CNC Metal Spinning Machine For Industry Fans

✔ Advantage: 15 Years Of CNC Metal Spinning Machine R&D, Production, And Sales

✔ Application: Funnels, Hoppers, Cans, Bowls, Dome Lids, Metal Spinning Components

✔ Material Thickness: Stainless Steel, Aluminum, Copper, Brass, Bronze And Mild Steel

✔ Spinning Software: Free Supporting Machine, No Need To Write Program Code Manually.

✔ High Efficiency: The Automated Processing Flow Greatly Improves Production Efficiency.

✔ Solution customization: 7*24 Online Service, Engineer Video Online Conference To Solve Pre-Sales Problems.

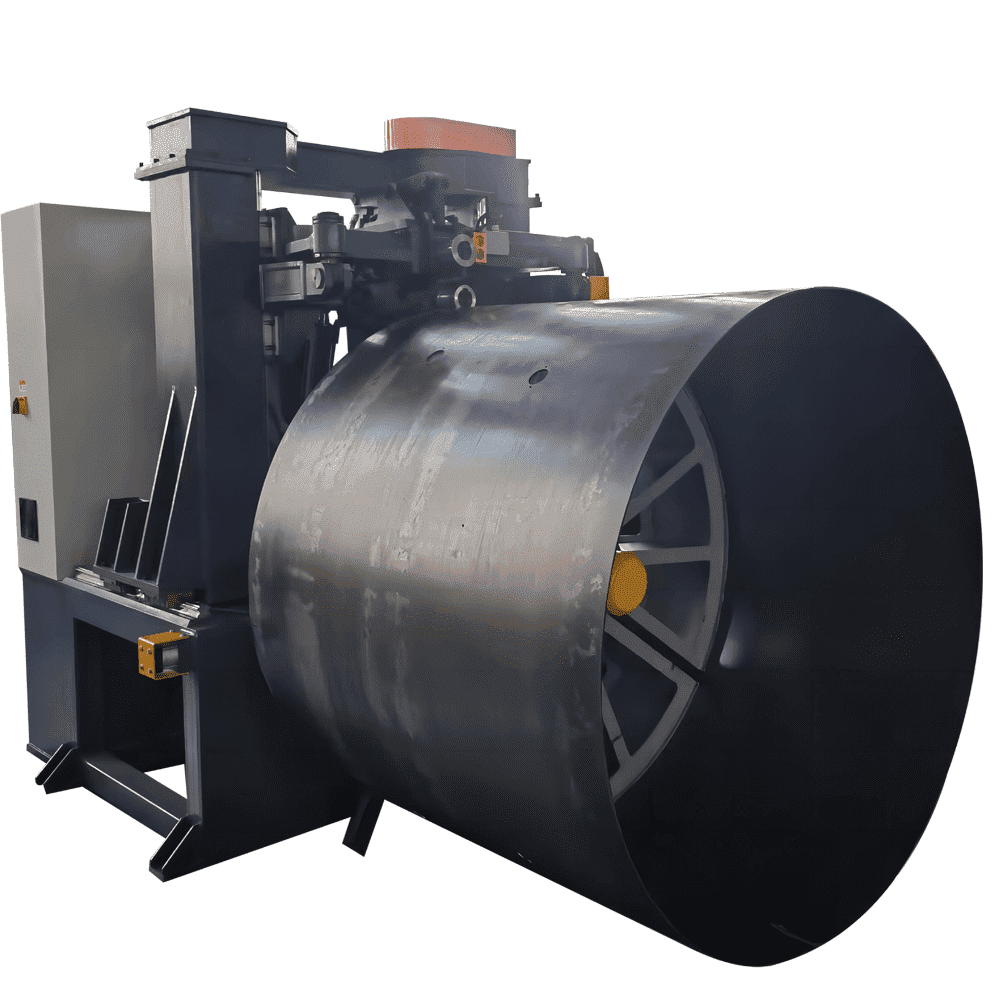

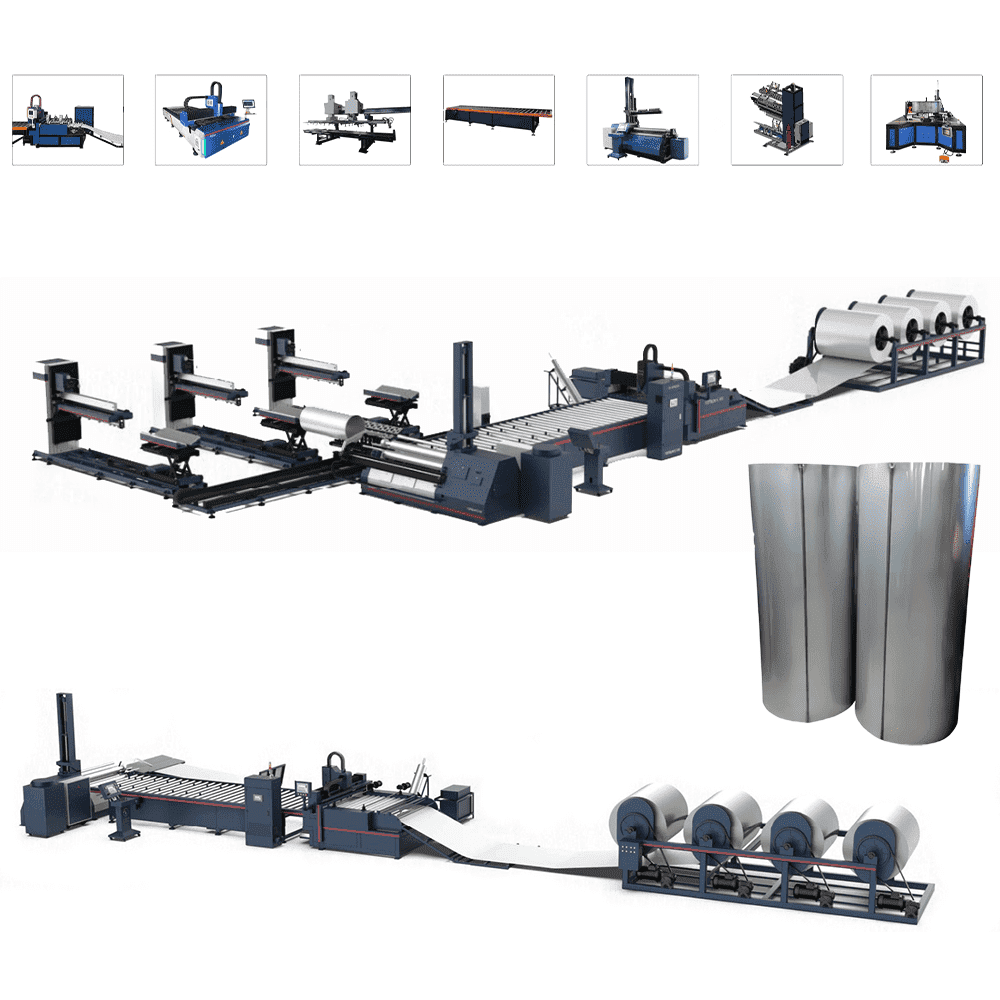

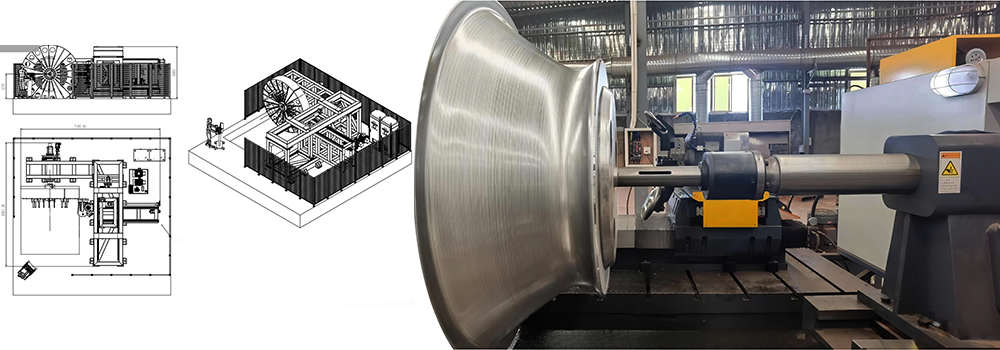

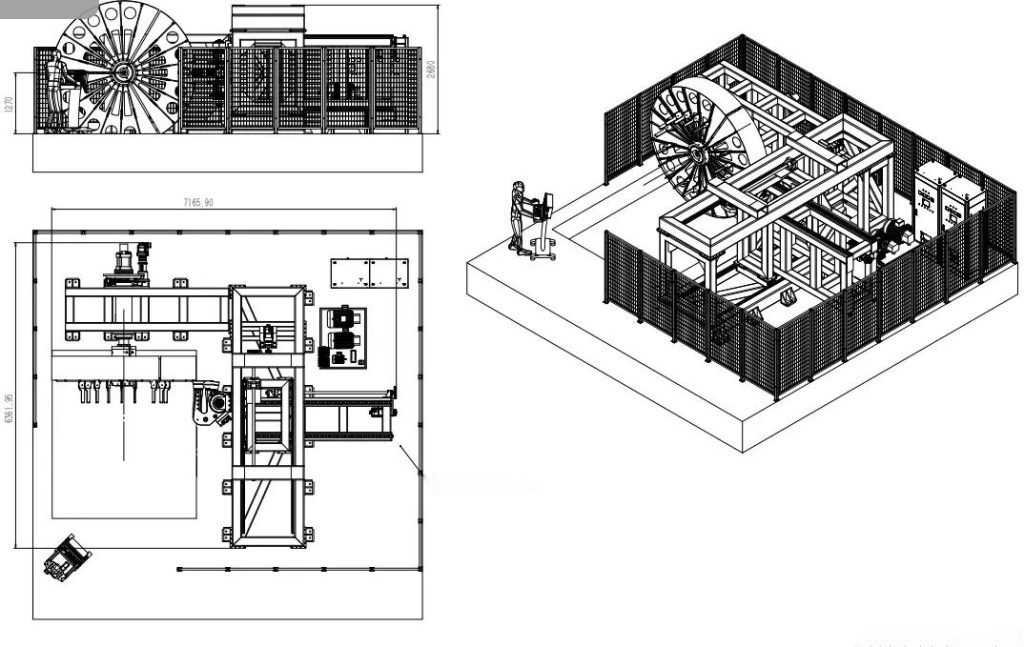

CNC Metal Spin forming machine For Industrial Fans A-Z Project:

1 CNC Metal Spinning Machine, 2 CNC Flanging Machine, 3 AI Automatic Welding, 4 Axial Flow Fans Forming Production Line, 5 Centrifugal Fans Forming Production Line, 6 Air Duct Production Line, 7Impellers OEM

