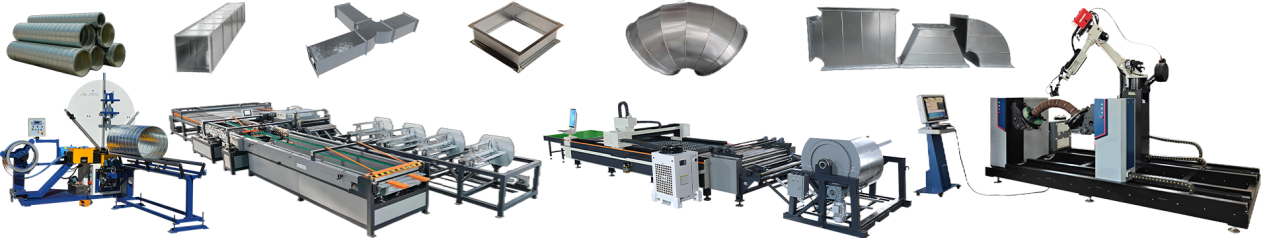

How to Make Rectangular HVAC Ducts?

Overview of Industrial HVAC Ducting

Industrial HVAC (Heating, Ventilation, and Air Conditioning) ducting systems are critical components in maintaining air quality and temperature control within commercial and industrial environments. These systems ensure the efficient distribution of air, whether heated or cooled, throughout buildings and facilities. HVAC ducts come in various shapes, sizes, and materials, with Rectangular HVAC Ducts being one of the most commonly used types due to their versatility and efficiency in space utilization.

