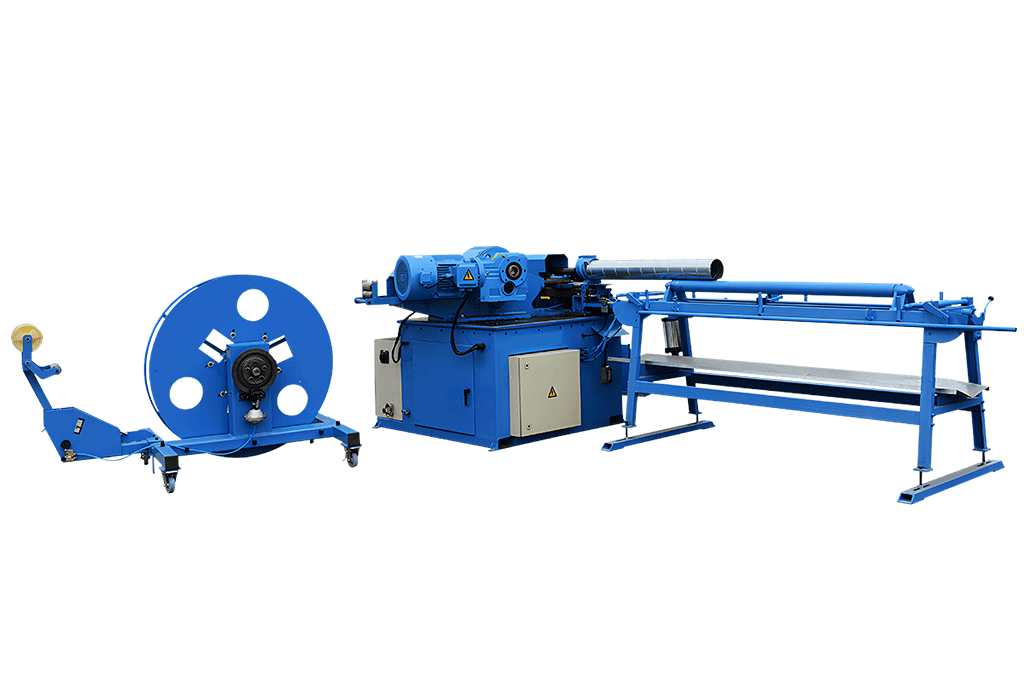

Spiral Duct Forming Machine ( Fixed mould)

