Flow Forming & Metal Spinning Machine For Military

Flow Forming & Metal Spinning Machine For Military

✔ Advantage: 18 Years Of CNC Metal Spinning Machine R&D, Production, And Sales;

✔ Application: Shells, missiles, fish, weapons, military industry, aerospace,Hydrogen Cylinder, Pressure Vessels;

✔ Material : Aluminum, Copper, carbon steel, iron, stainless steel, conventional alloys, special high temperature alloys;

✔ Spinning Software: Free Supporting Machine, No Need To Write Program Code Manually.

✔ High Efficiency: The Automated Processing Flow Greatly Improves Production Efficiency.

✔ Solution customization: 7*24 Online Service, Engineer Video Online Conference To Solve Pre-Sales Problems.

CNC Metal Spin & Forming A-Z Project For Military, Aerospace Industry:

Flow Forming Machines CNC Metal spinning Machines

Application of Flow Forming & Metal Spinning in the Military Industry

Altron is a factory with military processing qualifications and certificates! The representative machines are CNC Flow Forming Machine and CNC Metal Spinning Machine;

As the war between Russia and Ukraine spreads, many companies and dual-use factories have added machines and equipment for military parts processing. More and more industries are involved in military, military industry, artillery shells, missiles, drones, aviation, aerospace and other fields.

Accessories in the military field have high standards and requirements for size, precision and quality; Altron has been deeply involved in these fields for more than ten years, and has high-level technical experience and relevant case test data for accessories in different application fields, which can reduce the number of tests and test cycle processes for most products!

