Spiral Duct Forming Machine (Steel strip mould)

Spiral Duct Forming Machine For Steel Strip Mold

|

Machine Name |

Spiral Duct Forming Machine |

|

Model |

AC-LXFG(Steel strip mould) |

Relevant Files

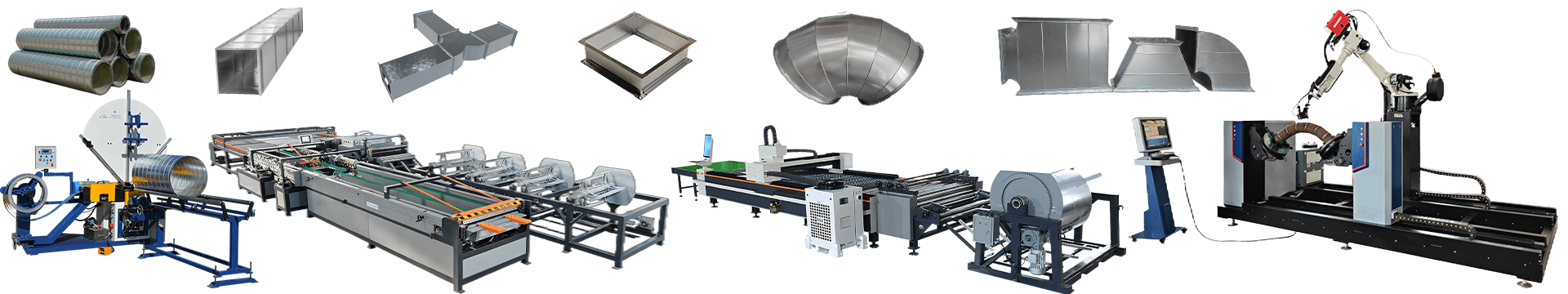

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project

Air Duct A-Z Project:

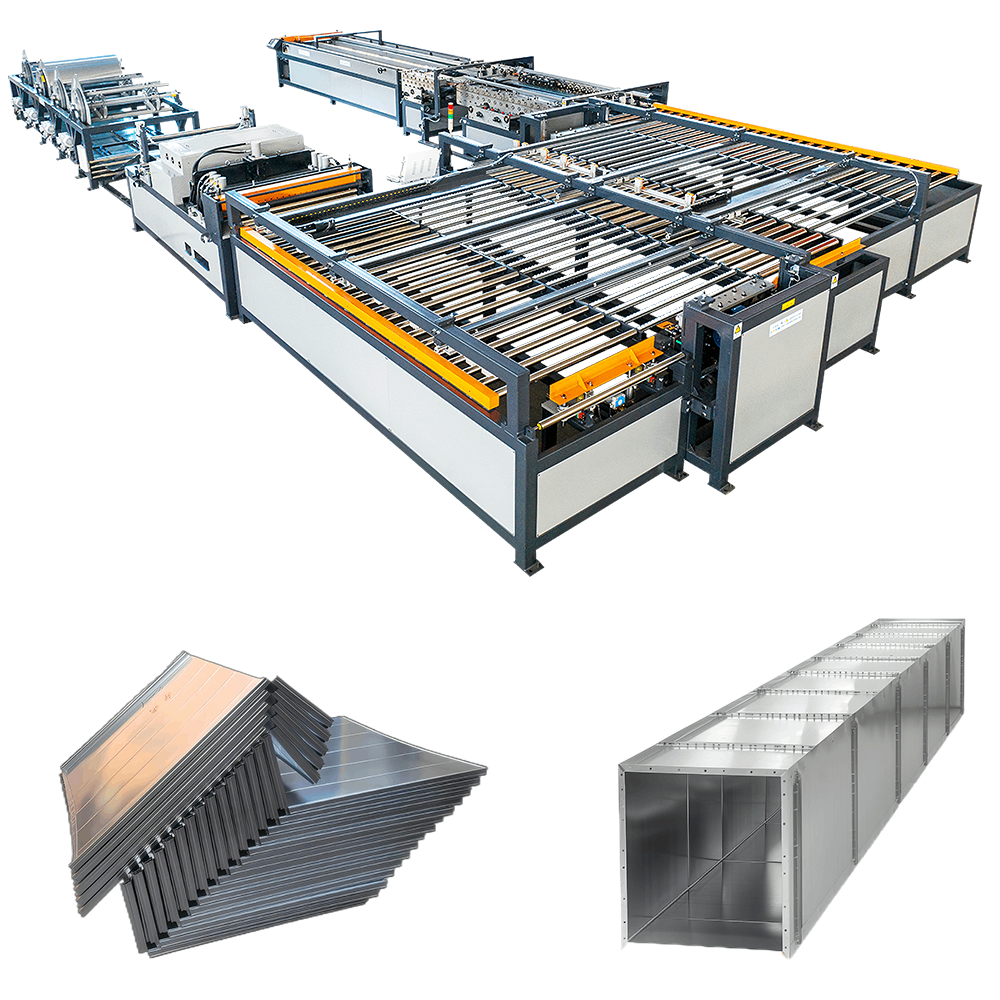

1 Rectangular duct forming line

2 Continuous laser cutting production line

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

The Spiral Duct Forming Machine is a specialized equipment designed for the efficient fabrication of round air ducts commonly used in HVAC systems. It employs a precise and automated process to transform flat sheets of metal into spiral ducts of various diameters and lengths, catering to diverse installation requirements.

Main technical features of spiral duct machine:

- Efficient production: The spiral duct machine bites out the bite bone shape through the strip steel strip coil at one time, and rolls it into a round tube along the spiral involute trajectory, while pressing the bite seam. This production method enables the spiral duct to be formed in one go without secondary processing, which greatly improves production efficiency.

- Excellent performance: The spiral duct has the characteristics of no welding, no air leakage, no water leakage, low noise, and low ventilation resistance. It has high pressure strength and can withstand high pressure loads without loss of deformation. In addition, the spiral duct has good sealing and small leakage, which reduces daily operating costs and energy consumption.

- Wide application: Spiral ducts are widely used in shipbuilding, ventilation, air conditioning, purification, bridge dust removal, airports, tunnels and other construction industries due to their excellent performance and low cost. Whether it is delivering cold air, hot air or exhausting oil smoke, or even the transportation of bulk materials, spiral ducts can do it.

- Easy installation: Spiral ducts are easy to install, with few contact points, small installation space and low installation cost. The manufacturer also adopted the methods of reducing sleeve, sleeve connection, flange connection, and belt connection to further simplify the installation process.

- Energy saving and environmental protection: The cross-section wetted perimeter of the spiral duct is small, the resistance along the way is small, and the energy loss is small. In the central heating project, the use of spiral duct as the outer layer of the heat preservation layer of the hot air pipeline can make the pipeline have a long service life and good quality.