- CNC metal spinning machine is precise and efficient, suitable for various metal forming;

- Intelligent control reduces labor costs;

- High repeatability ensures product consistency;

- Multi-functional and applicable to meet diverse production needs;

- Energy-saving and environmentally friendly, reducing energy consumption;

- Stable and reliable, improving production efficiency and quality.

Principle And Introduction Of Cnc Spinning Machine

CNC spinning is a complex metalworking process technology that changes the production process of rotationally symmetrical parts. It works by spinning metal sheets or tubes on a CNC-controlled CNC spinning machine while applying pressure through a dedicated spinning tool to plastically deform them into an axisymmetric shape. The process is able to create complex geometries with high precision and repeatability.

Advantages of CNC Spinning Machines

CNC spinning is a precision metalworking process that offers several advantages over traditional deep drawing methods.

CNC spinning machines are able to accurately form and guarantee the consistency of various metal materials during the spinning process (including special alloys such as aluminum, iron, copper, stainless steel and titanium). Secondly, CNC spinning improves productivity by reducing development time and minimizing material waste, especially in the industrial fan and air conditioning ventilation industry. In addition, CNC metal spinning helps to produce complex geometric rotational shapes without the need for high-powered machines and complex processes, thereby greatly reducing manufacturing costs.

Features of CNC Spinning

✔ Iemens CNC System & Siemens Drive Motor.

✔ CNC Metal Spinning Programming Software.