Flow Forming for Military Industry Case

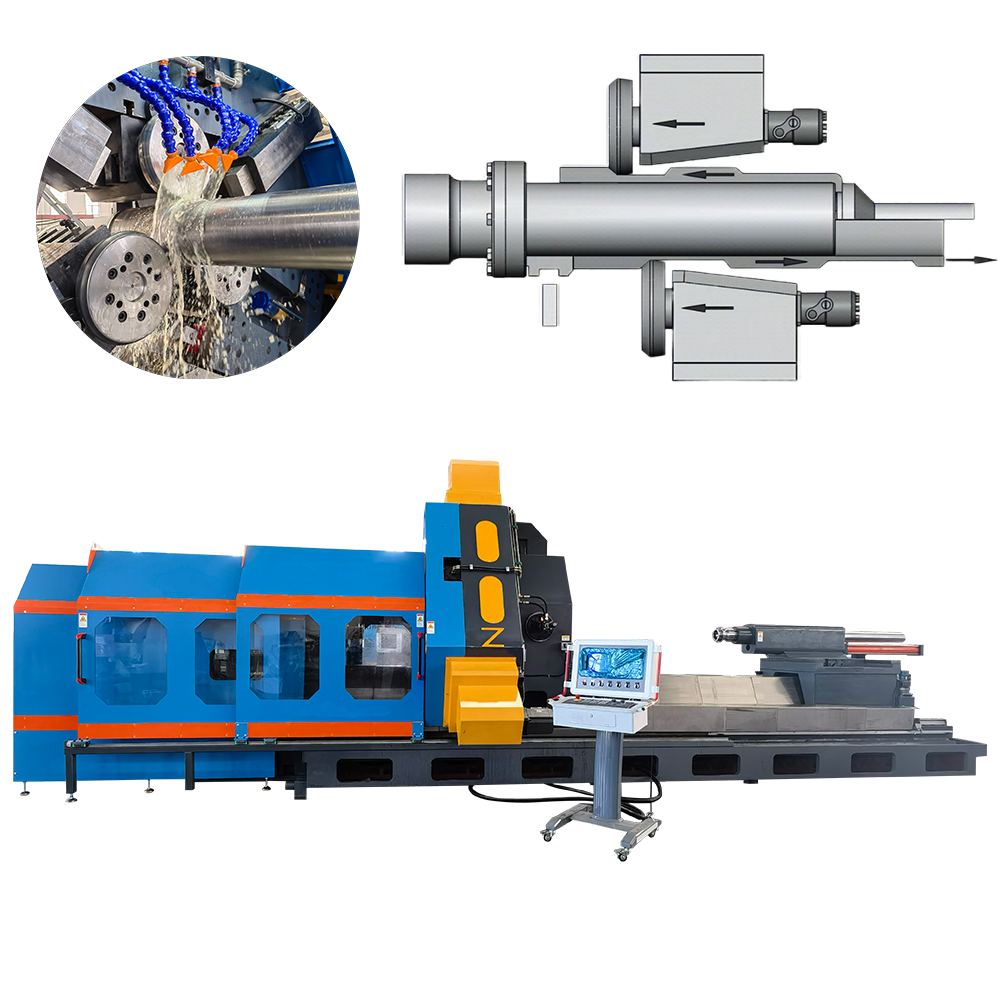

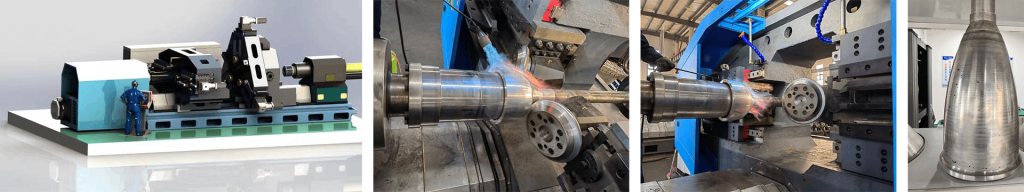

Flow Forming machine is a special metal spinning equipment for cylindrical hollow parts such as precision cylinders, high-pressure gas cylinders, servo hydraulic cylinders, engine housings, pressure vessels, etc. It is composed of 3 groups of 12-degree or 4 groups of 90-degree spinning rolls. It has a unique position in the application field of tube thinning and forming. It is a process link and equipment that cannot be replaced by other traditional processing industries. It is widely used in aerospace, aviation, military industry, chemical industry, pressure equipment and other fields.

Flow Forming Machine Technology & Functions:

- Spinning wheel synchronous or dislocation metal forming spinning;

- Forward spinning;

- Reverse spinning;

- Reverse spinning fixed length function;

- Siemens 840D control system;

- Spindle directional stop, convenient for mold installation and disassembly;

- Spindle unloading device;

- Slide unloading device;

- Water circulation spinning processing;

- Heating spinning protection;

- Manipulator cooperates with upper and lower workpieces;

