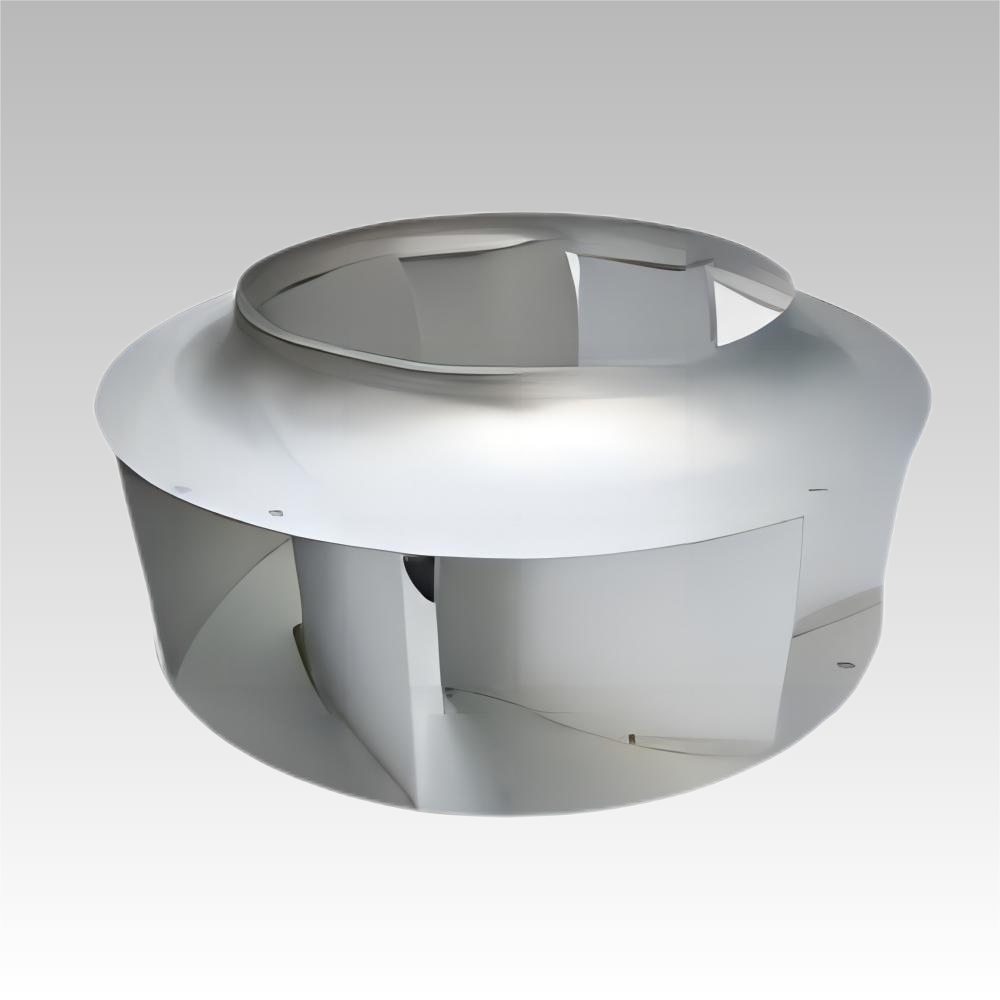

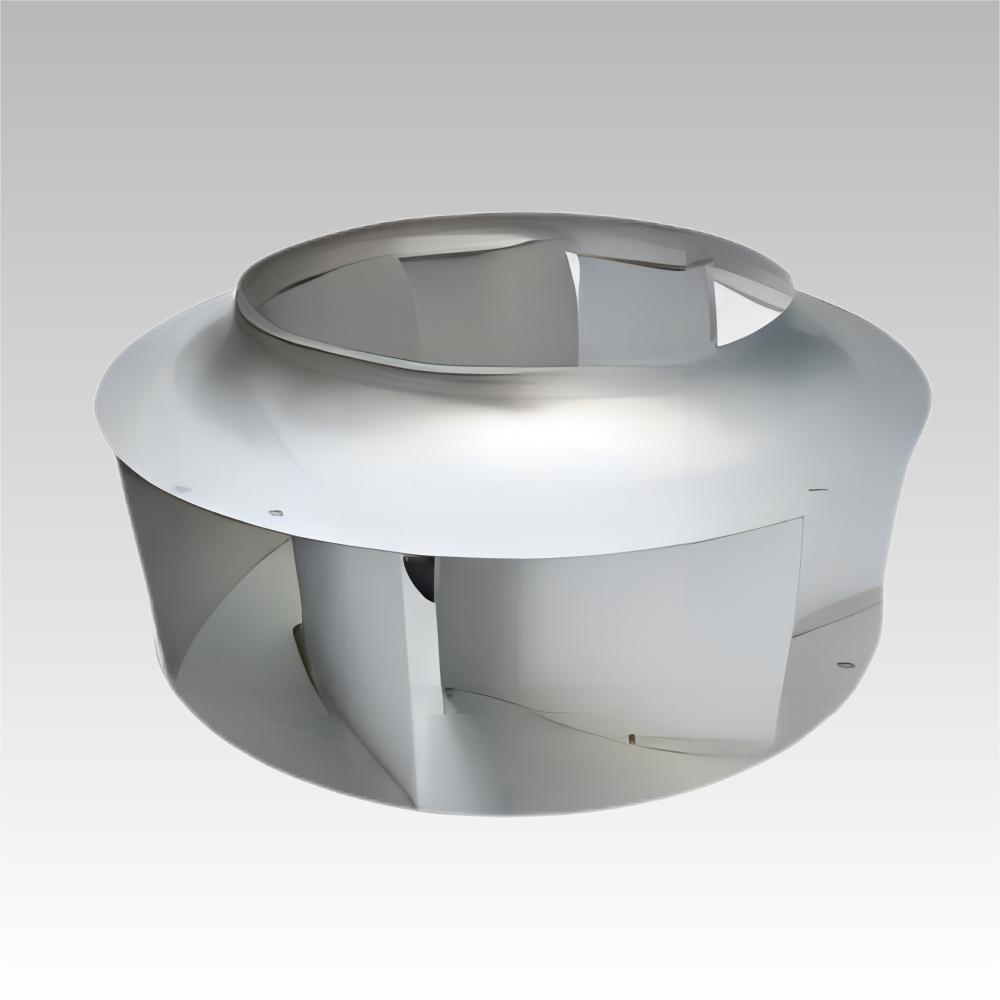

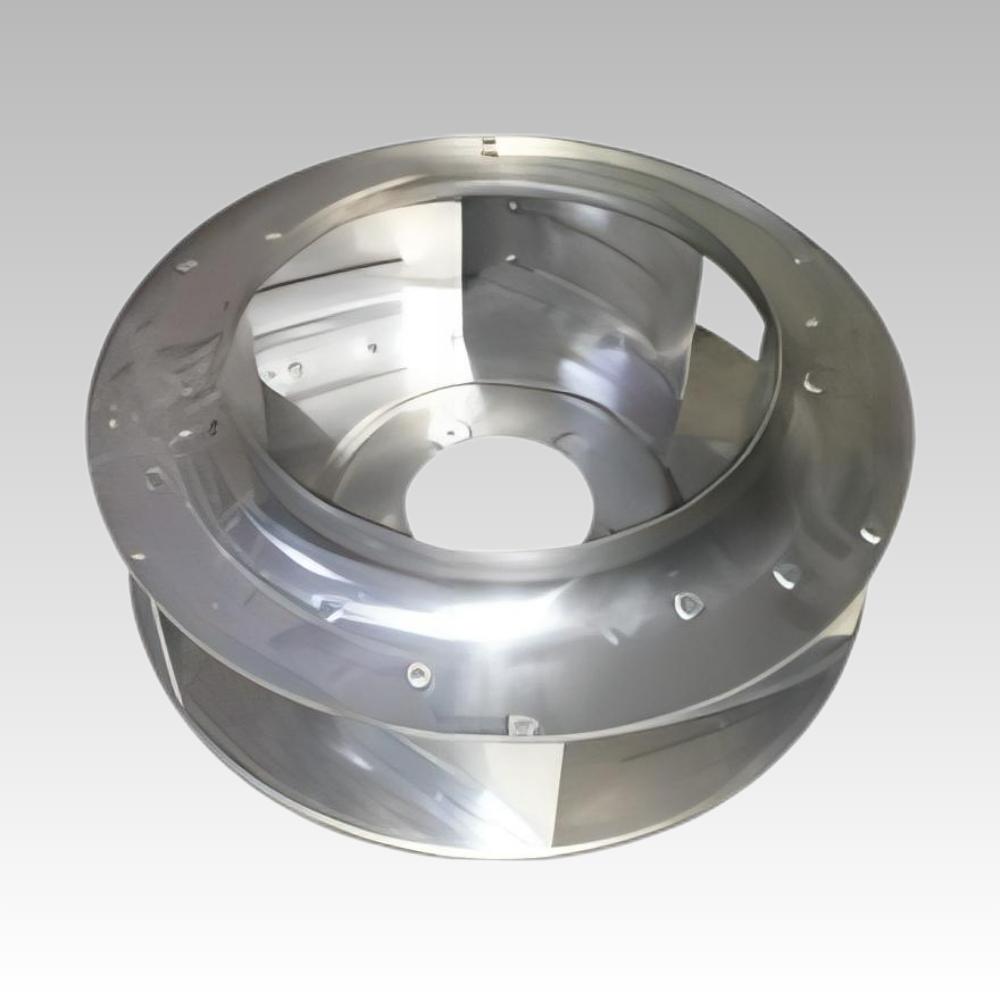

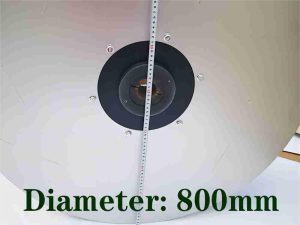

Backward Curved Impellers For Centrifugal Fan

Customized backward curved impellers

Electric Current Type : Full-Vortex, Open-Vortex, Non-Clog, Vortex, Closed, Semi-open

Model Number :AC202101213

Material :Stainless steel

Product name :Backward curved impeller for centrifugal fan

Type : centrifugal impeller blower fan impeller

Surface treatment :Welding ,Polishing and CNC metal spinning

Service: OEM\ODM

Color : Customers’ Requirements

Structure : Customers’ Requirements

Packing : Carton+ Wooden Box

MOQ : 50pcs

Machining Process : Lathing

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Backward curved impellers for centrifugal fan details

|

|

|

Application Range of Backward Curved Impeller

Centrifugal fans are ubiquitous in various industrial processes, providing crucial air movement solutions. Among the diverse fan designs, the backward curved centrifugal fan impeller stands out for its unique characteristics and versatile applications.

