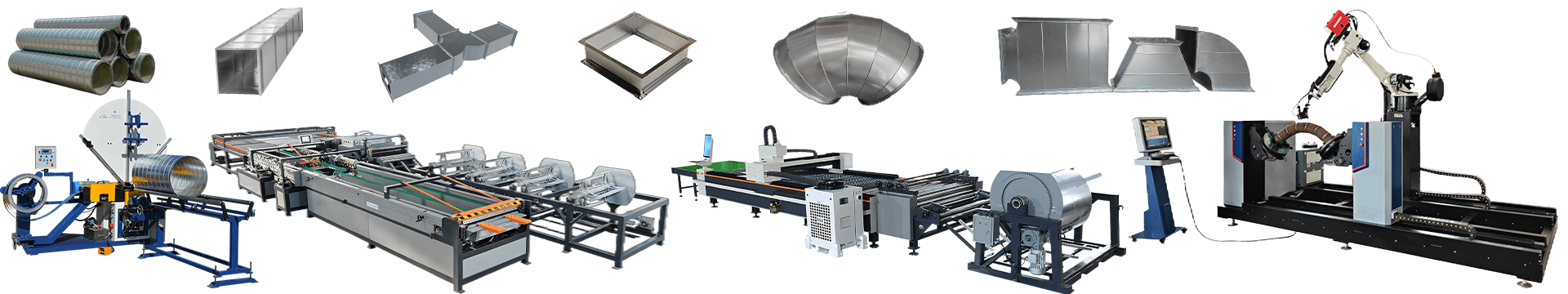

Elbow Ducts Robotic Welding Machines

Elbow Pipe Robotic Welding Machine for Elbow Duct & Oil Pipeline Elbows

|

Machine Name |

Elbow Duct Robotic Welding Machine |

|

Model |

AC-XMW (4-axis: 3-9 sections)(6-axis:3-13 sections) |

|

Application Industry |

Ventilation duct elbows, oil pipeline elbows and other metal elbow accessories |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Air Ducts A-Z Project:

1. Rectangular duct welding 2. Elbow duct welding 3. Duct forming

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

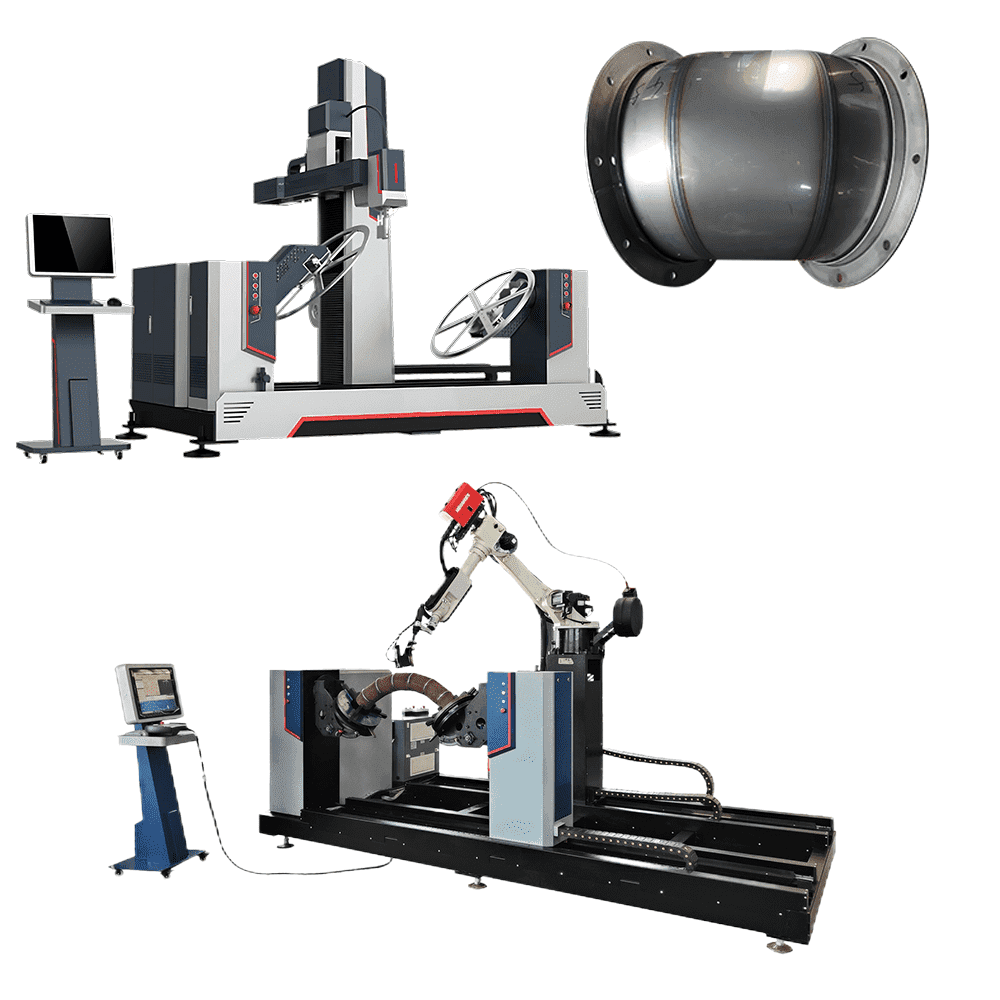