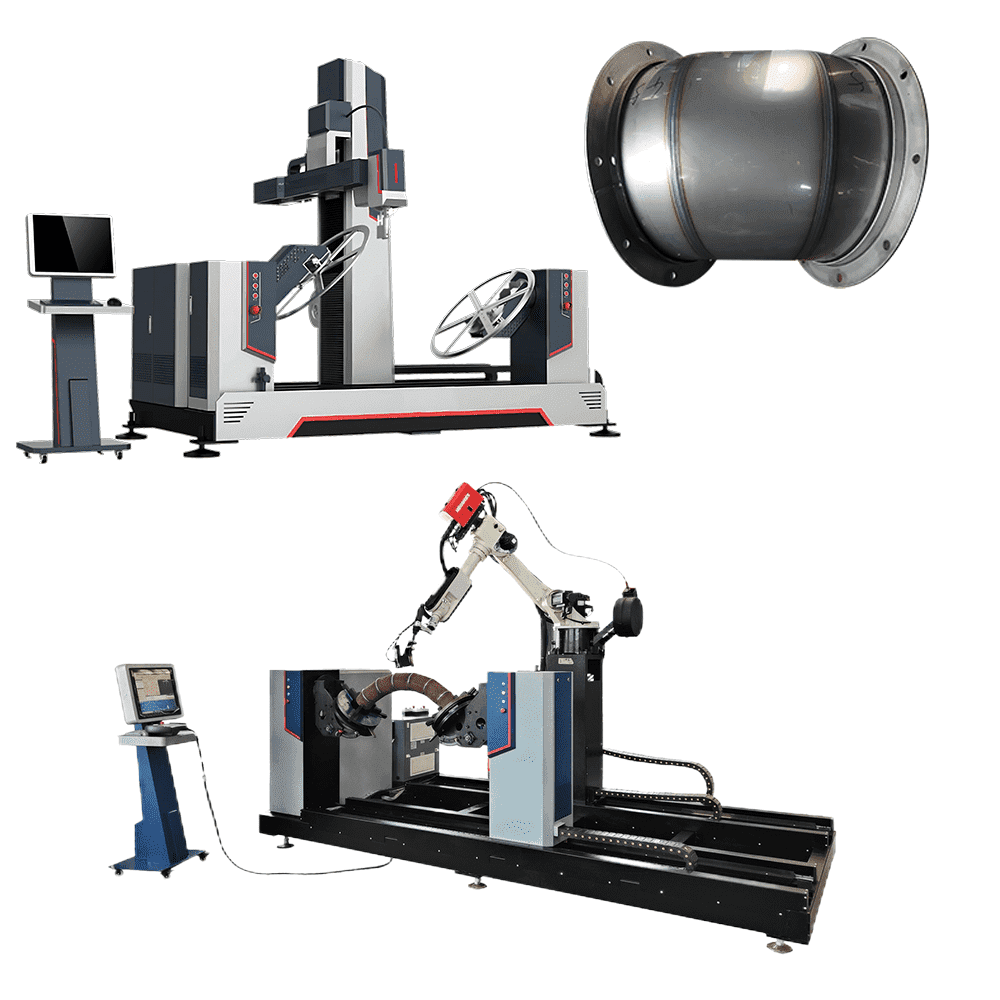

The main differences between the steel strip forming mold and the fixed mold in the spiral duct forming machine are:

1. Materials and applications: The steel strip forming mold is made of steel plate and is mainly used to shape the steel strip material into a spiral shape; while the fixed mold may be made of a variety of materials, and its design focuses more on maintaining the stable structure and size of the duct.

2. Functional characteristics: The steel strip forming mold is suitable for continuous and efficient production processes due to its high strength and wear resistance; the fixed mold focuses more on accuracy and stability to ensure that the formed spiral duct has a standard size and shape.

3. Operation and maintenance: The steel strip forming mold may need to be replaced or maintained regularly to adapt to different production needs; once the fixed mold is installed, it is usually more stable and requires less adjustment and maintenance.

How to choose the mold process for spiral duct machine? Fixed mold or steel strip mold?

Choose fixed mold to produce spiral duct

The mold size is fixed to produce spiral ducts with fixed specifications! The production efficiency is high, the mold installation is simple, and the duct quality is relatively stable. The disadvantage of the fixed mold is that the flexibility is low.

