Edited by: Engineer Joby

Edited by: Engineer Joby

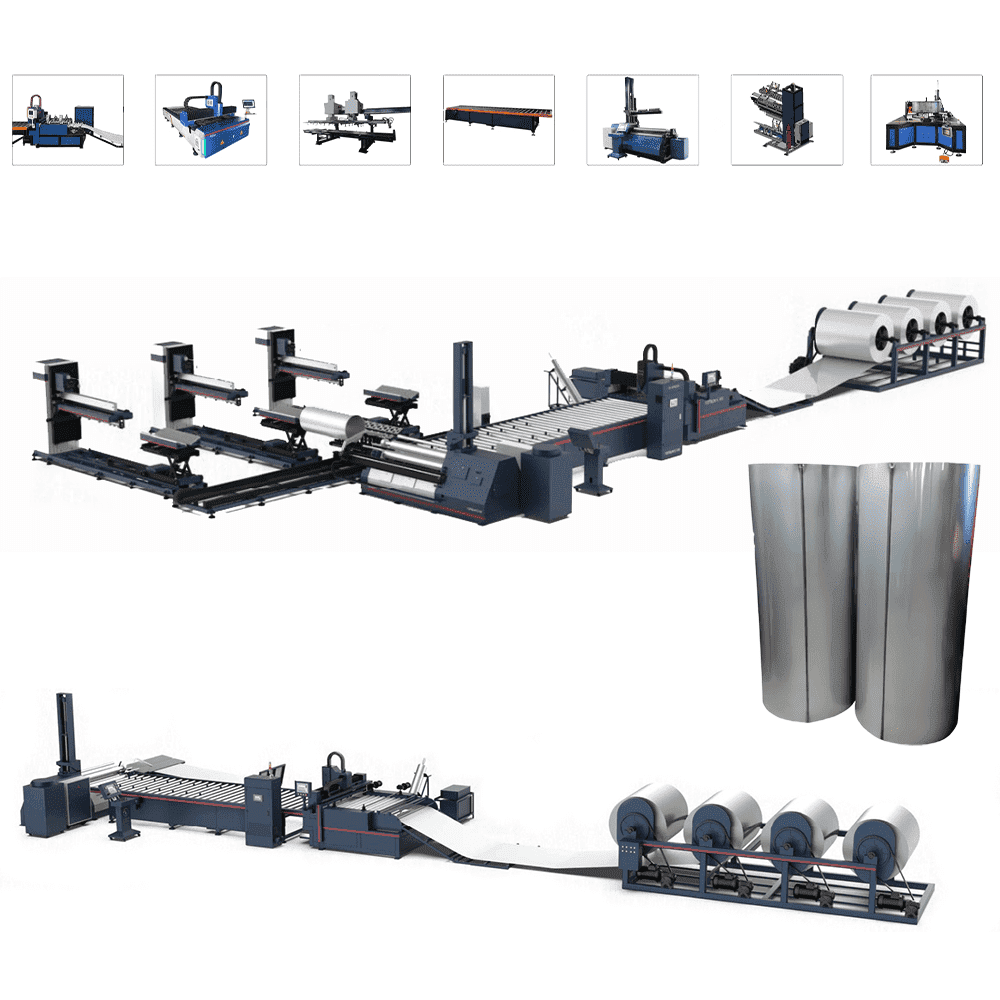

Rolling & Laser Welding Production Line for SUS cylindrical Tanks, forming, seam & girth welding customized for purifier manufacturers

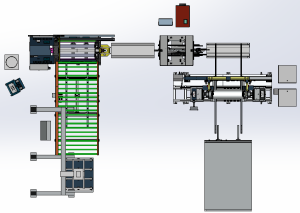

Rolling & Laser Welding Production Line Functions:

Laser Welding Production Line Videos

Automatic Welding Production Line Configuration:

Automatic loading and translation manipulator:

The translation manipulator is composed of laser cutting unloading and picking function, large torque servo synchronous lifting mechanism, servo translation positioning transmission, pneumatic plate separation device, imported suction cup rack (each suction cup is equipped with a vacuum logic valve), Yadeke pneumatic system, safety protection system and electrical system.

Plate conveying platform

The plate conveying platform adopts a roller structure, and transmits power through the RV reducer, sprocket and chain to realize the conveying function of the plate. The motor power is 1.5KW, the speed ratio is 25:1, and it also has a positioning function. The positioning motor is a servo motor with a speed ratio of 10:1.