Understanding the Backward Curved Centrifugal Fan Impeller

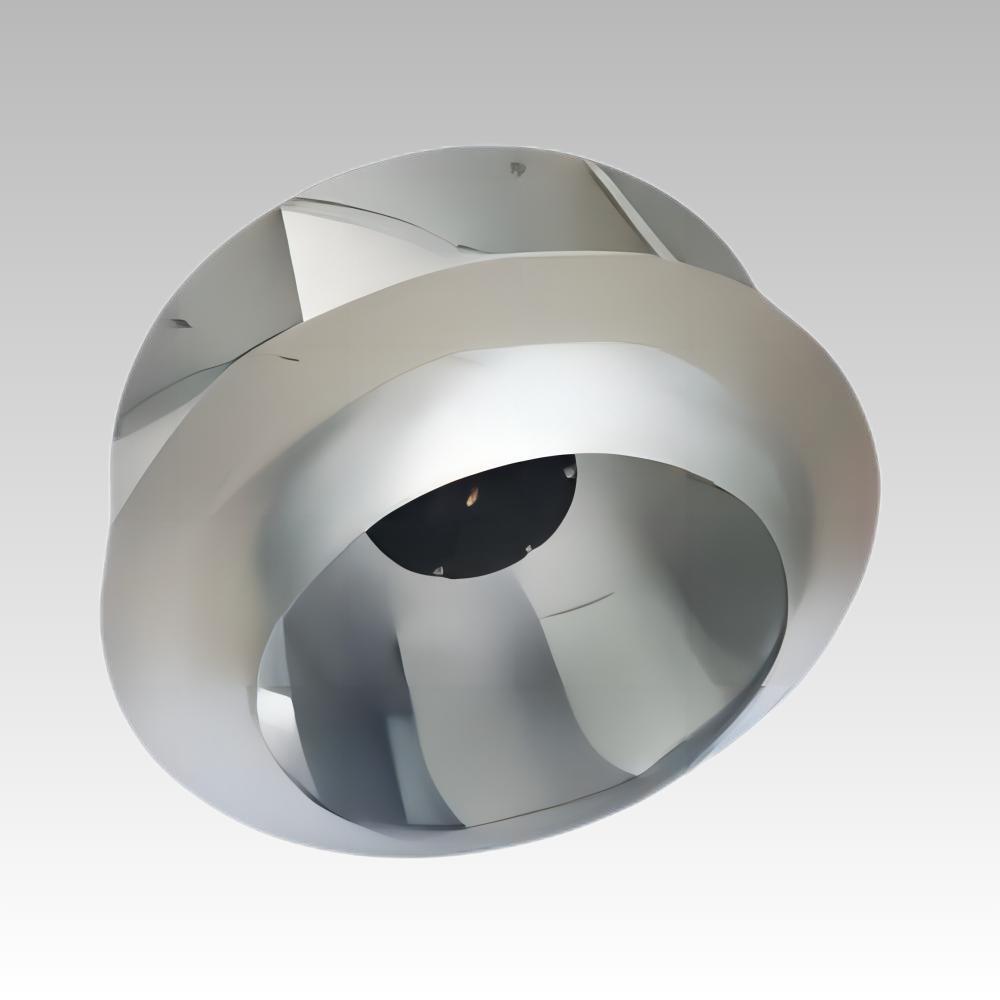

At the heart of this fan lies the impeller, a vital component responsible for generating airflow. The backward-curved impeller features blades curved away from the direction of rotation. This design allows for efficient airflow and pressure generation.

HVAC Systems

In HVAC applications, backward-curved centrifugal fans excel in delivering large volumes of air at moderate pressures. They are commonly used in air handling units, rooftop units, and ventilation systems, ensuring optimal indoor air quality and comfort.

Industrial Processes

In industrial settings, these fans play a crucial role in processes such as drying, cooling, and exhaust ventilation. Their ability to handle high temperatures and corrosive environments makes them suitable for diverse applications in manufacturing, chemical processing, and mining.

Energy Efficiency

With a focus on sustainability, industries are increasingly adopting energy-efficient solutions. Backward curved centrifugal fans stand out for their high efficiency, reducing energy consumption and operating costs while minimizing environmental impact.

Backward curved impeller video

Manufacturing Process of Backward Curved Impellers

Backward curved impeller plays a vital role in various industries such as industrial fans, HVAC systems, ventilation and air purification. Its efficient design ensures optimal airflow and pressure characteristics.

