Metal Inner Spinning & Flanging Machine For ventilation And Fans

Metal Inner Spinning & Flanging Machine For ventilation

✔ Advantage: 15 Years Of CNC Metal Spinning Machine R&D, Production, And Sales;

✔ Application: wall-mounted axial fan, roof fans , kitchen fans, Box fans, HVAC Condenser Fan, Frame axial flow fan…

✔ Material : Aluminum, Copper, carbon steel, iron, stainless steel;

✔ Spinning Software: Free Supporting Machine, No Need To Write Program Code Manually.

✔ High Efficiency: The Automated Processing Flow Greatly Improves Production Efficiency.

✔ Solution customization: 7*24 Online Service, Engineer Video Online Conference To Solve Pre-Sales Problems.

Industrial Fans A-Z Project:

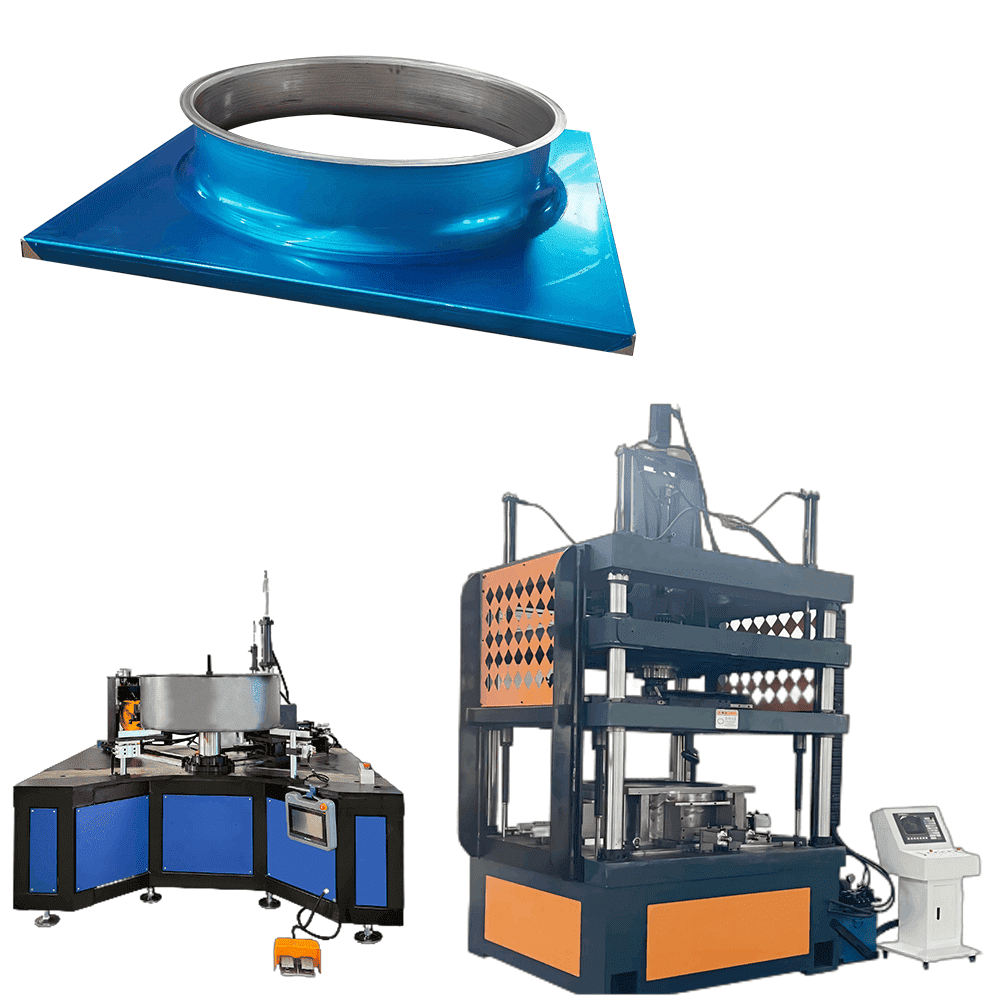

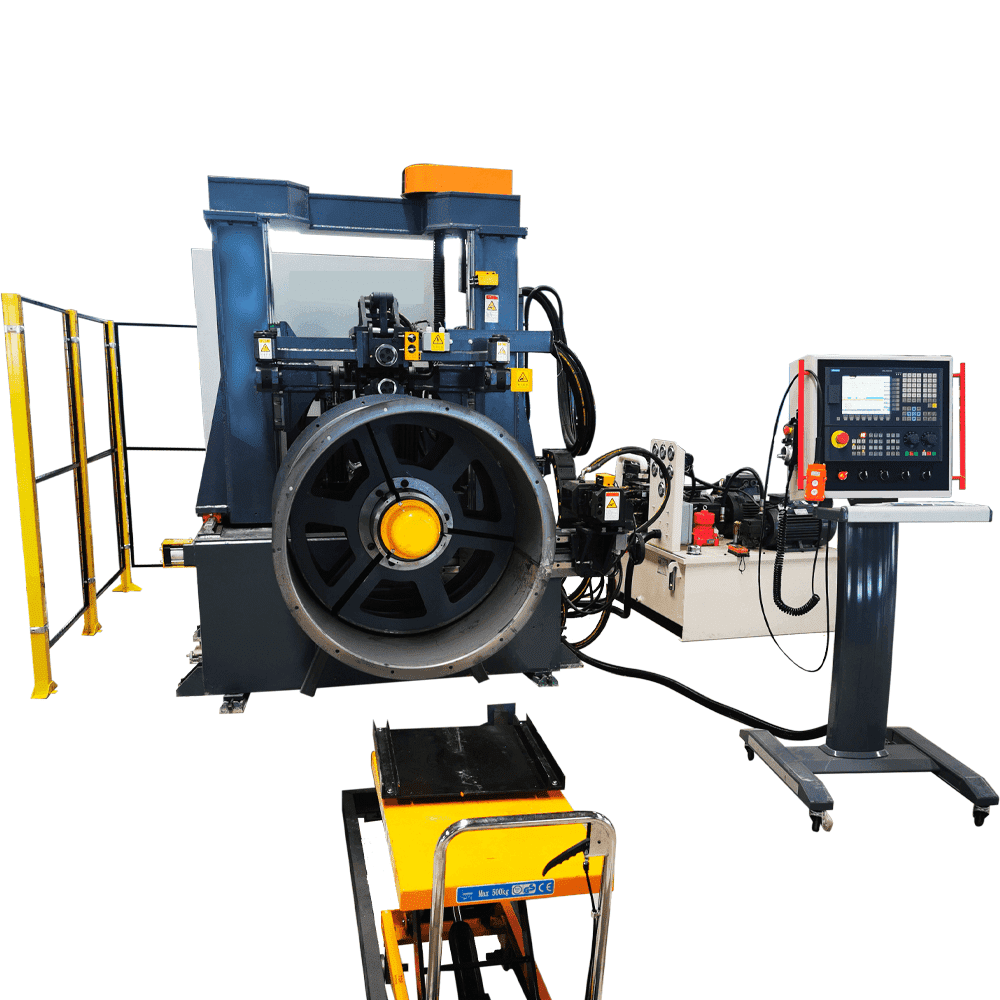

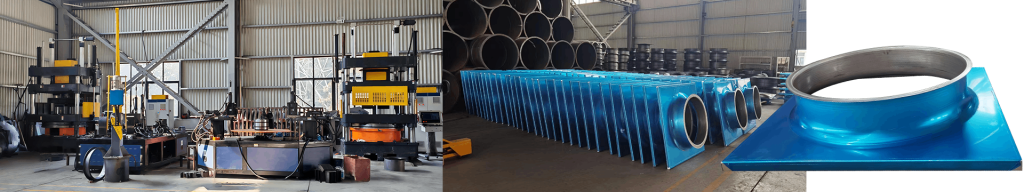

CNC Inner Spinning Machines CNC Flanging Machines PLC Flanging & Puching Mchines

Metal Inner Spinning & Flanging For Ventilation and Fans

In the fan ventilation industry applications such as wall-mounted axial flow fans, roof fans, kitchen fans, box fans

HVAC condensing fans, frame axial flow fans, external rotor fans, axial flow fans with plate rings, there is a square metal shrouds part that needs to be processed by Metal Inner Spinning Machine and Flanging Machine!