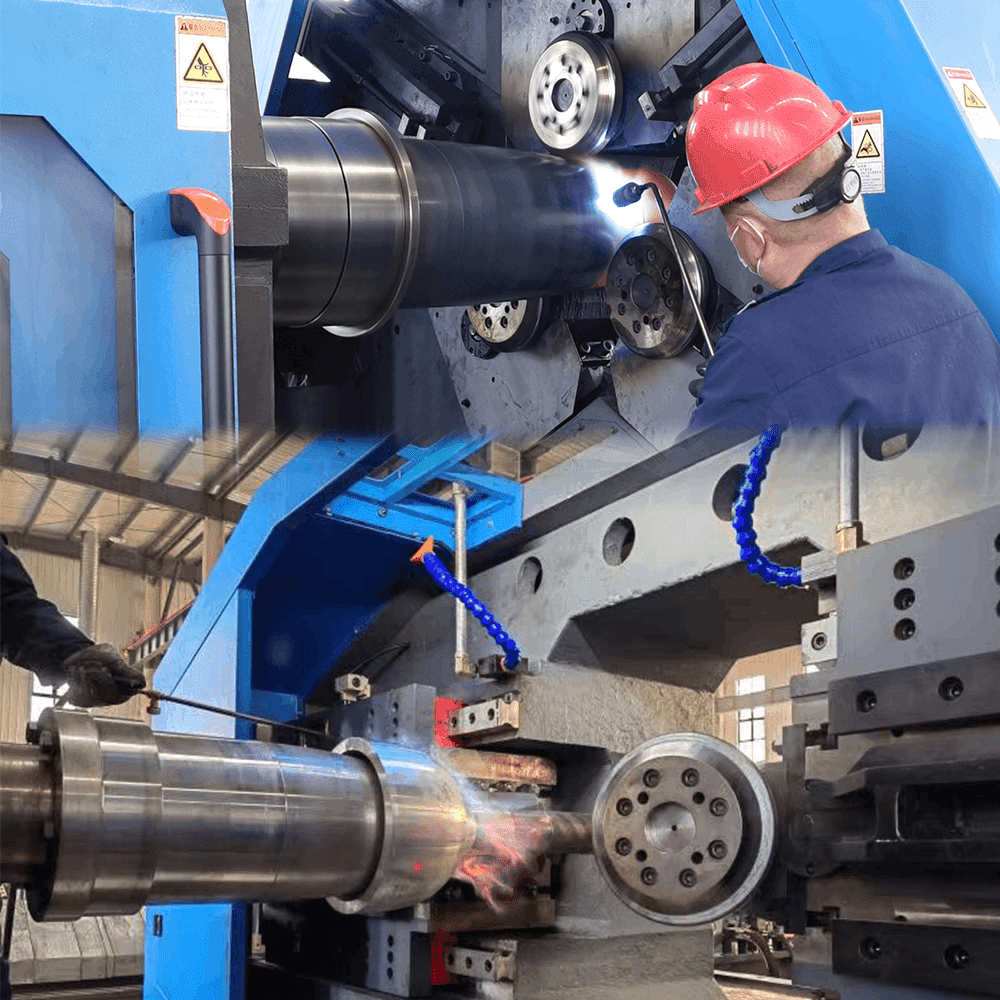

Altron upgrades Flow Forming machine in Leifeld, Germany

This is a Chinese company that has purchased 3 CNC flow forming machines from Altron and strongly requested to upgrade the flow forming spinning machine made in Germany that they purchased earlier. This is a special case. Normally, we do not participate in the modification or maintenance of equipment produced by other companies!

The high maintenance costs and maintenance cycles of German companies are unacceptable to this company! We were forced to renovate and upgrade! The driving principle of the original hydraulic servo cylinder was changed to servo motor control!

In terms of high-precision flow forming manufacturing experience and equipment research and development and production, we are not inferior to the technology of Germany and Japan! Our service quality is definitely higher than that of well-known CNC spinning manufacturers in developed countries, and the investment in machines is only about 30% of theirs!

Metal Spinning Machine for Military Industry Case

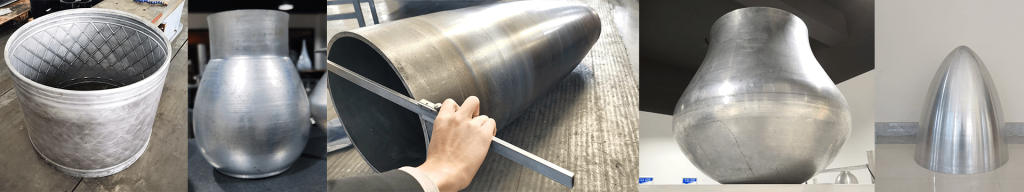

CNC spinning machines are divided into two types, heavy-duty and light-duty! Light-duty spinning machines are generally used in civilian industries, such as ventilation, fans, home photography, etc.; heavy-duty CNC spinning machines have high precision and strong processing capabilities, and are suitable for forming thicker metal sheets with higher yield strength!

The shapes that are representative of military and aerospace industries include pointed cones, copper cones, spheres, parabolas or arcs, etc. These parts are often made of special materials, not metal materials circulated in the market!

Metal Spinning Machine Technology & Functions:

- Shearing metal spinning;

- Neck shrinking spinning;

- Stretch spinning;

- Thinning and lengthening of tubes, surface hardening;

- Siemens 820D system,optional 840D;

- Spindle rotary cylinder unloading or installation of fixtures;

- Tool slide unloading device;

- Water circulation spinning processing and other cooling systems;

- Heating spinning device and protection;

- Manipulator cooperates with upper and lower workpieces and automatic connection;

Neck shrinking metal spinning head process for various sizes of small missile parts

Various sizes of small missile parts necking metal spinning head process

The heavy-duty spindle is installed with a specially designed fixture, which has a heat-resistant and cooling cycle device to ensure the stable production of the CNC spinning machine!

The spinning roller and the machine’s longitudinal and transverse work seat slide adopt a large-tonnage thrust design, and a bidirectional symmetrical spinning structure, which is mainly used to reserve a heating area for the heating device to protect the spinning roller from being directly heated by the heating device! Otherwise, it will cause the bearing to expand and the spinning roller will not be able to rotate!