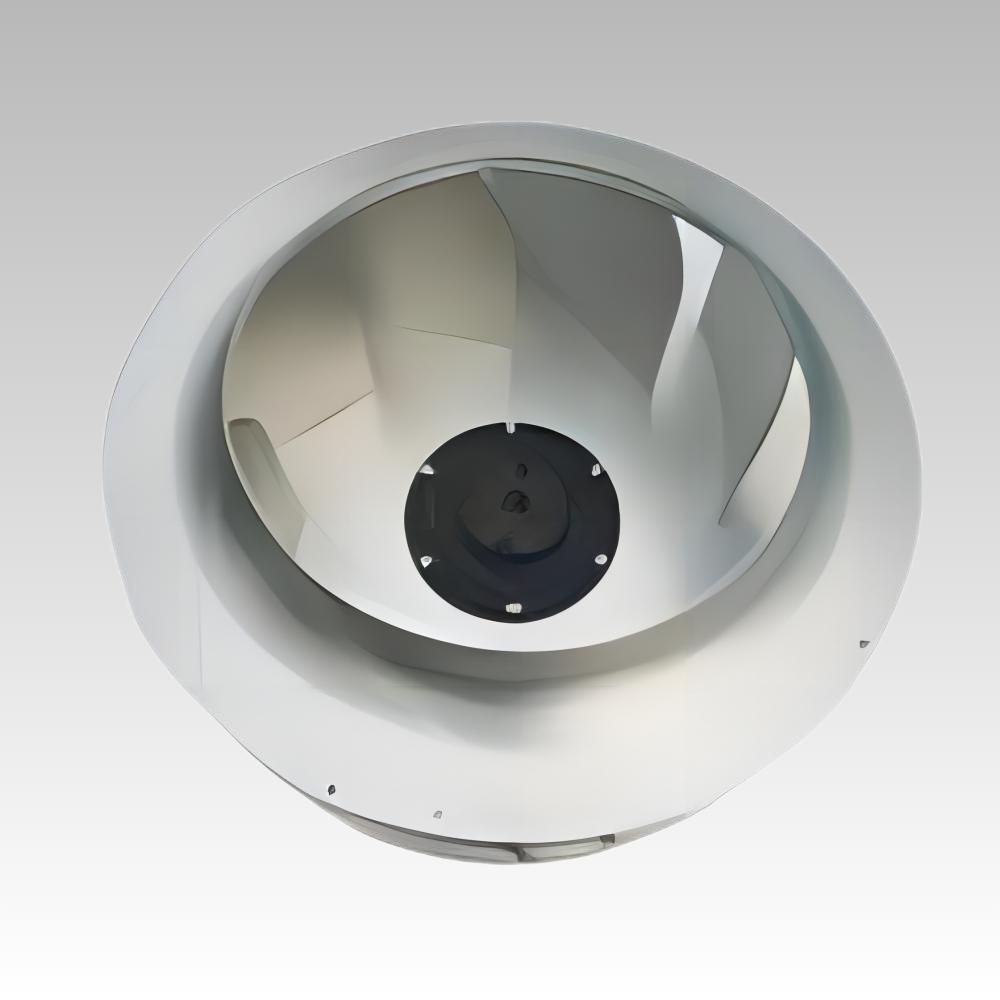

Design stage of backward curved impeller

The manufacturing of backward curved impeller is particularly important for meticulous design and verification. Engineers use advanced CAD and 3D software to model the complex geometry of the impeller, considering factors such as blade curvature, thickness and blade angle distribution. And use advanced simulation fluid verification system to analyze the impeller to ensure that the impeller achieves optimal performance and efficiency in operation.