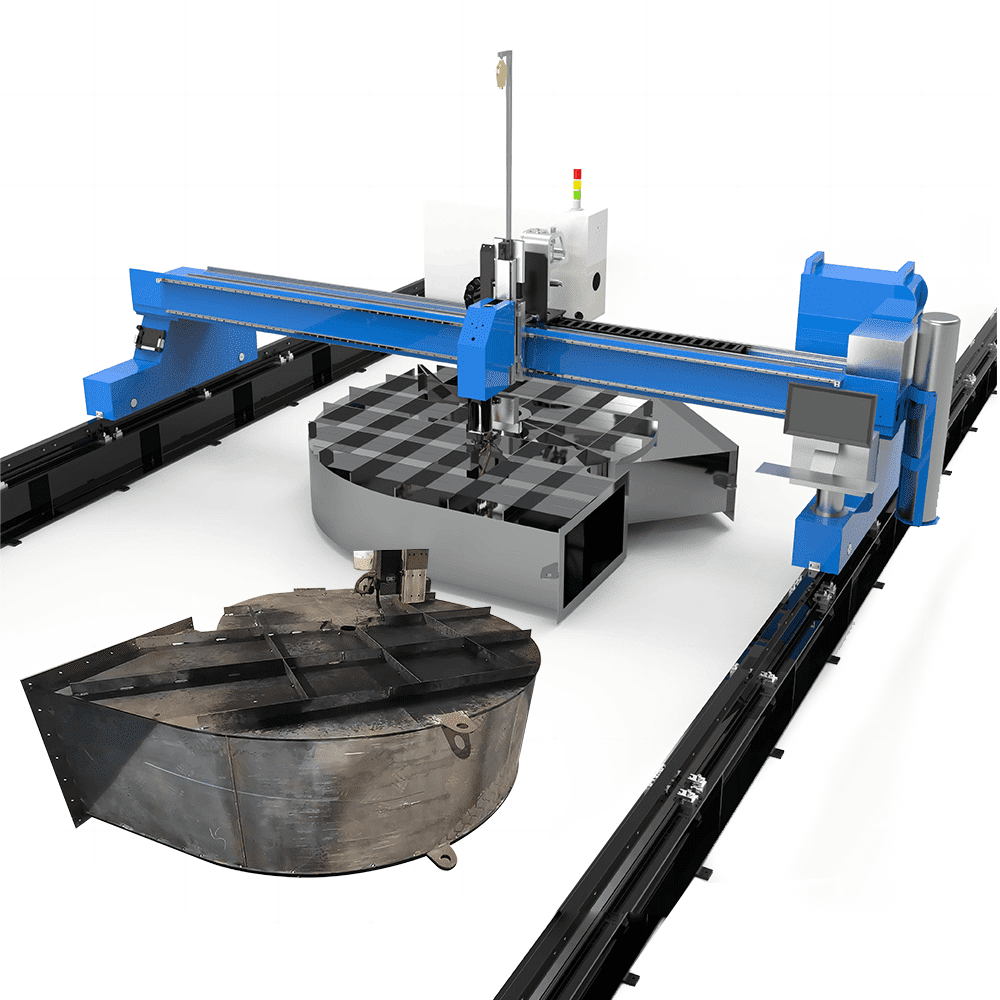

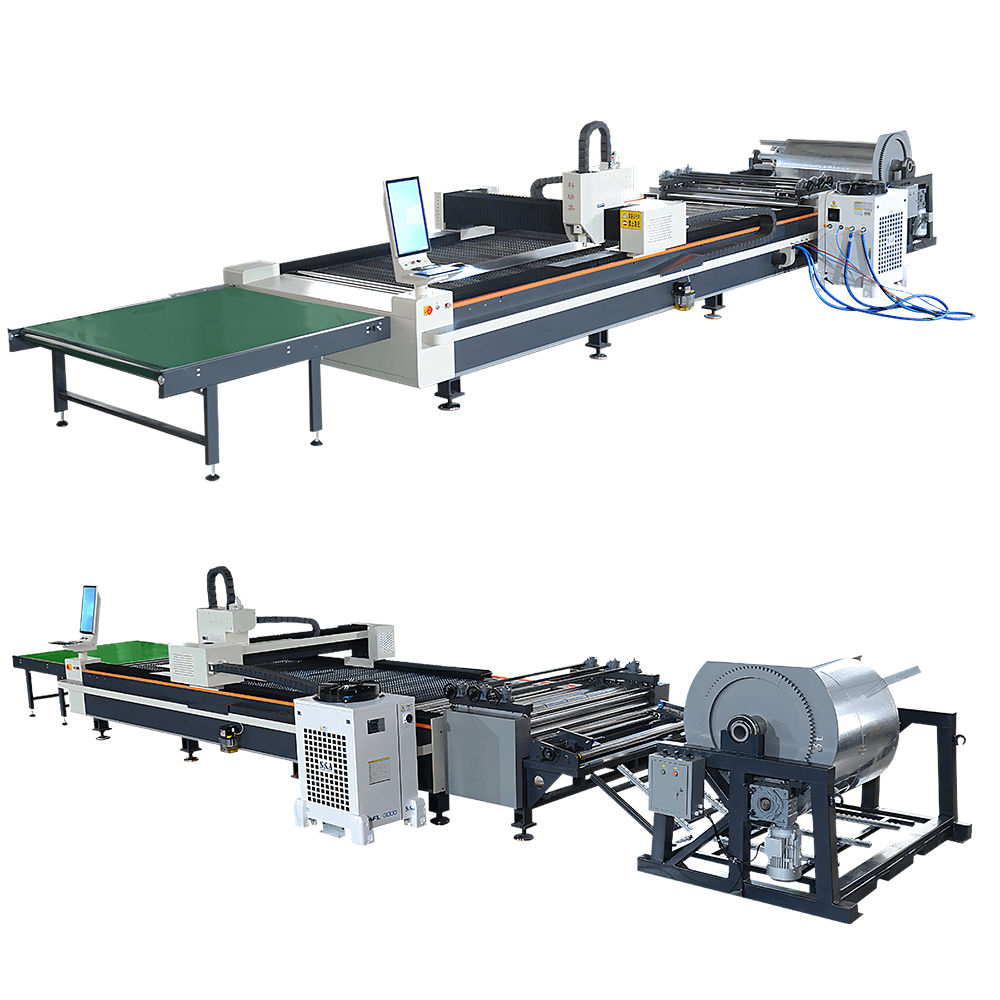

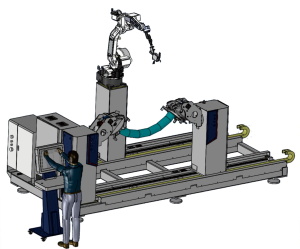

Altron’s Elbow Duct Robotic Welding Machine has two robot structures:

6-axis robot is used to weld Oil Pipeline Elbows, with a relatively small diameter of 100-400 mm, and a thicker material of 5-10 mm. Megmeet’s MP500FR welder is often used to weld carbon steel materials;

4-axis robot is used to weld Elbow Duct, with a relatively large diameter of 200-800 mm, and supports customized machine size, and the material is thinner by 1-5 mm. Different types of welders can be configured according to different welding materials, including gas shielded welding, argon arc welding, and laser welding. Lincoln 400TPX, Panasonic 350GL5, and innovative domestic lasers are often used.

Elbow Duct Robotic Welding Machine Video

Welding For Elbow Duct

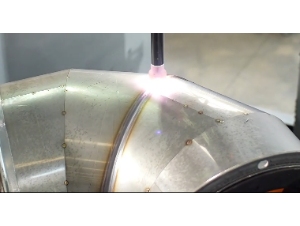

Elbow ducts are commonly used with MAG welding (Metal Active Gas Arc Welding), which has a good effect on automatic welding!

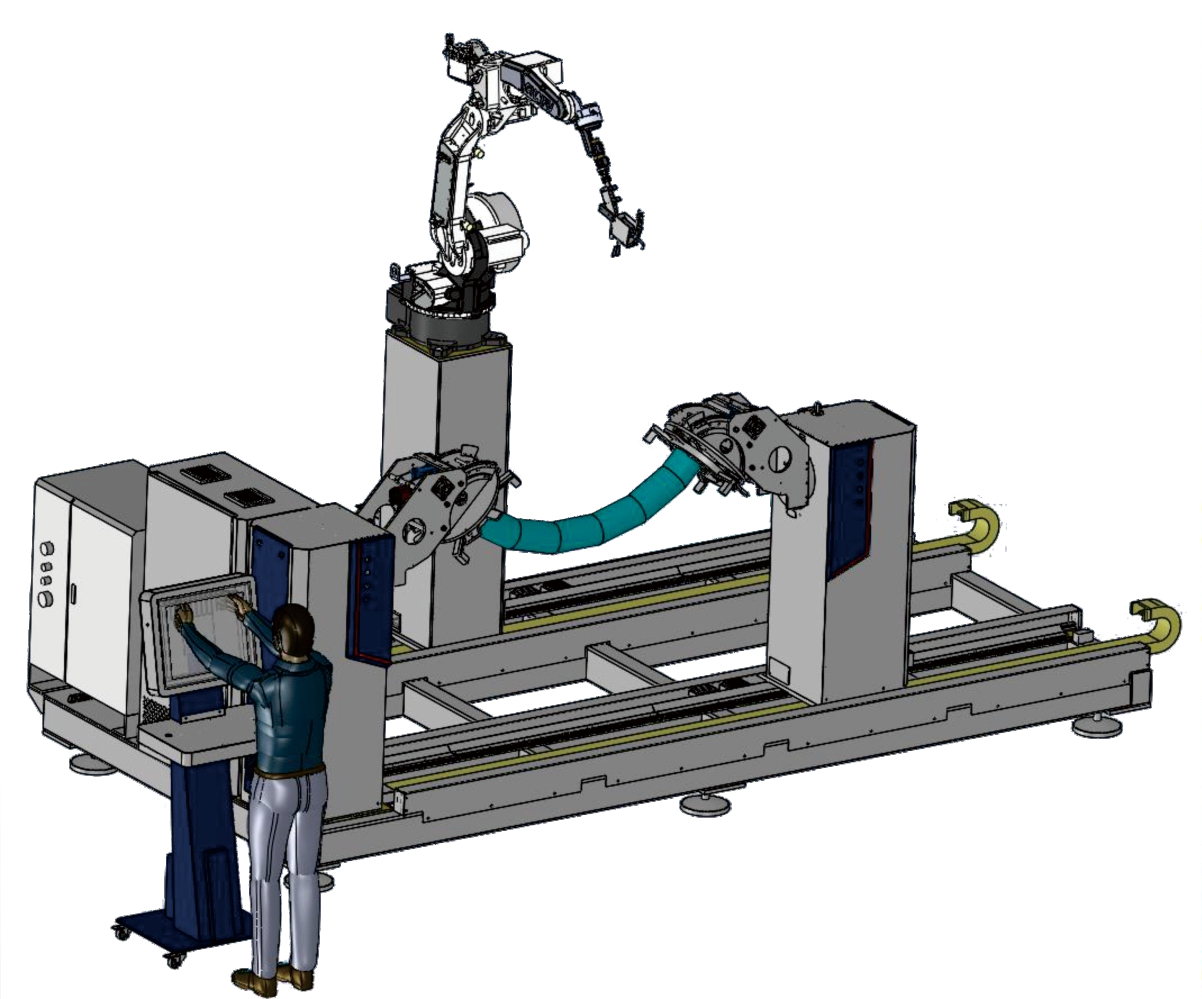

