Aluminum welded impeller-China’s New Robot Welding

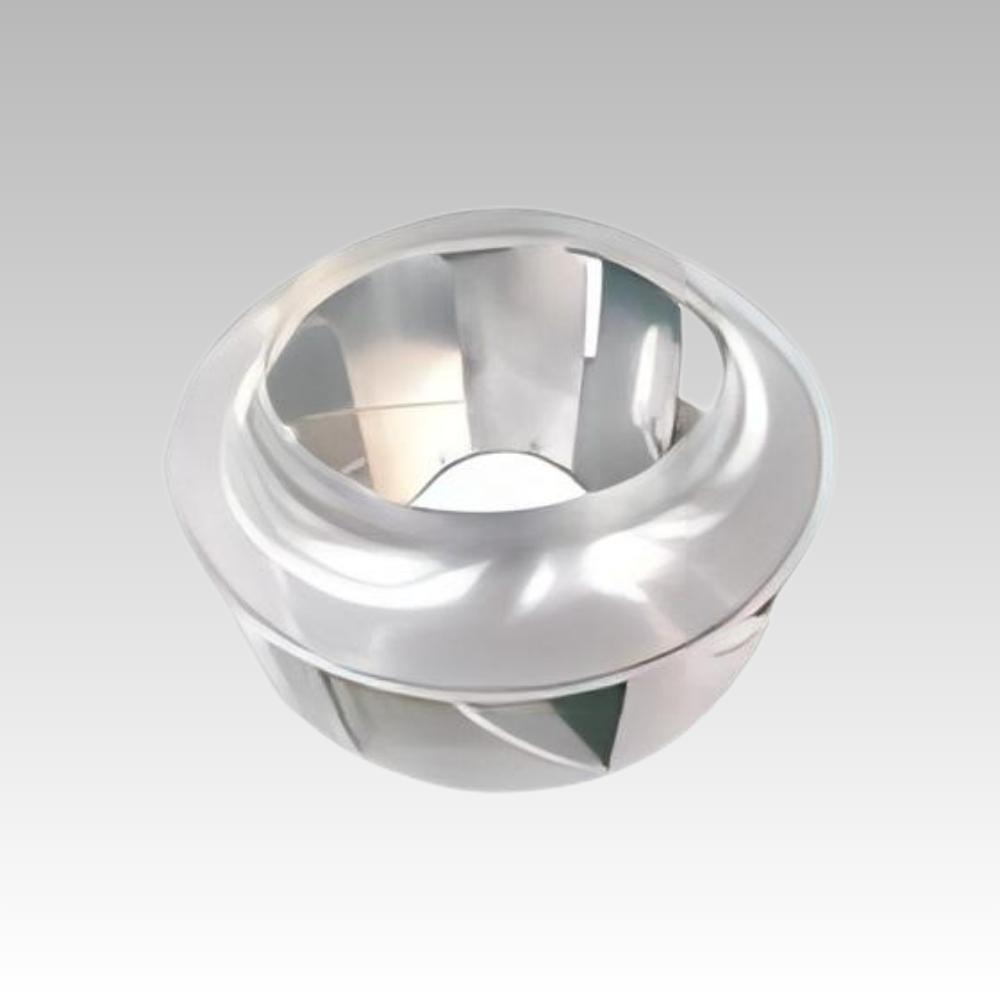

Aluminum welded impeller

Model Number: JS-LH-400

Material : Aluminum

Product name: china impeller

Type : china fan impeller

Process : Stamping and metal spinning

Color : Customized Colors

Surface treatment: Polishing

Service: OEM\ODM

Color : Customers’ Requirements

Structure : Customers’ Requirements

Packing : Carton+ Wooden Box

MOQ : 50pcs

Machining Process : Forming

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

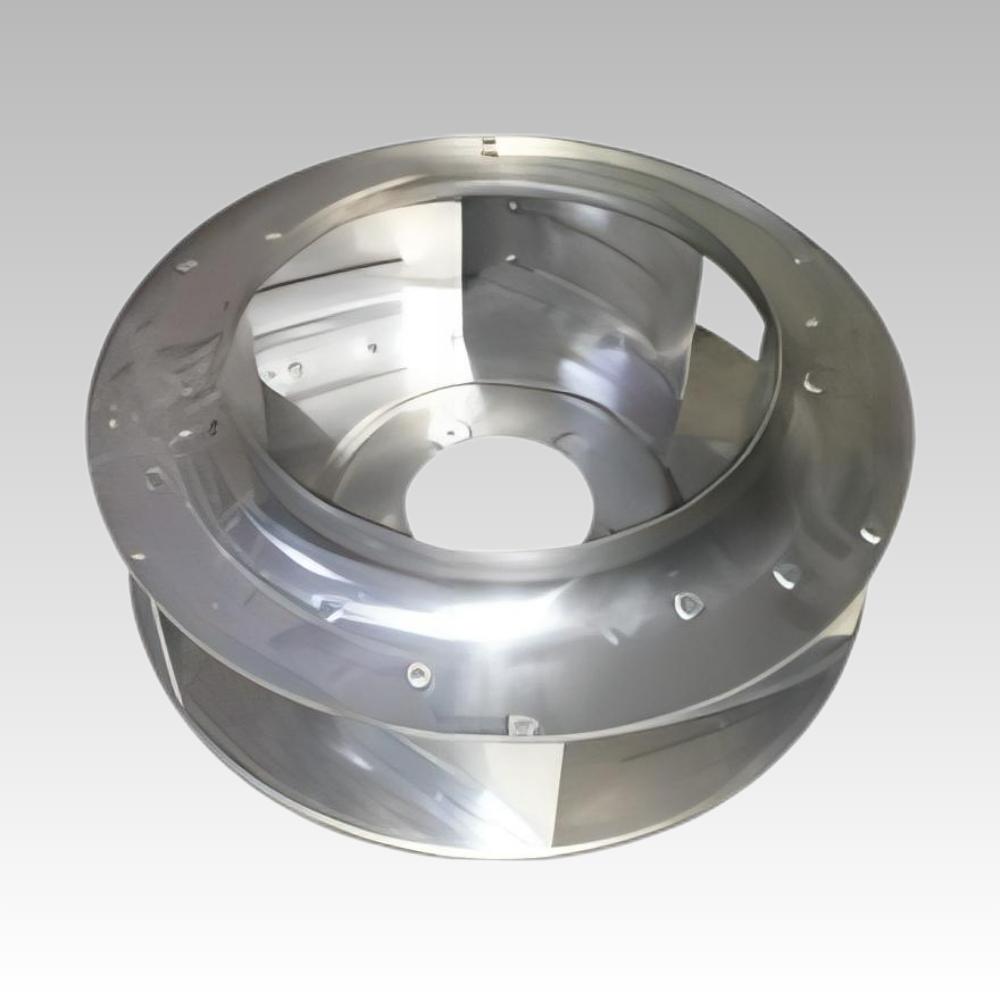

