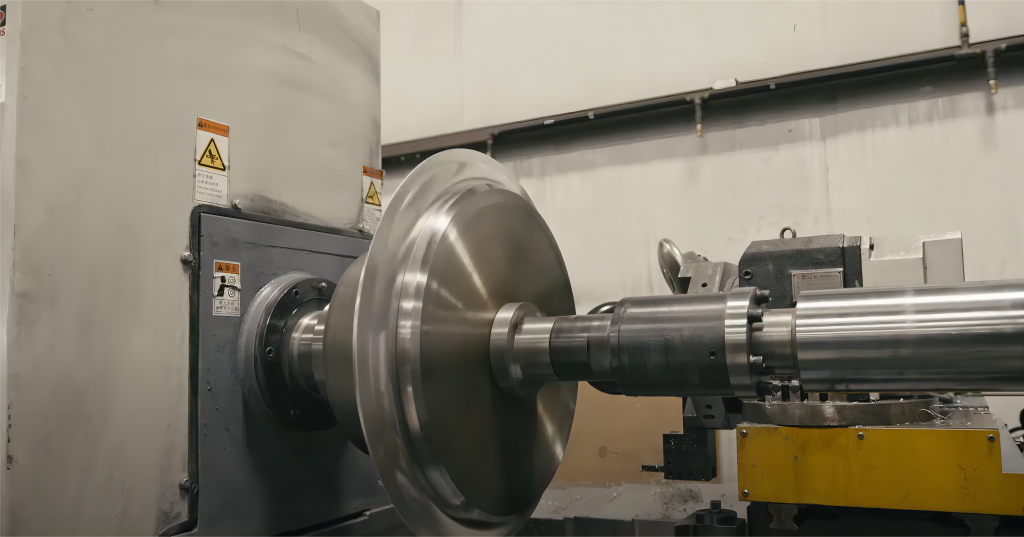

A CNC spinning machine sold to Turkey, processing stainless steel pipe joint expansion spinning technology

Buy our CNC rolling machine, straight seam welding machine and PLC custom flanging machine to process cone barrel flanging and punching

During CNC spinning machine training,

After the large aluminum barrel spinning training is completed, the customer independently operates the mass production

Solux from Mexico came to visit and confirmed the machine and signed a machine purchase contract.

A kitchenware company in Mexico purchased three CNC spinning machines to process stainless steel soup barrels. The customer independently wrote the program and completed the spinning training and assessment.

Jiangsu Shengjian purchased laser cutting, rolling and welding production lines

Brazilian shipyard purchases large-scale automatic gantry welding production line

In the early days, our 2000mm CNC flanging machine has been produced in Shanghai GM’s factory for more than 12 years.

Kruger Group purchased multiple CNC spinning machines and CNC flanging machines from our company and placed them in factories in Thailand, Vietnam and India. It purchased automatic impeller welding equipment and placed them in Nantong factory in Jiangsu.

Aozhong owns one of our early CNC spinning machines, which has been used for more than 15 years

We debug gantry automatic welding equipment in Shandong Weili

The carbon steel air inlet is processed by CNC spinning, using the idle spinning process.

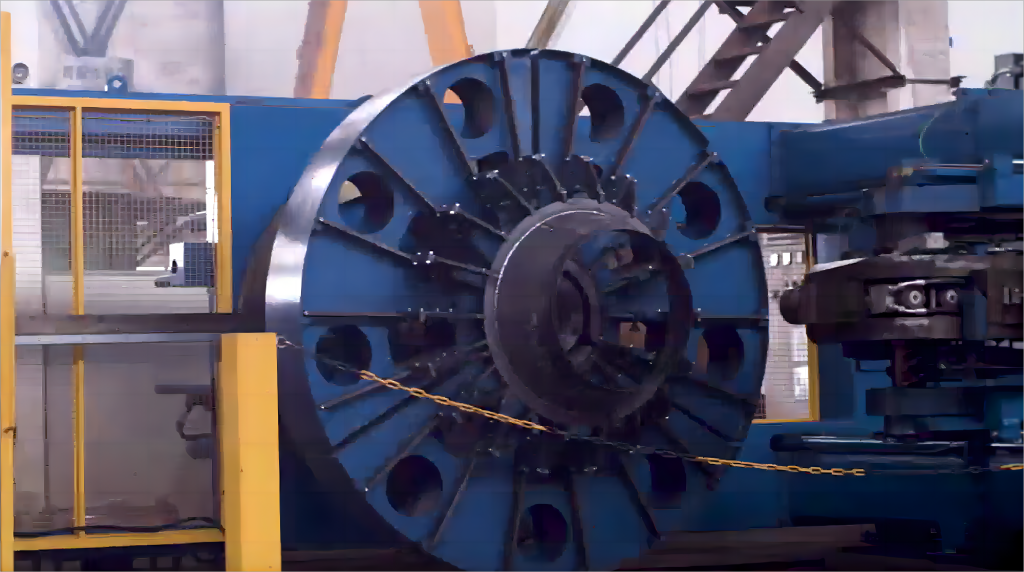

Hubei Shuangjian Blower Co., Ltd. uses 3 heavy-duty impeller welding robots

Hubei Sanfeng Co., Ltd. uses 2 heavy-duty impeller welding robots to process large industrial fan impellers.

Founder Joby Engineer History

Year 2008:

China’s lighting industry was an industry with a very high gold content at that time, the world-famous “Zhongshan Ancient Town”! Due to family relations, this was my first contact with metal spinning forming process. At that time, I was very curious about this technology when I was young and curious about science, so I tried to understand its forming principle and process. After several days of research, I found this technique consumes a lot of physical strength for workers and also harms the body. This is my understanding of manual metal spinning.

