Customized Air Duct Production Lines

Customized Air Duct Production Line For Ventilation Duct Manufacturers

|

Machine Name |

Customized Air Duct Production Lines |

|

Model |

AC-FG |

|

Application Industry |

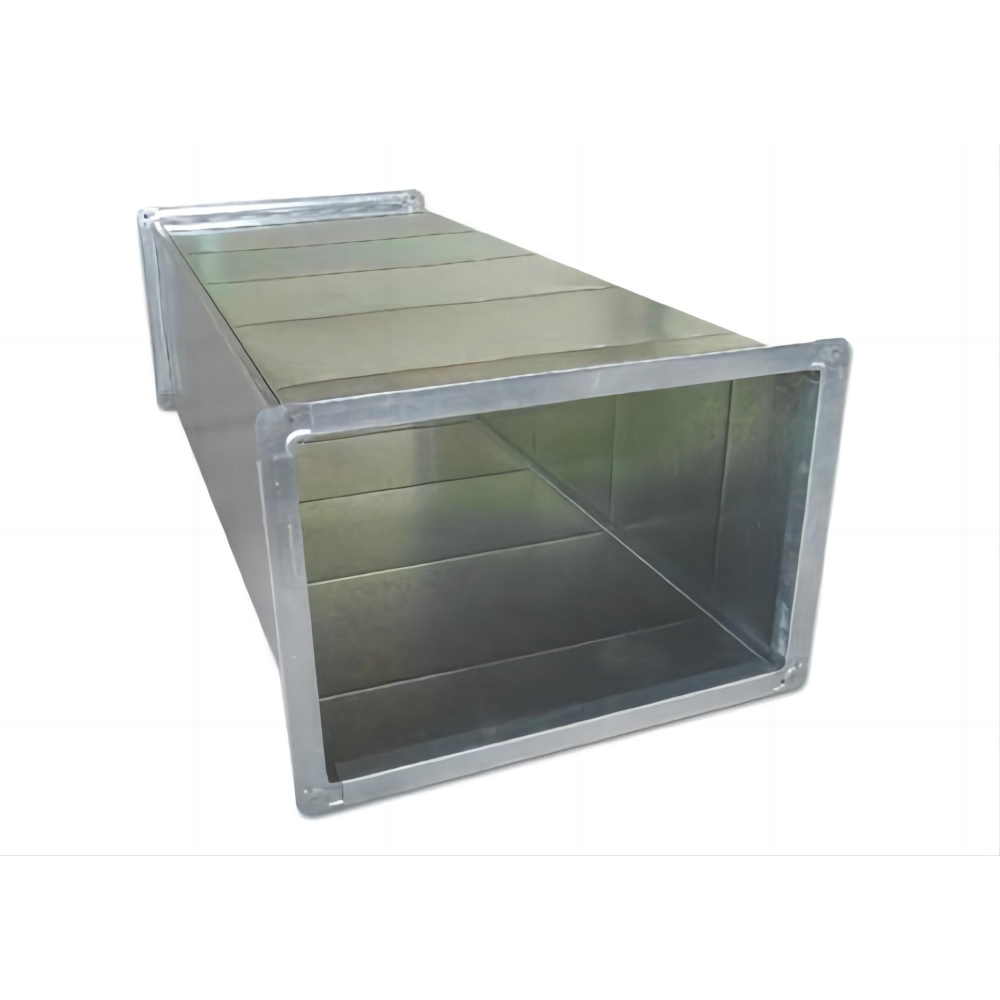

Rectangular ventilation duct |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

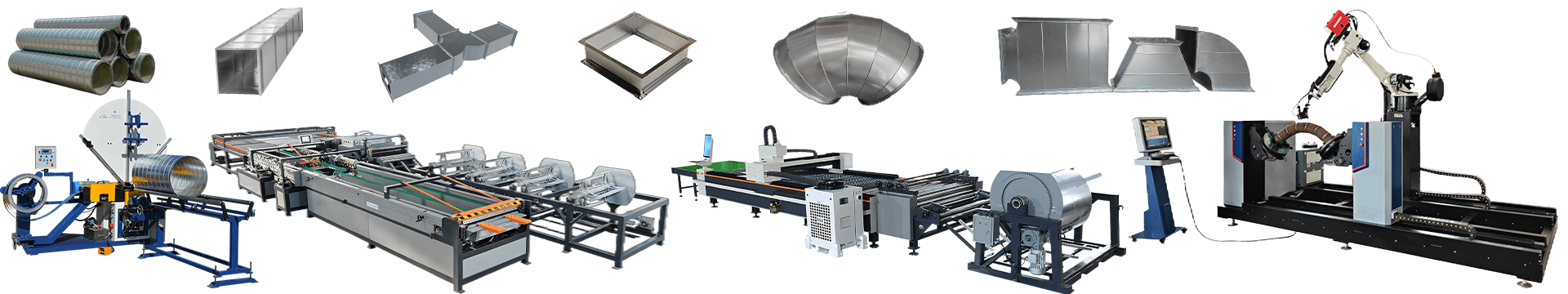

Air Duct A-Z Project:

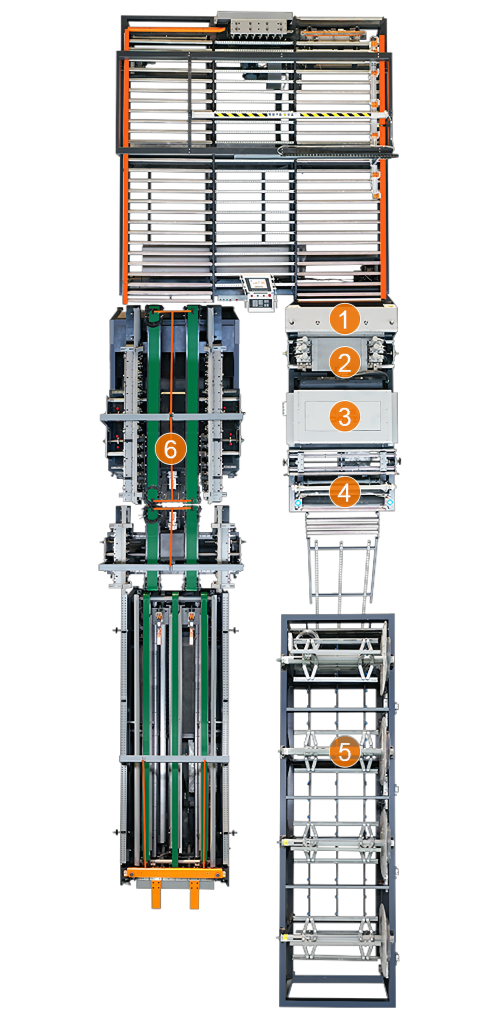

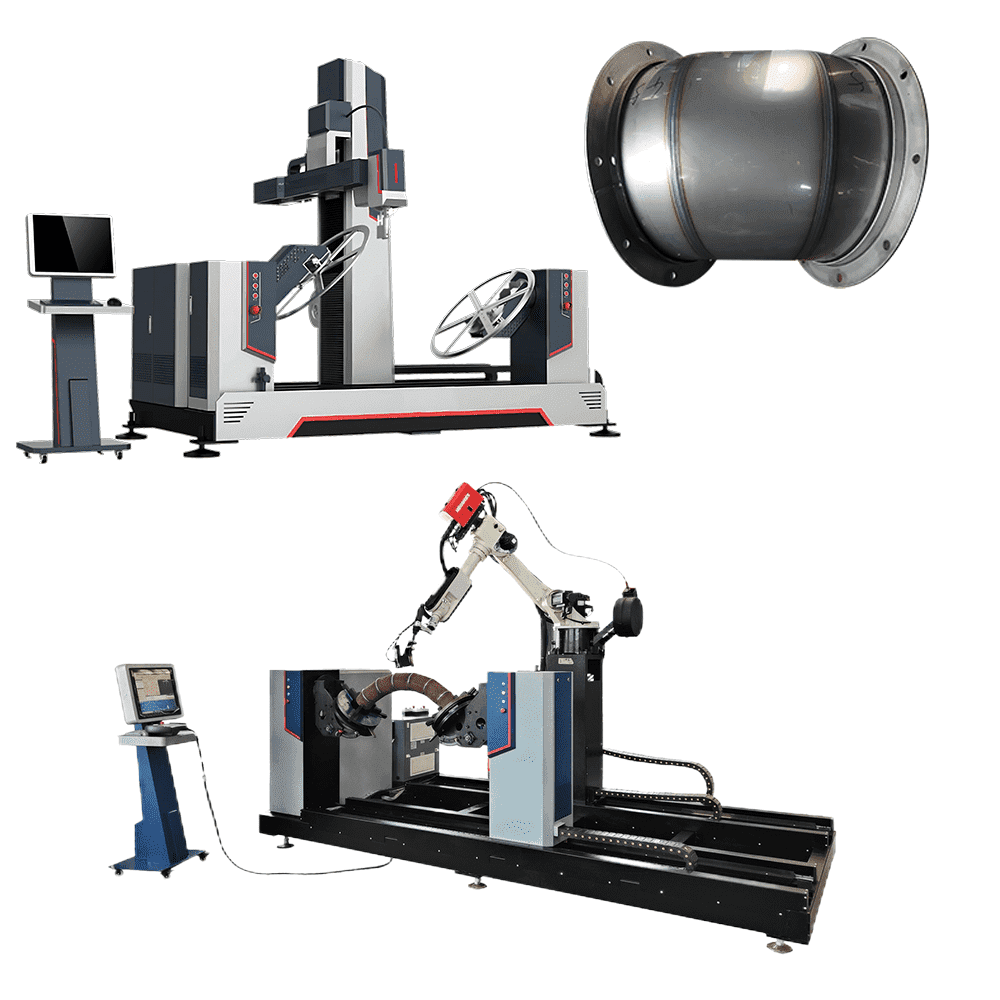

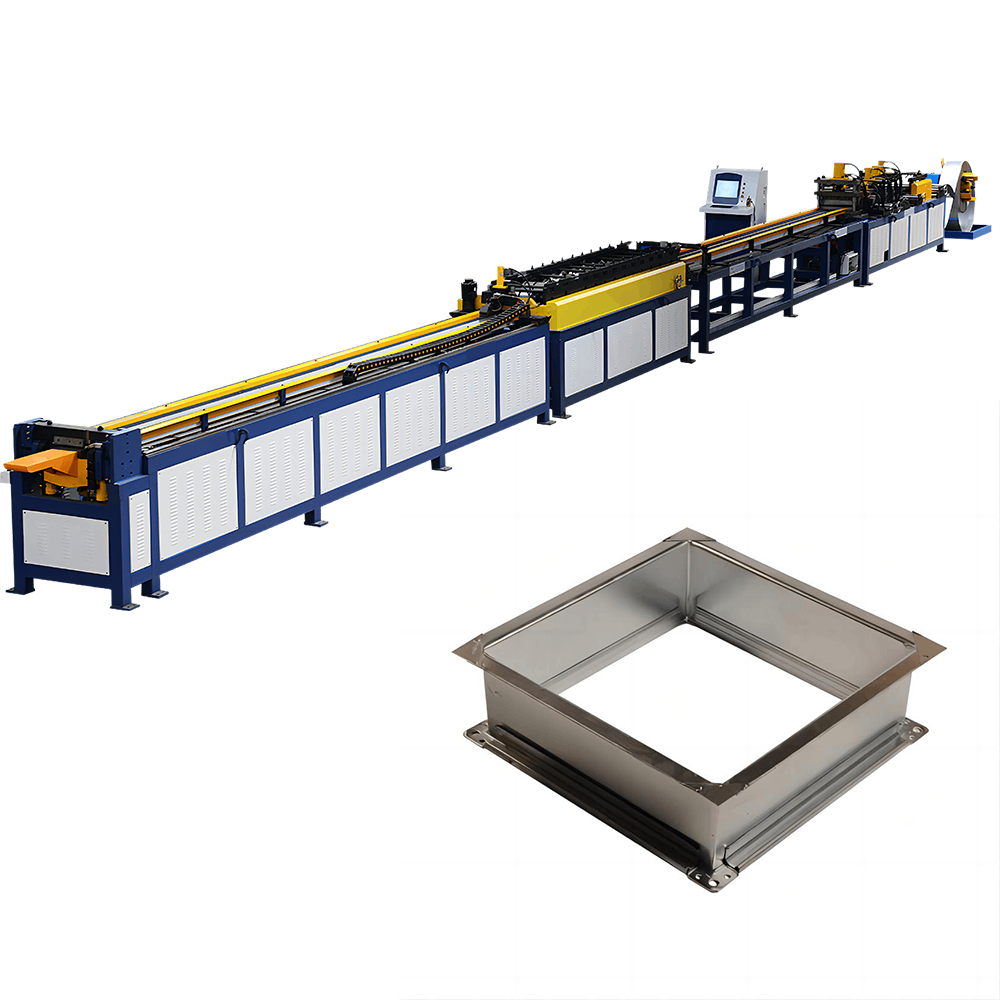

1Rectangular duct forming line 2 Continuous laser cutting production line 3Spiral duct production line 4 Damper housing production line 5 Rectangular duct welding 6 Elbow duct welding