Spiral Duct Forming Machine For Fixed Mould

|

Machine Name |

Spiral Duct Forming Machine |

|

Model |

AC-LXFG(Fixed Mould) |

Relevant Files

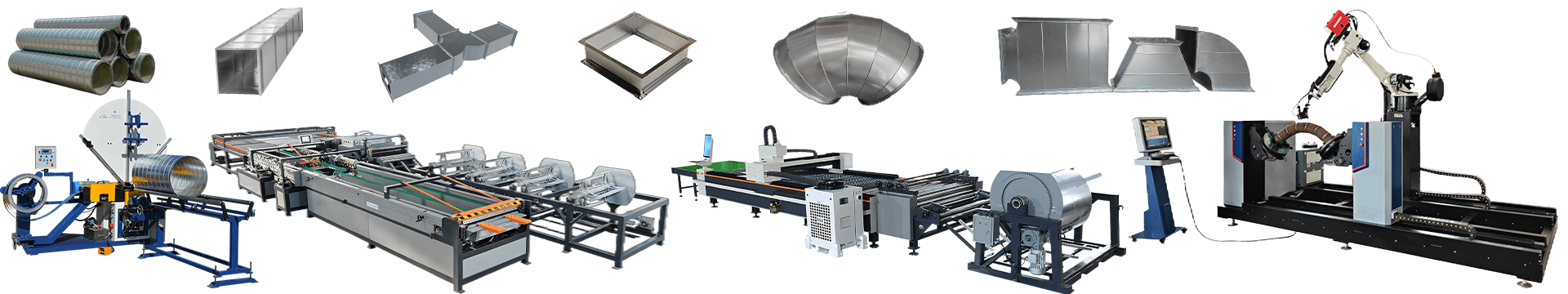

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project

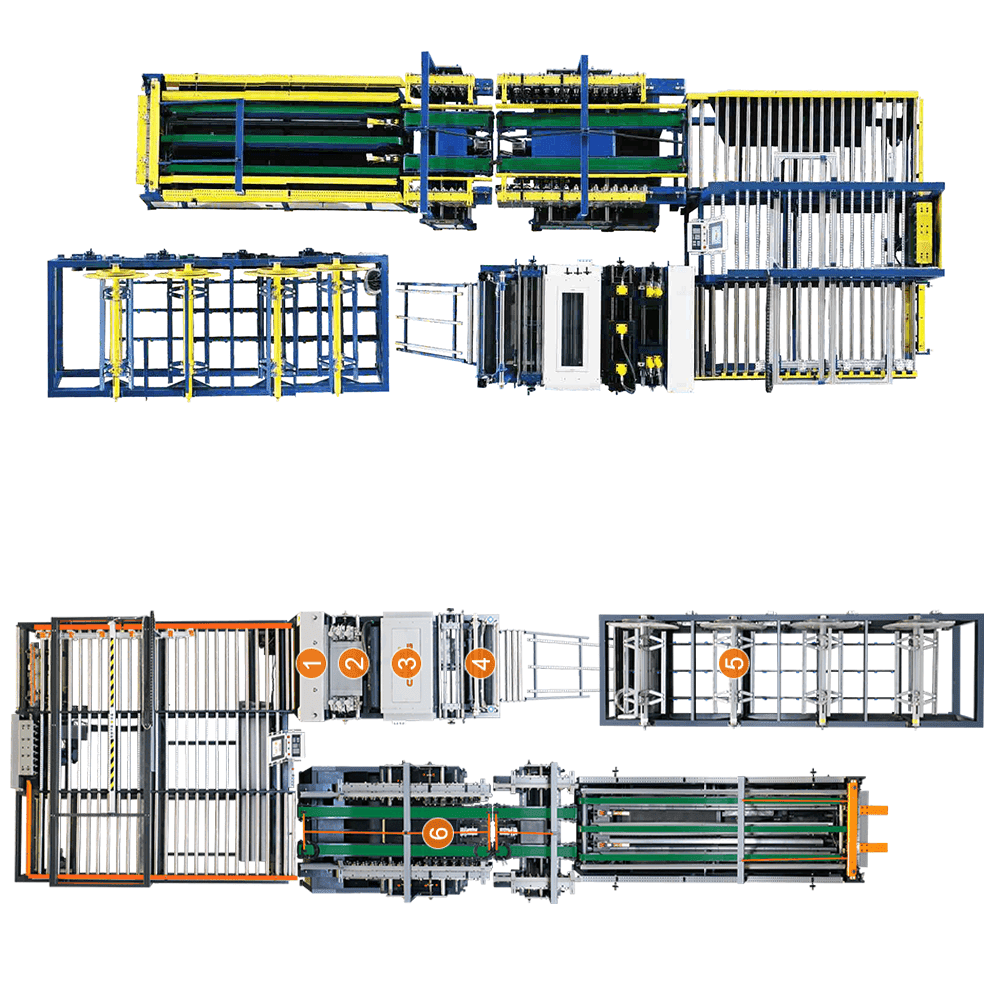

Air Duct A-Z Project:

1 Rectangular duct forming line

2 Continuous laser cutting production line

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Advantages of fixed mold spiral mold

1. High-precision processing:

The precise spiral duct mold design ensures uniformity and stability in the forming process from sheet to pipe. The high-precision spiral processing method makes the forming of duct products simple and more competitive in the market.

2. High-efficiency production:

The design of the fixed mold reduces the time for changing and adjusting the mold, and improves the production and efficiency of changing different duct sizes. In the steel belt mold, changing the size requires testing and parameter adjustment of the duct.