Year 2010:

Due to the rapid expansion of the Chinese lighting industry market and the increasing pressure of competition, the factory had to face relocation, so it chose Zhuhai, which developed very rapidly and lacked the metal industry. This gave me the opportunity to contact the factory again. During the installation and commissioning process after the relocation of the machine, the idea of personally operating the experiment came up, so I started to imitate the posture of the spinning master. This technique is not that simple and consumes much energy. .

I never gave up, so I started to consult the metal spinning master. After countless attempts…Finally, I completed the metal spinning of a simple product under the guidance of the master.

Year 2011;

This is a summer vacation and I found out that the master has left. Later, I learned that he was 52 years old, and because of his age, he could not support the high-intensity metal spinning work of ten hours a day. Before leaving, he taught two apprentices and taught them his life experience. It was not easy to change careers at the age of 50 at that time. The technical capabilities of the factory need to be reformed, and this manual metal spinning cold forming process will eventually be replaced by machines.

Year 2012:

After six months of postgraduate studies, investigations, and visits, the factory’s first CNC spinning machine was successfully contracted. Three months later, the CNC spinning machine was delivered to the factory. No one in the company knew about CNC machine tools, let alone Top spinning process and spinning programming. This stumped the company. My uncle had to go to the machine tool manufacturer to receive training for up to 3 weeks. But because he didn’t have a CNC foundation, it was very difficult to learn. In this way, the responsibility fell on me. I am full of interest in technology, and the learning effect is very significant, and I transferred the technology to the company’s technical manager. The company’s output has increased from manual metal spinning: 300 pieces per machine/8 hours to an automated CNC metal spinning machine: 1600 pieces per machine/8 hours, plus the machine will not be physically exhausted. Two shifts and three can be arranged Shift, the automatic spinning machine has achieved an efficiency of ten times the production capacity, and the quality has been reduced from the original 15% scrap rate to 1%.

Year 2013:

A machine can no longer meet the capacity requirements of the existing factory, so we start to add new equipment. Due to insufficient local peripheral resources and limited factory area, we will decide to relocate again. This time we choose Shenzhen, a city full of opportunities, and implement supporting facilities. Very complete. The factory expanded from one automated spinning machine to 5 metal spinning machines. Because the family’s metal spinning technology has matured and stabilized. An accidental opportunity allowed me to work in this famous spinning machine manufacturer.

Year 2015:

Relying on my own advantages, I have been promoted and deliberately cultivated by my superiors. This has brought me to a new level of metal spinning technical ability. Because I have received the influence of my family since I was young, the management team has played well in me An independent department for metal spinning processing was established.

Year 2016:

Spinning often produces a large number of batch products, which is a torment for me. In this way, I chose to give up the existing treatment, and I came to the spinning process department, which is a department that specializes in providing spinning technology services to customers, which allows me to further improve my metal spinning process technology and learn more about products Metal spinning technology, stainless steel auto parts metal spinning special metal molybdenum metal spinning titanium alloy metal spinning aviation material spinning powder cover metal spinning, constantly refreshing the technology of spinning metal.

Year 2017:

Since there is no way to complete the production requirements of composite products and mass products in the technical field of metal spinning, I will start to understand the process that is closely related tometal spinning: stamping, lifting, water, and annealing parameters of different materials, laser cutting, automatic polishing Welding, I left this famous cnc spinning machine company that gave me growth opportunities, and I am very grateful that this platform has brought me a broader network and opportunities.

Year 2018:

This company is an automated polishing machine manufacturer, which mainly conducts research and development of automated machines for the production of Industrial Fans, and builds an automated production line for Industrial Fans products. This gave me a better understanding of automated production lines, especially the polishing of large workpieces. The quality of products produced by automatic polishing machines is an essential element for high-end brands. Here I realized the coordinated production of metal spinning machine, stretching machine, punching machine, laser machine, polishing machine and welding machine, and completed the automatic production of a set of products through conveyor belt positioning device and manipulator.

Year 2020:

I chose to start my own business. It is very unfortunate that we encountered the epidemic at the very beginning, affected by the epidemic, China began to open gradually in April! Since I started planning my future development direction without going out for a long time at home, this made me firmer in my conviction. I started to inspect customers in the market as planned, CNC metal spinning machine, automated welding machine, circular cutting machine, Stretching machine, polishing machine, I found that these machines, these machines are not that simple to operate, so I need a partner who can make these operations easier, and gradually my team began to install them. Our core concept is to continuously improve customers’ use of machines to obtain higher production capacity, thereby enhancing the value of machines.

While the world is affected by the epidemic, in the second half of 2020, our team has completed skills training and upgrades for 42 domestic new and old customers, and 12 foreign fan spinning and ventilation metal spinning industry new customers remote video service training and teaching!

Altron Story To be updated..

Altron Manufactures And Provides Forming and Welding Solutions For:

- CNC Metal Spinning Machine,

- Multi-Roller Flow Forming Machine,

- Neck Spinning Machine,

- Internal Spinning Machine,

- Hub Spinning Machine,

- CNC Flanging Machine,

- Welding Robot, Rolling Machine,

- Seam Welding,

- Axial Flow Fan Production Line,

- Centrifugal Fan Impeller Welding,

- Centrifugal Fan Housing Welding,

- Air Duct Production Line,

- Spiral Duct Production Line,

- Rectangular Duct Production Line,

- Impeller Forming Production Line,

- Customized Industrial Fan Impeller,

- Laser Cutting Production Line,

- Laser Welding Solution, ect…