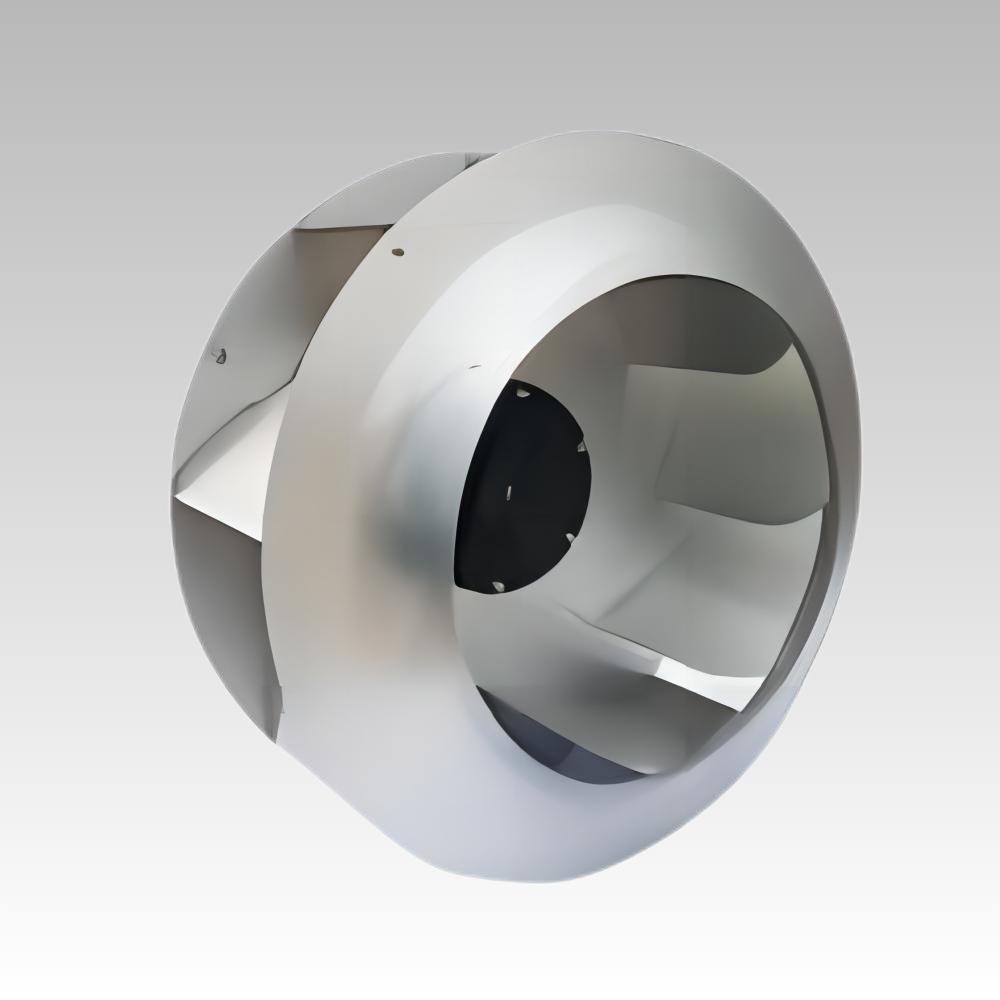

Material selection: ensuring the strength, life and working environment of the impeller

After the design is completed, the next step is material selection. Backward curved impellers are usually made of materials such as stainless steel, carbon steel, aluminum or composite materials. The choice of material depends on factors such as operating environment, required strength and corrosion resistance.

CNC Metal spinning impeller shrouds

CNC metal spinning is an important step in the manufacturing process of backward curved impellers. Computer numerical control (CNC) machines are used to accurately form the required impeller shrous arc according to design specifications. This process requires high precision to ensure that the blade geometry is uniformly in contact with the impeller shrou. The metal spinning process is particularly important for subsequent welding and dynamic balancing.

Deep-drawn blade forming and curvature

After processing, the flat blades undergo a forming process to achieve the desired curvature. This may involve techniques such as pressing, rolling or bending, depending on the material and design requirements. Maintaining uniform curvature of all blades is critical for balanced airflow and performance consistency.

AI robotic welding impeller

If the impeller consists of multiple components or blade segments, welding is necessary. Skilled welders use techniques such as TIG or MIG welding to firmly connect and assemble the components together. In recent years, due to the continuous reduction of welding workers around the world, AI visual automated welding can well replace manual welding, which can ensure the consistency of welding without compromising structural integrity. Welding quality is critical to ensure that the impeller can withstand working conditions without failure.

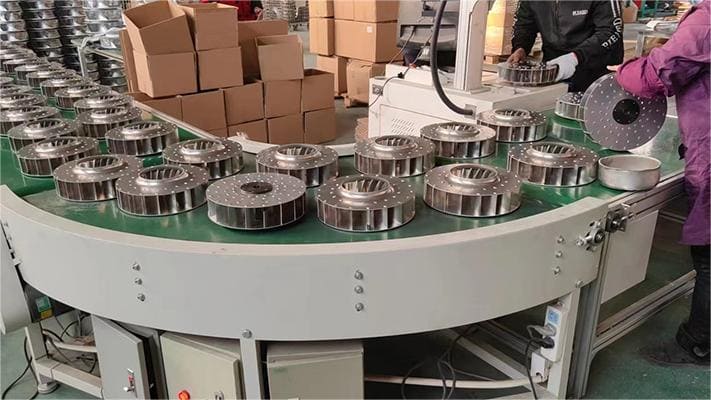

Impeller balancing forming

Balancing is a key quality control step in impeller manufacturing. Unbalanced impellers can cause excessive vibration, noise and premature wear during the operation of industrial fans. A dynamic balancing machine is used to measure and correct any imbalances by strategically adding or removing material. This ensures smooth operation and extends the life of the impeller and reduces the noise decibels generated during operation.