Classification of HVAC Ducts

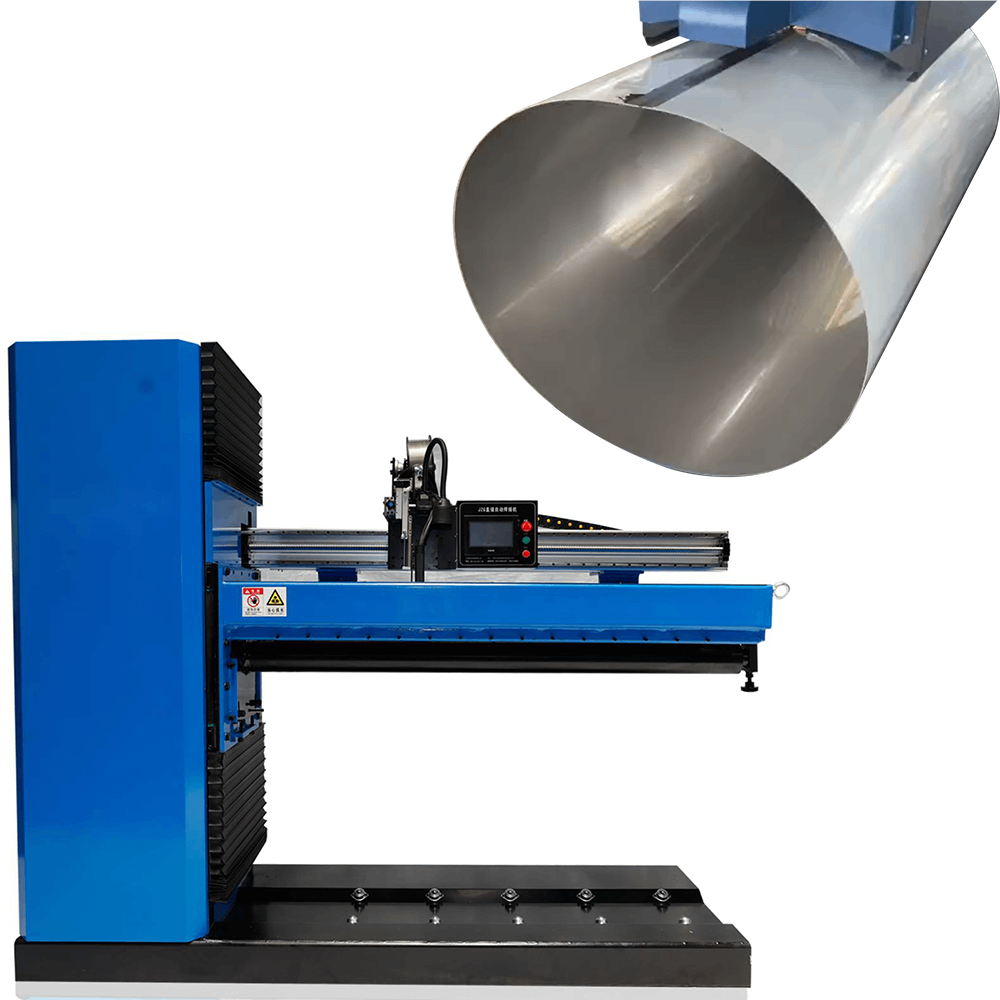

Manufacturing Spiral Duct

Spiral Duct Forming Machine

Altron’s Spiral Duct Forming Machine is at the forefront of innovation in the manufacturing of industrial Rectangular HVAC Ducts. As a leading R&D and production center, Altron provides comprehensive services to industrial fan and air duct manufacturers. Their Spiral Duct Forming Machine is a testament to their commitment to quality and efficiency.

Engineer Joby’s Contribution

Engineer Joby offers 7*24H online pre-sales meeting solutions, ensuring that clients receive the best technological guidance and support. This continuous availability is crucial for clients who need real-time solutions and technical assistance in their duct manufacturing processes.

Advantages of Fixed Mould Spiral Duct Machine

The Fixed Mould Spiral Duct Machine boasts several advantages, including a rapid feeding speed of up to 80 meters per minute. Each mold is designed to correspond to a specific pipe size, ensuring standardized dimensions without the need for adjustments. This machine supports materials like galvanized steel, stainless steel, and aluminum, with a strip thickness ranging from 0.4 to 1.2mm. The system is controlled by a PLC automatic control system and includes options for sawing cutting or the flying slitter. The duct diameters range from 50mm to 1600mm, and lengths can vary between 120mm and 8000mm.