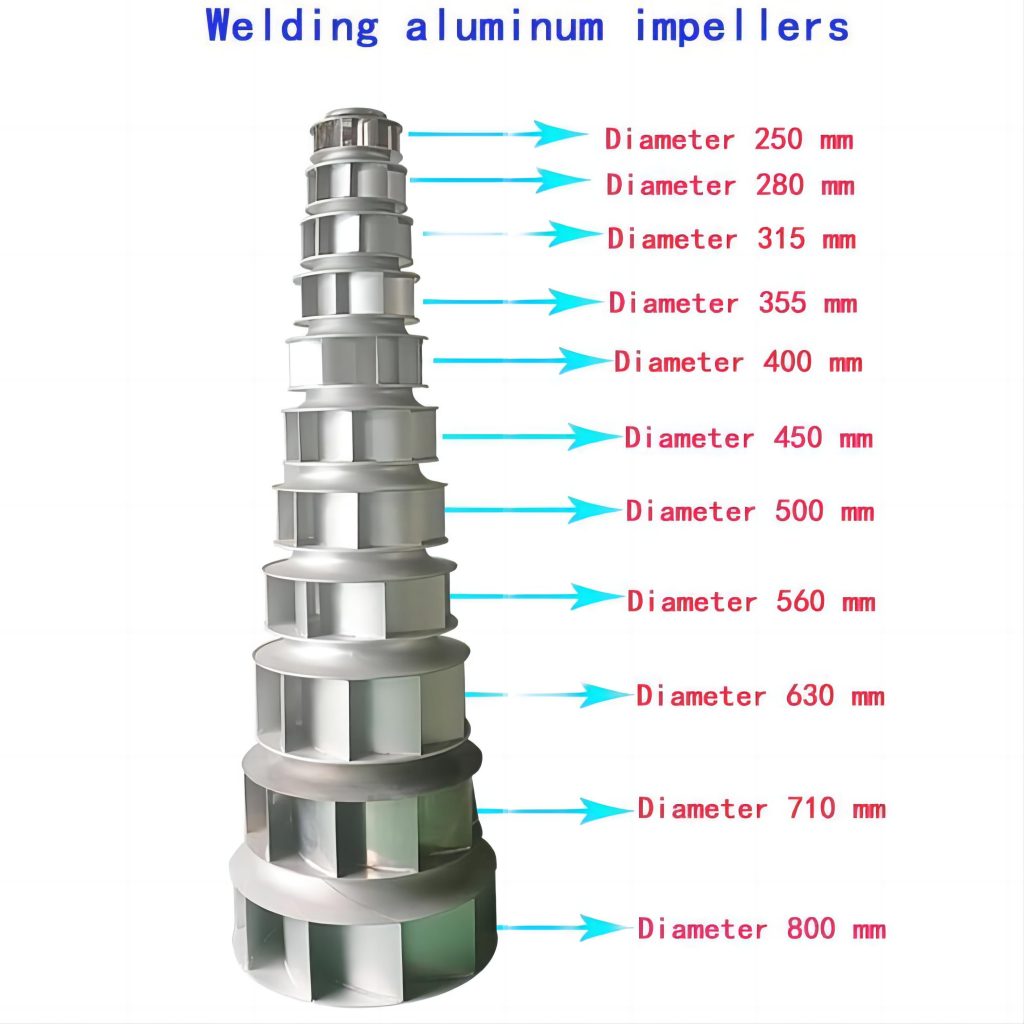

Details of aluminum welded impeller

Advantages of aluminum welded impellers

Light weight:

The specific gravity of aluminum is about 2.7 (usually aluminum alloy is used), which is nearly 3 times the specific gravity of steel 7.85. This lightweight feature enables aluminum welded impellers to reduce the load of the motor during operation and improve overall efficiency.

Significant energy saving effect:

Due to the good plasticity of aluminum, the blade shape is easier to process.

Strong corrosion resistance:

After aluminum is oxidized in the air, a dense oxide film is formed, which can effectively prevent further oxidation of aluminum. In the case of a slightly corrosive atmosphere, the performance of aluminum welded impellers is better than that of steel impellers, and it is more suitable for use in humid and highly corrosive environments.

Good mechanical strength: Although the strength of aluminum is lower than that of steel, aluminum welded impellers can still maintain good mechanical strength after reasonable design and processing.

