Flow Forming & Necking Machine For Hydrogen Cylinder

Flow Forming & Necking For Hydrogen Cylinder

✔ Advantage: 15 Years Of CNC Metal Spinning Machine R&D, Production, And Sales

✔ Application: Hydrogen Cylinder, Gas Cylinders, Pressure Vessels

✔ Material : Aluminum, 6061Aluminum Alloy;

✔ Spinning Software: Free Supporting Machine, No Need To Write Program Code Manually.

✔ High Efficiency: The Automated Processing Flow Greatly Improves Production Efficiency.

✔ Solution customization: 7*24 Online Service, Engineer Video Online Conference To Solve Pre-Sales Problems.

CNC Metal Spinning and Forming A-Z Projects for Hydrogen Storage & Oxygen Cylinder Industries:

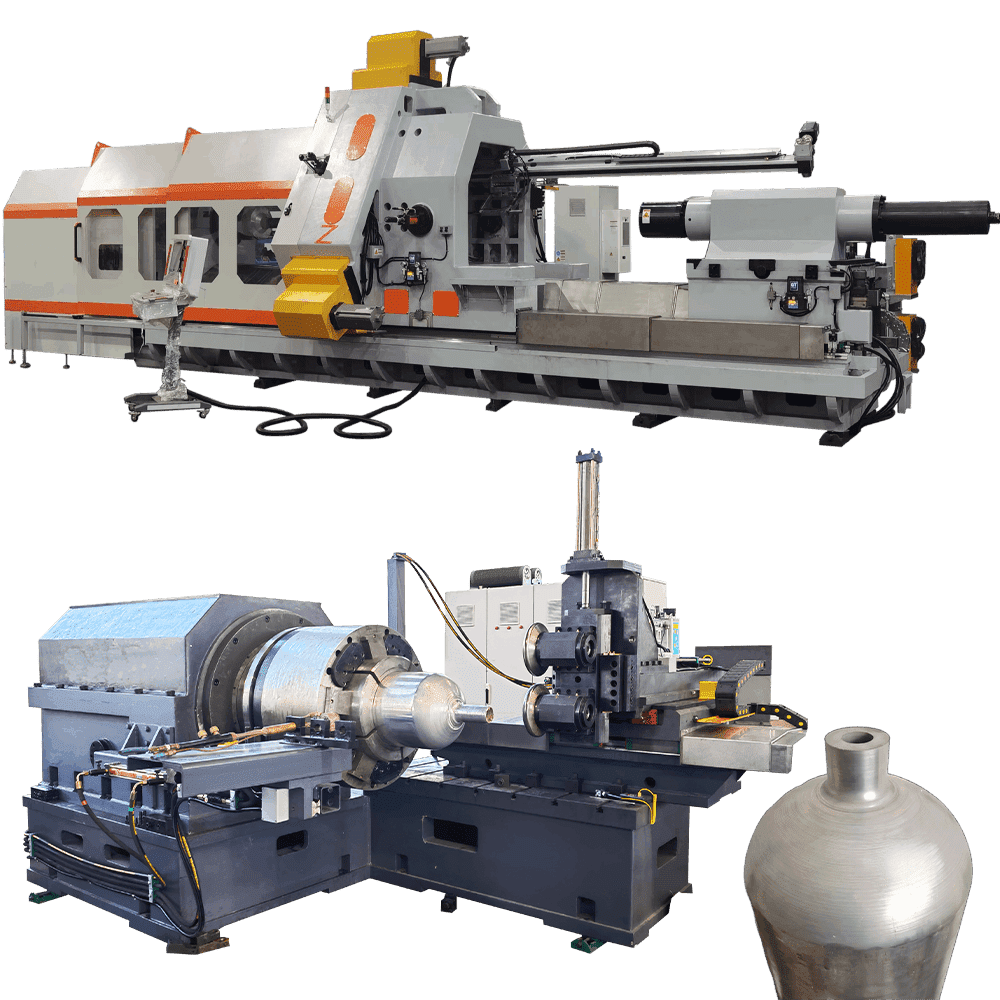

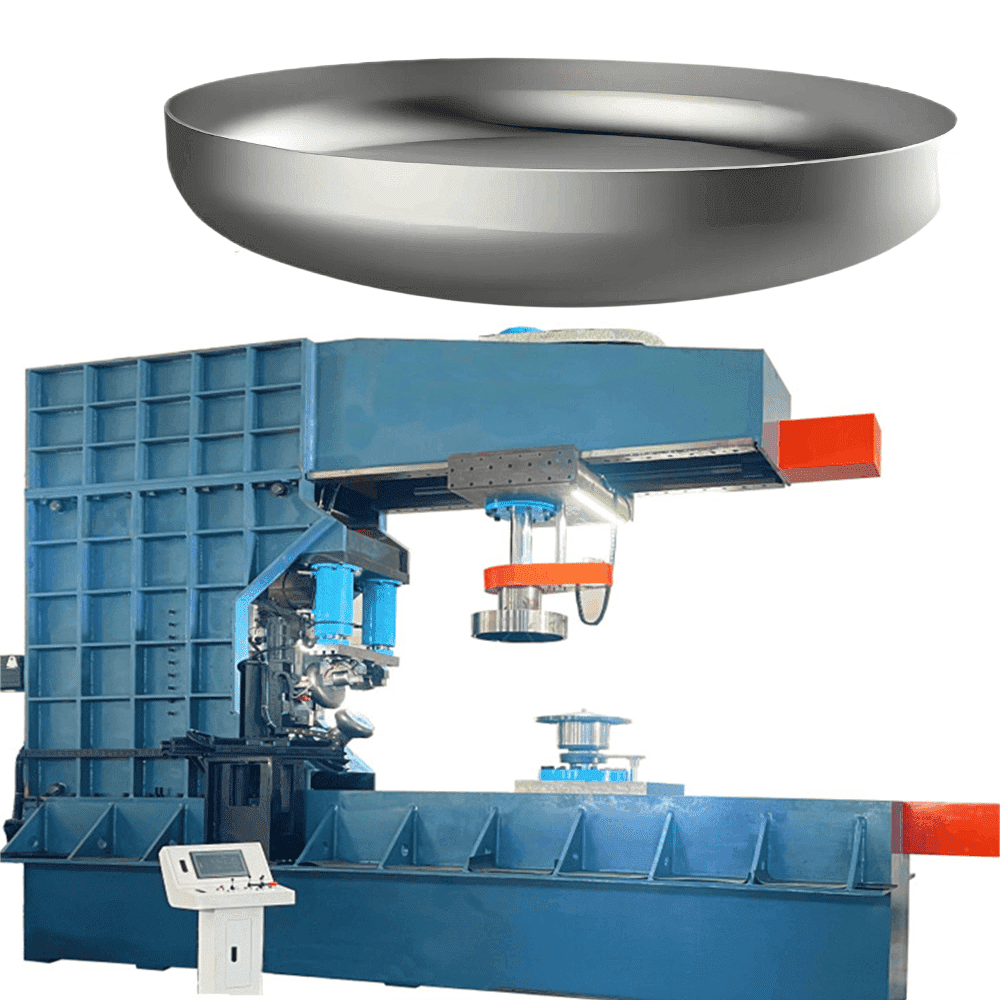

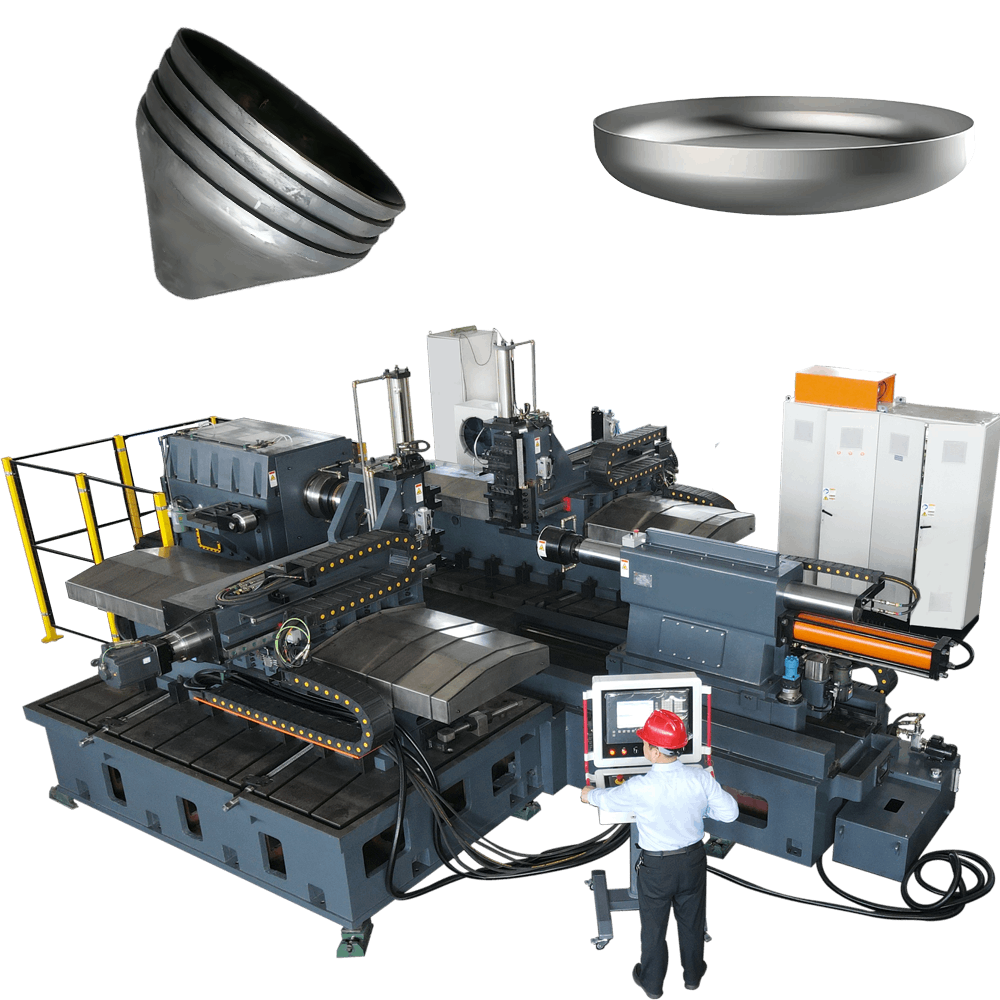

