Special Dynamic Balancing Machine for Industrial Fans

Dynamic Balancing Machine for Industrial Fan’s impeller

Machine Name | Dynamic Balancing Machine |

Model | ACDP-50-3000mm(Multiple models) |

Application Industry | Centrifugal fan impeller, axial flow fan impeller, mixed flow fan impeller, diagonal flow fan impeller, multi-wing impeller, etc. |

Technical Service | Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

Technical Guidance | 7*24 Online Service, Engineer Video Online Conference To Solve Pre-Sales Problems. |

Project Progress | 30-120 days |

Relevant Files | ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Industrial Fans A-Z Project:

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Advantages of dynamic balancing machine:

- The well-designed, solid and rellable brackets can effectively transmit mechanical force with low vibrationdamping and good rigidity.

- The sensor possesses high sensitivity and good lineartymaking the machine high efficiency.

- The permanent calibration brings high accuracy with apermission of large initial unbalance amount.

- Universal coupling driven offers stable power transmis-sion, fast startup and convenient operation.

- Applicable to rotors which can’t be driven by belt or needs

- ALTRON self-developed electronic measuring system, friendly human-machine intertace, easy operation.

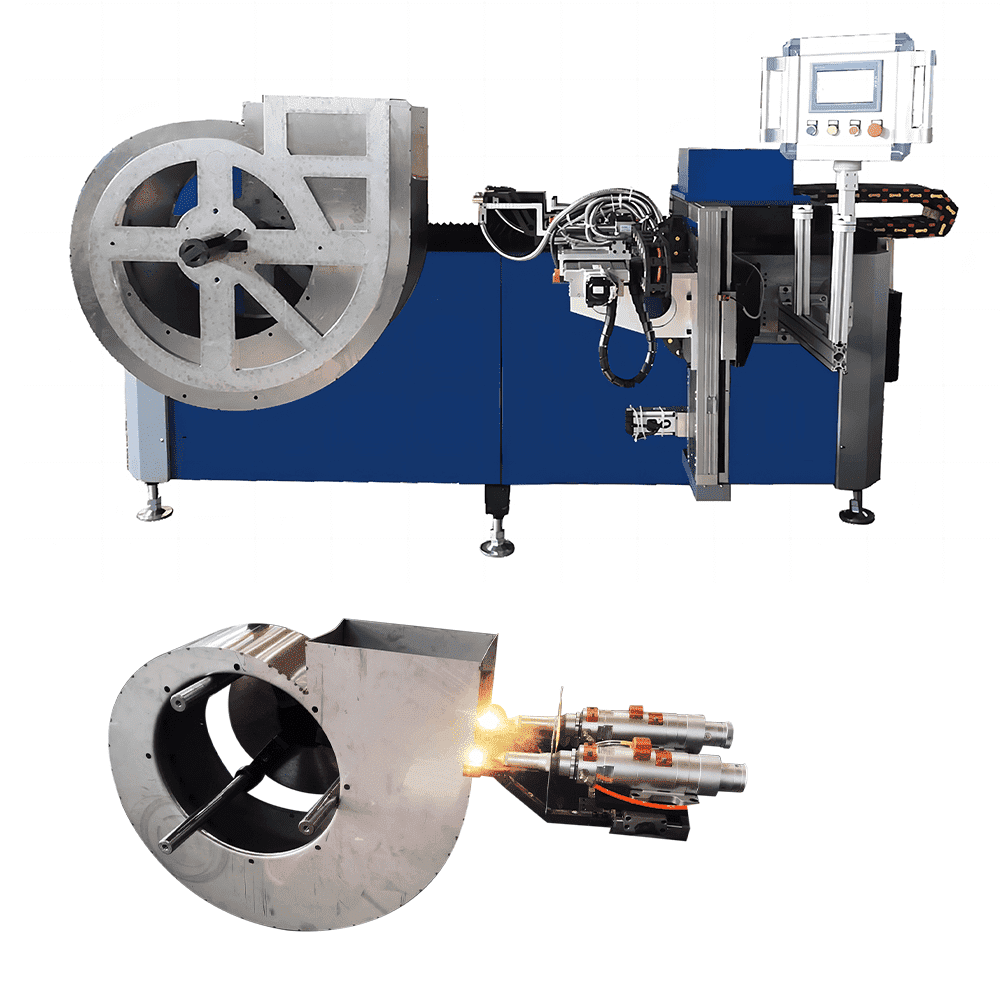

- ACPHW series balancing machines are particularly suitable for blowers, large motors, pumps, centrifuges, rubber rollers, drying cylinders, internal combustion engines, screen baskets and suspended rotors that cannot be driven by belts or require larger transmission devices.

- The universal coupling transmission device provides greater transmission power and works more stably. Belt transmission and universal point transmission can be selected on the same balancing machine.