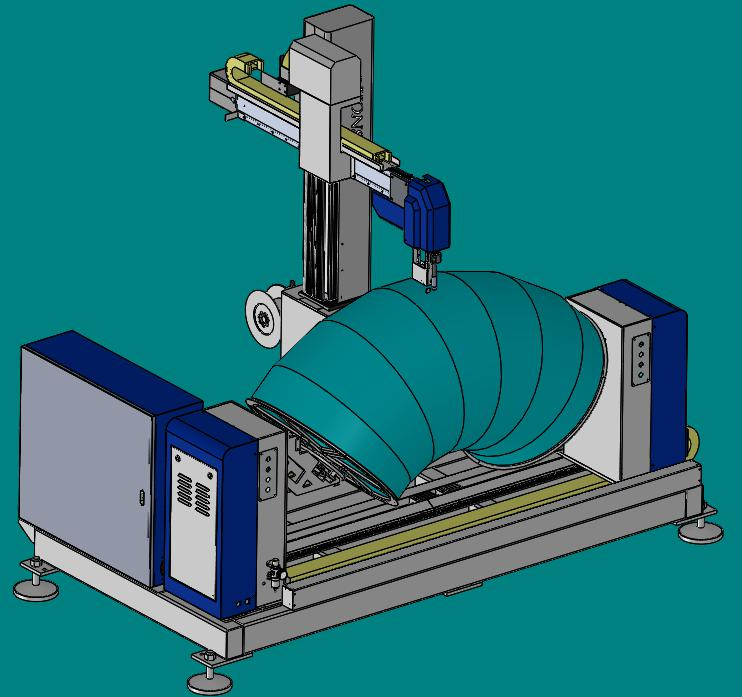

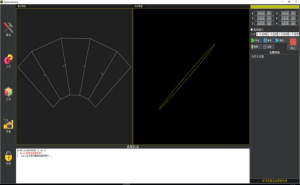

Elbow Duct Robotic Welding Machine realizes visual program setting. The system adopts input welding method to set the diameter and number of sections of the pipe elbow for welding. The weldable materials include carbon steel and stainless steel. MAG welding and laser welding can be selected;

The machine adopts touch screen and PLC program control, and is equipped with an intelligent detection system to realize the welding of elbows in all positions. Modular design can be quickly and easily combined into the required welding system according to customer requirements; the equipment comes with a 4-9 section elbow assembly graphic system, and the number of elbow sections and angles can be set by itself. The whole system adopts a weld correction system, and precise positioning welding is not required without programming.