✔ Optional: oil-cooled air conditioner; electric cabinet air conditioner; isolation transformer

✔ Metal Spinning Thickness Capability: 0.3-25mm.

✔ Metal Spinning Diameter: 0-3800mm.

✔ Metal Spinning Trajectory Visualization.

✔ Free Guide to Metal Spinning Technology.

✔ Supports Hot Metal Spinning.

✔ Supports Water Circulation Spinning.

✔ Powerful metal spinning turret; can cut, turn, bead, flanging,

✔ Spinning tools water cooling mechanism.

✔ The spindle is equipped with punching mechanism/servo spindle.

✔ The spindle is equipped with rotary cylinder and hydraulic chuck fixture.

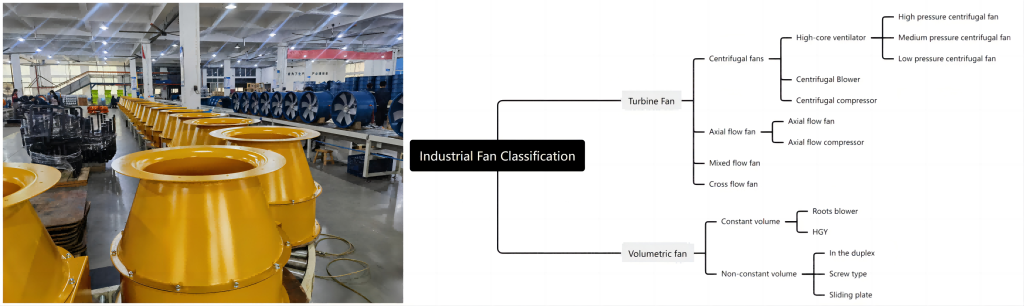

Overview of Industrial Fan Ventilation Industry

Scope of Industrial Fans

The industrial fan ventilation industry covers a wide range of applications, from cooling large manufacturing facilities to exhausting air pollutants in industrial environments. Industrial fans play a vital role in maintaining optimal air circulation and temperature control in various environments, including factories, warehouses, shopping malls, hospitals, buildings and agricultural facilities.

Development Trend of Industrial Ventilation

In recent years, environmental and health awareness has driven the continuous rise of the industrial ventilation industry. High-performance and energy-saving ventilation equipment comes from the unique and perfect design and manufacturing of fluid core components, and advanced materials are selected to improve durability and reliability. As a result, automated production and manufacturing will replace low-capacity manual manufacturing.

Altron provides automated production solutions for the entire process of metal forming and welding in the industrial ventilation fan manufacturing process; providing industrial fan manufacturers with turnkey automated production solutions.

Application of CNC spinning for industrial fan ventilation industry

CNC spinning machines provide high precision and efficiency in manufacturing fan components. This results in consistent and accurate parts, enhancing the overall

Precision and Efficiency

CNC spinning machines offer high precision and efficiency in manufacturing fan components. This ensures consistent and accurate parts, improving the overall product quality.

Diversified Production

CNC spinning technology is suitable for processing various metal materials and complex shapes, meeting the diverse production needs of industrial fan ventilation systems.

Cost Reduction

Automated production reduces labor and time costs, increases production speed, and lowers manufacturing expenses.

Environmental and Energy Efficiency

CNC spinning technology effectively minimizes material waste and energy consumption, aligning with environmental requirements and enhancing the company’s sustainability.

Enhanced Durability

The high-precision processing ensures that the fan components produced are more durable, extending product lifespan and reducing the frequency of maintenance and replacement.

Wide Application

CNC Metal Spinning technology is widely used in the manufacturing of industrial fan blades, housings, and other components, providing reliable technical support for the ventilation industry.

