Flanging machines For Axial Flow Fans

Flanging Machines For Axial Fans -Axial Flow Fans

✔ Advantage: 15 Years Of CNC Metal Spinning & FlangingMachine R&D, Production, And Sales;

✔ Application: Axial Flow Fan, Fire Fan, Roof Axial Flow Fan, Diagonal Flow Fan, Jet Fan, Subway Tunnel Fan, Ventilation Fan, Mixed Flow Fan, High-Flow Fan;

✔ Material Thickness: Stainless steel, galvanized sheet, aluminum and carbon steel, etc.

✔ Spinning Software: Free Supporting Machine, No Need To Write Program Code Manually;

✔ High Efficiency: Manufacturing axial flow fan cylinders! Solving the difficulties of metal automatic forming and welding!

✔ Solution customization: 7*24 Online Service, Engineer Video Online Conference To Solve Pre-Sales Problems.

Axial Fans A-Z Project:

1 CNC Rolling machine 2 Seam Welding machine 3 Axial Flow Fans Forming Production Line, 4 CNC Flanging Machines, 5 CNC Spinning Machine,6 AI Automatic Welding,

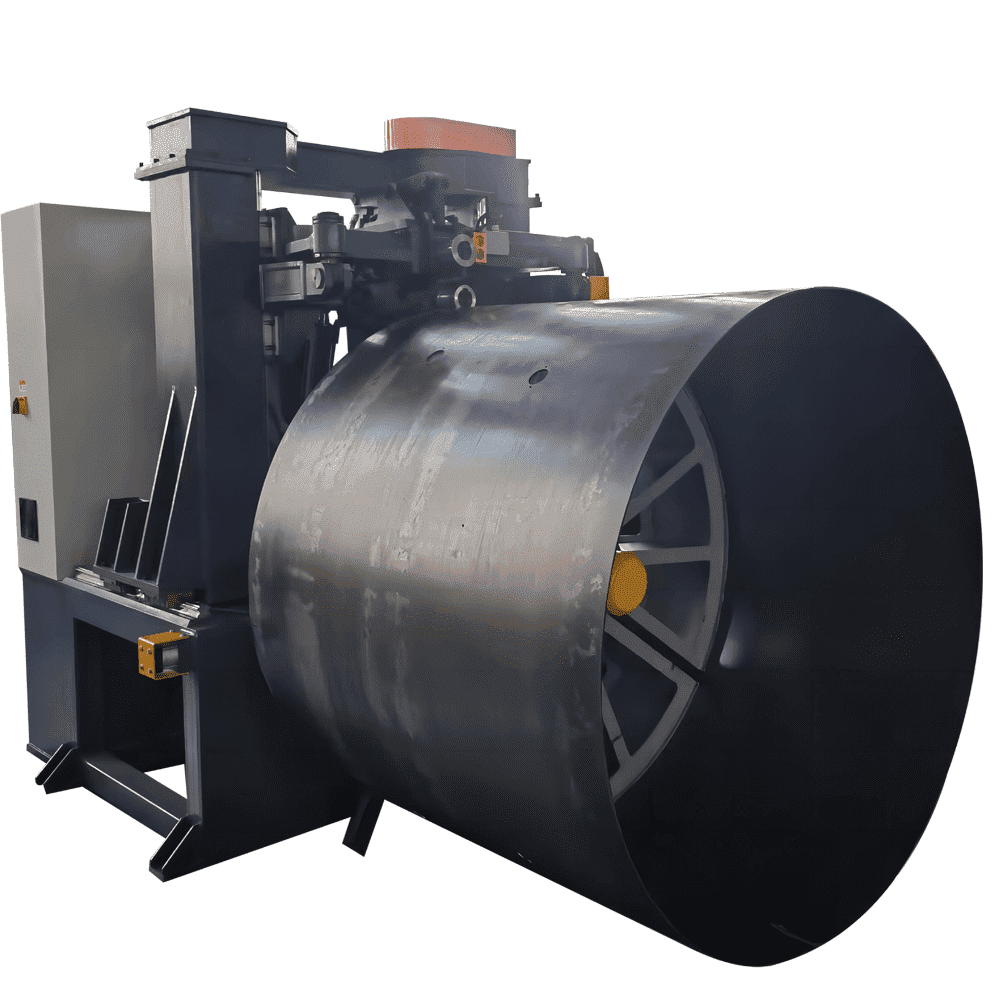

Altron provides industrial fan manufacturers with a variety of automated machines that can produce axial flow series ventilation fans of different structures! For example, these fans that work on the axial principle: Axial Flow Fan, Fire Fan, Roof Axial Flow Fan, Diagonal Flow Fan, Jet Fan, Subway Tunnel Fan, Ventilation Fan, Mixed Flow Fan, High-Flow Fan, etc.; these fans all have a circular duct structure! Different shapes of flanges, different impeller structures, duct lengths and diameters, different motor installation methods, etc..