Impeller surface treatment

Surface treatment is used to enhance the durability and performance of the impeller. This may include processes such as shot peening to remove surface defects, followed by coating or electroplating for corrosion protection. Surface finish also affects aerodynamic efficiency, so a smooth and uniform surface must be achieved.

Quality Inspection

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the impeller meets industry standards and customer requirements. Dimensional inspections, material testing and performance evaluations are carried out at various stages. The data of each impeller will be recorded and the number of the corresponding order will be produced. The final qualified impeller will be sent to the warehouse.

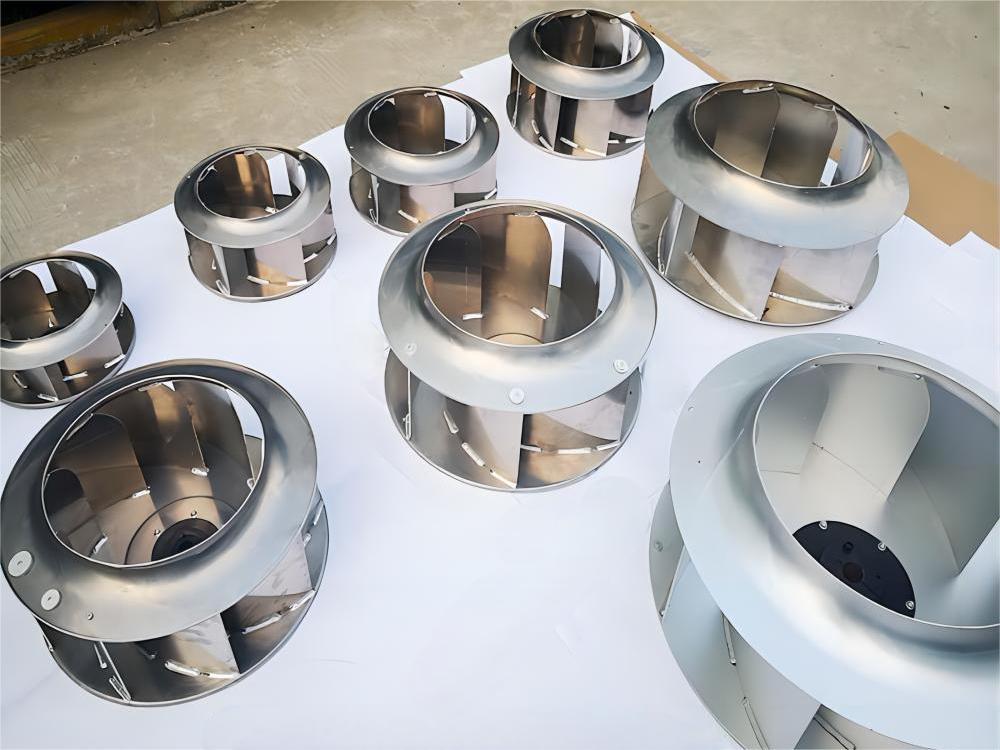

Exhibition of other impellers

|

|

|

|

|

|

|

|

Impeller Manufacturer Factory

Altron specializes in the design, R&D, manufacturing and sales of metal spinning, stamping metal parts, molds, centrifugal fans, machining, and metal parts required by the construction industry and other industries. With our rich experience and considerate service, we have been regarded as a reliable supplier by many international buyers. We do our best to satisfy you.