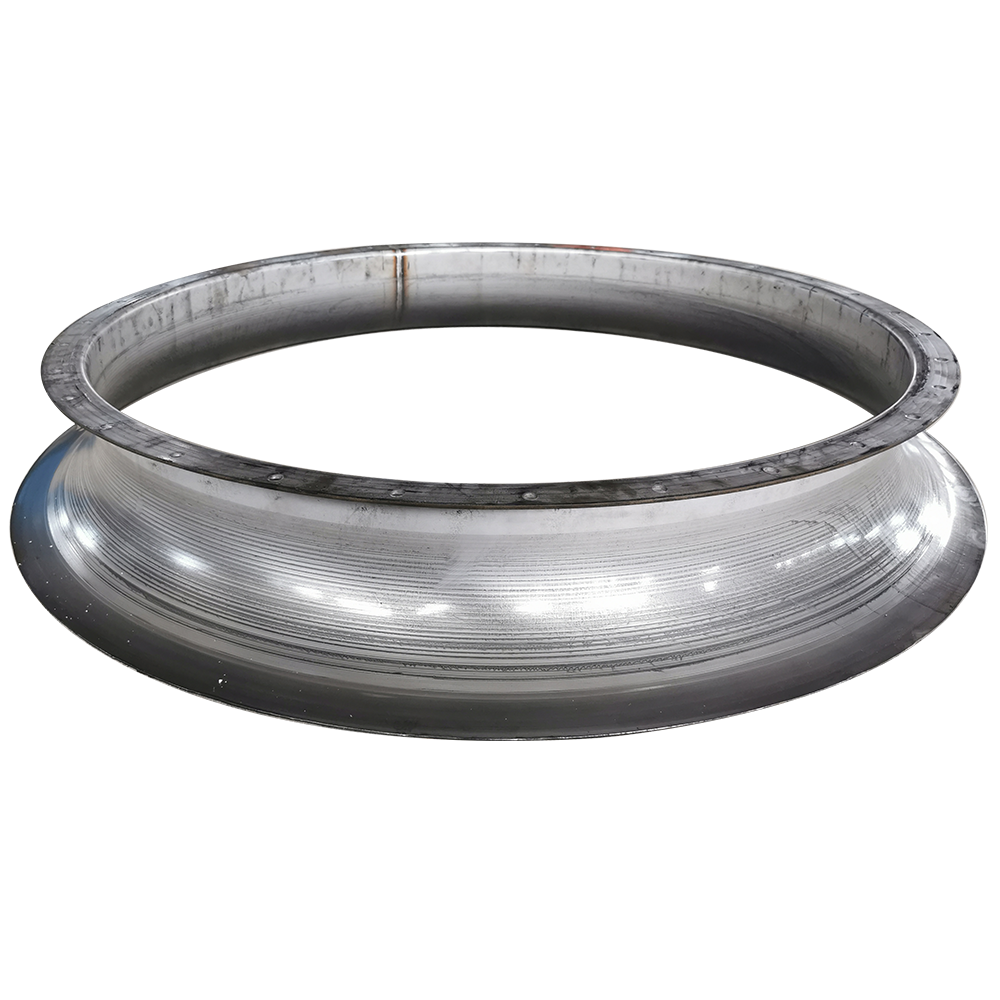

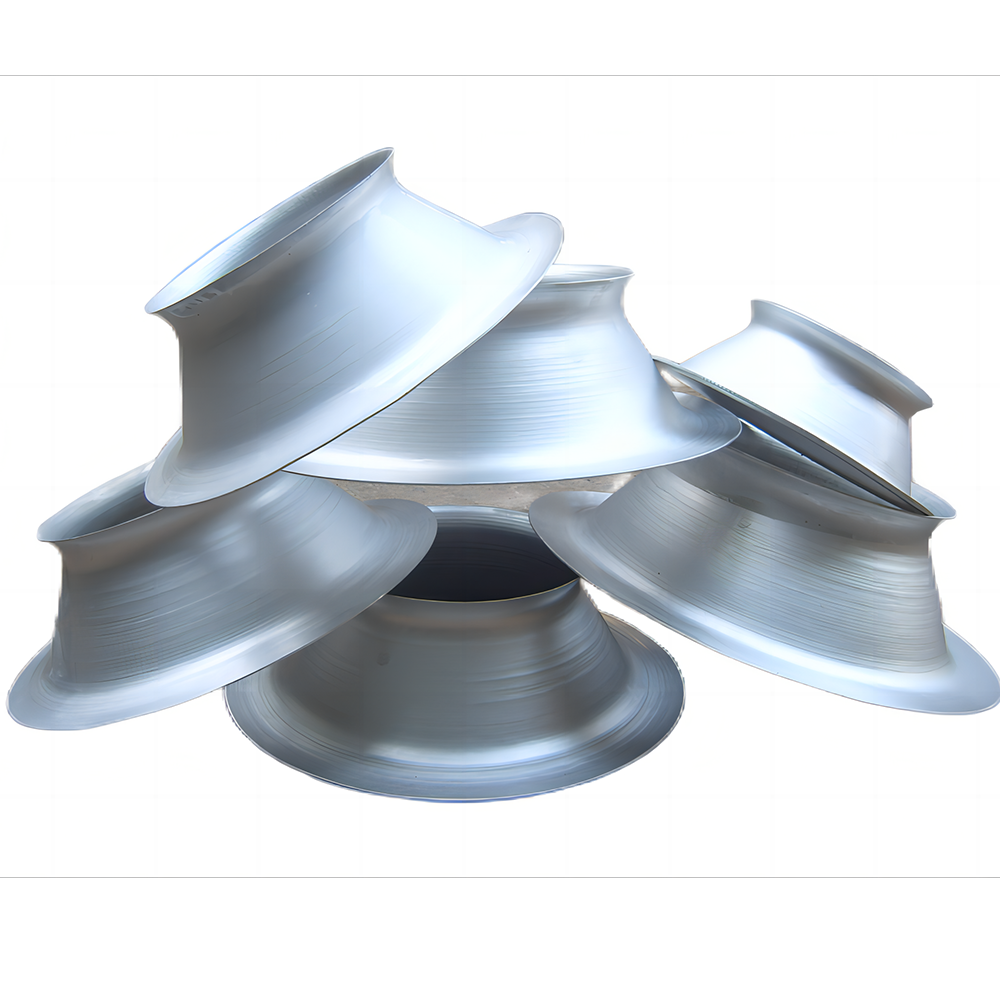

Case Display Of Industrial Fan Metal Spinning Forming

Case Display Of Axial Fans

Case Display Of Centrifugal Fans

Case Display Of Mixed Flow Fans

Case Display Of Roof Fans:

Success Case

✔ 15 years of experience in the field of metal spinning in the industrial fan industry,

✔ serving over 400 fan manufacturers,

✔ reasonable metal spinning solutions for fan accessories,

✔ industrial fan manufacturing moving towards automated production,

✔ automatic welding of industrial fans,

✔ automatic metal forming of industrial fans,

✔ OEM of industrial fan accessories

AlTRON Future development trend of CNC spinning

CNC Metal Spinning machines deliver exceptional precision and efficiency, allowing for the production of complex shapes with high consistency. They reduce material waste, enhance production speed, and offer flexible operation modes, making them ideal for high-volume manufacturing in diverse industries.

Advances in Data Spinning Technology

Enhanced Precision

Recent advances in CNC Metal Spinning technology have focused on improving the precision of the metal forming process. The integration of high-resolution sensors and feedback mechanisms can monitor and adjust key parameters such as spindle speed, feed rate and tool pressure in real time. This precise control ensures consistent part dimensions and surface finish, meeting the stringent quality standards of industries such as aerospace and automotive.

Automation Integration

Automation plays a key role in modern CNC Metal Spinning systems, helping to increase productivity and efficiency. Robotic loading and unloading systems combined with automatic tool changers enable unmanned operation and continuous production cycles. In addition, the integration of advanced software algorithms and machine learning techniques optimize tool paths and process parameters, further increasing output and reducing cycle times.

Material Versatility

Advances in CNC Metal Spinning technology have expanded its material processing capabilities to enable the manufacture of a wider range of materials. Improved tool design and cutting strategies can accommodate a variety of metals, alloys and even composites, allowing manufacturers to meet different customer needs. This versatility opens up new opportunities in areas such as renewable energy, where there is an increasing demand for lightweight materials and advanced alloys.