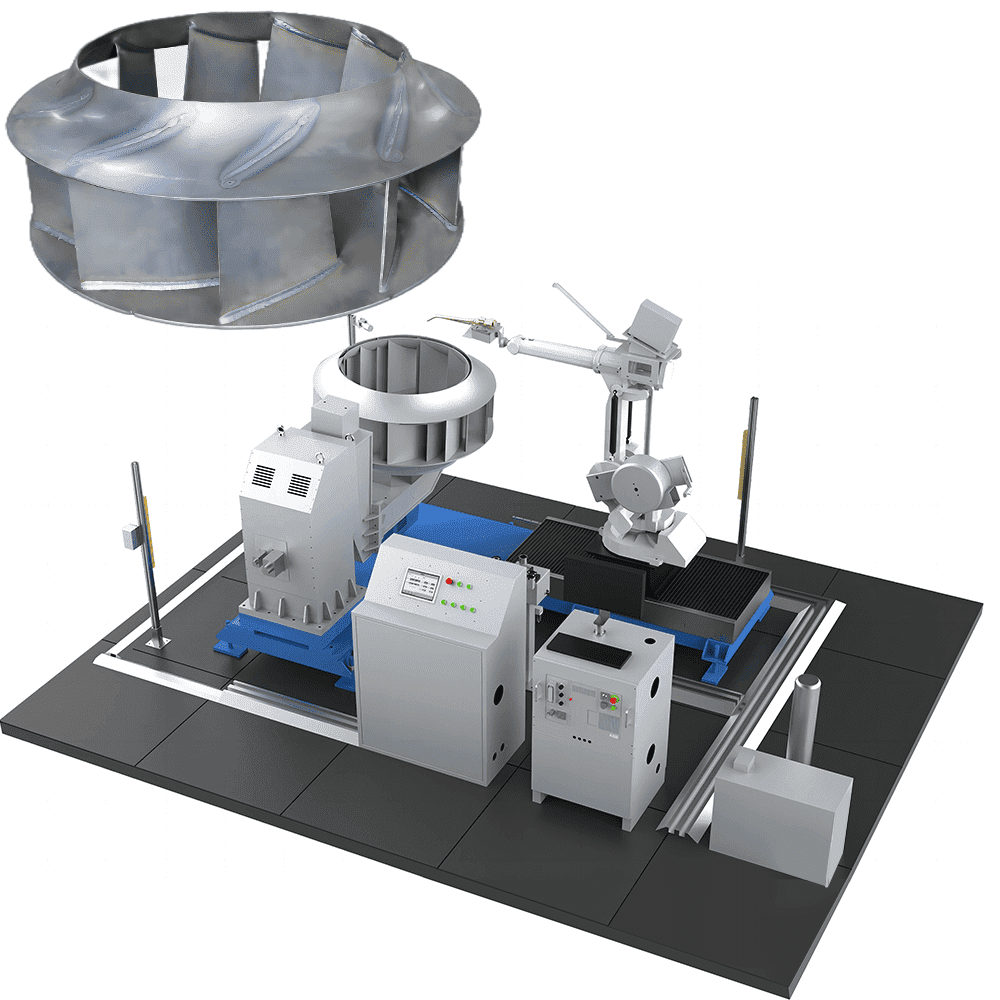

Automatic Welding of Rectangular Ducts

Robotic Laser Welding Machine

The robotic laser welding machine represents a significant advancement in the automatic welding of rectangular ducts. Designed to replace manual welding processes, this machine addresses the increasing costs and quality demands associated with traditional welding methods.

Components and Features

The machine consists of a six-axis robot ground track, a duct welding platform, and a visual query system, all controlled by an integrated control system. It can perform horizontal and vertical welding of duct flanges without human intervention. The double-station duct welding platform, equipped with a movable robot ground track, meets the needs of products of various specifications.

Automation and Efficiency

Through the use of program-parameterized input and visual laser detection, the machine automatically identifies weld positions and generates welding tracks. This process is managed via a touchscreen interface, featuring start, stop, and emergency stop buttons, ensuring user-friendly operation and enhanced safety.