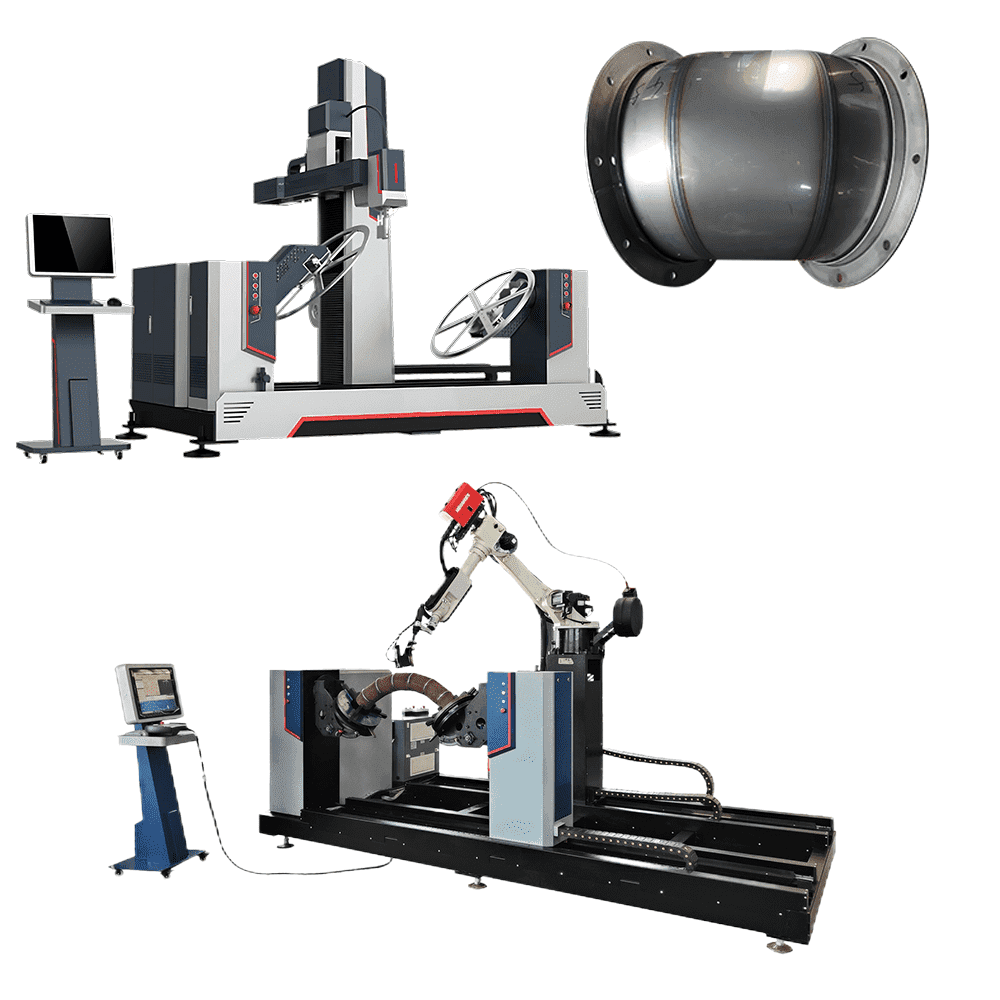

How to cut spiral duct?

Spiral Duct Forming Machine For Fixed Duct Mold mainly has two cutting methods, rolling cutting and plasma cutting!

Rolling cutting is suitable for thinner materials;

Plasma cutting is suitable for large diameter spiral ducts and thicker wall materials! For diameters greater than 1100mm and material wall thickness greater than 1mm, plasma cutting must be used.

Spiral Duct Production Video

Reference for production time of spiral duct: 800 diameter, 3m length:

3 minutes for making spiral duct, 2 minutes for plasma cutting (5 minutes per duct).

8 hours of working time can produce 96 ducts of 800 diameter spiral duct (about 85 ducts are calculated after debugging). The square number of 800 diameter spiral duct is 640

| Model No. | AC-LXFG(Fixed Mould)1602 |

| Tube Diameter | 80-1600mm |

| Tube Length | 120-8000mm |

| Suitable Material | galvanized steel, stainless steel, aluminum |

| Thickness of Strip | galvanized steel: 0.4-1.2mm stainless steel: 0.8mm aluminum: 0.4-1.2mm |

| Strip Width | standard 137mm up to 1mm thickness, 140mm above. Other widths on request |

| Production Speed | Max. 80M/min, depending on material |

| Lock Seam | outside tube |

| Cutting System | the patented flying slitter |

| Options | with automatic control system & length roller shear cutting device |

| Net Weight | 2900KG |

| Gross Weight | 3200KG |

| Packing Dimension | 3050×2000×1800mm |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.