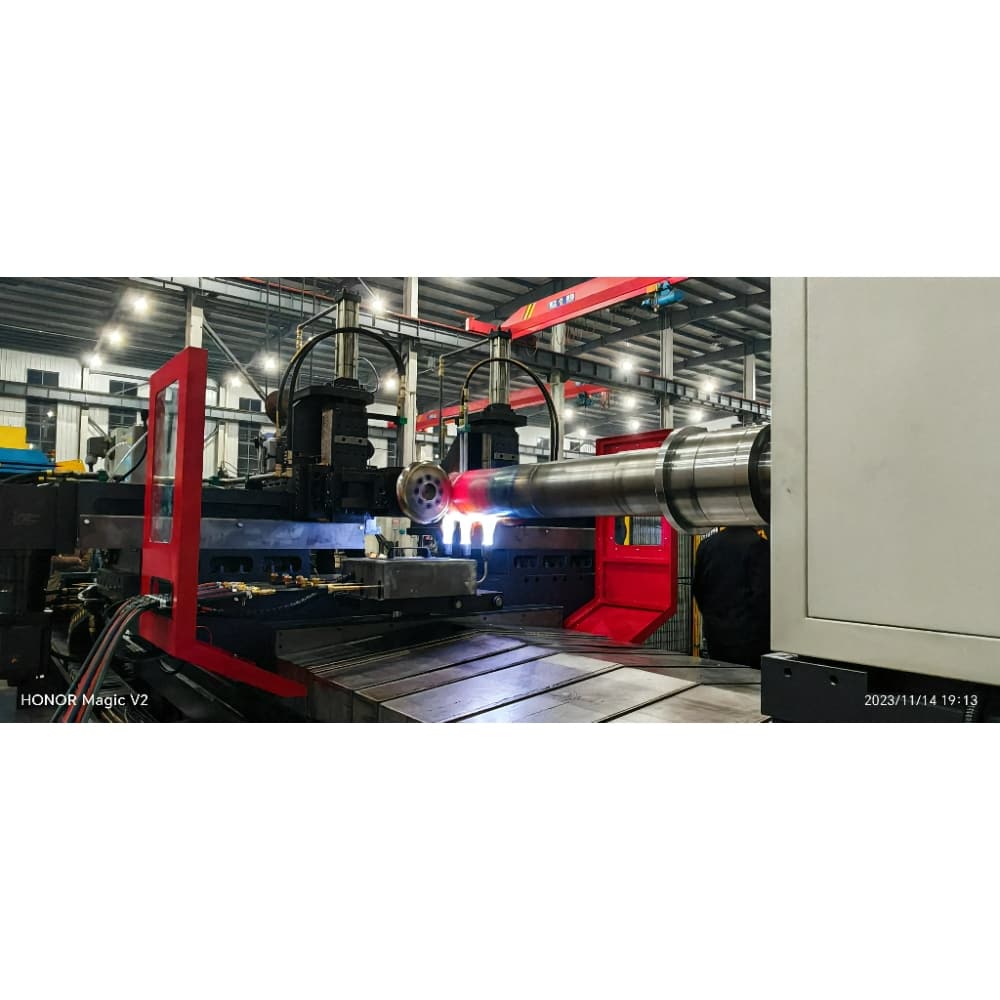

Metal forming manufacturing process combining flow forming and metal spinning

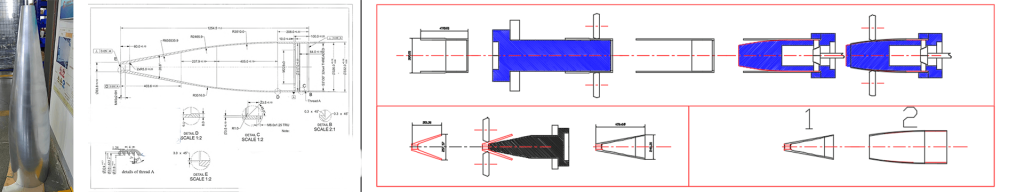

The shell of this torpedo needs to be processed using two processes, which has never reduced the manufacturing cost and difficulty! Achieve mass production mode:

This is a torpedo project from the United Arab Emirates. Due to manufacturing cost factors, the shell of the fish is spliced; the following figure shows the details and the process diagram of the processing:

1 part is completed by CNC spinning machine: using shearing process

The front part belongs to the warhead part with thicker wall thickness. The wall thickness size of the drawing has a gradient value of 18mm-12mm. Each point on the contour needs to be strictly tested. A measurement position point is taken with a length of 5mm! After spinning, the workpiece needs to be numbered and the measurement data is archived! Ensure the qualified rate of the product and reach the next turning process;

The core issues of metal spinning:

- The surface finish of the rough blank after turning;

- Annealing treatment before metal spinning;

- Temperature control during spinning;

- Design of demolding tooling after metal spinning;