What is the internal metal spinning process? What is the difference from traditional spinning!

Traditional ordinary metal is made by fixing a metal disc or workpiece in a mold and rotating it. The metal spinning roller rolls from the outside of the plate to make the metal plastically deformed, so as to form a metal rotating body workpiece!

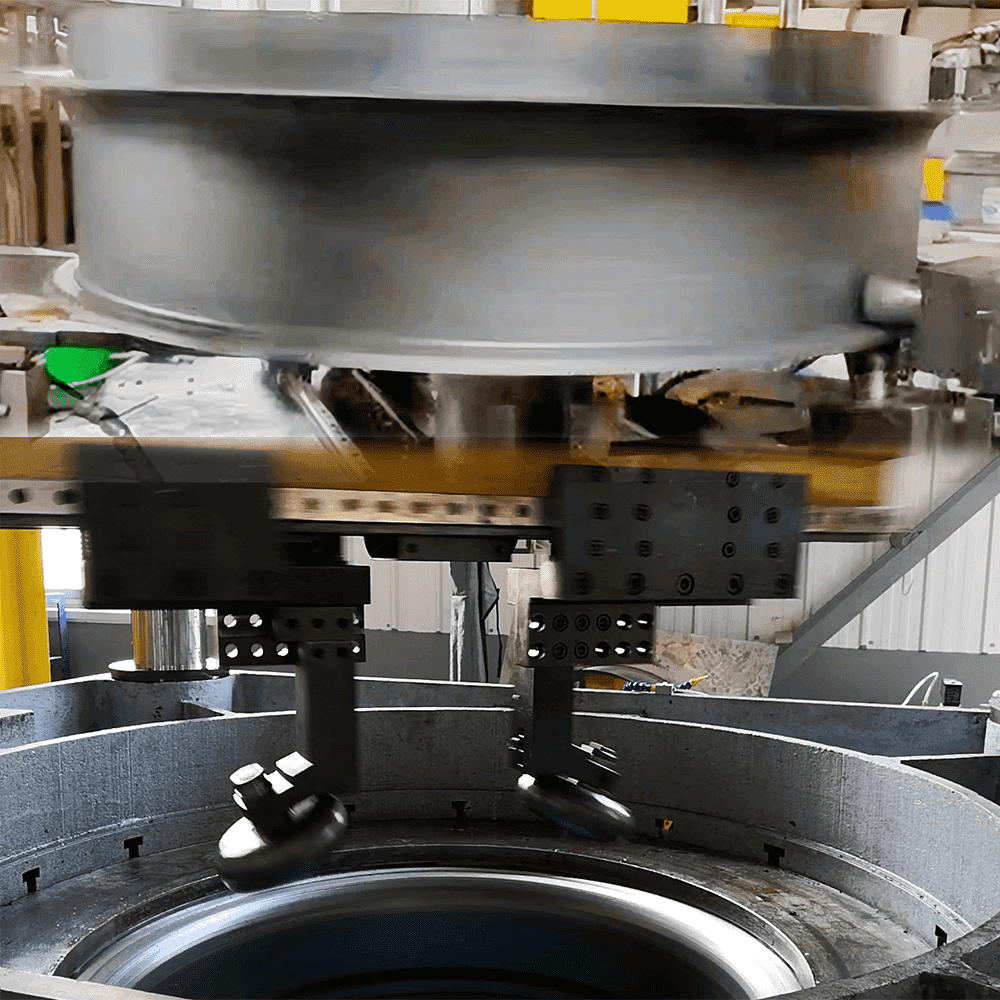

Metal internal spinning is exactly the opposite of traditional metal spinning! It is to fix the directional or shaped metal sheet in a mold or a special tooling. The CNC program controls the spinning roller and the mechanism to produce a rotating motion. At the same time, the entire spinning mechanism needs to roll from the inside to the outside according to the program to achieve 3-axis synchronous operation, and gradually form the metal sheet with a smaller diameter of the inner hole into a concave shape!

