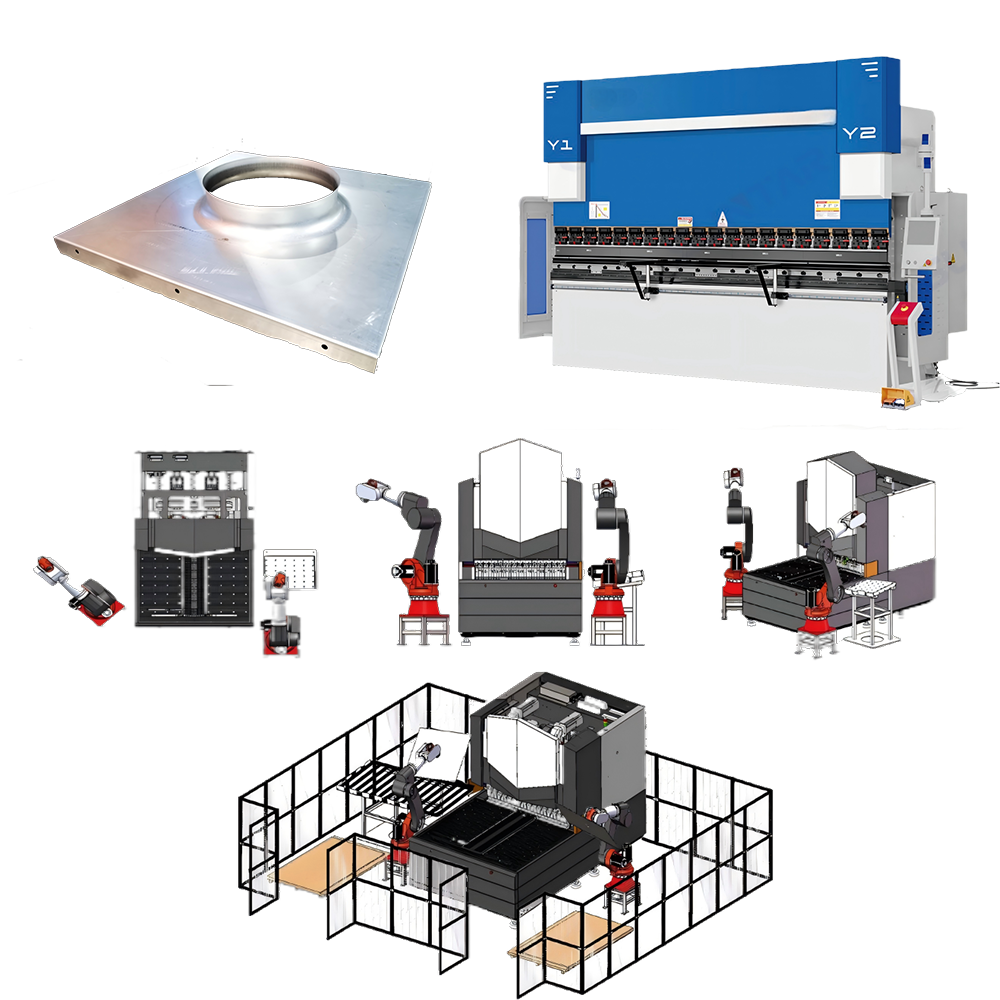

Flexible Bending Centers & Bending Machines

Bending Machine & Flexible Bending Centers For Sheet Metal Processing

|

Machine Name |

Bending Machine & Flexible Bending Center |

|

Model |

ACZW |

|

Application Industry |

Sheet Metal Bending & Forming Processing |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day / Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