Flow Forming Machines CNC Necking Machines

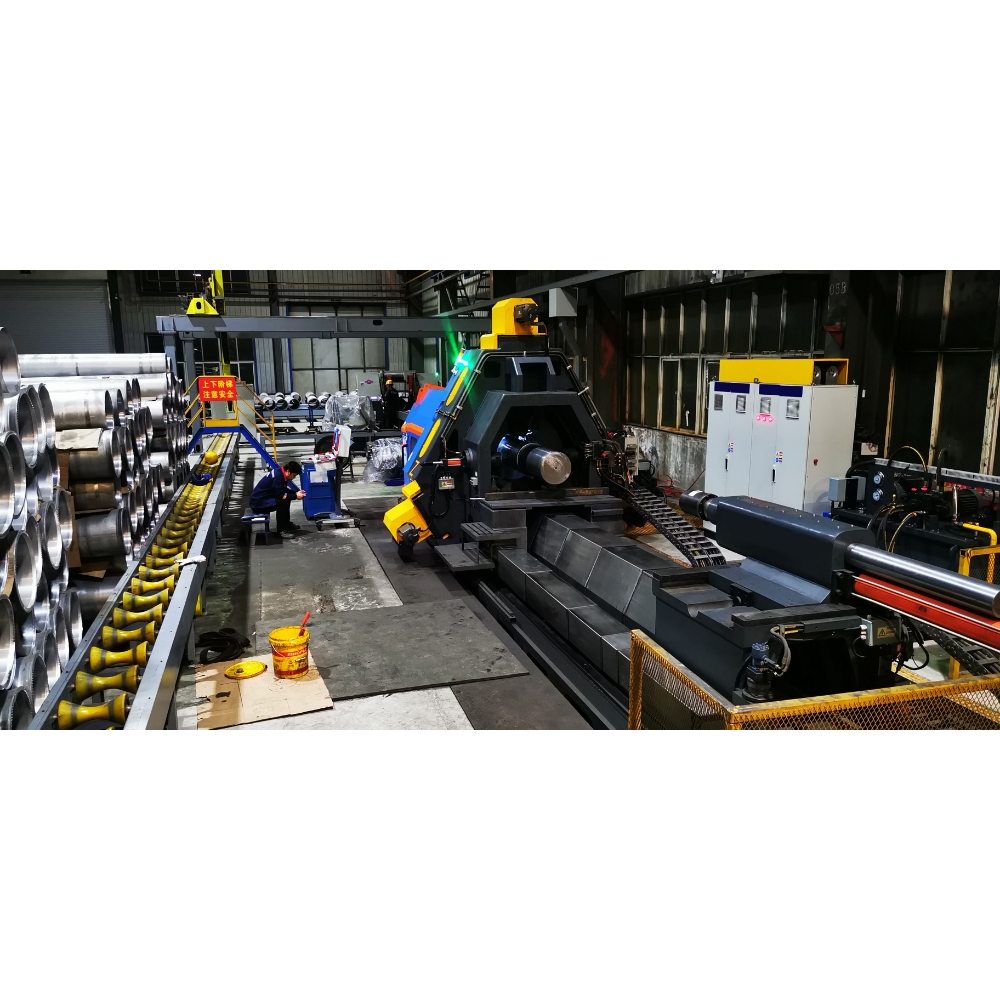

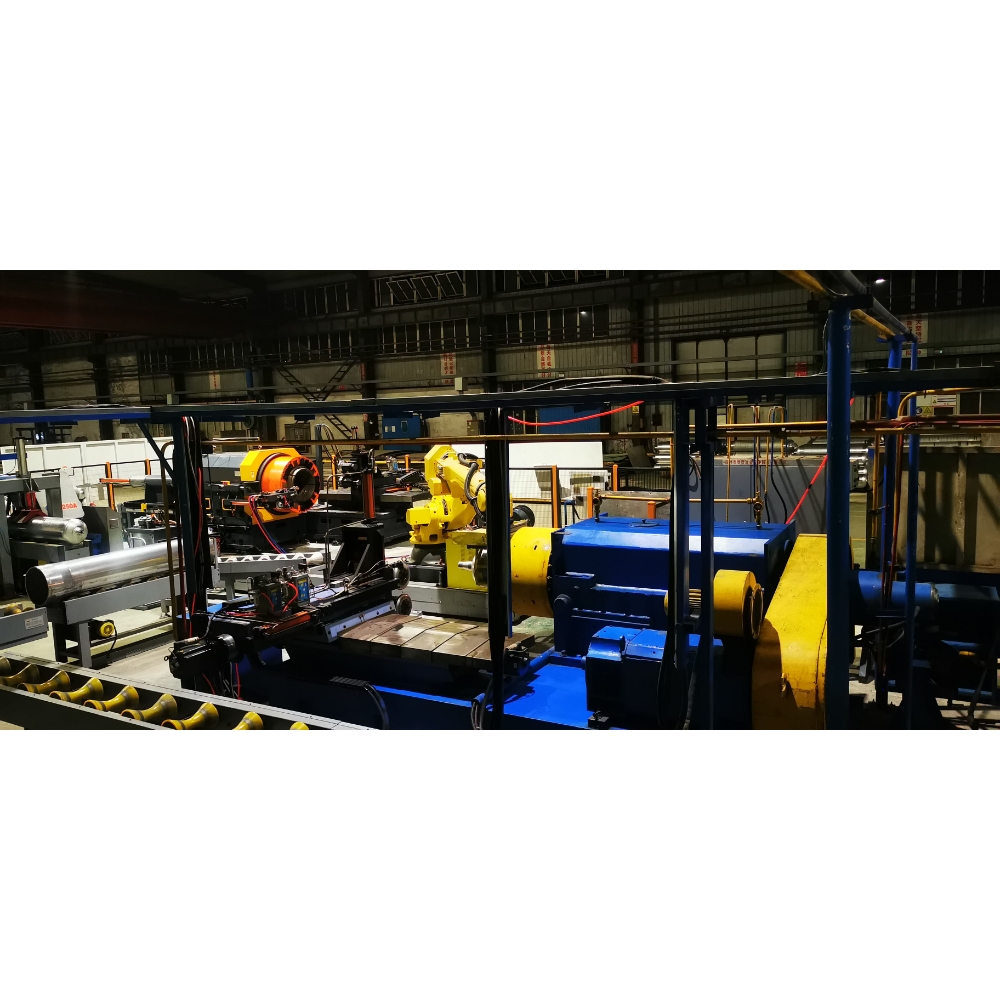

Entering The Hydrogen Cylinder Production Factory

Showing our project cases for the hydrogen energy field, Altron provides Flow Forming Machines and CNC Necking Spinning machines for hydrogen cylinder factory manufacturers! These are two core metal forming processes and are essential processing links!

Below I will describe the complete production process of a hydrogen cylinder one by one:

Processing Flow of Hydrogen Cylinder

- Raw material inspection

- Forging

- Sawing

- External turning

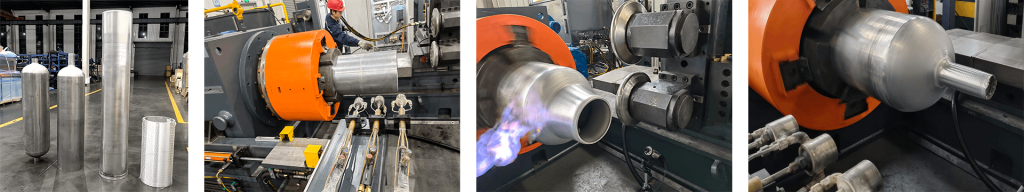

- Flow Forming spinning

- Fixed length, cutting

- Cleaning

- Inner surface inspection (grinding)