Video Of Dynamic Balancing Machine For Industrial Fan Impeller

Application Of Dynamic Balancing Machines On Industrial Fan Impellers:

As an important fluid power equipment, industrial fans are used in various fields. The balance state of the fan impeller is directly related to the operating efficiency, vibration noise and service life of the fan. Therefore, it is very important to balance the fan impeller.

1. The importance of fan impeller balance:

The fan impeller is the core component of the fan, and the airflow generated by rotation provides power for industrial production. Due to factors such as uneven materials, processing errors, and welding consistency during the manufacturing process, the impeller will be unbalanced. Unbalanced impellers will generate greater vibration and noise during operation, affecting the normal operation of the equipment, increasing energy consumption, and shortening the service life of the equipment.

2. Application of dynamic balancing machinery on industrial fan impellers

The application of dynamic balancing machinery on industrial fan impellers is mainly reflected in two aspects:

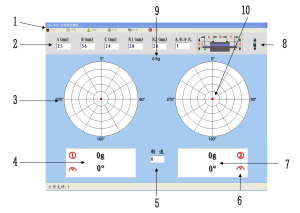

1. Unbalance detection:

By rotating the fan impeller, the dynamic balancing machinery can quickly and accurately detect the unbalance amount and distribution of the impeller, providing data support for balance adjustment.

2. Balancing adjustment guidance:

Based on the unbalanced detection results, the dynamic balancing machine can provide the operator with an accurate balancing adjustment plan and guide them to perform targeted adjustment operations to ensure that the impeller reaches an ideal balanced state.