We provide Axial Flow Fans manufacturers with:

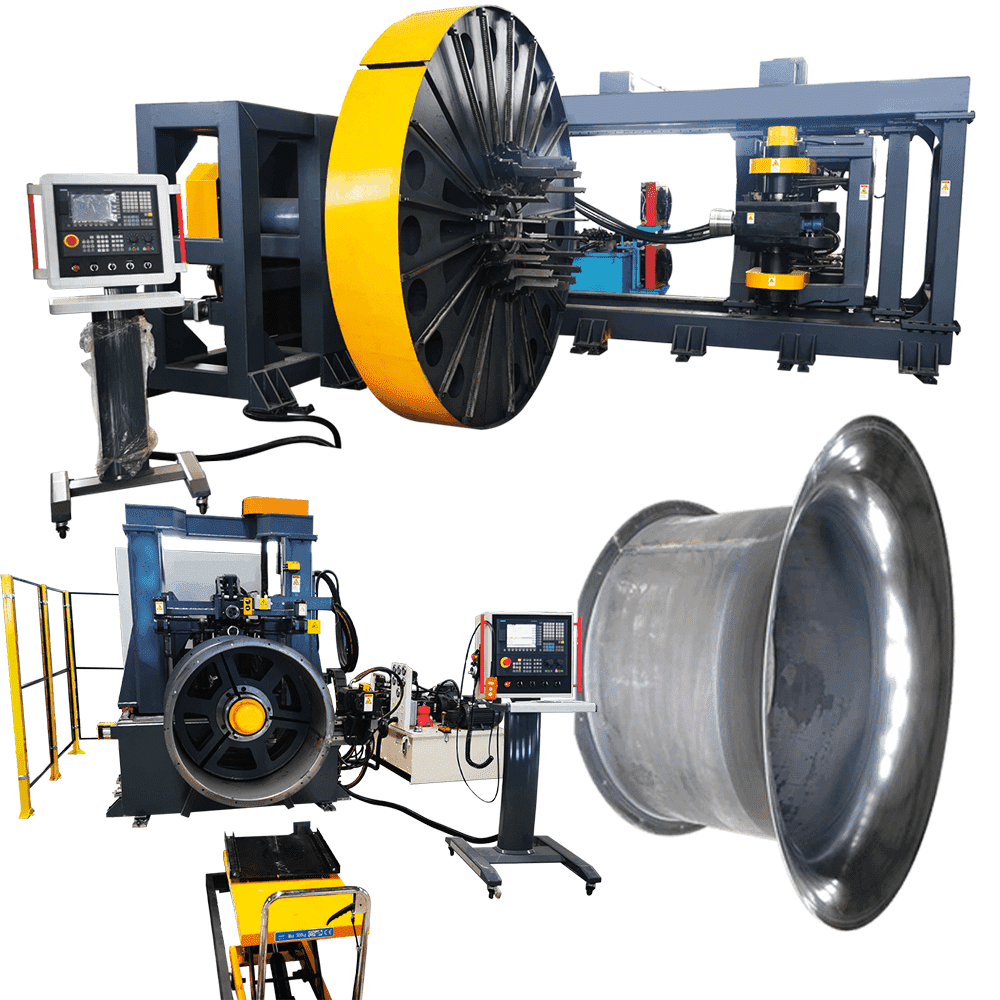

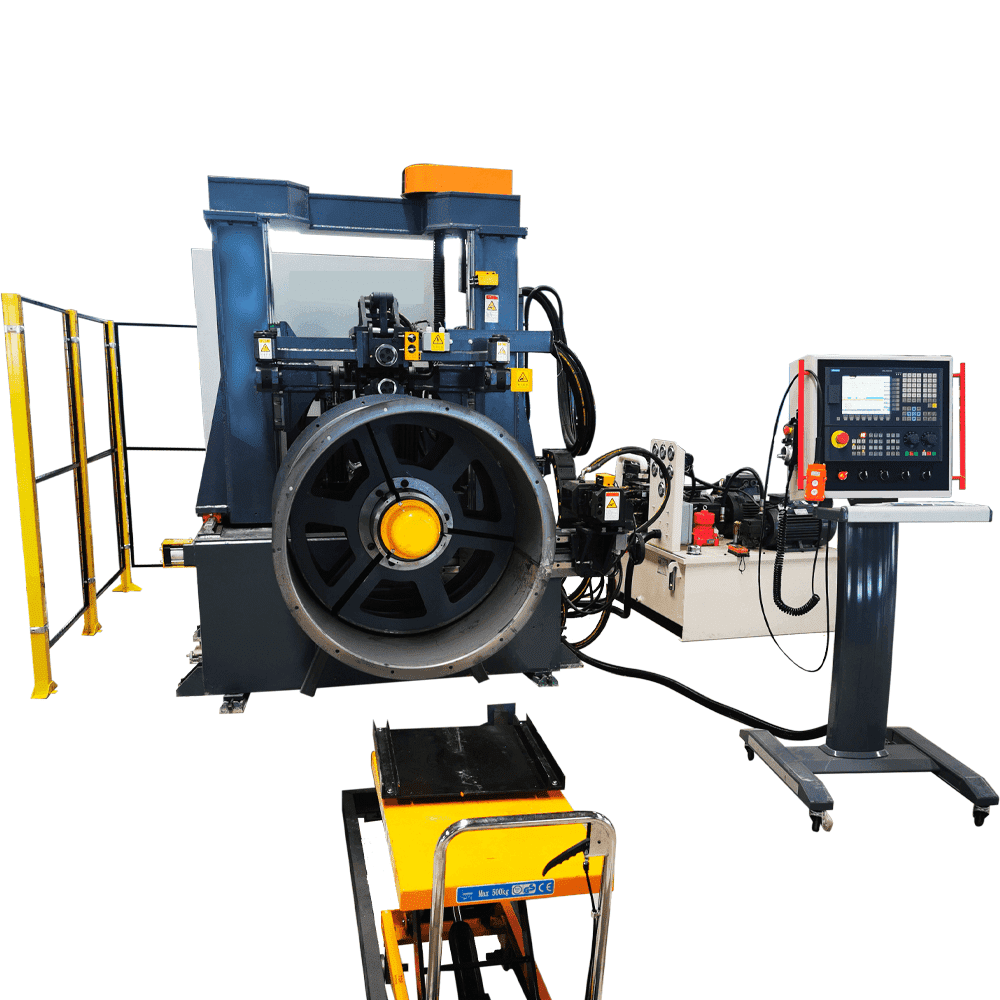

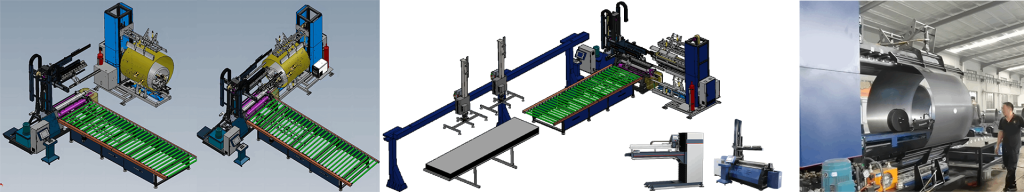

Altron’s ACFB series – 3 different sizes of CNC flanging machine models for customers to choose from, which can produce axial flow fan ducts and guides with diameters from 380-3000mm!

A variety of automatic rounding machines, straight seam welding machines, complete production lines for axial flow ducts, circumferential seam welding, impeller & motor bracket AI robot welding machines, and other peripheral machines! It can improve the production quality and efficiency of your axial flow fans!

How To Improve The Quality Of Axial Flow Fans?

Traditional manufacturing process of axial flow fans:

The traditional manual production method of wind tubes is to use an ordinary rolling machine to roll the metal plate, manually weld the longitudinal seam, and weld the circular flange ring on both sides! Later, a lot of money needs to be spent on machine grinding and polishing the weld;

Or in the mid-term, the production scale is expanded and semi-automatic machinery is used to produce wind tubes. The flange is flanging machine is used to flanging the flange, and drilling is done manually! It can be seen from the picture below: processing the flange edge by drilling will not only produce a lot of burrs! It also takes a lot of time to grind.

