U Shape Auto Duct Forming Line 5

Air Duct Forming Line For Ventilation Duct

|

Machine Name |

Air Duct Forming Line |

|

Model |

AC-FG-U5 |

|

Application Industry |

Rectangular ventilation duct |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

Air Duct A-Z Project:

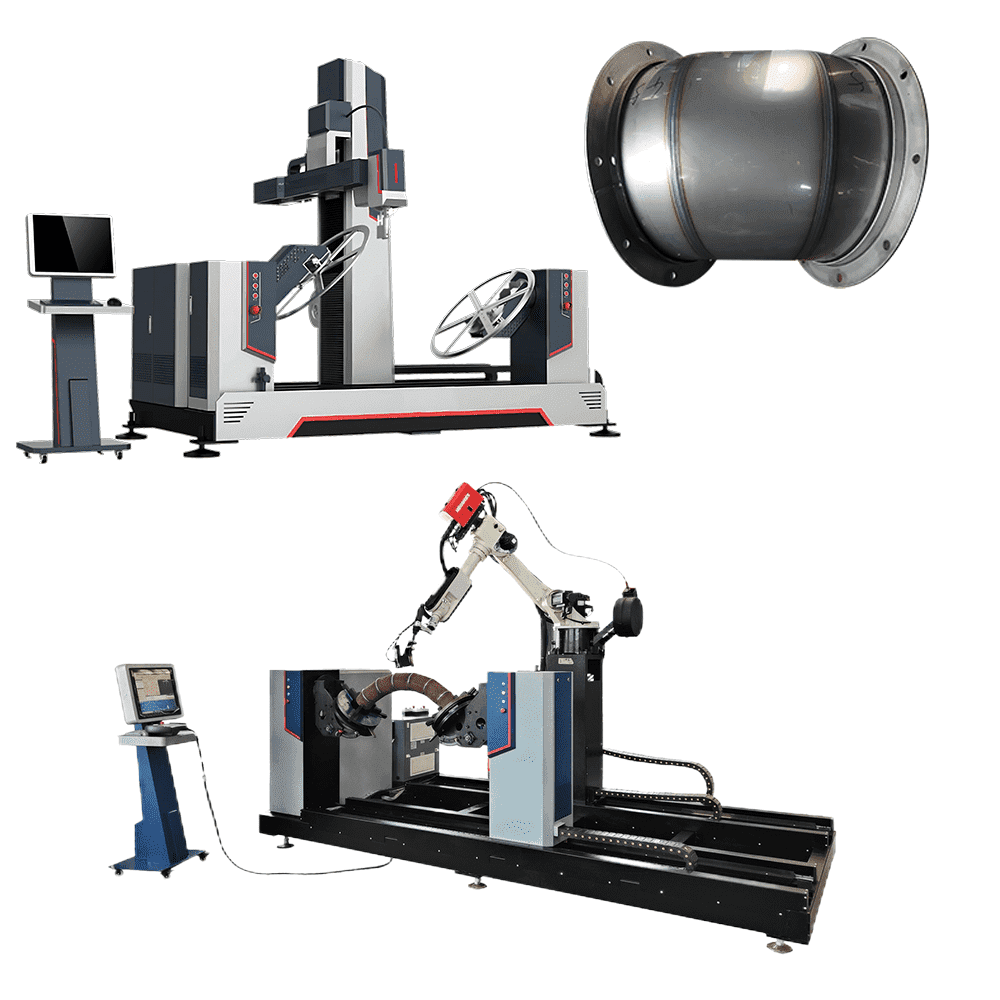

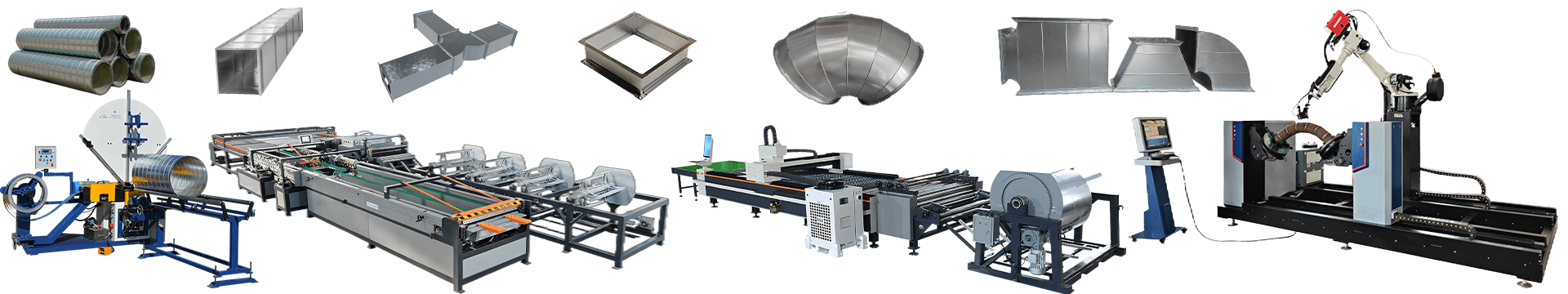

1Rectangular duct forming line 2 Continuous laser cutting production line 3Spiral duct production line 4 Damper housing production line 5 Rectangular duct welding 6 Elbow duct welding

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

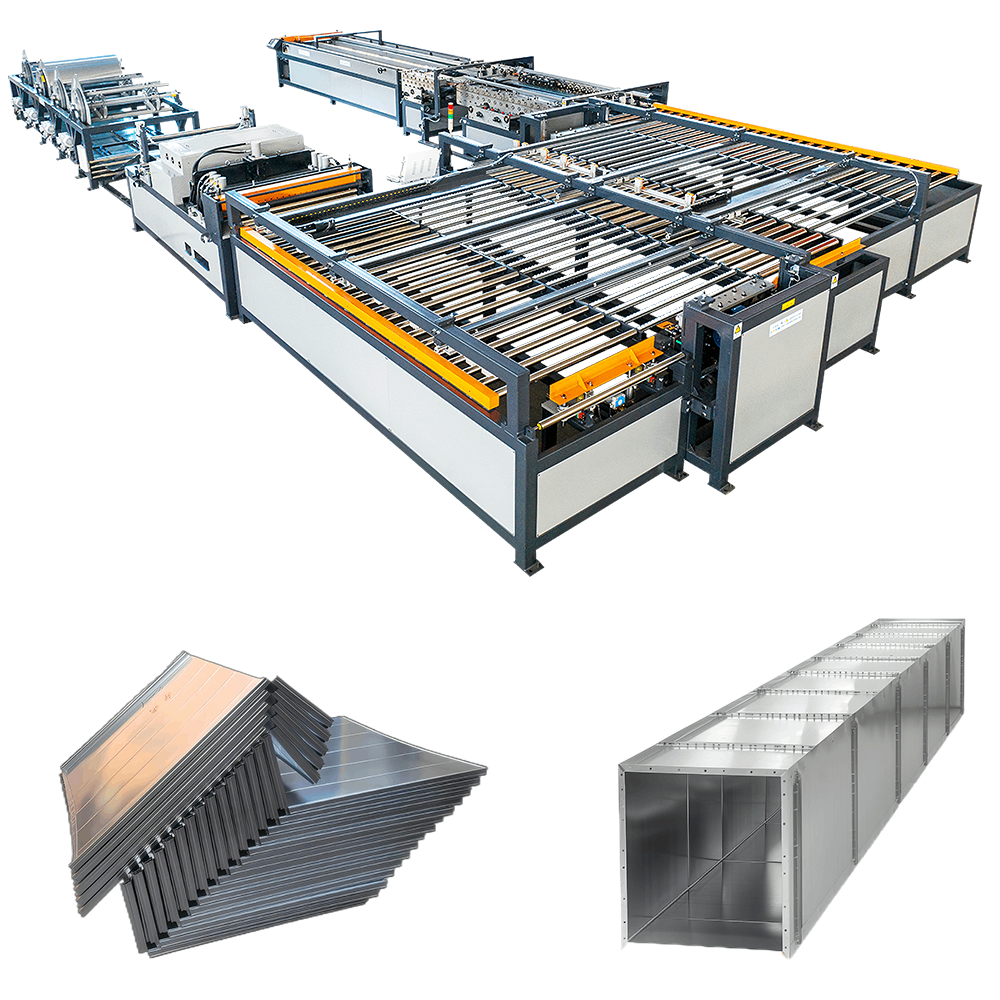

U-shaped automatic duct forming line 5 is for rectangular duct manufacturers to increase duct production output and upgrade the factory to an unmanned automated production workshop!

The daily output of the production line for forming TDF flange/angle iron flange or “C” type flange duct is 600 to 2500m².

During production, the size of the processed duct is input, and the U-shaped automatic duct forming line 5 fully automatically completes sheet unwinding, material leveling, duct edge pressing, duct slotting and punching (punching), shearing, high-speed Pittsburgh lock forming, TDF flange forming/angle iron flange forming, “C” type flange forming, plugging function, servo folding forming.