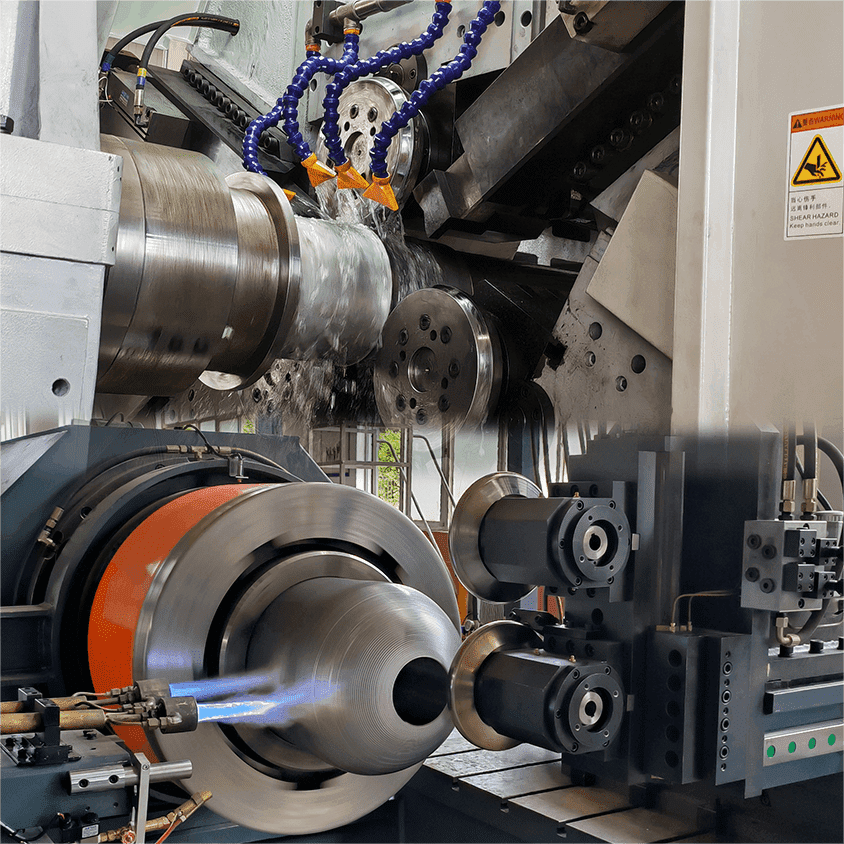

- Hot spinning and Necking

- Bottle mouth lengthening

- Transplantation marking

- Solution treatment

- Artificial aging

- Performance test

- Hardness test

- Bottle mouth thread processing

- High pressure cleaning

- Laser coding

- Bottle body grinding

- Non-destructive particle size

- Inner liner inspection

- Spraying

- Glue mixing

- Winding

- Curing

- Self-tightening and water pressure test

- Drying

- Valve installation

- Airtightness test

- Finished product inspection

- Fatigue and burst test

- Entry, filing

How to use Flow Forming & Necking Machine to make hydrogen cylinders

Process summary of Flow Forming:

- The limit thinning rate of 6061 aluminum alloy is 75%. If the value is exceeded, unstable production will occur: micro cracks, poor straightness, unstable internal and external dimensional accuracy;

- If the feed speed F is too high, it is easy to cause material accumulation in front of the spinning wheel; if the feed speed F is too low, the inner diameter will be enlarged and the ovality will increase;

- Offset spinning is to stagger the three spinning wheels to increase the spinning deformation within an appropriate range, thereby reducing the number of spinning times and improving the spinning efficiency;

Process summary of necking spinning:

- Heating spinning will increase the wall thickness of the mouth;