Because there are too many unstable factors in the production process, the previous manual welding and the later grinding tooling need to cooperate with each other. During the grinding process, it is found that the air duct that is not welded well needs to be returned for manual welding again; so there will be factors of unstable quality and appearance;

Other production quality issues:

- The elliptical roundness of the wind tube: affects the clearance of the impeller blades rotating in the wind tube, directly leading to problems such as low energy efficiency and high noise of the fan;

- Uneven grinding of the weld seam: affects the appearance. After the wind tube is sprayed with powder, the uneven position will become more obvious;

- Deviation of the flange hole position: causes the screws to be unable to penetrate the flange hole when installing the axial flow fan and the air duct, making the installation more difficult.

Automated production line improves the quality of axial flow fans

In order to improve the quality of axial flow fans, we must invest in a fully automated production model to eliminate the unstable factors of manual production!

Altron’s Automated Production Of Axial Flow Fans:

Altron can fully automatically produce from coiling to axial flow fan cylinders, and can customize the automated axial flow fan forming line according to the actual production needs of the customer’s factory! It can be divided into several production modules:

- Automatic rolling production line for axial flow fans;

- Automatic welding production line for axial flow fans;

- Automatic flanging and punching machine for axial flow fans;

- Robotic welding of motor brackets and impellers for axial flow fans;