The U-shaped automatic duct forming line 5 can be equipped with an 8-ton or 10-ton hydraulic unwinder to increase the single coil processing cycle of the duct production line.

An automatic unloader can also be selected at the end of the production line to realize the unmanned production line.

U Shape Auto Duct Forming Line 5 Features:

- Small floor area and material processing saving mode;

- The folding platform adopts servo feeding, accurate positioning;

- Adopt touch screen and keyboard input dual mode;

- Simple and convenient for blank sheet opening;

- Support stainless steel welding duct processing mode;

- Export and print production record data (optional);

- Data exchange with BIM (optional);

- Support hole punching, TDF flange hole punching and square beading function (optional);

- “C”shape flange and plugging function (optional);

- Pittsburgh lock forming in front (optional).

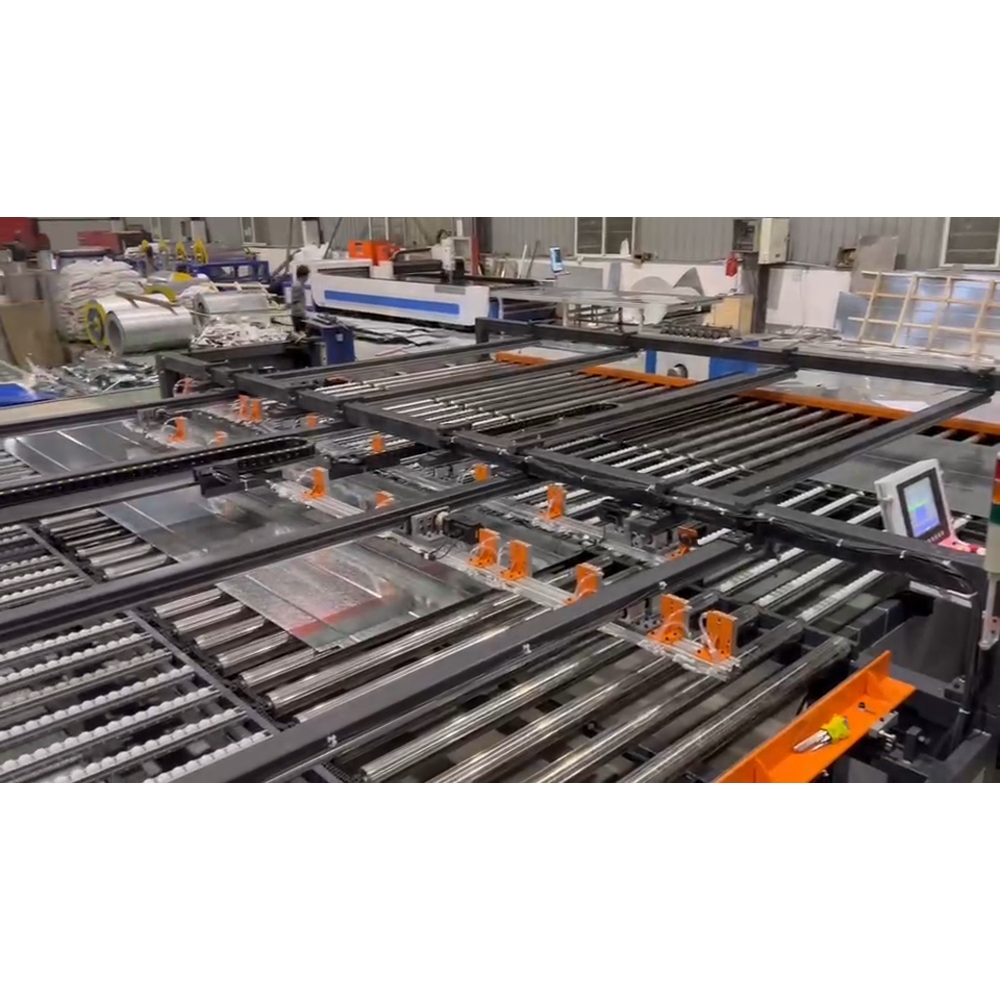

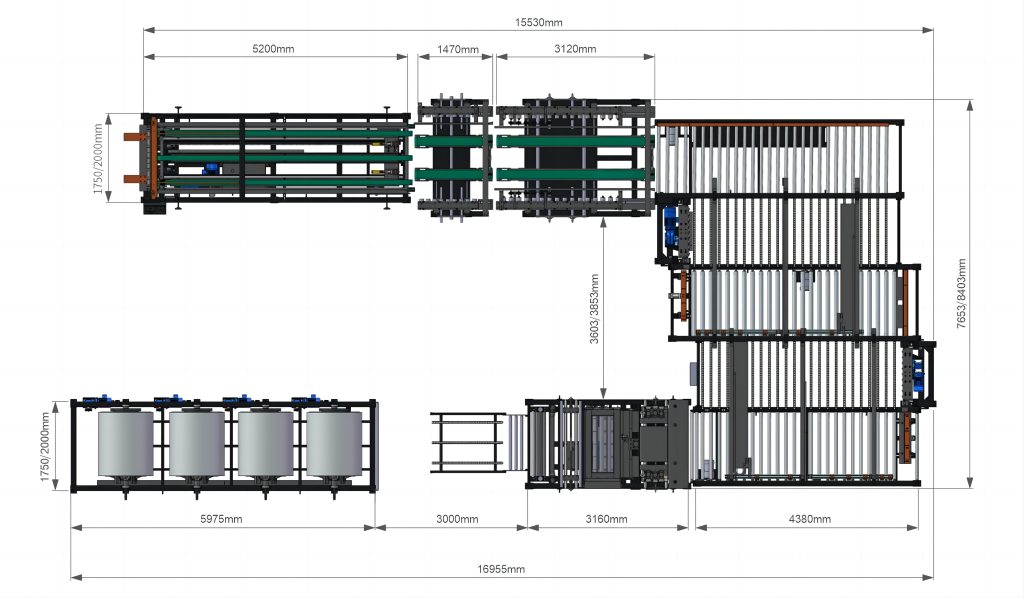

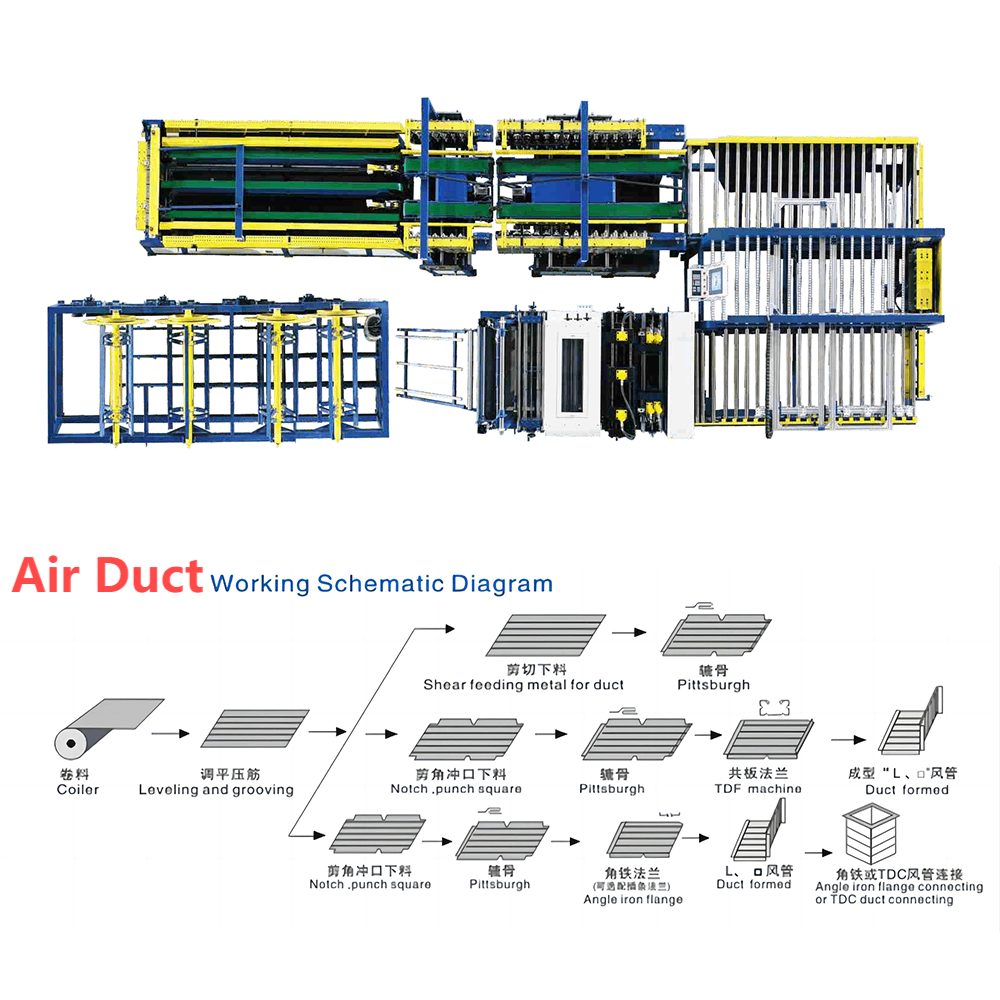

U Shape Auto Duct Forming Line 5 Work Flow

- Decoiler(total 4 coilers)

