CNC Head Metal Spinning Forming Machine

CNC Metal Spinning Machine For Heads & Tank

|

Machine Name |

Metal Spinning forming Machine |

|

Model |

AC-FTXY |

|

Application Industry |

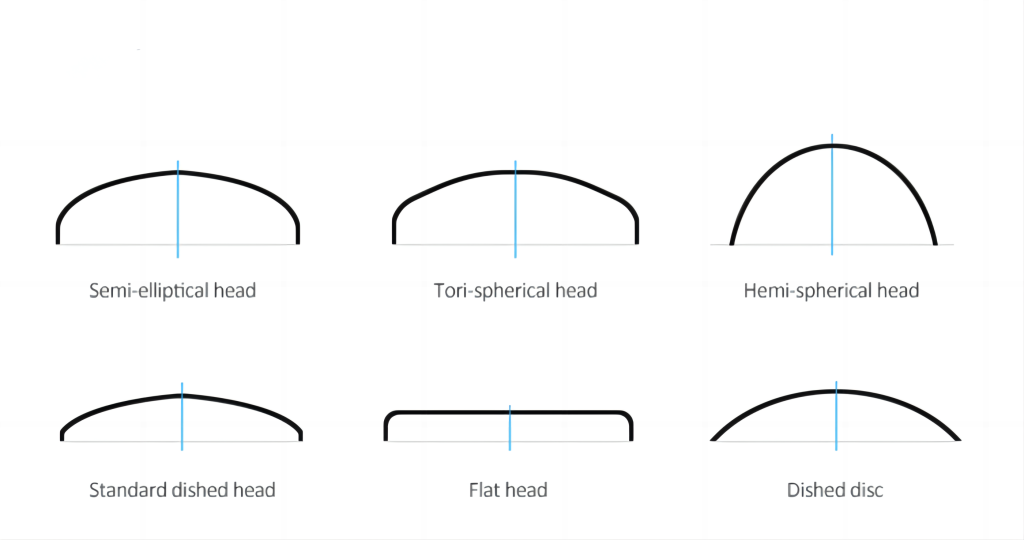

Semi-elliptical head;Standard dished head;Tori-spherical head;Flat head;Hemi-spherical head;Dished disc |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

Metal Container A-Z Project:

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

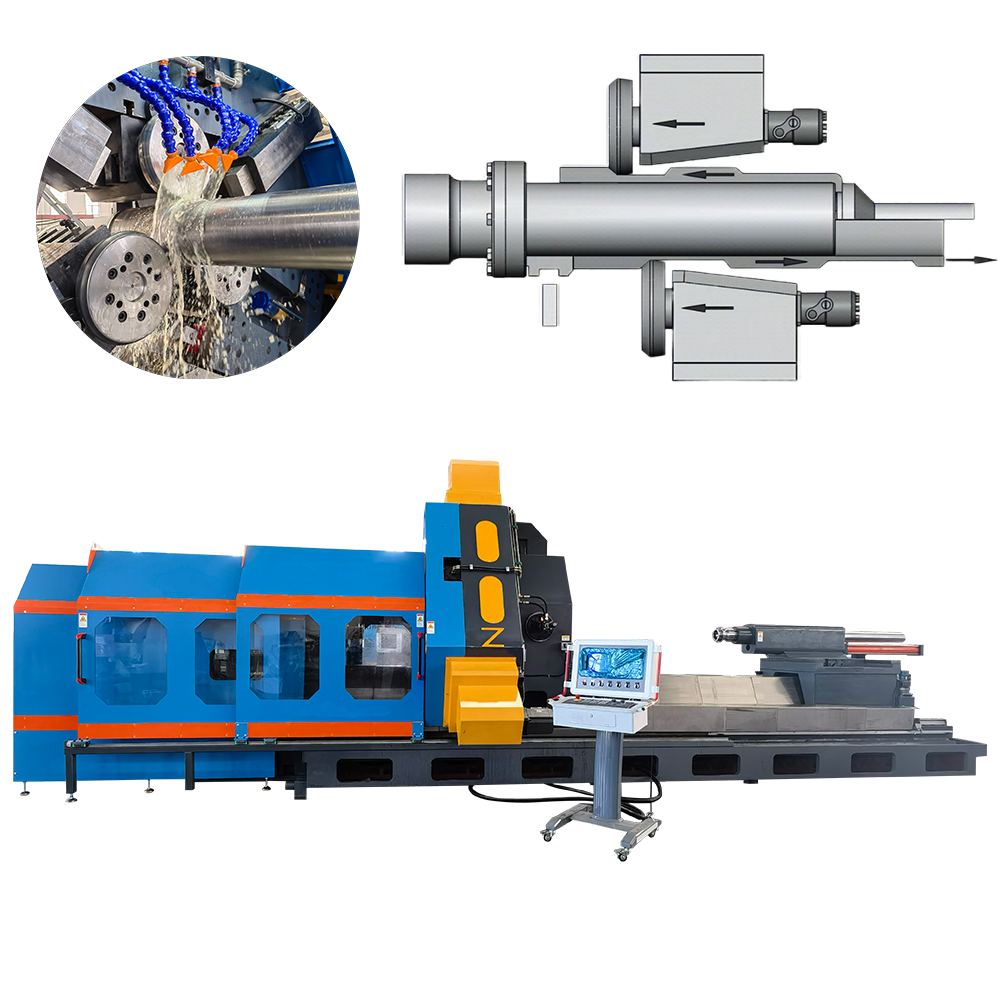

Introduction to the production line of metal head forming spinning machine

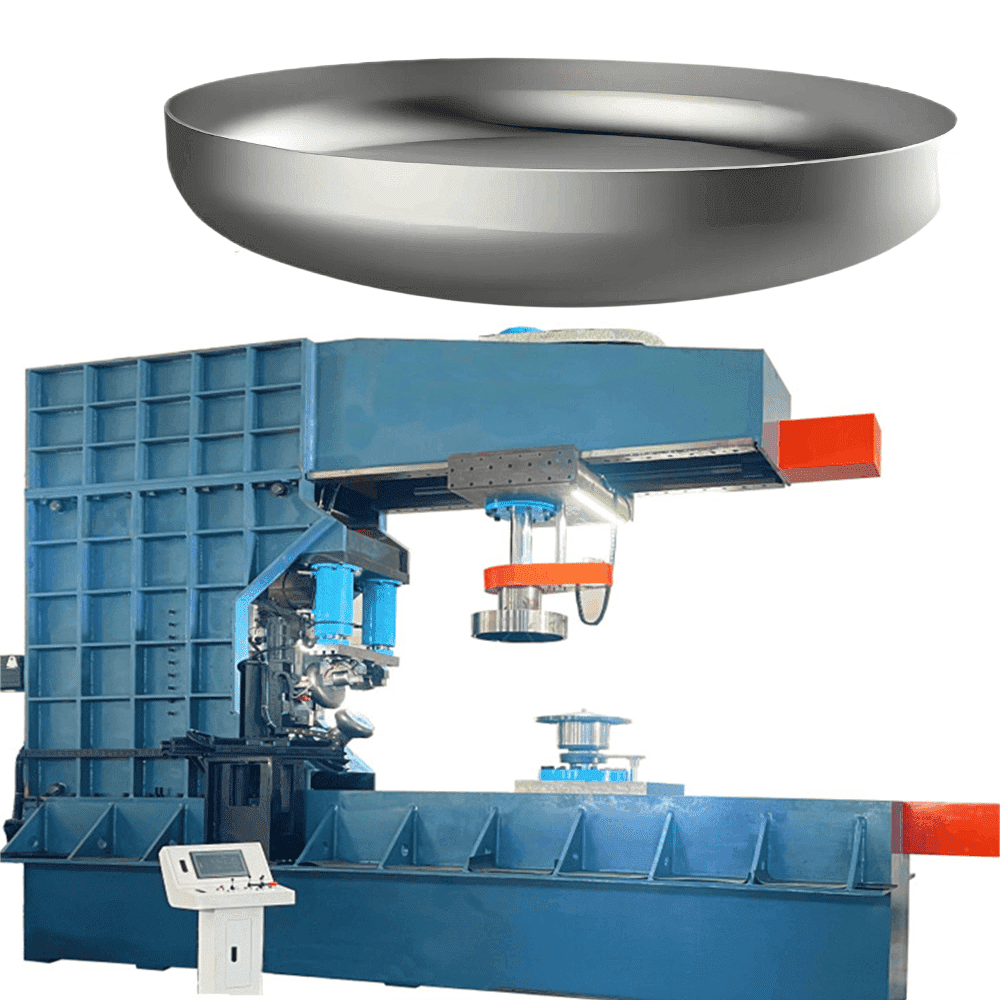

Manufacturers of metal industrial heads for tanks and pressure vessels need a hydraulic press for the bottom of the head, and a CNC head hydraulic spin forming machine.

ALTRON provides high performance and efficient yet stable machines. The production line combines a cutting-edge disc head press with automatic manipulators, spinning and flanging machines to achieve the reliability of head size production and meet the quality and stability of disc head manufacturers for welding and splicing.