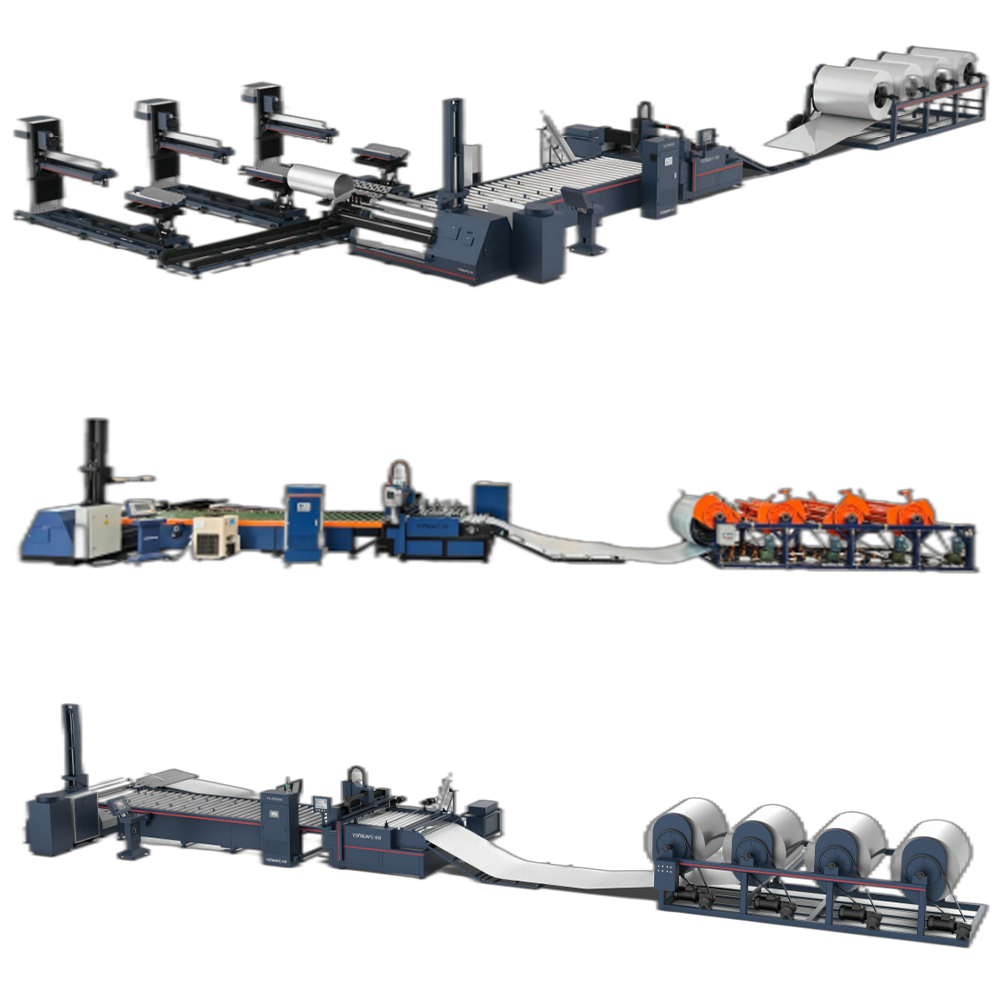

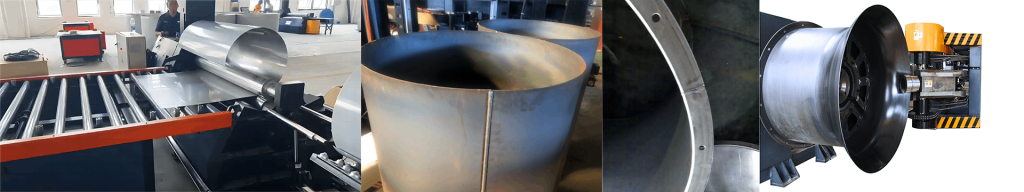

1.Automatic rolling production line for axial flow fans;

This is a complete rolling production line, which mainly includes the functions of rolling to leveling plate, laser cutting, servo conveyor feeding, 4-roll hydraulic automatic rolling machine, and roll unloading device;

It realizes fully automatic rolling production, automatic loading, automatic rolling, and automatic unloading; it can significantly improve production efficiency and product quality !

Rolling Production line Parameters:

- Plate width: 1500mm Max;

- Roll diameter: 300-1500/2000mm/or customized;

- Material thickness: 1-3mm/or customized;

- Material: stainless steel, carbon steel, galvanized plate;

- Rolling speed: 3-6m/minute;

- Production line power: 16KW

2.Automatic welding production line for axial flow fans:

This is a production line that combines rolling and seam welding, which mainly includes the functions of rolling to leveling plates, laser cutting (or plates with fixed width, which are loaded by a translational robot arm), servo conveyor belt feeding, four-roller hydraulic automatic rolling machine, roll conveyor trolley, and multiple seam welding machines;

It realizes fully automatic rolling production, automatic loading, automatic rolling, automatic welding, and automatic unloading; it can significantly improve production efficiency and product quality.

Parameters of the rolling & welding production line:

- Plate width: 1500mm Max;

- Roll diameter: 400-1500mm/or customized;

- Material thickness: 1-4mm/or customized;

- Material: stainless steel, carbon steel;

- Production efficiency: 3-4/minute per piece (diameter 600mm; height 500mm as an example);

- Production line power: 35KW/different solutions will increase with the number of machines.

In addition to the application in the industrial fan industry, it can also be used in the production and manufacturing of cylindrical welded pipes in fire-fighting equipment, ventilation ducts, water heater storage containers, automotive energy industries and other industries; the degree of customization of this production line is extremely high!

- The feeding method can be laser-cut sheets or coils!

- The cutting method can be rotary hydraulic shears or laser cutting!

- After coiling is completed, multiple seam welding machines can be selected according to production capacity (up to 3-4 for one coiling machine); because the speed of coiling is about 3 times that of welding!