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

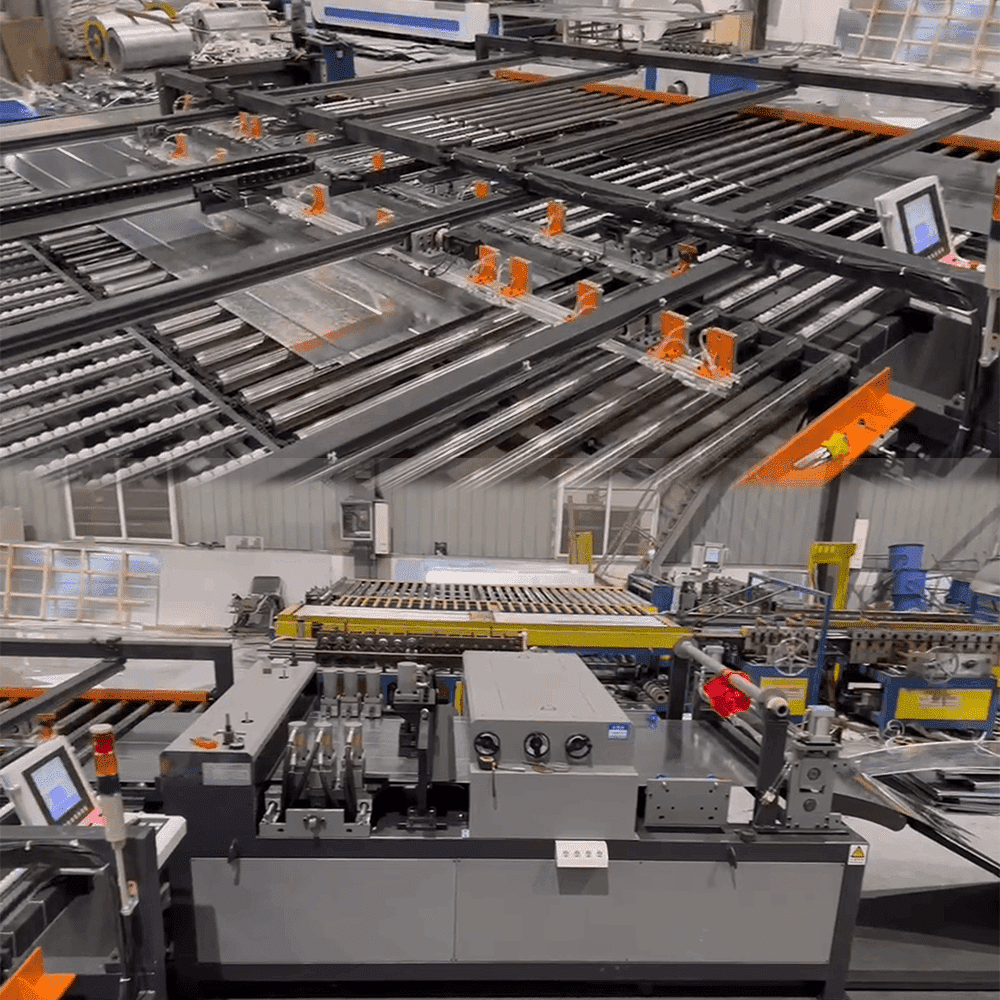

As the end of industrial ventilation, air ducts are also a type of product with a large output, and have higher efficiency and output requirements during the production process!

Altron’s improves customized air duct production lines and provides customized services for ventilation air ducts. According to the production capacity and output of air duct manufacturers and factory layout, we customize the production line of exclusive factories!