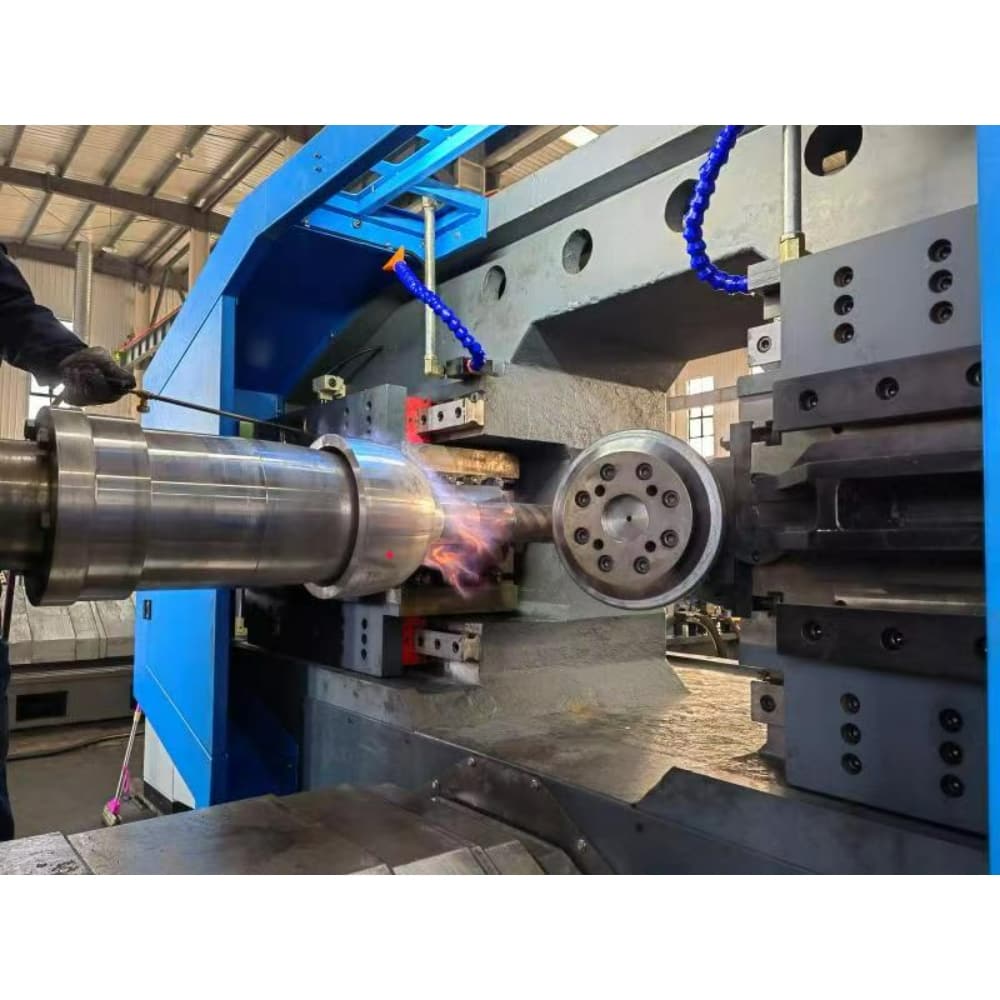

2 part is completed by flow forming machine: using thinning spinning and necking spinning processes

The rear end of the torpedo shell is completed by thinning and elongation process and necking process. The 3-roller flow forming spinning machine is used to thin the tube blank, from 25mm tube to 10mm uniform wall thickness tube!

Then replace the necking core, use the necking process, and then heat it to form it!

The core issues of flow forming:

- The wall thickness of the flow-formed tube must be greater than the wall thickness required by the drawing;

- A small necking cannot thicken the material;

- Annealing treatment before metal spinning to prevent embrittlement;

- Temperature control during spinning;

- Design of demoulding tooling after metal spinning;

Summary of torpedo shell processing:

In multi-process forming projects, the internal structure of the material changes, and the traditional cold metal spinning process has many unstable factors! When the metal material is heated, the yield strength decreases, making metal spinning easier and the material’s ductility coefficient higher!

In the heating spinning project, we must use a double-roller metal spinning machine. The 3-roller metal flow forming machine is heated. There is no uniformly heated position, and it can only be produced in manual mode. It is not safe!

In the later project plan, the slide part of the strong spinning machine and the flow forming machine can be more slippery! Achieve one machine to complete two processes!

Military, Aerospace, Aerospace, Spinning Parts Display

Altron’s Development Principles In The Military Field

War brings pain and disaster to people. Falling behind will lead to being beaten!

I only hope to defeat unfair oppression with powerful military force, and I don’t want weapons to bring disaster and war to mankind!

Altron’s Factory Video

please contact me and Joby engineers will give you a detailed plan.