Rolling & welding for axial fans video

3.Automatic flanging and punching machine for axial flow fans

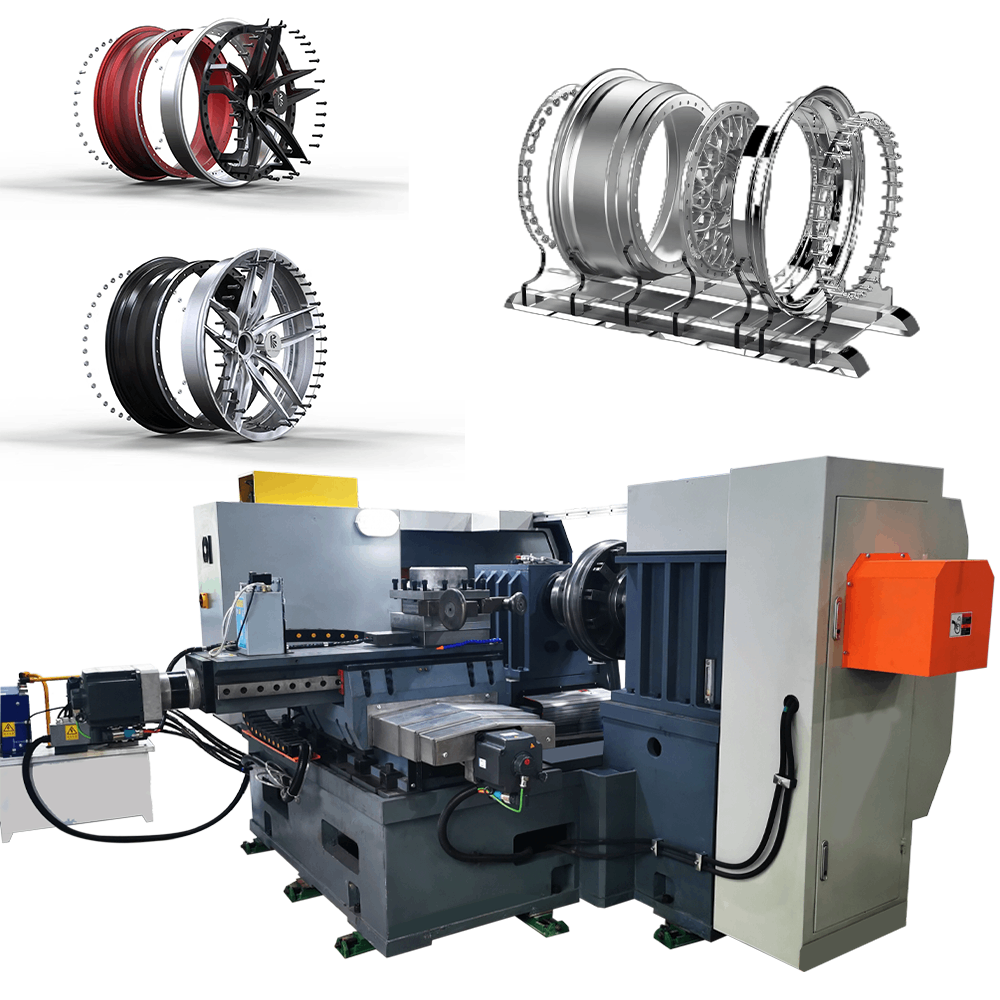

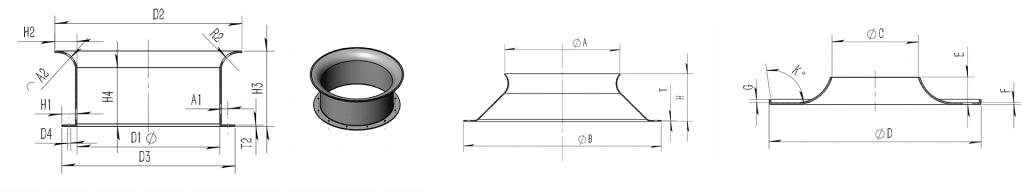

Altron has been manufacturing CNC flanging machines for more than 14 years. In 2009, it manufactured a 2500mm diameter CNC flanging machine for Shanghai General Motors, which worked well! The current three mainstream models are 3000/2000/1600mm, and they are suitable for different fan factories! The most commonly used is ACFB1605, which is mainly for small and medium-sized axial fans! This flanging machine has been upgraded for 5 generations, and its performance and operation are excellent!

Advantages of CNC flange flanging machine:

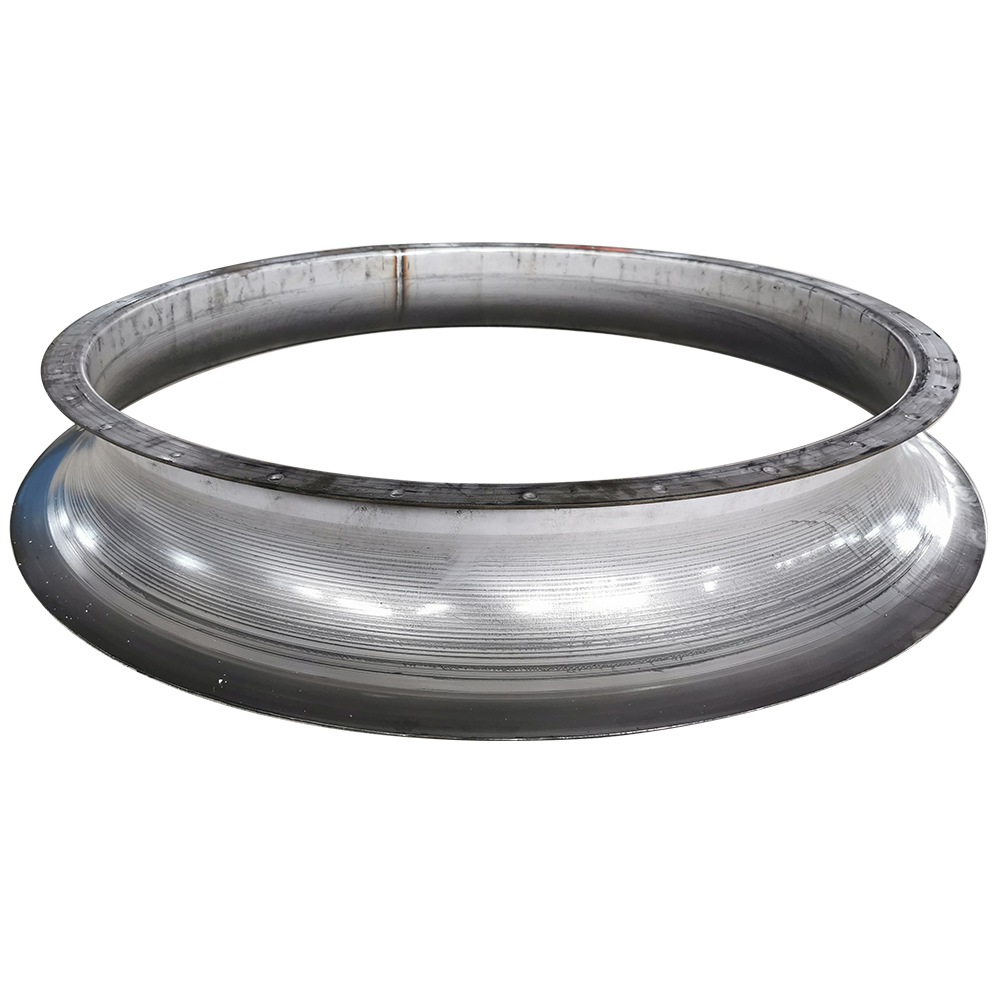

- Standard 90-degree flanging and punching, 0-92-degree flanging;

- Can produce large-diameter and tunnel, jet and other axial fan inlets and outlets with arc flanges;

- Can also produce inlet tapers and impeller shrouds for large centrifugal fans, especially high-hardness materials such as stainless steel;

- Siemens system, easy to operate! The 90° flange and small R arc flanging only need to modify: the wind tube of the axial fan, the angle of the flange or the R value; the number of punching holes; the safe position. There is no need to write auxiliary programs in the single-time flanging forming program;

- For large arc flanging, if multiple spinning is required, we have automatic programming software to complete the automatic production of program codes!