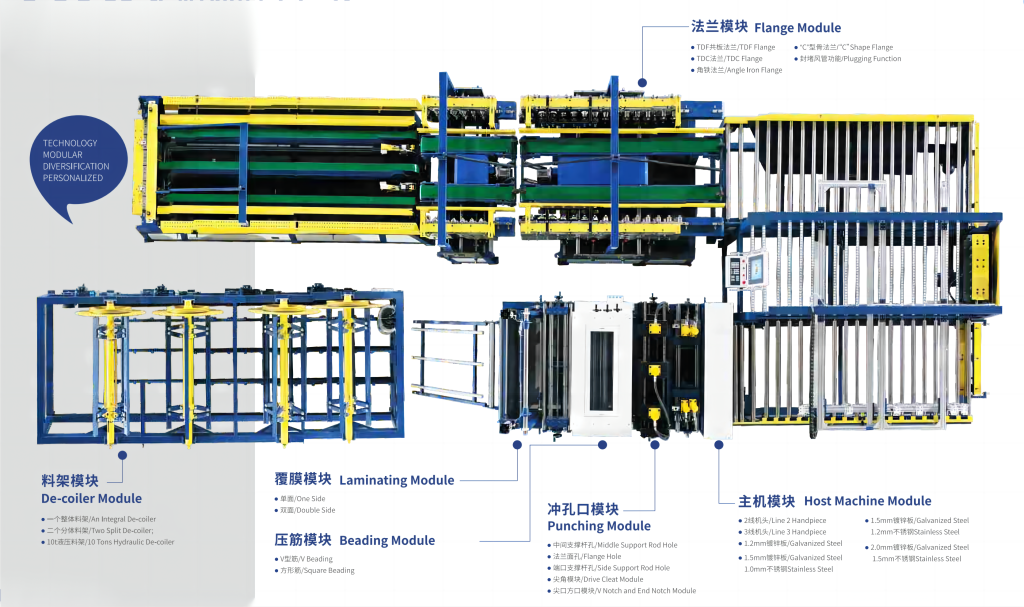

Duct Production Line Function Introduction

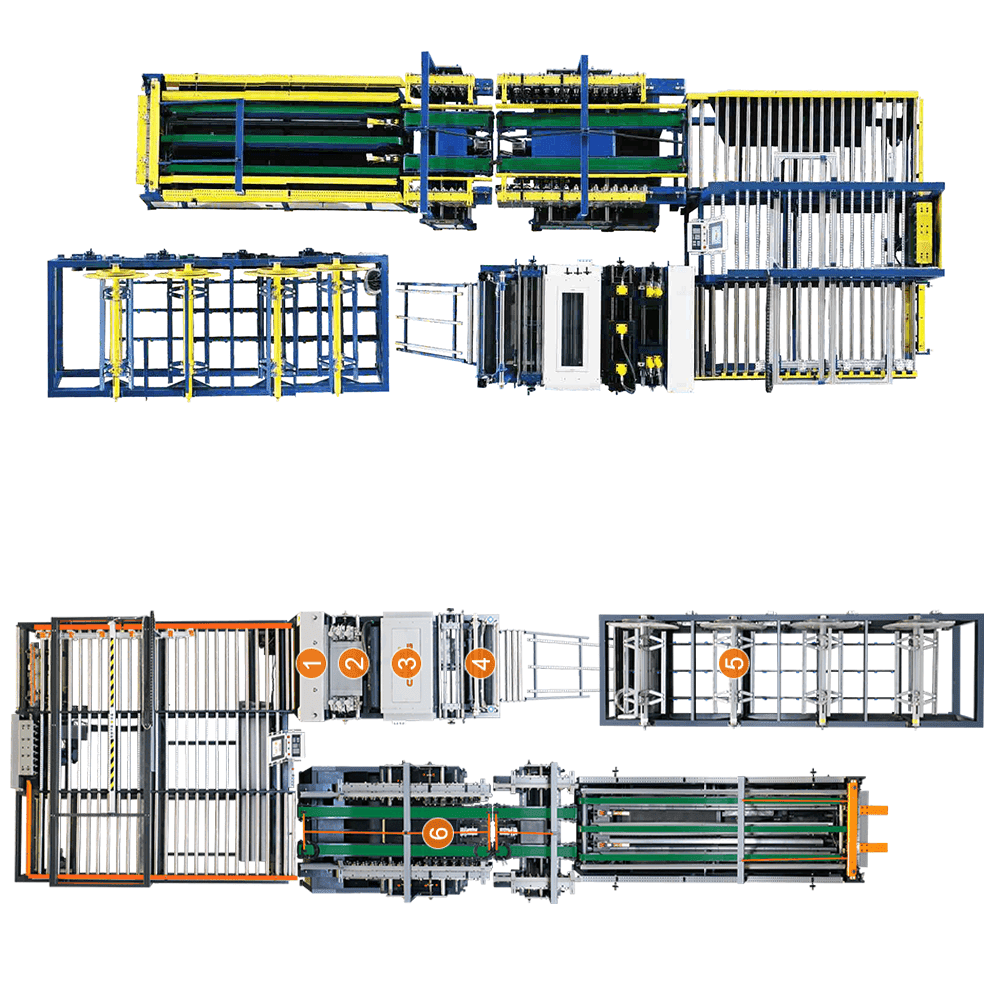

How to design a complete rectangular duct production line?