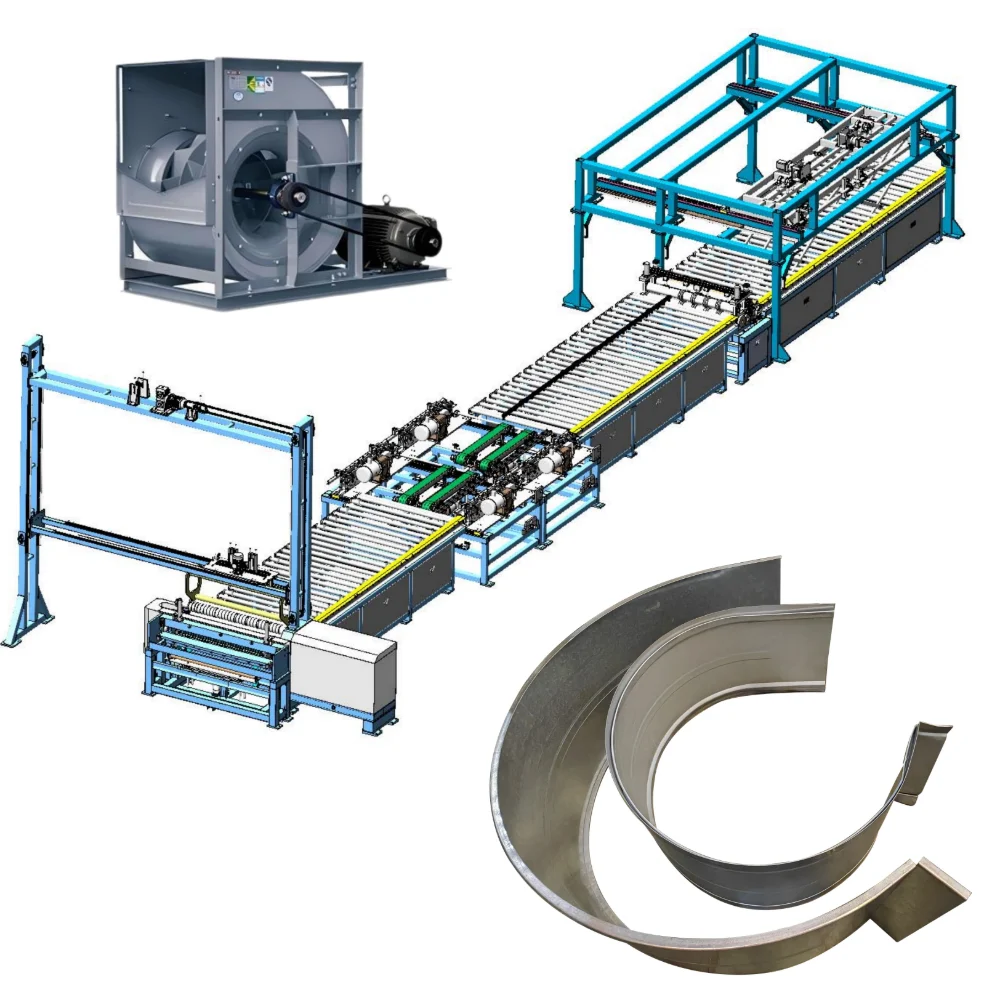

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Industrial Fans A-Z Project:

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

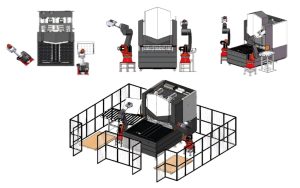

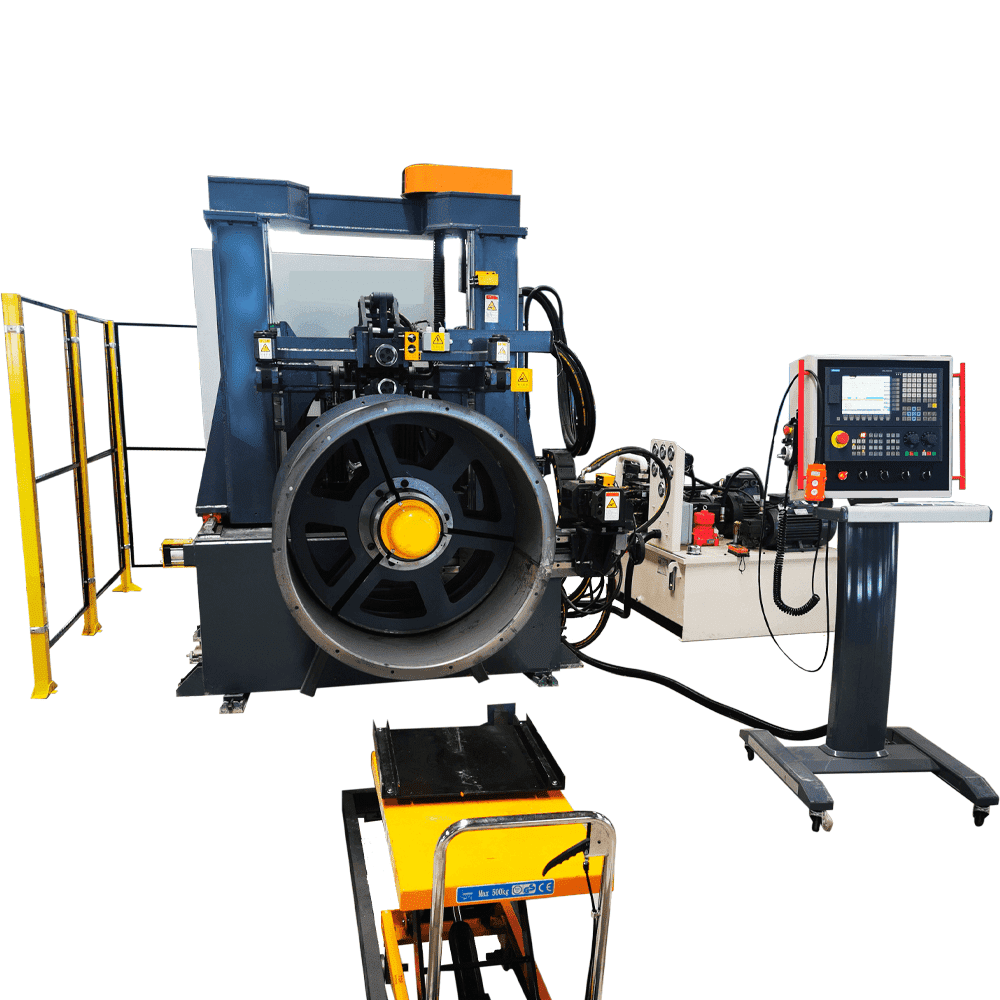

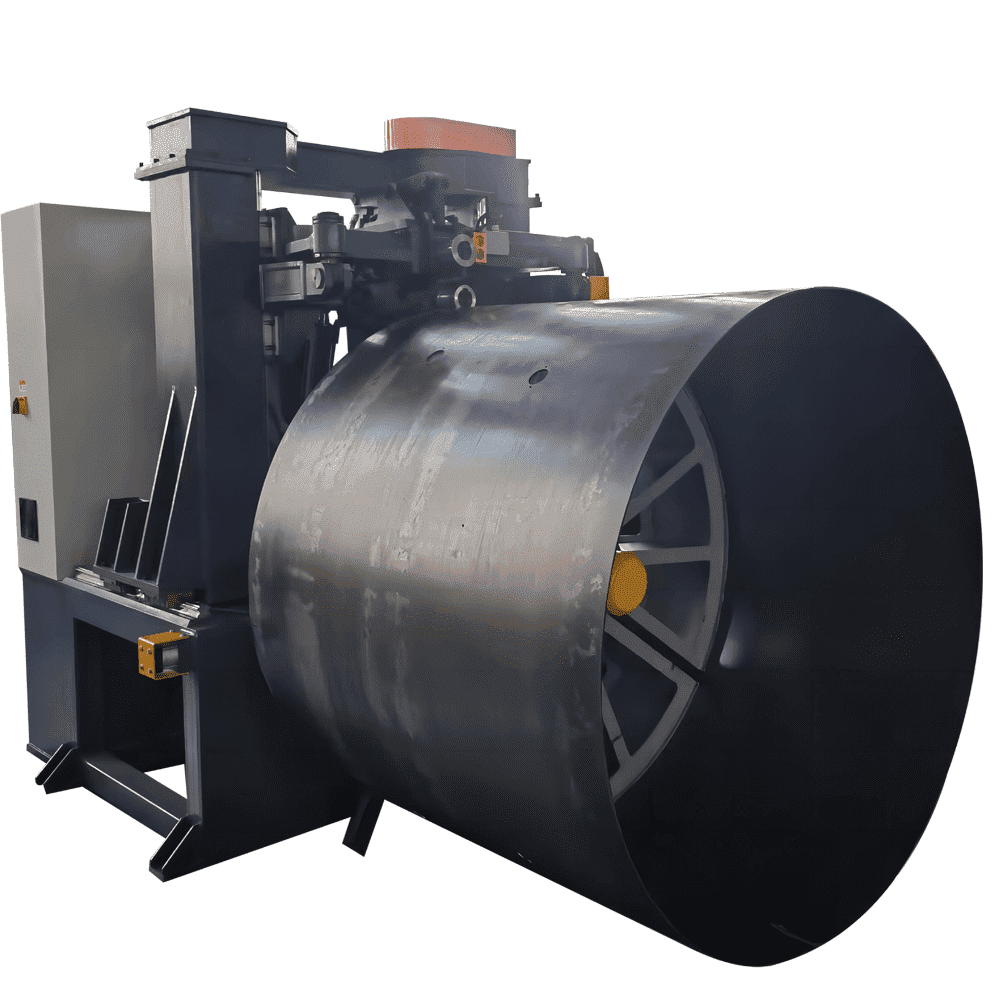

Altron Bending Machine solution mainly provides auxiliary production for industrial fans, which is closely related to the processes before and after the production of industrial fans!