CNC Internal Metal Spinning Machine Working Video

Advantages of internal metal spinning machines:

- The flatness of large flange edges is eliminated after processing;

- Products with square anisotropic flange edges can be processed;

- The flange edge holes can be completed before laser cutting;

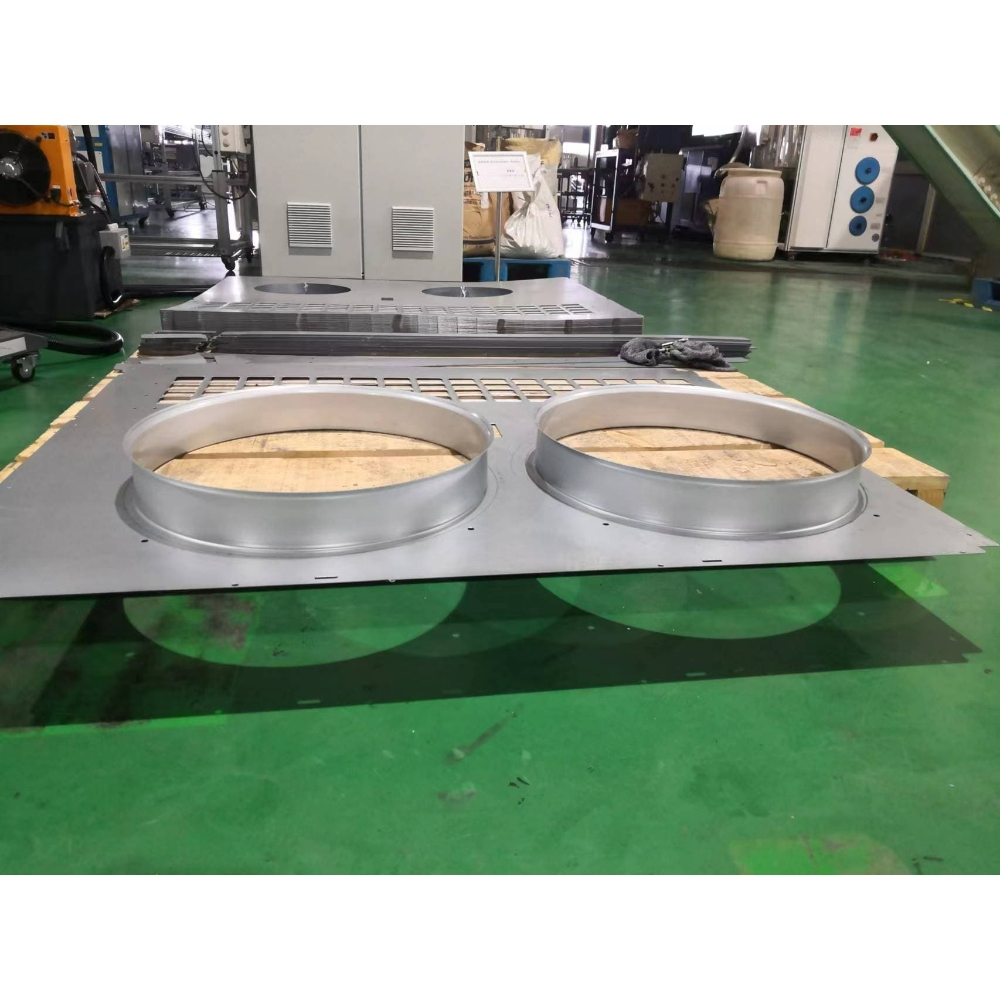

How To Flanging And Punching After Inner Metal Spinning?