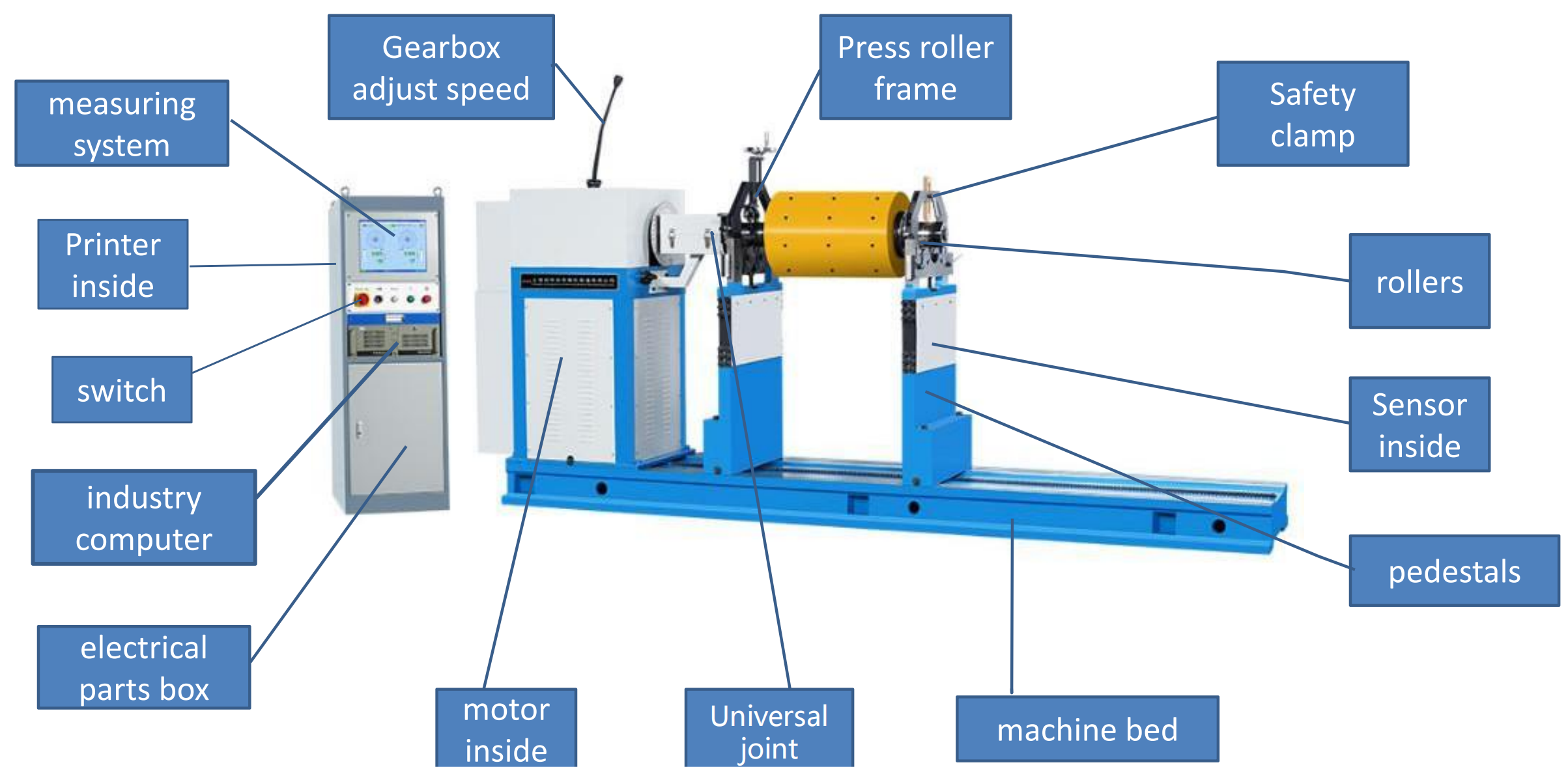

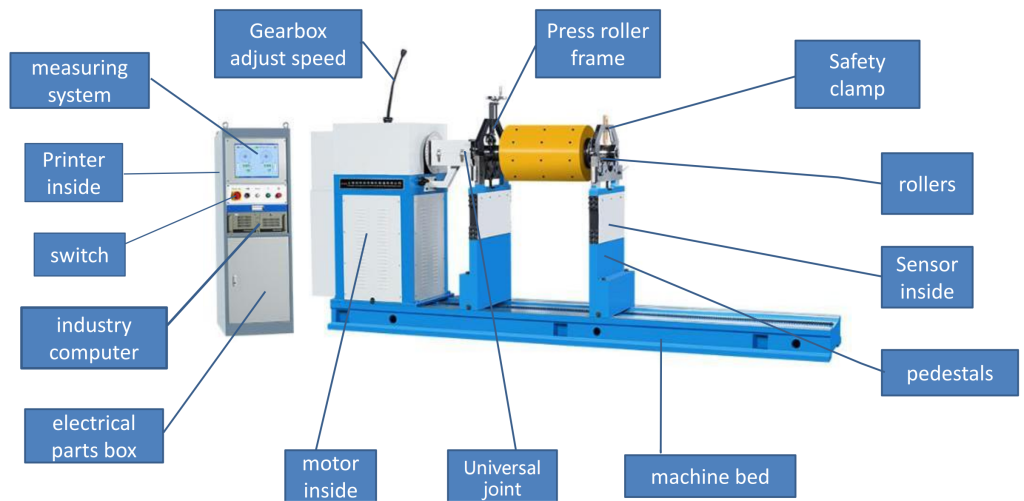

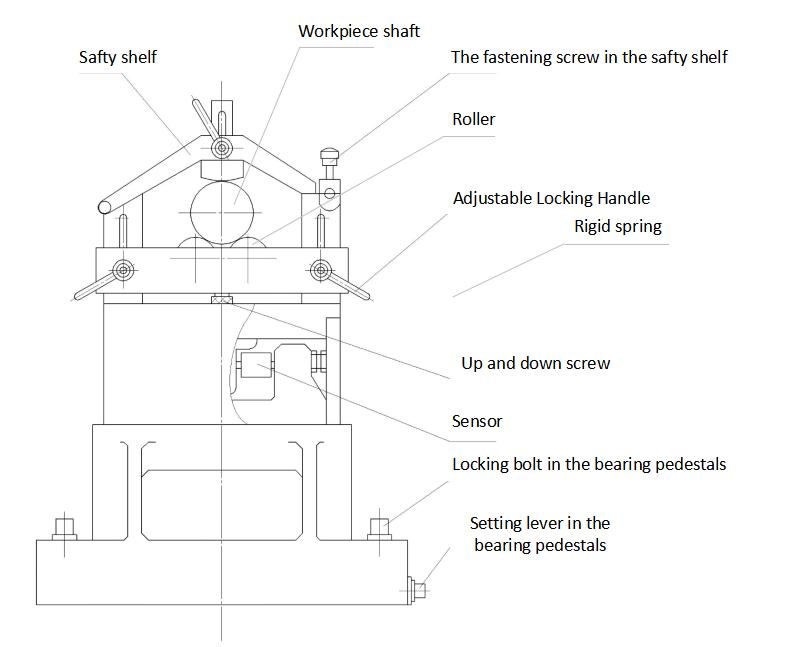

Composition Of Balancing Machine:

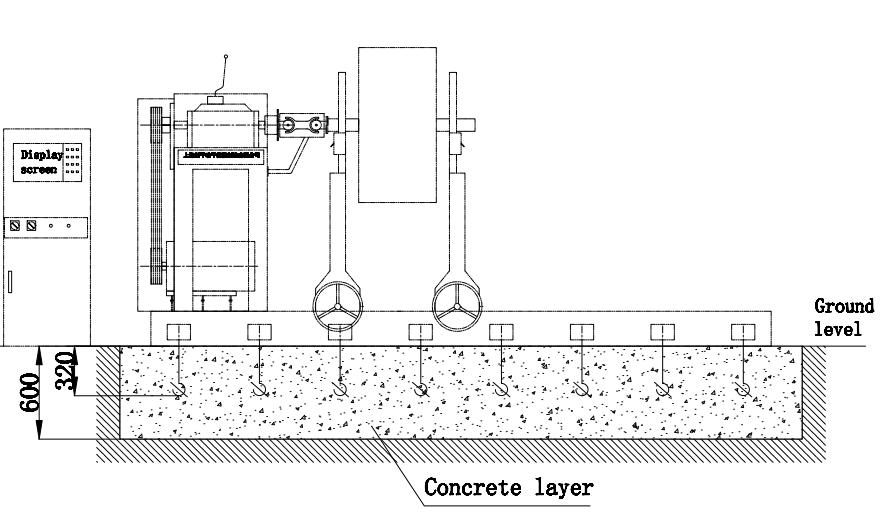

Impeller Balancing Machine Installation Drawings

Dynamic Balancing Machine Bearing Pedestals Structions:

Operating System Of Dynamic Balancing Machine

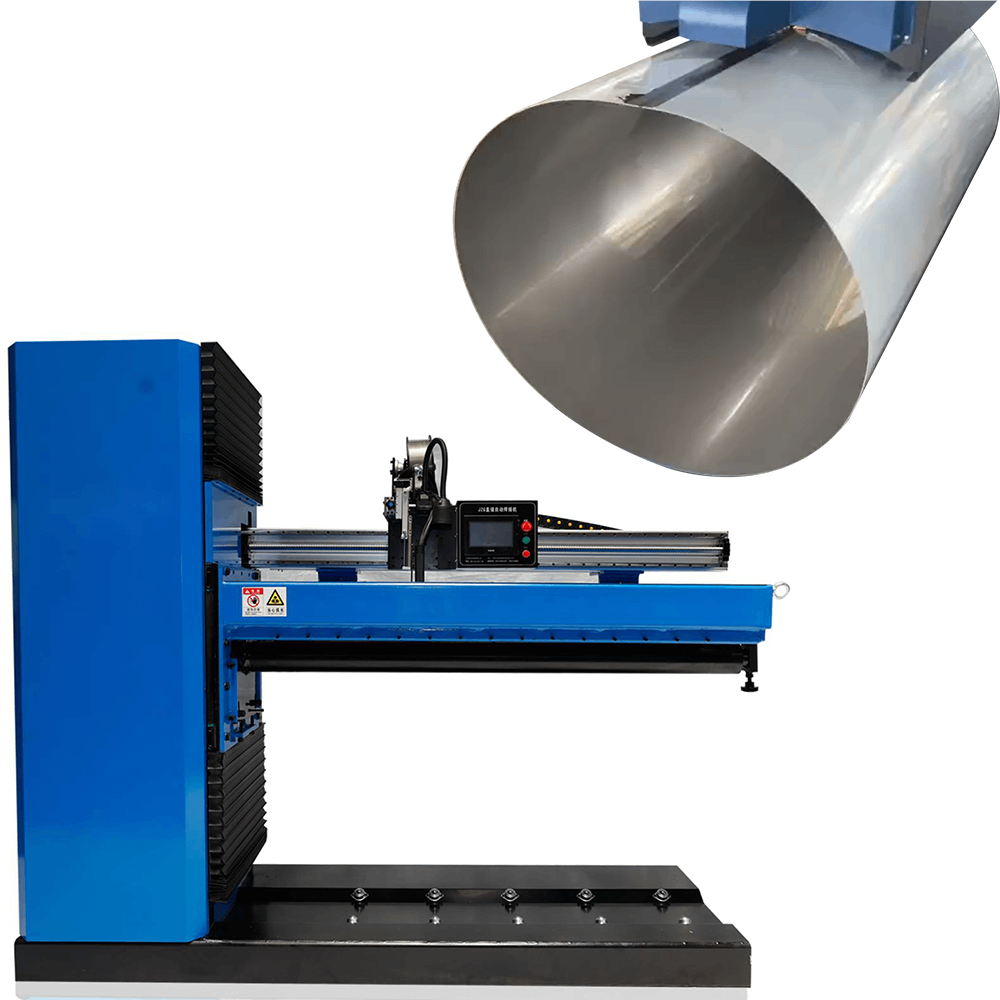

Balance Picture Of Fan Impeller

Special Balancing Machine For Large Diameter Fan Impellers

TIPS

(1) For large diameter workpieces: It is recommended to use two bed bases separately and dig holes accordingly.

(2) The end box (universal driven joint part) can be moved on the bed.

(3) This solution is cost-effective and suitable for fan manufacturing and maintenance industries.

Altron Can Provide Complete Solution For You, Pleas Share Your Job Specs:

Q1: Which kind of fan impeller you need balance for ? A1 : eg: axial fan, blowers, centrifugal fan

Q2: What’s weight range of fan impeller ? A2 : Max weight : _______ kg ; Min weight : ______ kg

Q3: What’s weight range of fan impeller ? A3 : Max weight : _______ kg ; Min weight : ______ kg

Q4: What’s diameter range of fan impeller ? A4 : Max weight : _______mm ; Min weight : ______ mm

Q5: What’s working speed of fan impeller ? A5 :Working speed :_____ rpm

Q6: What’s motor power (KW) of fan impeller in the real working use? A6 :Motor power :_______ KW

Dynamic Balancing Machine for Industrial Fans