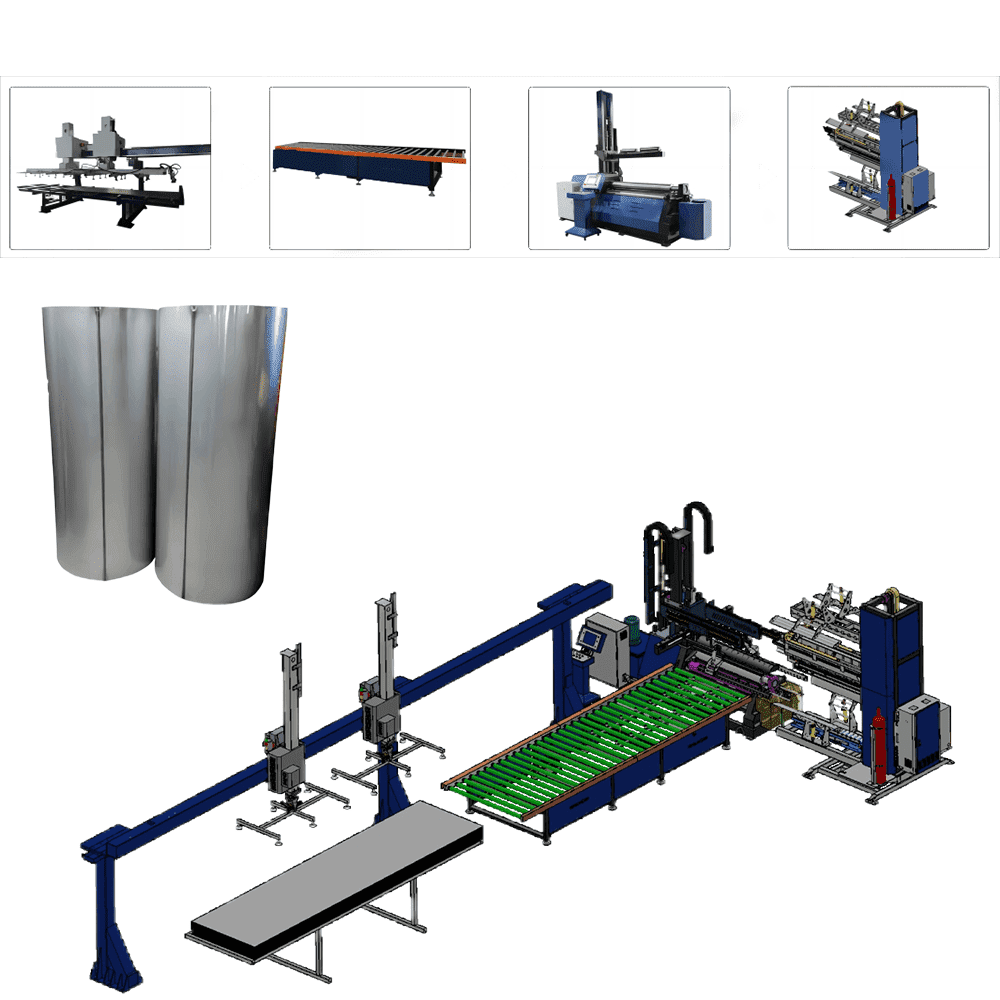

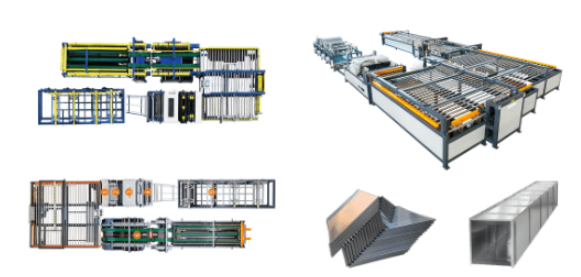

Rectangular Duct Forming Line

Comprehensive Production Process

Altron’s Rectangular Duct Production Line showcases their dedication to streamlined and efficient duct manufacturing. The production line handles the entire process from coiling to forming, including automatic feeding, laminating, rib pressing, punching, notching, flange formation, and duct plugging. This highly automated line can process ducts at a speed of 18 seconds per piece, with daily output exceeding 3,000 square meters.

Customization and Flexibility

Altron offers customized Rectangular HVAC Ducts production lines to meet specific client needs. Modules available include an integral or split de-coiler, single or double-sided laminating, V or square beading, and various punching options. The host machine module and flange module are also customizable, supporting materials like galvanized steel and stainless steel.

Efficiency and Output

The rectangular duct forming line is designed for maximum efficiency and high output. With its advanced automation and precision engineering, it significantly reduces labor costs and production time while ensuring high-quality duct manufacturing.

Processing Technology of Rectangular Air Ducts

Stages of Processing

The processing technology of rectangular air ducts involves several critical stages. Initially, raw materials are selected based on specific requirements, such as durability, corrosion resistance, and cost-effectiveness. The materials are then cut to size using automated cutting machines, ensuring precision and reducing waste.

Forming and Assembly

Once the materials are cut, they are formed into the desired shapes using advanced machinery. This step often involves bending and folding processes to create the rectangular profile. The formed pieces are then assembled using various techniques, such as welding or flanging, to create a complete duct section.

Quality Control

Throughout the processing stages, strict quality control measures are implemented to ensure that each duct meets the required standards. This includes checking dimensions, inspecting welds, and testing for air leakage. Advanced technologies, such as visual inspection systems and automated testing equipment, are used to maintain high-quality output.

