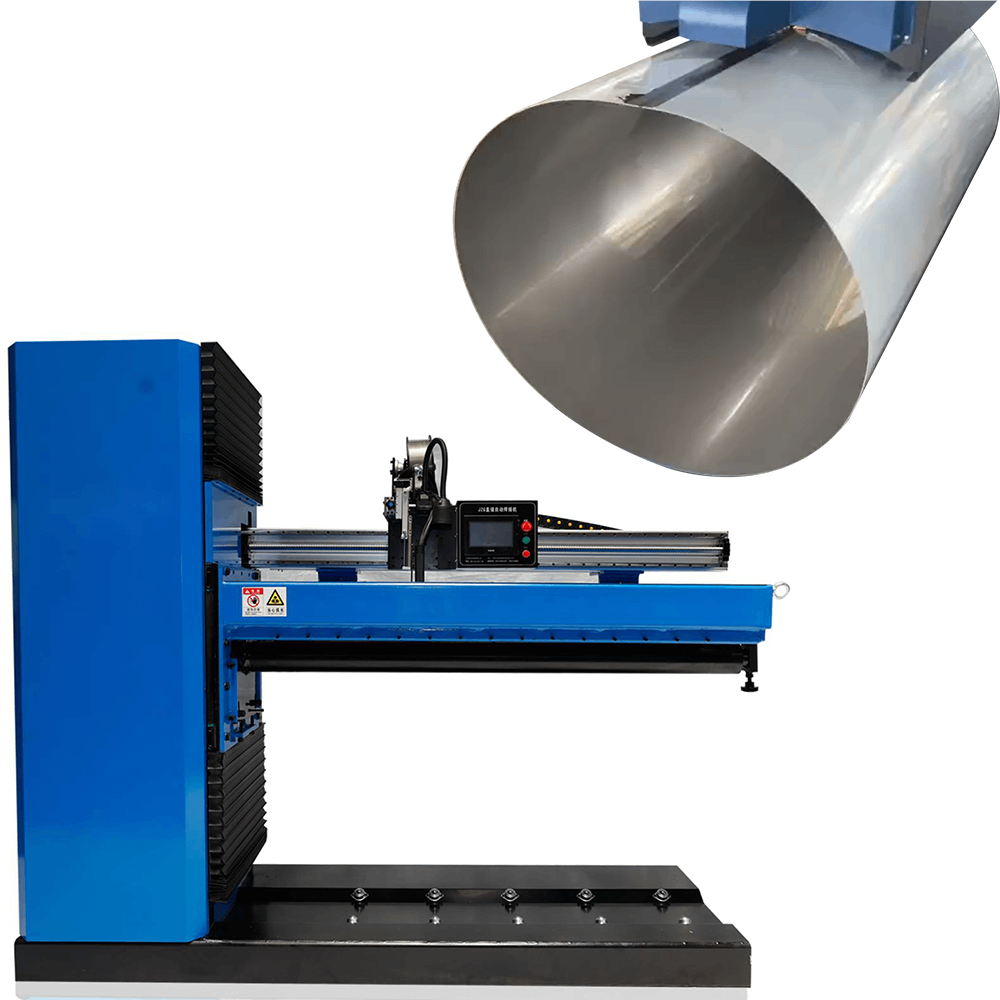

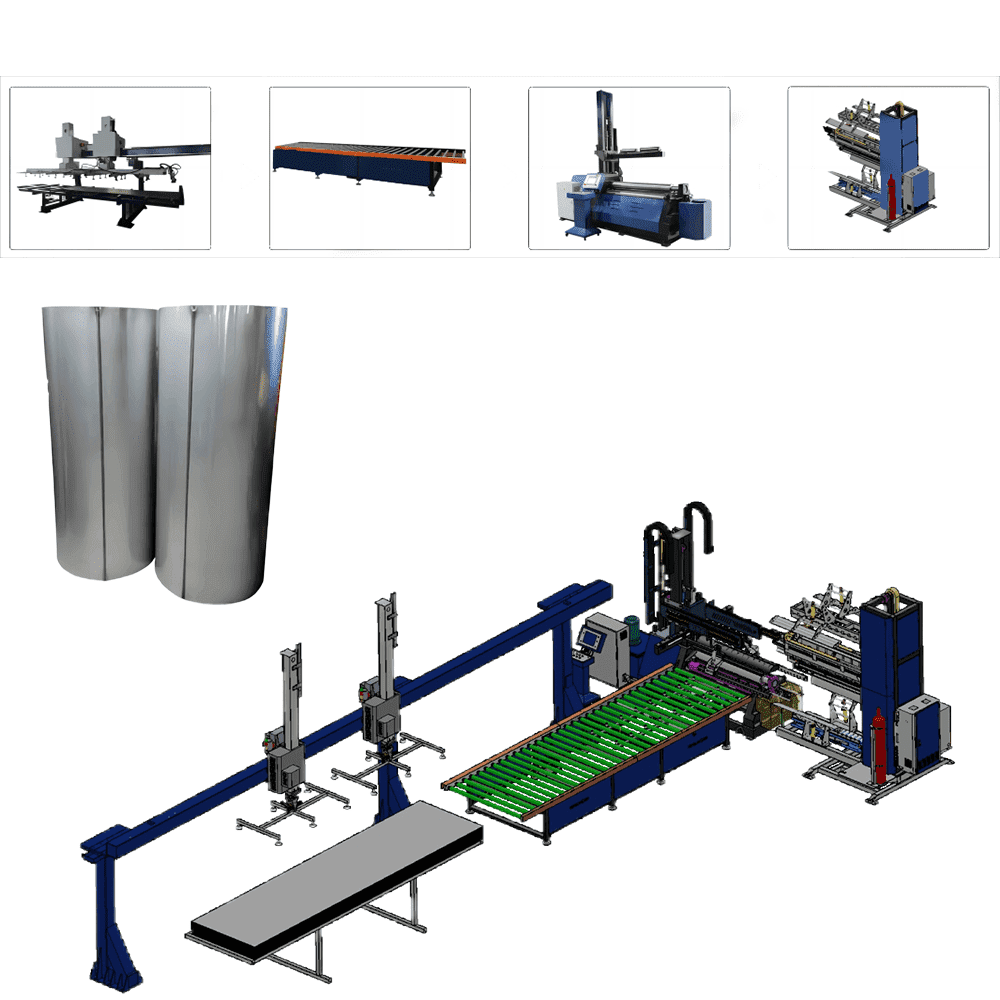

Customized Lift-Type Seam Auto Welding Solution

Scope of application:

The lifting type straight Seam Welding Machines tool is mainly suitable for straight seam butt welding of carbon steel, stainless steel and other metal workpieces and thin plate workpieces.

The structural forms of workpieces that can be clamped and welded by the straight seam welding machine include:

metal sheet,

Cylindrical workpiece,

conical tube,

truncated cone,

and box-shaped structures,

Flat splicing joints,

etc.

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Customized Lift-Type Seam Auto Welding Machine Function

- Compared with the traditional pressure plate type straight seam automatic welding machine, this equipment adds a large cantilever and cross beam that can be lifted and lowered electrically.

- The design principle of this equipment is to use a piano-pressing mechanism to provide balanced workpiece clamping and cooling effects. During welding, excess heat on the workpiece is quickly discharged from the weld to reduce the possibility of burn-through of the weld and the damage to the workpiece. Warping and deformation.

- This equipment can be used for single-sided welding and double-sided forming. Many weldable metal materials can be welded on this automatic welding machine, such as stainless steel, carbon steel, weldable aluminum alloys and other metal materials.

- Advanced control system, humanized human-machine operation interface, high degree of automation, stable and reliable performance.