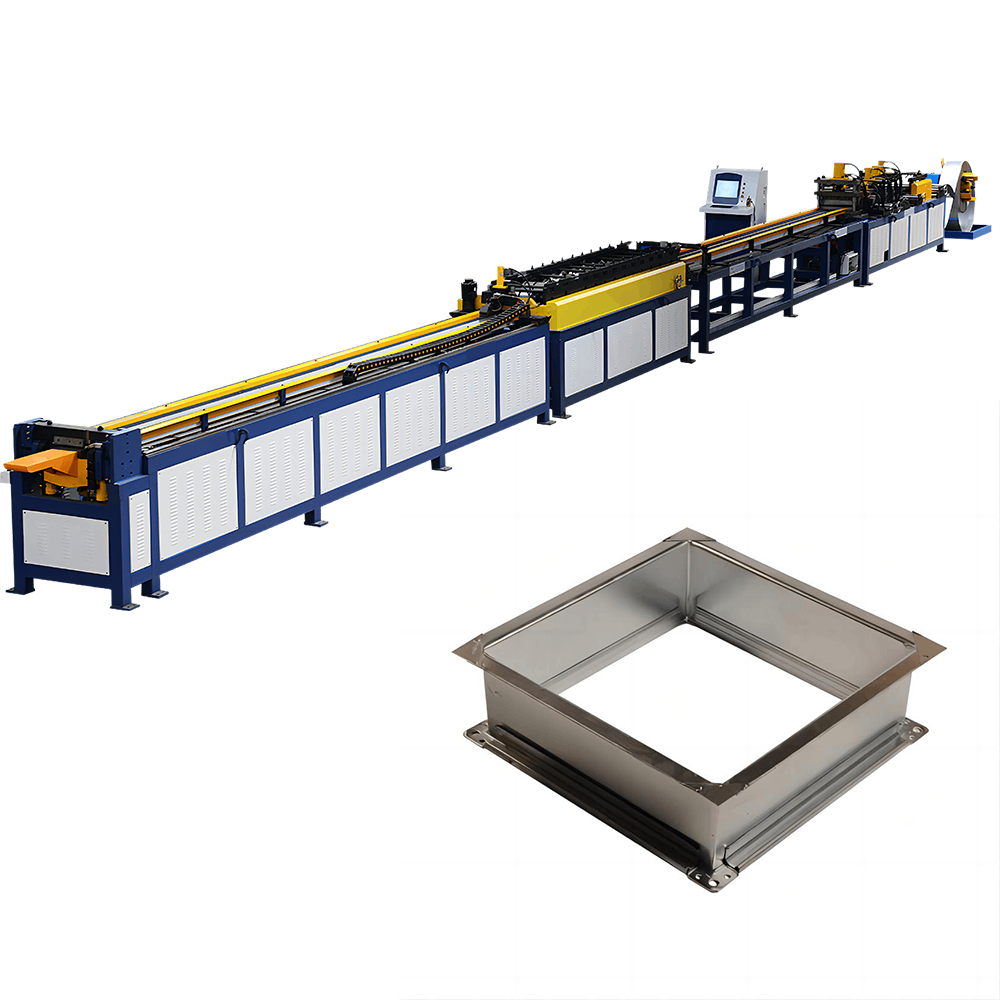

Choose steel strip mold to produce spiral duct

The steel strip mold provides a more flexible production method. Adjusting the steel strip and replacing different sizes of steel strips can produce spiral ducts of different sizes. The production of different sizes is highly flexible, and the cost of the steel strip is relatively cheap.

Altron is the choice of spiral duct manufacturers

Fixed molds are suitable for mass production of spiral ducts of a single specification, and steel strip molds are suitable for the production of spiral ducts of various specifications and sizes.

Spiral Duct Production Video

| Model No. | AC-LXFG(Steel strip mould)1500 |

| Tube Diameter | 80-1500mm |

| Tube Length | 120-8000mm |

| Suitable Material | galvanized steel, stainless steel, aluminum |

| Thickness of Strip | 0.4-1.2mm (galvanized steel) |

| Width of Strip | 137-140mm |

| Strip Speed | 1-45m/min |

| Lock Seam | outside tube |

| Controlling System | PLC automatic control |

| Main Motor Power | 5.5KW |

| Cutting Motor Power | 4KW |

| Cutting System | sawing cutting |

| Weight | 2200KG |

| Packing Dimension | 2700×1700×2300mm |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Spiral Duct Forming Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Spiral Duct Forming Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.