Material Selection for HVAC Rectangular Ducts

Choosing the Right Materials

Selecting the appropriate materials for Rectangular HVAC Ducts is crucial for ensuring their performance and longevity. Common materials include galvanized steel, stainless steel, and aluminum, each offering distinct advantages.

Galvanized Steel

Galvanized steel is widely used due to its excellent corrosion resistance and cost-effectiveness. It is suitable for various environments and provides a durable solution for HVAC ducting. The zinc coating on galvanized steel protects against rust and extends the lifespan of the ducts.

Stainless Steel

Stainless steel is preferred for its superior strength and resistance to corrosion, making it ideal for applications in harsh environments, such as chemical processing plants or areas with high moisture levels. Its high durability ensures a longer service life and reduces maintenance needs.

Aluminum

Aluminum is chosen for its lightweight properties and ease of fabrication. It is also resistant to corrosion and is an excellent choice for applications where weight is a critical factor. Aluminum ducts are easy to install and offer good thermal conductivity.

Application of Rectangular Air Ducts

Versatility in Use

Air Rectangular HVAC Ducts are highly versatile and are used in a wide range of applications. They are essential in large commercial buildings, industrial facilities, and residential complexes, providing efficient air distribution and ventilation. Their design allows for easy integration into various architectural plans, making them a preferred choice for HVAC engineers and contractors.

Industrial Applications

In industrial settings, rectangular air ducts are crucial for maintaining air quality and temperature control. They are used in manufacturing plants, warehouses, and processing facilities where consistent airflow is necessary to remove contaminants, regulate temperatures, and ensure a safe working environment. These ducts can handle large volumes of air and are often custom-designed to meet specific industrial requirements.

Commercial and Residential Applications

In commercial buildings such as offices, shopping malls, and hospitals, rectangular air ducts are used to distribute conditioned air throughout the spaces efficiently. They help maintain a comfortable indoor climate, essential for the well-being of occupants and the proper functioning of business operations. In residential applications, rectangular ducts are commonly used in HVAC systems to ensure even air distribution and enhance energy efficiency.

Different Shapes and Applications of HVAC Rectangular Ducts

Galvanized Sheet

Durability and Corrosion Resistance

Galvanized sheet ducts are widely used due to their durability and excellent resistance to corrosion. The zinc coating on galvanized steel protects the ducts from rust, making them suitable for various environments, including those with high humidity or exposure to moisture. This material is cost-effective and provides long-lasting performance, making it a popular choice for many HVAC applications.

Ease of Installation

Galvanized sheet ducts are relatively easy to fabricate and install. They can be cut, bent, and shaped to fit specific design requirements, ensuring seamless integration into HVAC systems. The material’s rigidity also helps maintain the structural integrity of the ducts, preventing deformation over time.

Applications

These ducts are commonly used in both commercial and industrial settings. They are ideal for ventilation systems in warehouses, factories, office buildings, and residential complexes. Their robust nature and resistance to environmental factors make them suitable for various applications, ensuring reliable air distribution and ventilation.

Stainless Steel

Superior Strength and Hygiene

Stainless steel ducts are known for their superior strength and resistance to corrosion, making them ideal for demanding applications. This material is particularly suitable for environments requiring high hygiene standards, such as hospitals, laboratories, and food processing facilities. Stainless steel ducts do not rust or corrode, ensuring a clean and safe air distribution system.

Longevity and Low Maintenance

The durability of stainless steel means these ducts have a long service life and require minimal maintenance. They can withstand harsh environmental conditions and are resistant to chemicals, making them a reliable choice for various industrial applications. The low maintenance needs translate to cost savings over the duct’s lifespan.

Applications

Stainless steel ducts are used in applications where hygiene and durability are paramount. They are common in pharmaceutical plants, hospitals, laboratories, and other cleanroom environments. Additionally, they are used in industrial settings where exposure to chemicals or high temperatures is a concern.