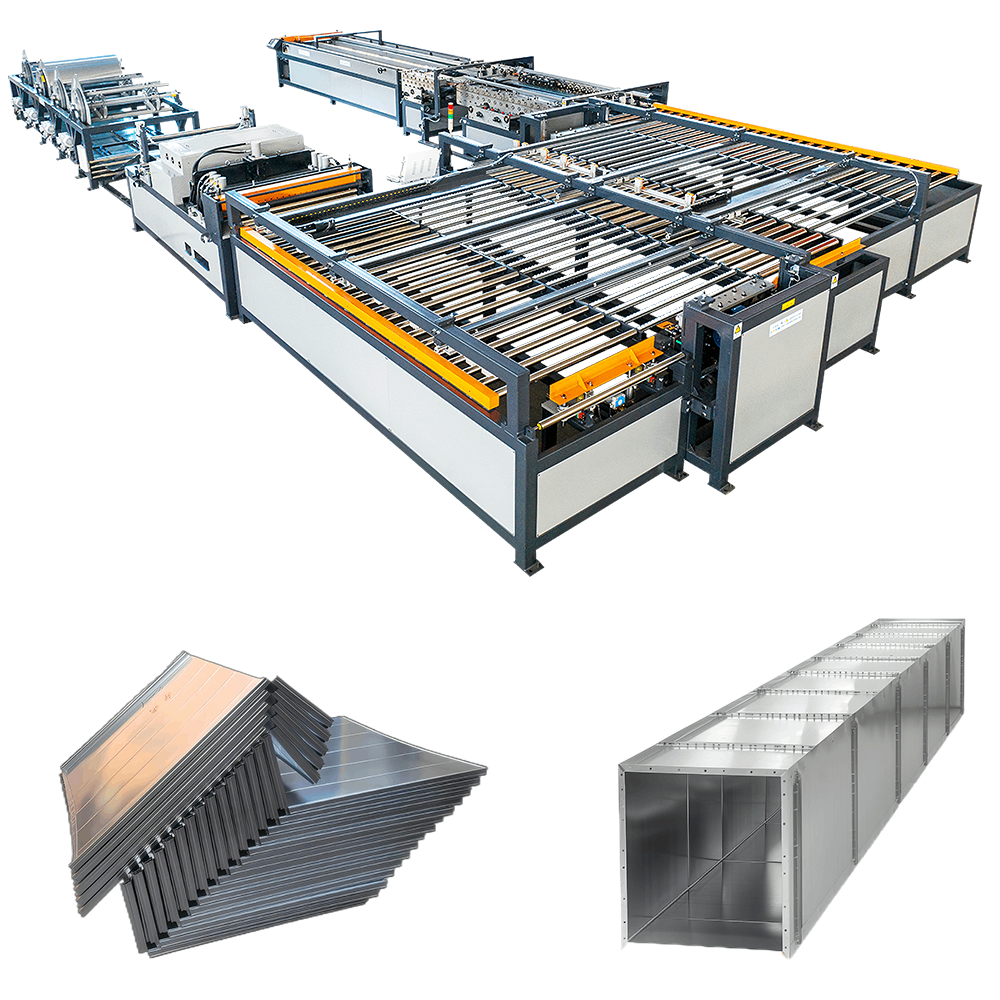

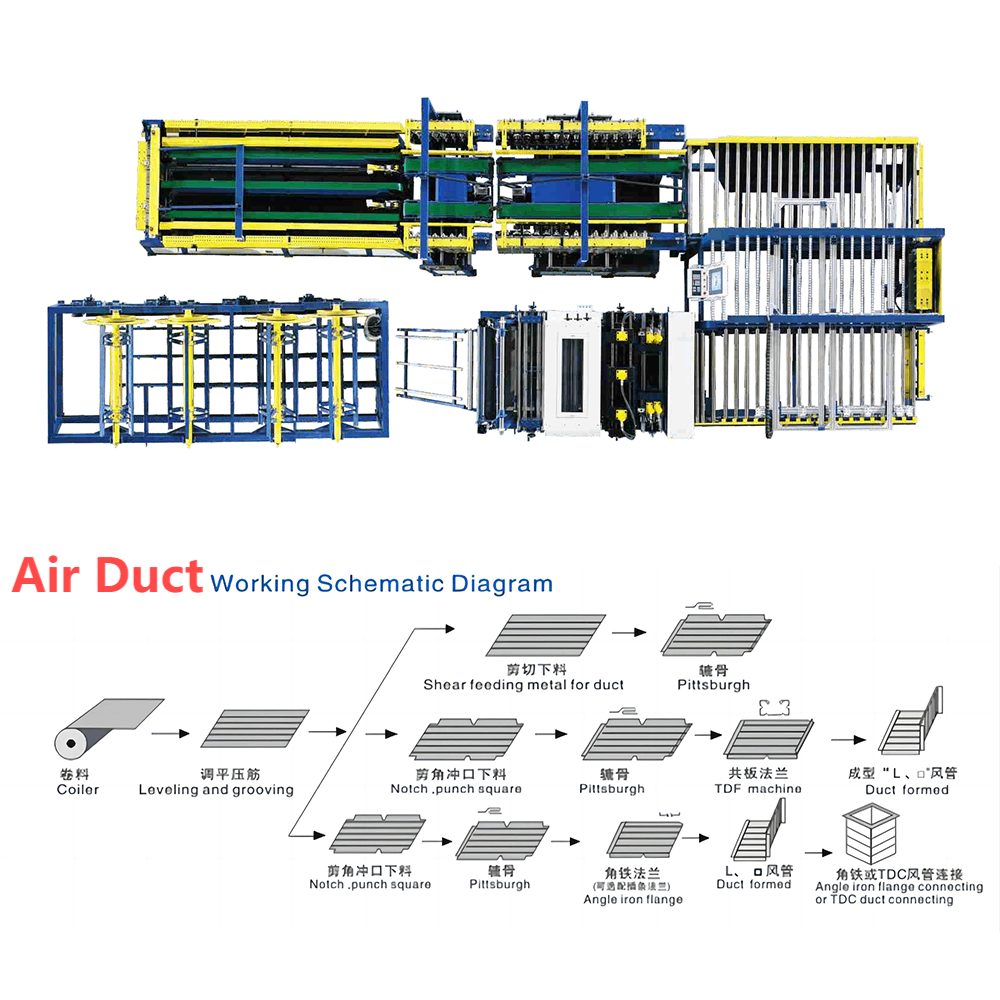

The duct production line is for duct forming, and the entire process is completed by a system and multiple machines.

In simple terms, the entire process from coil unloading to duct forming is formed by machine processing equipment switching different processes to form metal sheets of different shapes. The production process does not involve manual operation.