Metal head manufacturing starts with laser cutting of sheet metal and cutting of circular blanks. The processing capacity of the standard head production line is within 10 mm of stainless steel plates; the disc press is used with a special pressing mold to process the convex arc position of the metal head through multiple repeated impacts. This action is systematically performed in an automatic cycle managed by the CNC system, which also guides the manipulator to evenly distribute the impact force on the bottom of the dished head, allowing it to gradually eliminate internal stress and form to the desired shape.

After the bottom contour of the metal head is formed, the metal head spinning machine begins to spin the outer contour of the butterfly head. The bottom of the head is fixed by the upper and lower hydraulic cylinders. The large-diameter hydraulic forming wheel and the head spinner The pressure wheel spins once according to the set trajectory. Most heads are cold formed. In special materials, an annealing process is used to eliminate the internal stress of the material, making the production of industrial heads more consistent; in large quantities During the production process, CNC control is used to ensure the consistency of the outer diameter data of the head; to ensure that the dished end meets precise specifications, the ALTRON head spinning machine can be added with a chamfering tool for girth seam welding. Strength and welding water permeability have better results.

Metal Head Bottom Hydraulic Press Machines

Videos Of Metal Head Bottom Hydraulic Press Machines

Videos Of Metal Head External Spinning Flanging Forming Machine

Common problems in large diameter head forming

A head with a larger diameter will have greater internal stress, commonly known as metal rebound. There will be a certain deviation between the theoretical head diameter and the actual formed head. We can solve the outer diameter tolerance through compensation in the CNC system.

How to control the size accuracy of the mouth after the head is formed

As the radius of the metal head is adjusted, the forming wheel rotates in conjunction with the inner contour mold and manipulates the material to achieve the desired curvature, a long operation that causes delamination of the sheet metal. It ensures the best forming effect, minimizes material thinning, and achieves flanging and spinning forming in a few times.

Altron’s high-quality metal head flanging machines have absolute advantages in this industry.

Classification Of Metal Heads

CNC Head Metal Spinning Forming Machine Device parameters:

|

Total equipment power |

78kw |

|

Power supply type |

380v Three-phase four-wire |

|

Equipment Specifications |

6500x4200x1700 |

|

Device Weight |

32T |

|

control method |

Motion Controller |

|

Drive mode |

Electro hydraulic drive |

|

Operation interface |

touchscreen |

|

Hydraulic pressure |

21mpa |

|

Processing diameter (mm) |

700-4000 |

|

Processing length (mm) |

0-1200 |

|

Processing thickness (mm) |

Stainless steel 10mm |

|

Device functions |

Flanging Trimming |

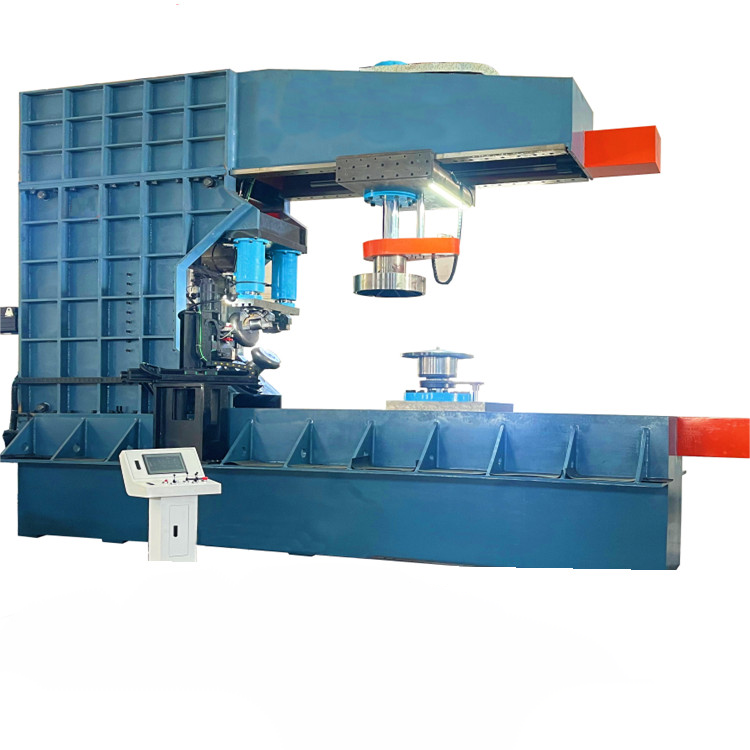

Basic machine information

|

Spinning strength |

High power rotation |

|

Pressure supply type |

Hydraulic |

|

Turn around |

forward |

|

Metal Material |

Stainless steel |

|

Riveting principle |

Orbital model (BM series) |

|

Rotation deformation conditions |

Cold spinning |

|

Spinning pulley type |

Rolling V pulley |

|

Number of spinning wheels |

Double |

|

finished product |

Pressure vessel |

|

Finished shape |

Special shape |

Metal head forming machine video

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.