Smart Manufacturing Solutions

The emergence of the concept of smart manufacturing has driven innovation in CNC Metal Spinning technology. The integration of IoT sensors and data analysis platforms helps achieve real-time performance monitoring and predictive maintenance. By leveraging big data and machine learning algorithms, manufacturers can optimize production plans, minimize downtime, and proactively resolve equipment failures, thereby improving overall operational efficiency and competitiveness.

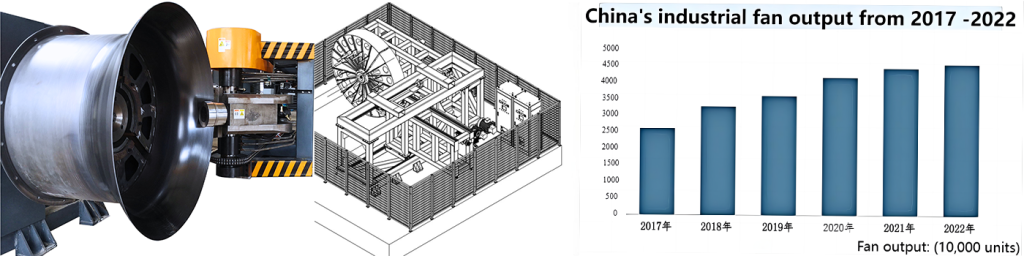

Changes in demand for industrial fan ventilation industry

Industry Fans are widely used for ventilation, dust removal and cooling in factories, mines, tunnels, cooling towers, vehicles, ships and buildings, ventilation and draft in boilers and industrial furnaces; cooling and ventilation in air conditioning equipment and household appliances; drying and selection of grains, wind tunnel wind sources and inflation and propulsion of hovercraft, etc.

Quote the 2022 China Industrial Fan Market Report! From 2017 to 2022, my country’s fan output showed an overall upward trend. In 2022, China’s fan output was 45.8655 million units, an increase of 3.01% year-on-year.

The Wide Expansion of CNC Spinning Applications

Diverse Industrial Sectors

CNC spinning applications have expanded significantly across diverse industrial sectors, ranging from aerospace and automotive to electronics and renewable energy. This versatile metalworking process offers unparalleled capabilities for producing complex geometries and high-precision components, making it indispensable in modern manufacturing operations seeking efficient, cost-effective solutions.

Aerospace Industry

In the aerospace industry, CNC spinning finds extensive use in fabricating engine components, structural elements, and aerodynamic surfaces. Its ability to produce lightweight, high-strength parts from aluminum, titanium, and other aerospace-grade materials meets the industry’s stringent performance and safety standards while reducing overall weight and fuel consumption.

Automotive Sector

In automotive manufacturing, CNC spinning plays a crucial role in producing exhaust systems, wheels, fuel tanks, and other critical components. Its flexibility in processing various metals and alloys allows for the creation of lightweight yet durable parts that enhance vehicle performance, fuel efficiency, and overall driving experience.

Different Metal Shapes by CNC Spinning

CNC Metal Spinning facilitates the production of a diverse range of metal shapes through a precision metalworking process. By rotating a metal blank on a CNC-controlled lathe and applying pressure with specialized tooling, various shapes such as cylinders, cones, hemispheres, and complex geometric profiles can be formed with exceptional accuracy and repeatability.

Cylindrical Shapes

CNC Metal Spinning excels in forming cylindrical shapes, commonly used in applications such as pipes, tubes, and housings. By controlling the feed rate and tool path, precise dimensions and surface finishes are achieved, meeting tight tolerance requirements in industries like plumbing, construction, and manufacturing.

Conical Shapes

The versatility of CNC Metal Spinning extends to the fabrication of conical shapes, essential in industries such as aerospace, automotive, and industrial machinery. By adjusting the tool pressure and spindle speed, tapered components like funnels, cones, and diffusers are formed with consistent wall thickness and smooth contours, ensuring optimal performance and structural integrity.

More complex geometric shapes

In addition to standard shapes, CNC Metal Spinning enables the creation of complex geometric profiles with intricate features and contours. Using advanced CAD/CAM software and multi-axis machining capabilities, components such as domes, paraboloids, and irregular forms are produced with precision and efficiency, fulfilling the demands of specialized applications in research, prototyping, and custom manufacturing.