When the factory encounters low efficiency of manual bending when producing sheet metal bending, Altron intelligent flexible bending center can help you solve the sheet metal forming problem! The equipment automatically positions and bends, and it takes an average of thirty seconds to complete a workpiece! Good consistency in metal bending and forming!

Automatic Bending Video

Automatic Bending By Robot Or Manual Hydraulic CNC Bending

Overview Of Bending Machine

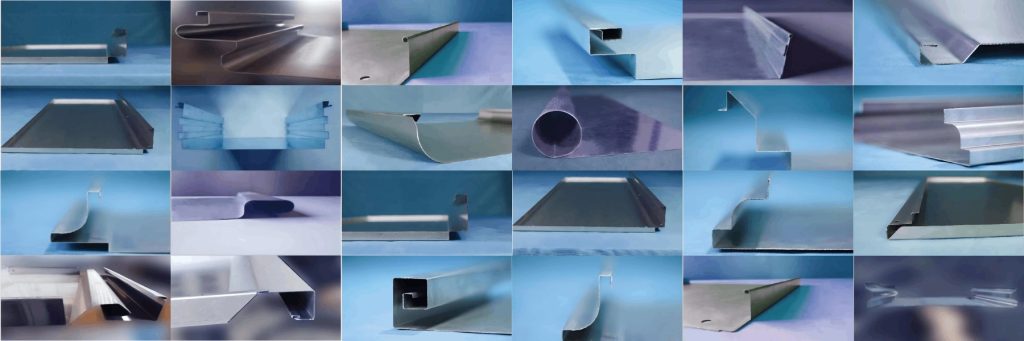

Sheet Metal Bending Effect And Shape

Sheet Metal Bending Detail Effect

In the following pictures you can find the bending situation and solution that suits you! If you need special customization, please contact us, Altron will provide you with a detailed solution as soon as possible!

| Parameters | 1400P | 2000P | 2500P | Customized | |||

| Max. bending speed | 0.2 second/time | 0.2 second/time | 0.2 second/time | ||||

| Max. bending width | 1400 mm | 2000 mm | 2500 mm | ||||

| Bending hight | 170 mm | 170 mm | 170 mm | ||||

| Rated voltage | 380v | 380v | 380v | ||||

| Total Motor power | 38 KW | 77 KW | 77 KW | ||||

| Average power | about 1.8Kw | about 2.5Kw | about 2.8Kw | ||||

| Noise | about 50dB | about 50dB | about 50dB | ||||

| Machine dimension | 440*190*290cm | 510*265*330cm | 565*300*340cm | ||||

| Total Machine weight | about 12t | about 16t | about 19t | ||||

| Max. bending thickness (thicker panel customizable) |

304 stainless steel: 1.2mm | 304 stainless steel: 1.2mm | 304 stainless steel: 1.2mm | ||||

| Carbon steel: 1.5 mm | Carbon steel: 1.5 mm | Carbon steel: 1.5 mm | |||||

| Aluminum :2.0 mm | Aluminum :2.0 mm | Aluminum :2.0 mm | |||||

| Minimum sheet thickness | 0.35 mm | 0.35 mm | 0.35 mm | ||||

| Foursides forming, minimum inner size | 140*190 mm | 140*190 mm | 140*190 mm | ||||

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

I recently received the Bending machine and I must say that I am extremely satisfied with my experience so far. The training video provided was comprehensive and helped me understand the setup and operation of the machine. The after-sales service has been exceptional, with patient and helpful support staff guiding me through any questions or concerns I had.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

I was pleasantly surprised by how simple the equipment was to operate. With the clear instructions and intuitive interface, I was able to get the machine up and running quickly. The user-friendly design made it easy for me to grasp the controls and make adjustments as needed.

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The efficiency of the equipment has exceeded my expectations. It has significantly reduced labor costs and improved productivity in our bending processes. The quality of the bends produced by the machine is excellent, and I no longer have to worry about inconsistencies or uncertainties that were common with manual work. This has increased the acceptance of our products among our customers.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

I am extremely pleased with the performance of the equipment and the support provided by the company. I highly recommend this bending system to others in need of efficient and reliable bending solutions.