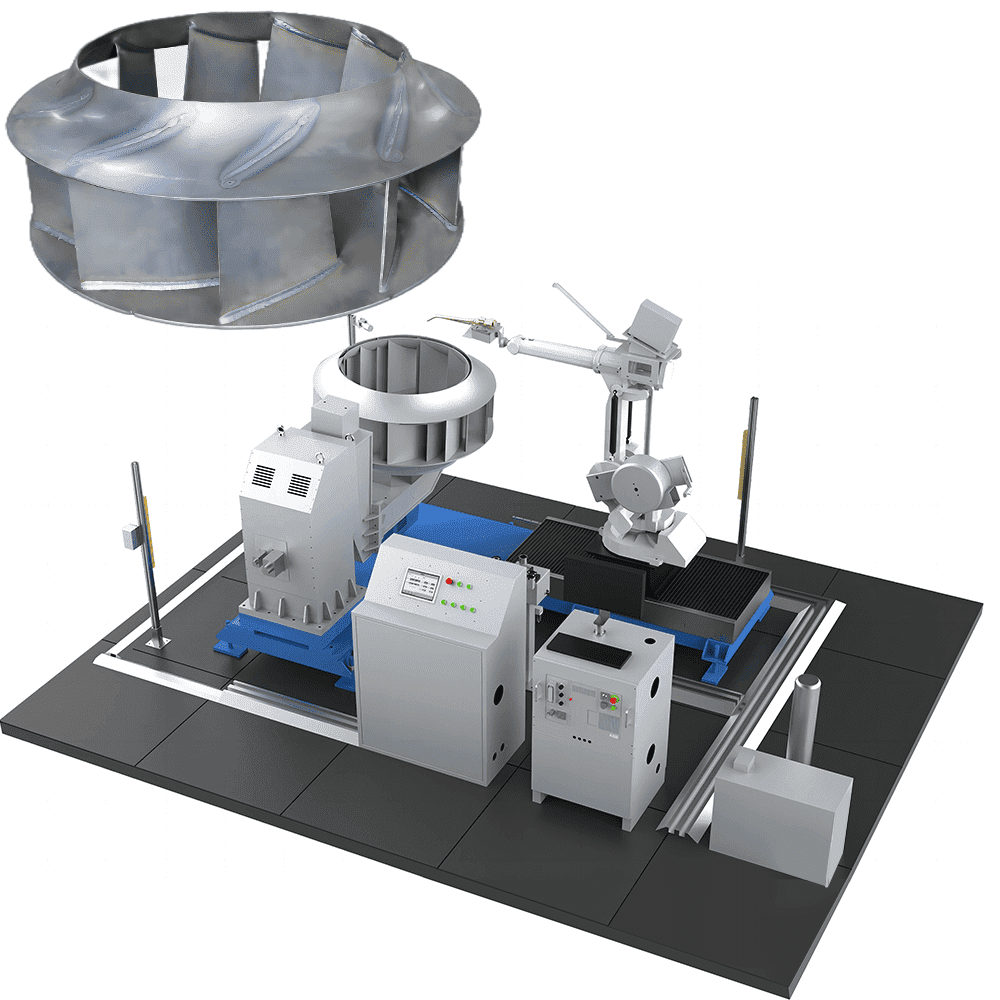

- It can integrate TIG tungsten arc welding, MIG/MAG gas metal arc welding, PAW plasma welding, SAW submerged arc welding and other welding power sources and welding guns to form an automatic welding system.

Large Custom Rolling Machine And Seam Welding Machine Video

What manufacturing problems can Seam Welding solve?

- Splicing of metal plates, manufacturing of larger metal plates;

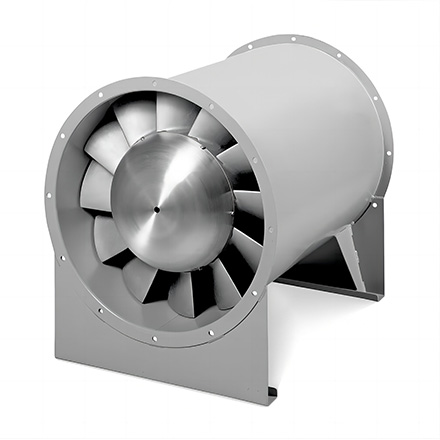

- Manufacturing of cylindrical cylinders, such as process fan cylinders;

- Manufacturing of conical cylinders, such as ventilation ducts;

- Welding of box-shaped structures, such as trash cans, mechanical housings and other metal products;

- Etc.

Configuration

Introduction to Customized Automatic Straight Seam Welding Machine

The liftable straight seam automatic welding machine is used to complete the straight seam welding of cylindrical stainless steel, galvanized sheets, carbon steel and other metal materials.

An automated welding system designed for line welding. This machine has high working efficiency, easy operation and is suitable for mass production. Department

The system consists of welding machine tools, straight seam welding control systems and welding power sources. This equipment uses a fixed workpiece and a moving welding gun.

way to complete the welding.

Advantages of this equipment:

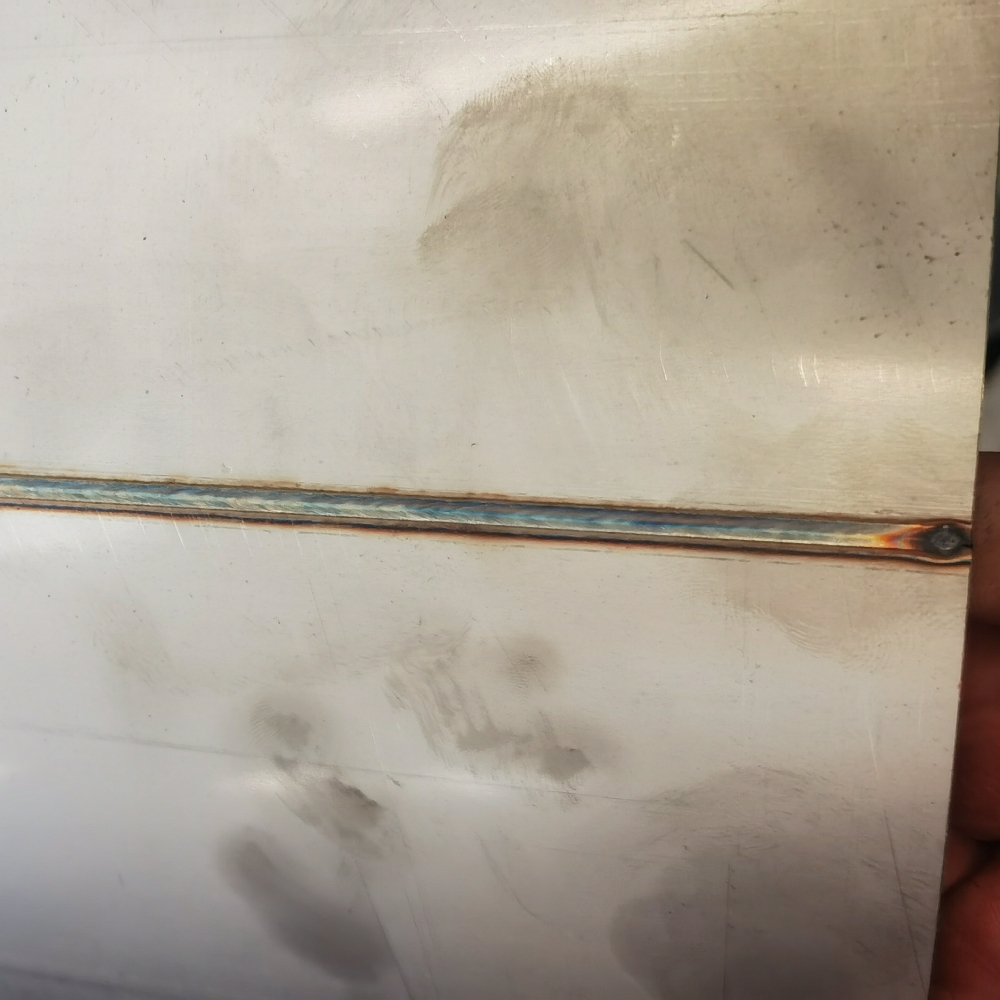

1) Provide stable and continuous compression and cooling effects in the entire weld direction, reducing the welding heat-affected zone and post-weld deformation

shape.

2) The overall structure of the cantilever and beam of this equipment can be lifted electrically, and pulleys are installed at the bottom. Compared with traditional fixed

The fixed bed has a larger processing diameter range, making workers’ operations more convenient and labor-saving, and improving efficiency.

3) Ensure the dimensional accuracy of the welded products by reducing welding deformation and shrinkage.

4) The bushing ensures the forming effect on the back side, and better surface quality can be obtained through front and back protection.

Seam Welding Machine Main Structures

The entire equipment adopts a cantilever structure, with a welding execution system attached to the crossbeam installed on it. The welding execution system follows a straight line

The guide rail moves smoothly in a straight line and at a constant speed, and is dragged by the motion mechanism. The welding gun regulator is installed on the linear guide rail to complete the movement.

Welding process of paired work pieces. This equipment uses a pneumatic compression clamp to ensure that the butt joints are compressed within the welding length. Book

The equipment has optional functions such as simulation and actual welding.

A brief introduction to the main structure of the machine tool:

Seam Welding Machine Pressing mechanism

It adopts a pneumatic pressing structure. The pneumatic pressing structure provides downward pressure along the entire length of the weld. The pressing mechanism can ensure that the joints fit well before welding.

The main shaft of the straight seam welding machine supports the work piece, and the pneumatic pressing mechanism drives the work piece to be pressed. The welding trolley moves along the straight

The linear guide rail moves smoothly in a straight line and is dragged by the motion mechanism. The welding gun regulator is installed on the linear guide rail to move.

Complete the welding process of the work piece.

Opening and closing the door: When loading and unloading materials, it is in a lifted state. Before the pressing mechanism is pressed down, rotate it downwards and hang it on the right side of the mandrel to ensure

There will be no disturbance when the mandrel is pressed.