- Main machine(leveling,beading,notching,shearing)

- Transferring platform01

- Movable high-speed Pittsburgh lock-forming machine

- Transferring platform 02

- Duplex TDF flange forming machine

- Seno moto driven material feeding and folding platform or(C shape flange)

- Servo motor material feeding platform and hydraulic folding

Duct production steps:

Unwinding → Laminating → Leveling → Beading → Punching (middle hole, flange hole) → Punching corners (pointed mouth, square mouth) → Cutting to size → Transfer platform → Biting platform → Double-machine linkage common plate flange (TDF) forming → Angle steel flange small right-angle edge forming → Robot servo feeding and folding forming → Discharging

U Shape Auto Duct Forming Line 5 video

U Shape Auto Duct Forming Line 5 Details

Different Types Of Air Ducts Sample

|

|

|

|

|

| Model No. | Material and Thickness (mm) |

Max. Width (Standard) (mm) |

Max. Working Speed (m/Min) |

Coiler Max. Weight (KG) |

Dimensions (L×W×H) (mm) |

Power (KW) |

Weight (KG) |

| AC-U5-1250 | 0.5-1.2/Galvanized steel | 1250 | 15 | 7000 | 14500×4950×1500 | 36 | 12500 |

| AC-U5S-1250 | 0.5-1.5/Galvanized steel 0.5-1.0/Stainless steel |

1250 | 15 | 7000 | 16000×4950×1500 | 39 | 13500 |

| AC-U5SS-1250 | 0.5-1.5/Galvanized steel 0.5-1.2/Stainless steel |

1250 | 15 | 7000 | 17000×4950×1550 | 45 | 16000 |

| AC-U5-1500 | 0.5-1.2/Galvanized steel | 1500 | 15 | 7000 | 14500×5500×1500 | 36 | 13500 |

| AC-U5S-1500 | 0.5-1.5/Galvanized steel 0.5-1.0/Stainless steel |

1500 | 15 | 7000 | 16000×5500×1500 | 39 | 15000 |

| AC-U5SS-1500 | 0.5-1.5/Galvanized steel 0.5-1.2/Stainless steel |

1500 | 15 | 7000 | 17000×5500×1550 | 45 | 17500 |

Basic parameters of U Shape Auto Duct Forming Line 5

01) Material: ordinary low carbon steel cold plate, galvanized plate, stainless steel plate

02) Plate thickness: 0.5-1.2mm (stainless steel), 0.5-1.5mm galvanized plate (ordinary carbon steel)

03) Coil width: 1219mm/1250mm

04) Coil weight: 7000kg

05) Coil inner diameter: Φ480-Φ600mm

06) Coil outer diameter: Φ1200mm (maximum)

07) Feeding speed: 15m/min (maximum)

08) Single duct sheet unfolded length: 600mm-4000mm

09) Sheet length error range: ±0.5mm

10) Duct bending error range: ±1mm

11) Rib: standard “V” type (Slope spacing: 250mm)

12) Control system: Fully computerized industrial numerical control

13) Main power supply: 380V/50Hz/3 phases

14) Hydraulic pressure: 7-10MPa

15) Air pressure: 0.6-0.8MPa

16) Line operation mode: U-type

17) Overall dimensions: 17000×4850×1500mm

18) Total power: about 43kW

19) Total weight: about 16t

Air Duct Working Forming Principle Diagram

U Shape Auto Duct Forming Line 5 video

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

We have been using the Double-Roller Rounding Machine in our metalworking shop, and it has exceeded our expectations. The machine’s precision and efficiency have significantly improved our rounding process, saving us time and effort.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Its user-friendly interface makes it easy for our operators to achieve precise rounding results consistently. We highly recommend this machine to anyone in need of reliable and high-quality rounding

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The Double-Roller Rounding Machine has become an essential part of our fabrication process. Its versatility and efficiency have revolutionized the way we round materials.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We can now handle a wide range of materials with different thicknesses, and the machine consistently delivers precise rounding results. It has significantly improved our production efficiency and customer satisfaction. We are extremely pleased with this investment.

.jpg)