Composite Materials

Lightweight and Flexible

Composite materials offer a lightweight and flexible alternative to traditional metal ducts. These materials can be engineered to provide specific properties such as thermal insulation, sound absorption, and fire resistance. The flexibility of composite ducts allows for easier installation and customization to fit complex ductwork designs.

Energy Efficiency

Composite ducts often have built-in insulation, which helps reduce energy loss and improve the overall efficiency of HVAC systems. This feature is particularly beneficial in applications where energy efficiency is a priority, such as in green buildings and sustainable construction projects.

Applications

Composite Rectangular HVAC Ducts are used in various applications, including commercial buildings, residential complexes, and specialized industrial facilities. Their lightweight nature makes them easy to handle and install, while their customizable properties ensure they meet specific performance requirements.

How to Use Automated Machines to Produce HVAC Rectangular Ducts

Advanced Manufacturing Processes

The production of HVAC rectangular ducts has been revolutionized by the use of automated machines. These machines streamline the manufacturing process, ensuring precision, efficiency, and consistency. Automated systems handle tasks such as cutting, bending, welding, and assembling, reducing the need for manual labor and minimizing errors.

Cutting and Forming

Automated cutting machines are used to precisely cut raw materials into the required sizes. These machines use advanced technologies such as laser cutting, which ensures clean and accurate cuts. The cut pieces are then fed into forming machines that bend and shape them into the desired rectangular profiles. This process is controlled by computer systems, ensuring uniformity and precision.

Welding and Assembly

Automated welding machines, such as robotic laser welders, are employed to join the duct sections. These machines offer high precision and can perform both horizontal and vertical welds. The use of robotic systems reduces labor costs and ensures consistent weld quality. Once welded, the ducts are assembled and subjected to quality control checks to ensure they meet the required standards.

Why Choose Altron’s Rectangular HVAC Duct Machines?

Cutting-Edge Technology

Altron’s rectangular HVAC duct machines are equipped with the latest technology, ensuring efficient and high-quality production. Their machines feature advanced automation, including PLC control systems, robotic welding, and precision cutting tools. This technology ensures that each duct is manufactured to exact specifications, maintaining high standards of quality and performance.

Customization and Flexibility

Altron offers a range of machines and production lines that can be customized to meet specific client needs. Whether it’s a fixed mold spiral duct machine or a comprehensive rectangular duct production line, Altron provides solutions that cater to various requirements. Their machines can handle different materials, sizes, and shapes, offering flexibility and versatility in duct manufacturing.

Expert Support and Service

Altron stands out for its exceptional customer support and service. Engineer Joby, for example, provides 7*24H online pre-sales meeting solutions, ensuring clients receive the best technical guidance. This level of support helps clients optimize their manufacturing processes and troubleshoot any issues that may arise. Altron’s commitment to customer satisfaction is evident in their comprehensive service offerings, from installation to maintenance and technical support.

Efficiency and Cost-Effectiveness

Altron’s automated machines enhance manufacturing efficiency, reducing labor costs and production time. The precision and consistency offered by these machines result in high-quality ducts that require minimal rework. This efficiency translates to cost savings for manufacturers, making Altron’s machines a cost-effective investment for HVAC duct production.

Innovation and Reliability

With a focus on innovation and reliability, Altron continues to lead the industry in HVAC duct manufacturing. Their machines are designed to handle the demands of modern production environments, ensuring durability and long-term performance. By investing in Altron’s machines, manufacturers can stay ahead of industry trends and meet the evolving needs of their clients.

Conclusion

Altron’s expertise in the production of Rectangular HVAC Ducts, supported by advanced machineries like the Spiral Duct Forming Machine, robotic laser welding systems, and Rectangular Duct Production Line, showcases their commitment to innovation and quality. Their comprehensive approach, from material selection to automated processing, ensures the efficient and reliable production of high-quality HVAC ducting systems. Whether for industrial, commercial, or specialized applications, Altron’s solutions provide the necessary performance and durability to meet the demanding needs of modern HVAC systems.