Our experienced engineers specialize in CNC machine tools, allowing us to meet your customized requirements to support your OEM/ODM services. We can meet any of your bulk order requirements. The products sell well in domestic and foreign markets, such as the United States, Europe, the Middle East, South Africa and other countries and regions, and are well received by customers.

|

|

|

|

|

|

|

|

|

|

|

|

Industry Fans Impeller Metal Material:

- aluminum alloy,

- titanium alloy,

- stainless steel,

- galvanized plate,

- manganese steel,

- etc.

Industry Fans Products Are:

Machine Room Fan Impeller, Seeder Fan Impeller, Hot Air Circulation Fan Impeller, Grain Cooling Single-Tube Fan Impeller, Tobacco Dryer Impeller, Marine Fan Impeller, Oil And Fume Purification Impeller, Volute-Less Fan Impeller, Roof Fan Impeller, Cooling Fan Impeller, Condenser Side Fan Impeller, Oven Oven Impeller, Special Fan Impeller For Sock Machine, Textile Cotton Suction Fan Impeller, Textile Traveling Cleaning Machine Impeller, Commercial Fan Impeller Such As Hotels And Shopping Malls, High Temperature Resistant Centrifugal Fan Impeller, Double-Stage Fan Impeller, Kiln Fan Impeller, Heating Furnace Fan Impeller, Down-The-Hole Drilling Rig Dust Removal Impeller, Industrial Purifier Fan Impeller, Ffu (Fresh Air) Fan Impeller, Laboratory Equipment Fan Impeller, Polishing Dust Removal Fan Impeller, Burner Impeller, Electric Sweeper Impeller, Combustion Support Fan Impeller. Drying Equipment Impeller, High-Pressure Vortex Fan Impeller, Moxibustion Equipment Moving Impeller, Smoke Purification Impeller, Washing Equipment Impeller, Dryer Impeller, Pulse Bag Dust Removal Impeller, 9-12, 9-19, 9-26 High-Pressure Centrifugal Impeller, Boiler Induced Draft Fan Impeller, Food Machinery Equipment Impeller, Cnc Spindle Fan Cooling Impeller, Forward And Backward Inclined Multi-Wing Impeller, Air Guide Ring, Non-Standard Customized Volute, Customized Fan, etc.

FAQ

Who are we?

Our factory is based in Jiangsu, China, starting from 2017. Our products are soldto South Asia(30.00%), Eastern Asia(25.00%),

Eastern Europe(25.00%), North America(20.00%). There are total about 51-100 people in our office.

How can we guarantee quality?

Alwaystesting the pre-production sample before mass production

Always doing the final Inspection before shipment

What can you get from us?

Stamping parts, mould, impellers, mechanical processing, Centrifugal fan and so one

Why choose us?

We have rich experience of 20 years on the impellers, fans and other hardware accessories. The professional designer to create the

new related products, the skilled mechanic to test the products again and again ensure get a perfect products.

What services can we provide?

Delivery Terms: FOB, CFR, CIF, DDP

Payment : USD, CNY

Payment Type: T/T, L/C

Packing & Delivery

|

|

|

|

|

|

|

|

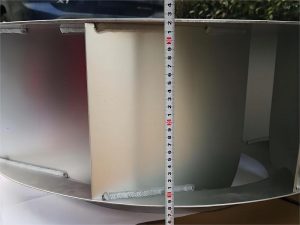

Customers provide information & negotiate impeller solutions:

- Provide fan impeller pictures + impeller dimensions; Altron will provide corresponding impellers.

- Provide impeller drawings; customized production will be completed by Altron (requires 5-55 days delivery time).

- Provide information on the use of industrial fans, application industries, wind pressure, air volume, materials of main components, wall thickness and strength of industrial fans.

- Customize impellers or accessories according to actual needs

Industrial fan impeller sample

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wind cabinet aluminum welded outer rotor impeller

FFU inner rotor impeller

Double inlet aluminum welded impeller

Punker impeller

Wing impeller

Wing impeller

FFU outer rotor impeller

Aluminum welded impeller

Aluminum riveted impeller

High pressure impeller

Medium pressure impeller

Forward and backward impeller

Oven impeller

Oven impeller

Radiator impeller

Double inlet multi-wing type

Multi-wing impeller

Voltage

High speed impeller

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.