Video of Aluminum Welded Impeller

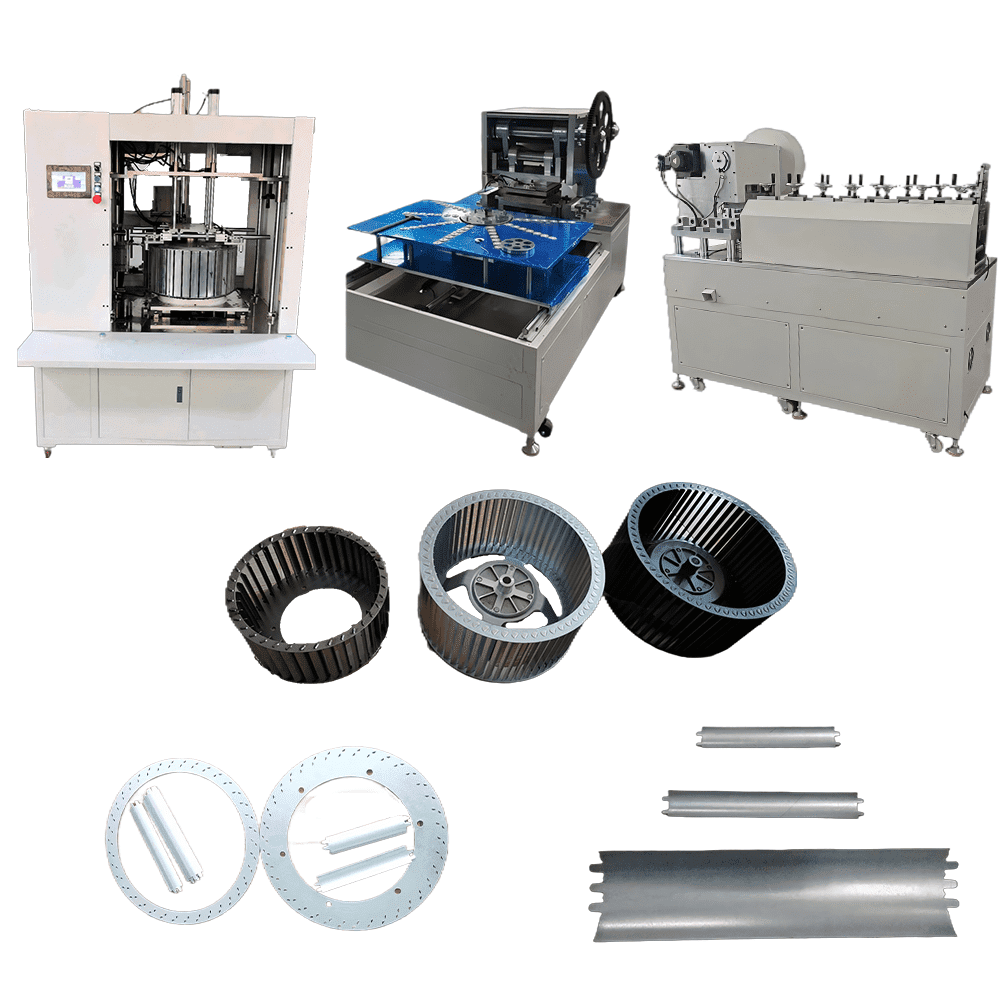

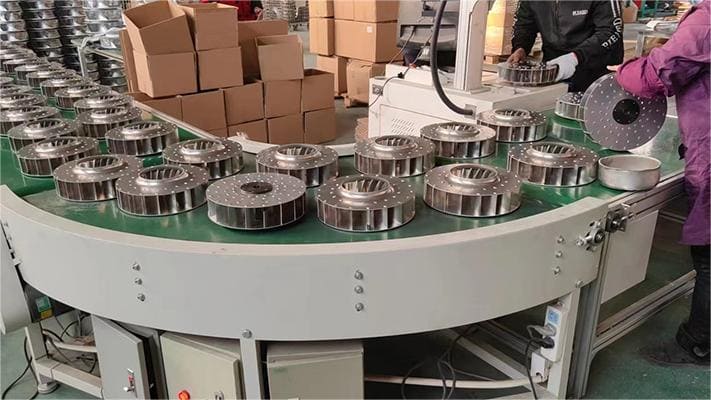

Testing Equipment

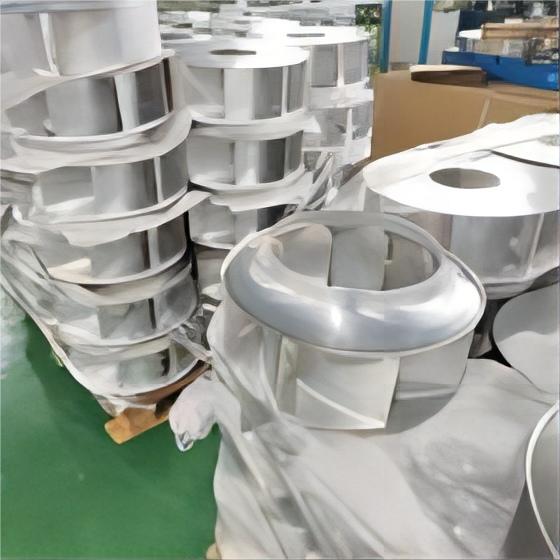

Sample impeller

|

|

|

|

|

|

|

|

Company Profile

Altron specializes in the design, R&D, manufacturing and sales of metal spinning, stamping metal parts, molds, centrifugal fans, machining, and metal parts required by the construction industry and other industries. With our rich experience and considerate service, we have been regarded as a reliable supplier by many international buyers. We do our best to satisfy you.