Drawings of shapes that can be processed by flanging machines

Flanging Machine Video

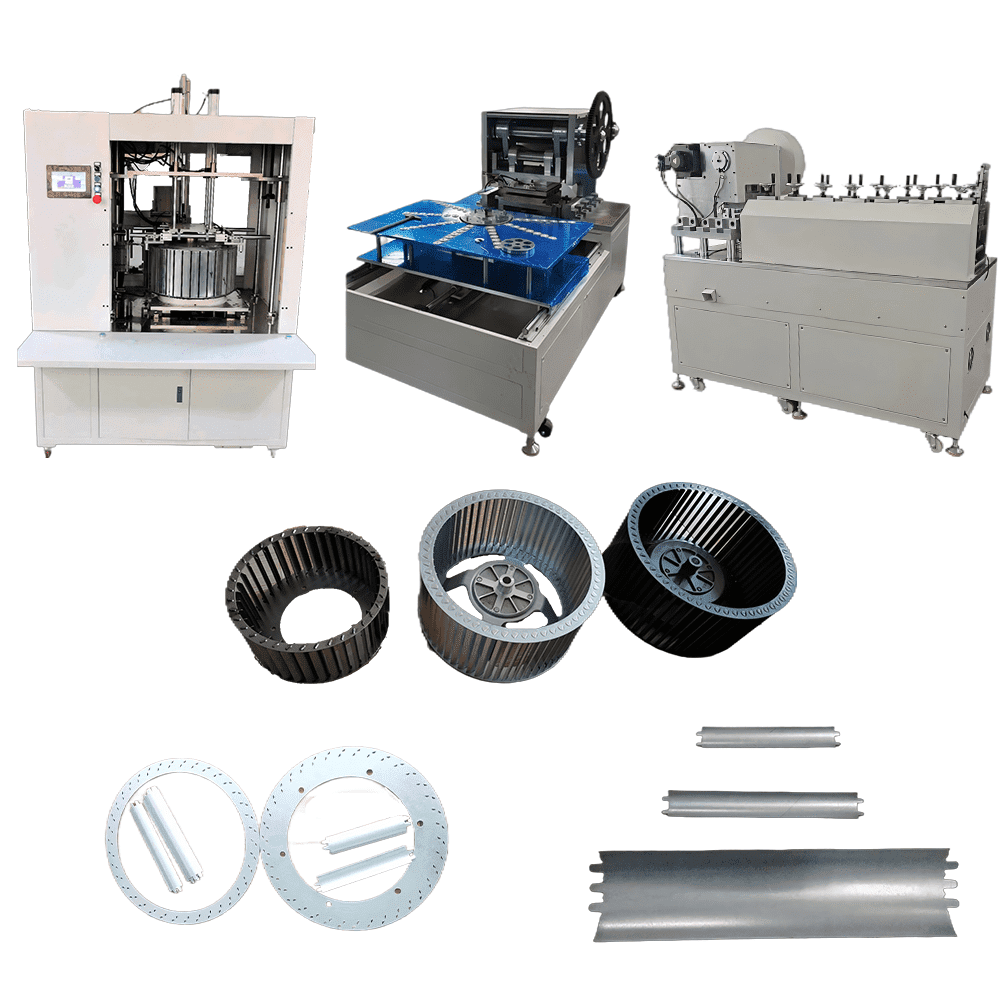

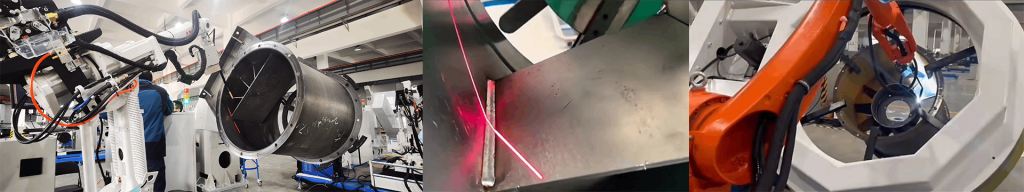

4.Robotic welding of motor brackets and impellers for axial flow fans

Altron has extensive experience in AI robot welding. The machine was originally designed for welding blades of centrifugal fan impellers. In the eight years of practical experience, industrial fan factories have continuously proposed visual tracking welding of axial fan brackets and guide vanes! Our AI algorithm uses a high-speed industrial camera to find the location of the weld, and with the aid of laser ranging, the robot will produce pixel points based on the captured photos, and then control the welding gun to weld the identified position;

We mainly use ABB robots, and if multi-axis synchronous linkage welding postures are required, we will choose to use Kuka robots!

Parameters and advantages of AI visual welding machine:

- Welding workpiece diameter: 300-3800mm;

- Workpiece weight: 10800KG;

- Visual tracking welding system, no need for complex tooling and positioning! Because the impeller production and

- Simple positioning, no need for precise positioning, scanning and correcting welds;

- The weld quality is stable and the efficiency is higher than manual, especially on large workpieces;

- The weld does not need to be polished;

- It reduces the manufacturer’s dependence on high-tech welding workers;

- The high degree of automation improves the corporate image;

Welding Video

Altron Is Always With You In The Manufacture Of Axial Flow Fans

Altron’s automation solution solves the forming of the axial fan cylinder and the welding and assembly of axial fan accessories, such as the impeller, motor bracket, guide, axial fan frame, etc. In terms of how to improve the performance of axial fans, we have an open attitude and have always discussed with customers how to use automated machines to achieve ideal results. Improving the quality and performance energy efficiency of axial fans is Altron’s ultimate goal!