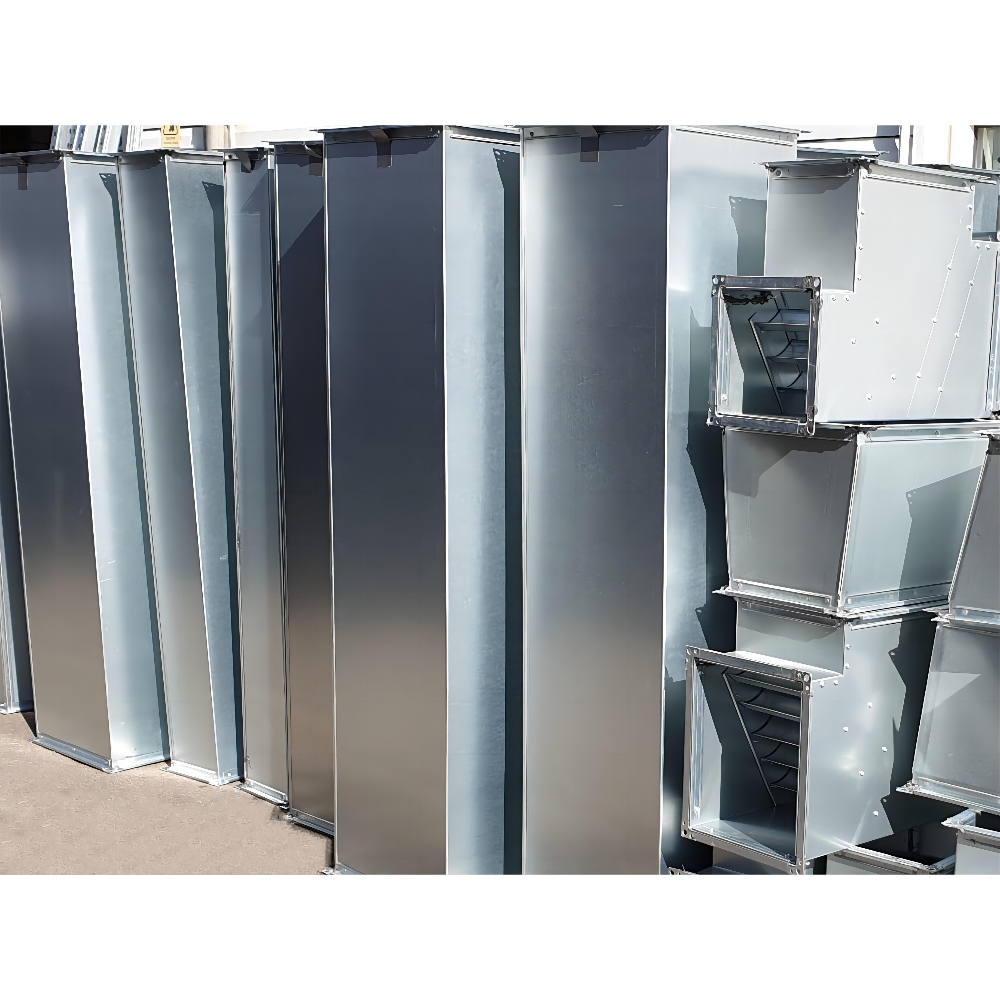

The duct production line mainly completes the common plate flange angle iron flanging forming or C-type flange forming, with a processing speed of up to 18 seconds, and a daily processing speed of more than 3,000 square meters. The duct production line can automatically complete unrolling, punching and shearing, and high-speed joint head biting.

The plate flange angle iron flange flanging sealing function, four-fold square and other functions can add C-bone square inner flange sealing head and other functions.

The duct production line is linear or U-shaped, with a small footprint, material-saving processing mode, high production efficiency, effectively improving the production efficiency of ducts and reducing labor costs.