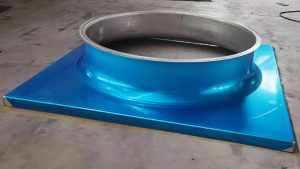

After the inner spinning of the square metal panel is completed, it is transferred to the flange flanging machine for the next processing step: the designed and manufactured inner dimension tightening mold corresponding to the inner hole diameter is installed on the flange flanging machine. The main shaft rotates and the flanging roller flanging the outer edge flange, which plays the main role in strengthening the structure. At the same time, the indexing punching is completed on the machine!

PLC Flanging machine working videos:

Metal Inner Spinning & Flanging Can Be Used In Those Industries:

|

|

|

|

|

|

|

|

|

Wall-Mounted Axial Fan

|

Metal Inner Spinning & Flanging Machine For ventilation And Fans Metal Inner Spinning & Flanging Machine For ventilation And Fans |

If you are manufacturing this type of industrial fans and ventilation and refrigeration equipment, please contact Altron and customize a reasonable solution based on your actual production situation!

Advantages Of Using Internal Metal Spinning Machines And Flanging Machines To Process Square Fan Parts

- Compared with traditional deep drawing molds, the development cycle is short;

- The mold cost is low, accounting for only 10% of the deep drawing mold;

- Simple shape contour modification and timely adjustment of fan performance;

- The mold structure is highly versatile, suitable for early development and small and medium-sized batch fan orders;

Internal Spinning Machine Processing Capacity Range:

- Internal spinning contour range: straight edge, arc, small amplitude trumpet expansion buckle;

- Inner hollow diameter: 300-1500mm

- Material thickness: 1-3mm

- Internal spinning depth: 200mm (depending on the size of the inner hole and the ductility of the material)

- Burning mouth width: 20mm Max

- Sheet width: 1600mm Max

- Sheet length: no limit;

- The narrowest flange edge is 65mm Min;

- Single-hole or multi-hole square metal fan panels, air conditioning ventilation guide plates, centrifugal fan inlet funnels, impeller shrouds, roof fan bases, etc. can be processed;

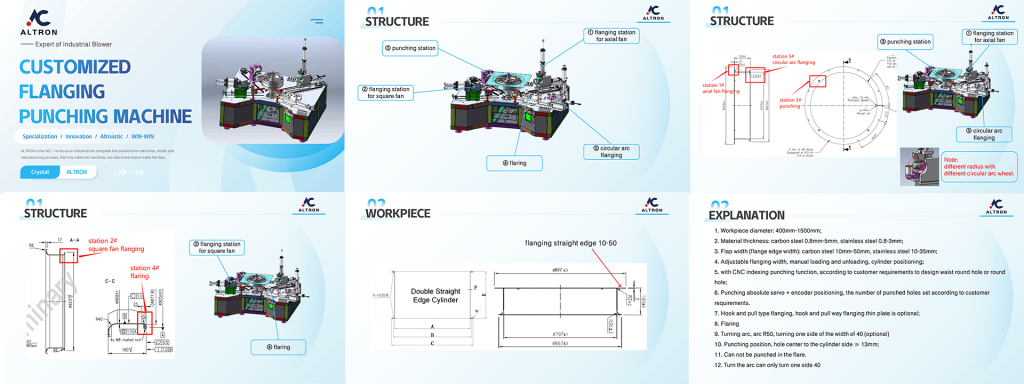

Customized square plate flanging machine for ventilation fan industry:

Showing the machine design and details of Altrom for a famous fan manufacturer in Germany. The machine can realize multiple functions and actions at the same time:

- Clamping type flanging (flanging with a thickness of 2mm or more)

- Hook-pull type flanging (flanging with a thickness of less than 2mm)

- Flanging of small bell mouth

- Gradually punching with laser sensor can automatically find the weld seam, making the punching neat and beautiful!

This is a multi-functional PLC automatic flanging machine, which can still produce standard axial flow fan ducts. This is a practical and wide flange flanging machine, especially in the field of industrial fans and ventilation!

Altron’s Factory Video

please contact me and Joby engineers will give you a detailed plan.