Our experienced engineers specialize in CNC machine tools, allowing us to meet your customized requirements to support your OEM/ODM services. We can meet any of your bulk order requirements. The products sell well in domestic and foreign markets, such as the United States, Europe, the Middle East, South Africa and other countries and regions, and are well received by customers.

Industry Fans Impeller Metal Material:

aluminum alloy, titanium alloy, stainless steel, galvanized plate, manganese steel, etc.

Industry Fans Products Are:

Machine Room Fan Impeller, Seeder Fan Impeller, Hot Air Circulation Fan Impeller, Grain Cooling Single-Tube Fan Impeller, Tobacco Dryer Impeller, Marine Fan Impeller, Oil And Fume Purification Impeller, Volute-Less Fan Impeller, Roof Fan Impeller, Cooling Fan Impeller, Condenser Side Fan Impeller, Oven Oven Impeller, Special Fan Impeller For Sock Machine, Textile Cotton Suction Fan Impeller, Textile Traveling Cleaning Machine Impeller, Commercial Fan Impeller Such As Hotels And Shopping Malls, High Temperature Resistant Centrifugal Fan Impeller, Double-Stage Fan Impeller, Kiln Fan Impeller, Heating Furnace Fan Impeller, Down-The-Hole Drilling Rig Dust Removal Impeller, Industrial Purifier Fan Impeller, Ffu (Fresh Air) Fan Impeller, Laboratory Equipment Fan Impeller, Polishing Dust Removal Fan Impeller, Burner Impeller, Electric Sweeper Impeller, Combustion Support Fan Impeller. Drying Equipment Impeller, High-Pressure Vortex Fan Impeller, Moxibustion Equipment Moving Impeller, Smoke Purification Impeller, Washing Equipment Impeller, Dryer Impeller, Pulse Bag Dust Removal Impeller, 9-12, 9-19, 9-26 High-Pressure Centrifugal Impeller, Boiler Induced Draft Fan Impeller, Food Machinery Equipment Impeller, Cnc Spindle Fan Cooling Impeller, Forward And Backward Inclined Multi-Wing Impeller, Air Guide Ring, Non-Standard Customized Volute, Customized Fan, etc.

|

|

|

|

|

|

|

|

|

|

|

|

FAQ

Who are we?

Our factory is based in Jiangsu, China, starting from 2017. Our products are soldto South Asia(30.00%), Eastern Asia(25.00%),

Eastern Europe(25.00%), North America(20.00%). There are total about 51-100 people in our office.

How can we guarantee quality?

Alwaystesting the pre-production sample before mass production

Always doing the final Inspection before shipment

What can you get from us?

Stamping parts, mould, impellers, mechanical processing, Centrifugal fan and so one

Why choose us?

We have rich experience of 20 years on the impellers, fans and other hardware accessories. The professional designer to create the

new related products, the skilled mechanic to test the products again and again ensure get a perfect products.

What services can we provide?

Delivery Terms: FOB, CFR, CIF, DDP

Payment : USD, CNY

Payment Type: T/T, L/C

Packing & Delivery

|

|

|

|

|

|

|

|

Customers provide information & negotiate impeller solutions:

- Provide fan impeller pictures + impeller dimensions; Altron will provide corresponding impellers.

- Provide impeller drawings; customized production will be completed by Altron (requires 5-55 days delivery time).

- Provide information on the use of industrial fans, application industries, wind pressure, air volume, materials of main components, wall thickness and strength of industrial fans.

- Customize impellers or accessories according to actual needs

Industrial fan impeller sample

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.