Machine introduction

|

|

Advantages

- The MAG welding system for multi-section elbows is designed for automatic welding of elbow air duct butt joints. It realizes visual program setting. The system adopts the input welding method and sets the pipe elbow diameter and number of sections for welding. Weldable materials include carbon steel. Stainless steel, MAG welding and laser welding can be used;

- The equipment has reasonable structure, easy operation and advanced technology. It adopts touch screen and PLC programmed control, coupled with an intelligent detection system, it can realize the welding of elbows in all positions. Modular design can be quickly and easily combined into the required welding system according to customer requirements;

- The equipment comes with a 4-9 section elbow assembly graphics system, which can self-set the number of elbow sections and angles. The entire system adopts a welding seam correction system, eliminating the need for programming for precise positioning and welding.

Operation Process:

- The workpieces are assembled by spot welding in advance and placed on the welding fixture.

- By controlling the equipment fixture, adjust it to the corresponding position, start the expansion clamp, and position the workpiece.

- Set the movement speed and direction of the machine head and appropriate welding parameters. The entire welding specifications and welding process parameters must be determined after trial welding of certain workpieces and correction of each parameter before determining the final welding parameters.

- Including: welding speed, welding voltage, welding current, wire diameter selection, etc.

Welding For Oil Pipeline Elbows

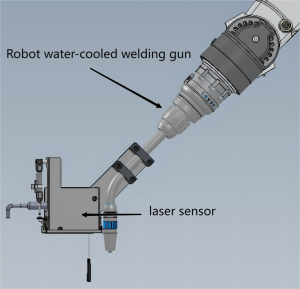

The heavy-duty pipe bending welding robot is composed of: 6-axis welding robot, positioner, ground rail, welding seam scanning system, heavy-duty fixture, control system, and welding power supply. It is used to replace manual welding of shrimp bending. No manual intervention is required during the welding process. Manual operation only requires loading before welding and unloading after welding. Based on graphic parameter settings, laser scanning is used for real-time modeling, and welding seams are accurately fitted to meet the correction requirements of irregular products. The product is simple to operate and easy to use. Reduce weld bead simulation running steps. Improve efficiency.

Machine introduction

|

|

Advantages

- Completely non-contact welding, no vibration;

- Open system and adjustable parameters;

- Work piece clamping is convenient, no precise positioning is required, and the operation is simple and easy to use;

- General operation failures will automatically alarm and stop, making it safe and easy to use;

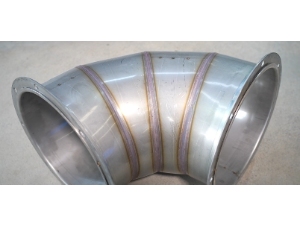

- The welds are beautiful, the welding quality is reliable, and no grinding is required.

Elbow Duct & Oil Pipeline Elbows Welding Effect

|

|

|

|

|

|

|

|

Welding For Elbow Duct-4-axis robot

|

Total Power |

Max operating speed |

Machine Weight |

Repeat Positioning |

|

15kw |

12mm/S |

1200KG |

±0.1mm |

Welding For Oil Pipeline Elbows-6-axis robot

|

Total Power |

Power Supply |

Welding Speed |

Maximum Operating Speed |

|

5kw (Excluding Welding Machine) |

380v/50hz |

1-20mm/S |

200mm/S |

Elbow Duct Robotic Welding Machine Parameters

- Workpiece parameters:

- Workpiece diameter: 108~426mm/200-800

- Workpiece sections: 3~13 sections/4-9 sections

- Workpiece wall thickness: 1-5mm/5~10mm

- Workpiece weight: M<100kg/0.6T

- Equipment size: 6200*2650*4000 (length*width*height)

- Equipment weight: 3000kg

- Applicable materials: carbon steel, stainless steel, galvanized sheet.

- Equipment welding machine: Megmeet 500; laser welding, argon arc welding GIT;Lincoln 400TPX, Panasonic 350GL5, Innovative domestic lasers

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.