Duct Production Line Video

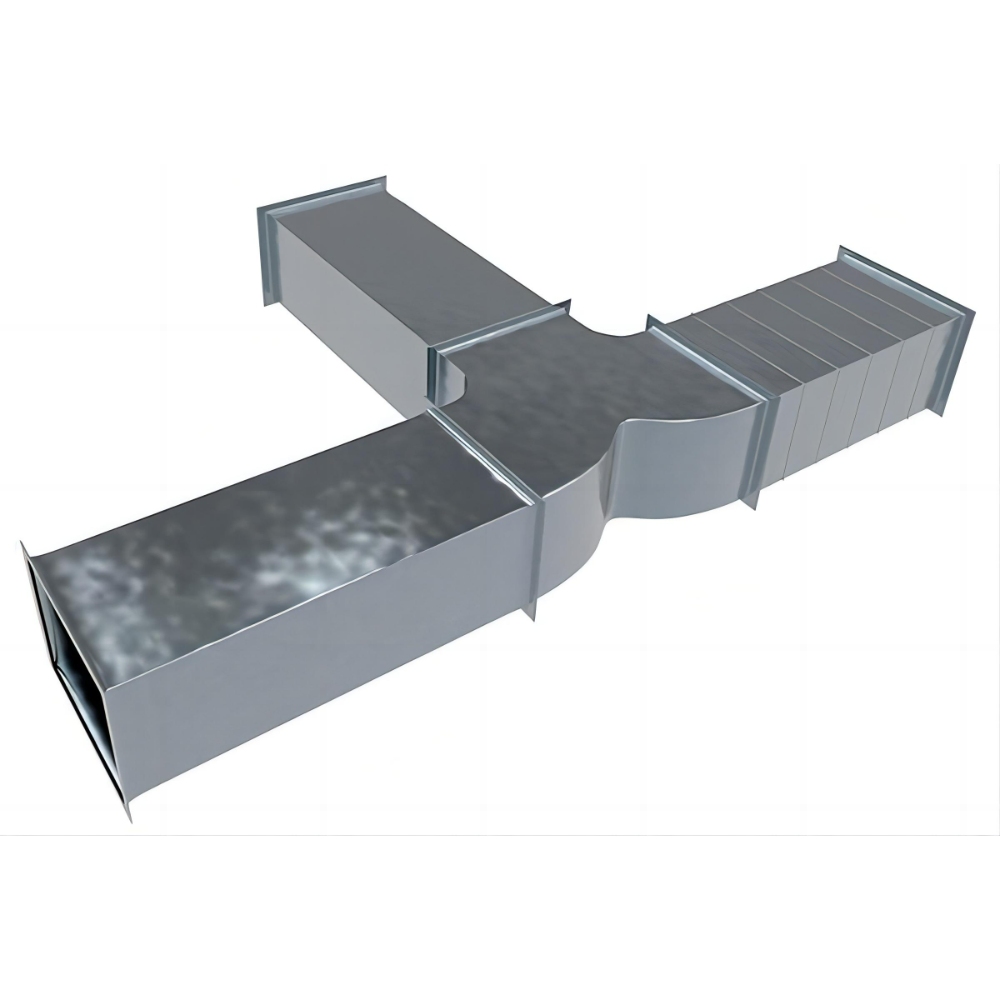

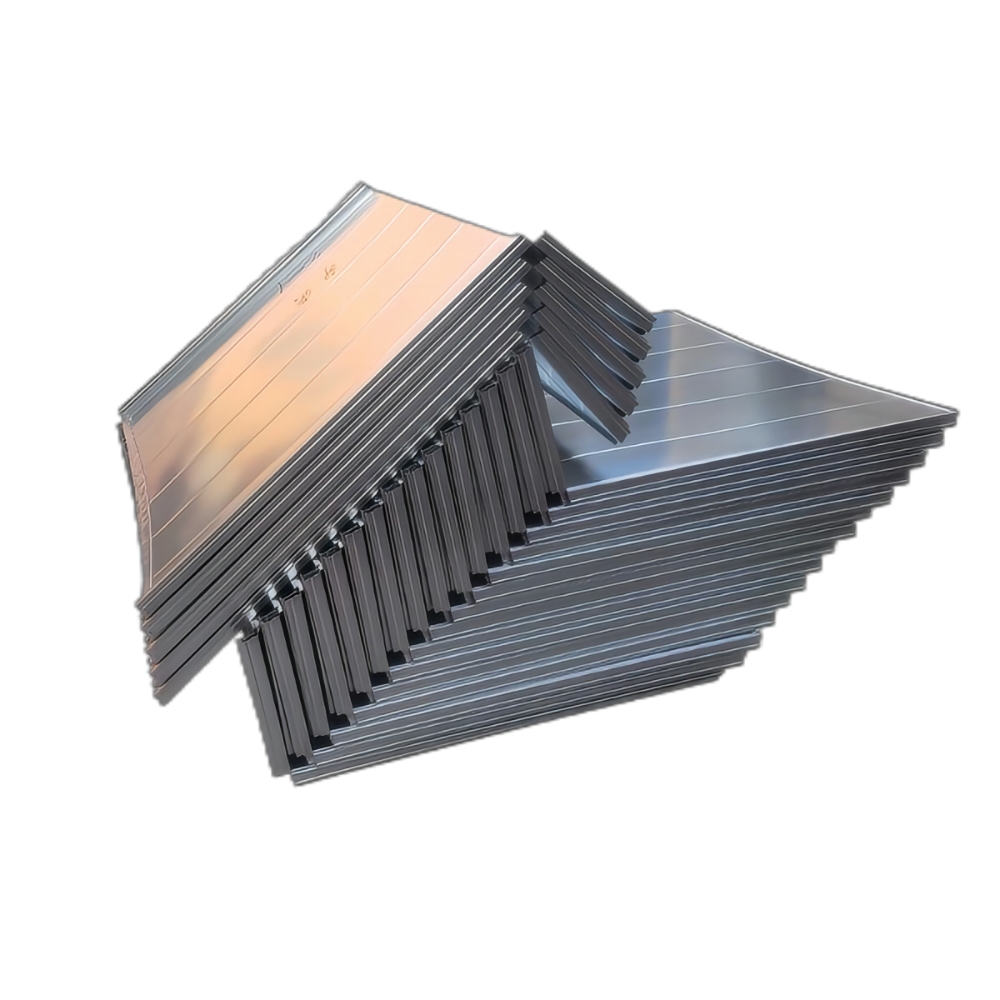

Different Types Of Air Ducts Sample

|

|

|

|

|

Customized Duct Production Line Module

Air Duct Working Forming Principle Diagram

| Coiled material Leveling Grooving |

|

|

|

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.