- If the temperature is too low, the plastic change of the tube material is too small;

- If the temperature is too high, the material will melt, resulting in delamination and cracking;

- Selection of spinning wheel: Use a wheel with a large fillet radius (spinning wheel data is not publicly described)

- Small-diameter straight section spinning should be long, and the thickest wall thickness after forming is in the middle part;

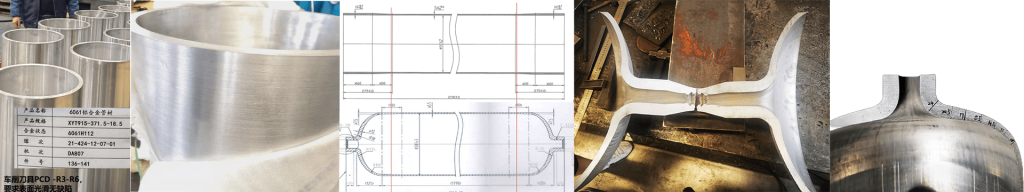

Production Of Hydrogen Cylinders Is Testing Data:

- The surface of the hydrogen cylinder pipe must not have: scratches, impurities, cracks, etc.

- Surface finish Ra2.0;

- The straightness of the pipe after fowFlow forming is less than 0.15%;

- The deviation of the inner and outer diameters is 1% as required by the drawing;

- The temperature of the necking spinning is controlled between 350-450°

- After the necking is completed, the bottom thickness of the mouth must be greater than 20mm, and the margin is reserved for machining threads

Altron’s Hydrogen Cylinder Processing Equipment Selection

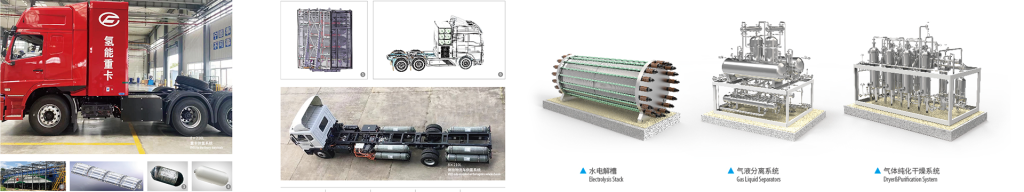

Application Of Hydrogen Cylinders

- Vehicle High-Pressure Hydrogen Supply System And Related Products

- Water Electrolysis Hydrogen Production Equipment

Altron provides high quality machines and services to hydrogen cylinders manufacturers:

Altron’s Factory Video

please contact me and Joby engineers will give you a detailed plan.