Lining: There is a copper lining on the mandrel, a forming groove is processed on the copper lining, and a protective air hole is processed on the bottom.

A series of small holes communicate with the formed groove on the front side of the bushing on the back side of the weld. Ensure the forming and heat dissipation during work piece welding and work piece welding

Seamed back protection.

Welding gun traveling mechanism

It is used to realize the automatic welding process of the welding gun, with high transmission precision, adjustable moving speed, and automatic idle and rapid return. weld

The connecting car moves along a straight line, and the linear motion guide rail adopts precision linear square rail, and the motion trajectory has good straightness. Traveling gear motor

It has large starting torque and excellent output characteristics. The maximum welding length of this machine reaches 1500mm.

Welding gun lifting mechanism

This machine controls the pneumatic actuator through the program to automatically raise and lower the welding gun. The welding gun can be adjusted in the welding position through the gun adjuster.

section, by adjusting the welding position, the welding gun can be in a better welding position. The adjustment in the vertical direction is mainly to adjust the end of the welding gun

The distance between the head and the work piece sets the length of the welding arc and establishes the voltage of the welding arc. Horizontal and lateral adjustments are mainly

Adjust the welding gun tip to align with the seam.

Seam Welding Electrical control system

The whole machine control adopts PLC programmable controller to realize a series of automatic positioning of the welding gun, automatic welding, automatic return, etc.

Automate actions and simulate and demonstrate process parameters.

The equipment has a “manual/automatic” conversion function. In the “manual” state, the welding machine does not arc, and can adjust the welding speed,

A series of process parameters such as welding length and welding position can be adjusted, and the “automatic” state can realize the automatic welding process. Other,

The welding length of the work piece can be adjusted according to needs.

Seam Welding Working principle and working procedures

- Center the workpiece to be welded on the core axis of the equipment, and click the pressing module (or step on the foot switch) on the touch screen human-machine interface.

The pressing mechanism automatically presses down to compact the work piece.

- Then click the start welding module on the touch screen human-machine interface, and the equipment will automatically complete: (Welding gun lowers ®Automatic arc starting ®Welding gun

Walk and start welding).

- After reaching the predetermined weld length, automatically complete: (arc closing ® welding gun lifting ® welding gun return), remove the workpiece,

After completing a work cycle, the equipment is equipped with an “emergency stop” button, which cuts off all power and stops the equipment in an emergency.

Video of Air Duct Rolling Welding Flanging Production Line

Welding Machine Finished Effect

|

Main parameters of pressure plate straight seam automatic welding machine |

||||||||

|

Device model |

600 |

1000 |

1250 |

1500 |

2000 |

2500 |

3000 |

Other customized |

|

Equipment control power |

Single phase 50Hz AC220V |

See remarks |

||||||

|

welding power source |

Three-phase 50Hz AC380V |

|||||||

|

Welding form |

TIG tungsten arc welding, MIG/MAG gas metal arc welding, PAW plasma welding, SAW submerged arc welding |

|||||||

|

Welding workpiece thickness (mm) |

0.5-4 |

0.7-12 (Note: Depending on the length, plate thickness, material and process method, the weldable plate thickness is also different, the plate thickness is for reference only) |

||||||

|

Welding workpiece diameter (mm can be customized) |

80-700 |

110-800 |

130-1000 |

150-1200 |

170-1300 |

≧200 |

≧220 |

|

|

Welding workpiece length (mm can be customized) |

≤600 |

≤1000 |

≤1250 |

≤1500 |

≤2000 |

≤2500 |

≤3000 |

|

Seam Welding Main parameters of equipment

- Product model: Customized automatic straight seam welding machine

- Equipment control power supply:220V/50Hz

- Welding machine control power supply:380V/50Hz

- Rated load duty cycle:Continuous

- Welding gun fine adjustment distance: ≧50mm

- Operation interface:Touch screen human-machine interface

- Cross beam transmission form: Precision linear square rail + roller screw

- Cooling method: Copper rapid heat conduction + water cooling circulation system

- Airbag protection: Yes, there is an airbag anti-splash mechanism

- This machine can be equipped with welding modes: argon arc welding self-melting, argon arc welding automatic wire feeding, CO2 welding

- The length range of the welding work piece of this machine: ≦3000mm

- Diameter range of work piece welded by this machine:¢400-3000mm

- Overall dimensions of the device: Approximately 2600 mm long x 850 mm wide x 2350 mm high/Customized

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Seam Welding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.