Hydraulic CNC four-roller rolling machine

CNC automatic 4roller rolling forming, which is composed of upper shaft, lower shaft and side shaft respectively. The shaft material is 42CrMo, the surface is treated with medium frequency, the heat treatment hardness is HRC54~56, and the surface is hard chrome plated after fine processing to ensure that the surface finish reaches 0.8. The machine is provided with a hydraulic drive device to provide rotational driving force. The lifting and lowering of the clamping and side rollers are realized by the oil cylinder. Each shaft is composed of two oil cylinders. The lifting and lowering synchronization function of each shaft is realized through the hydraulic balance system and the electrical control system. With automatic discharge function, the rolled product is pushed out to the weld alignment mechanism through the automatic discharge mechanism.

Weld alignment mechanism

Automatically find the weld, the barrel workpiece transition mechanism is responsible for the barrel docking CNC rolling machine and tunnel seam welding machine, with its own power and the function of finding the weld, can accurately align the workpiece and send it to the tunnel seam welding machine.

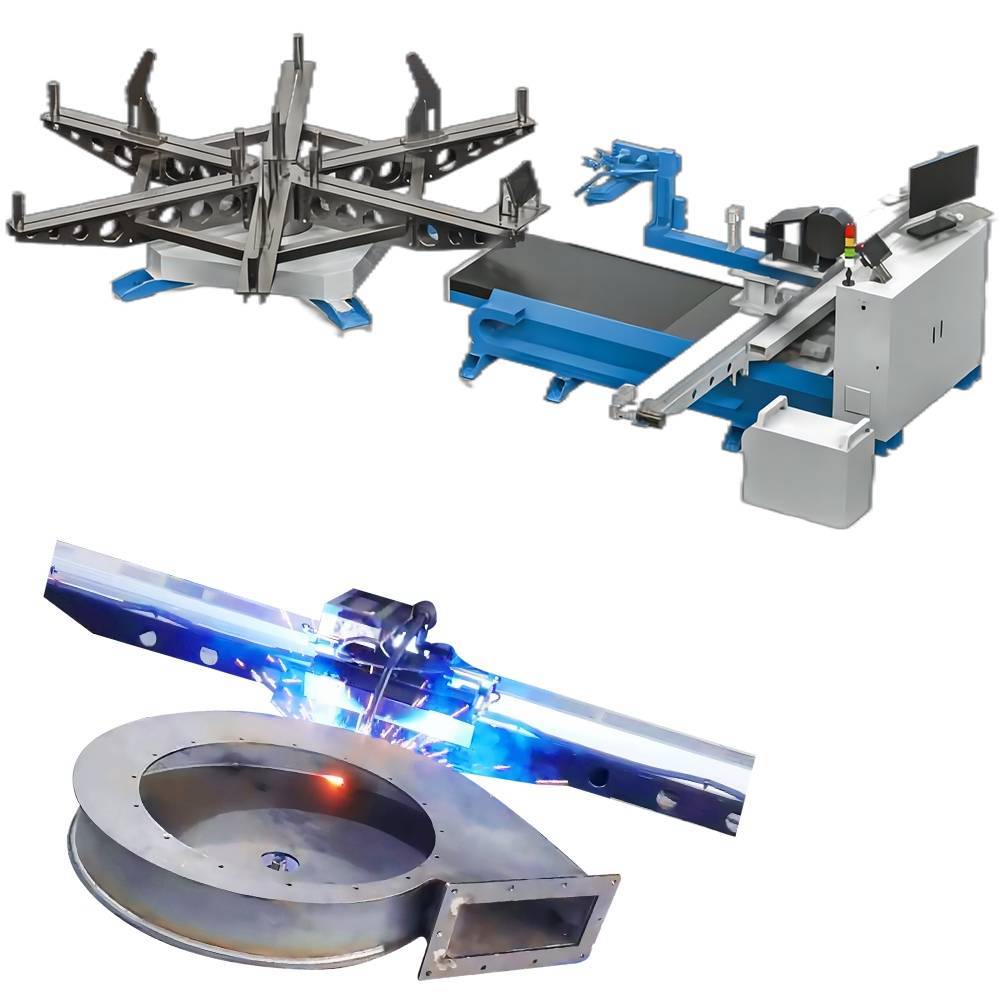

Tunnel laser seam welding machine

The tunnel seam laser welding machine is responsible for automatically aligning the rolled workpiece sent in and then pressing it, laser welding, with gas protection function to prevent weld oxidation, and after welding is completed, it is pushed out from the discharge end to the transfer platform.

Discharging transfer platform for seam welding

The discharging transfer platform after the seam welding machine is completed is connected to the tunnel seam welding machine and the double welding gun circumferential seam welding machine. It also has the function of storing materials. When the efficiency of welding circumferential seams and longitudinal seams is inconsistent, it can play a role in turnover and improve production efficiency!

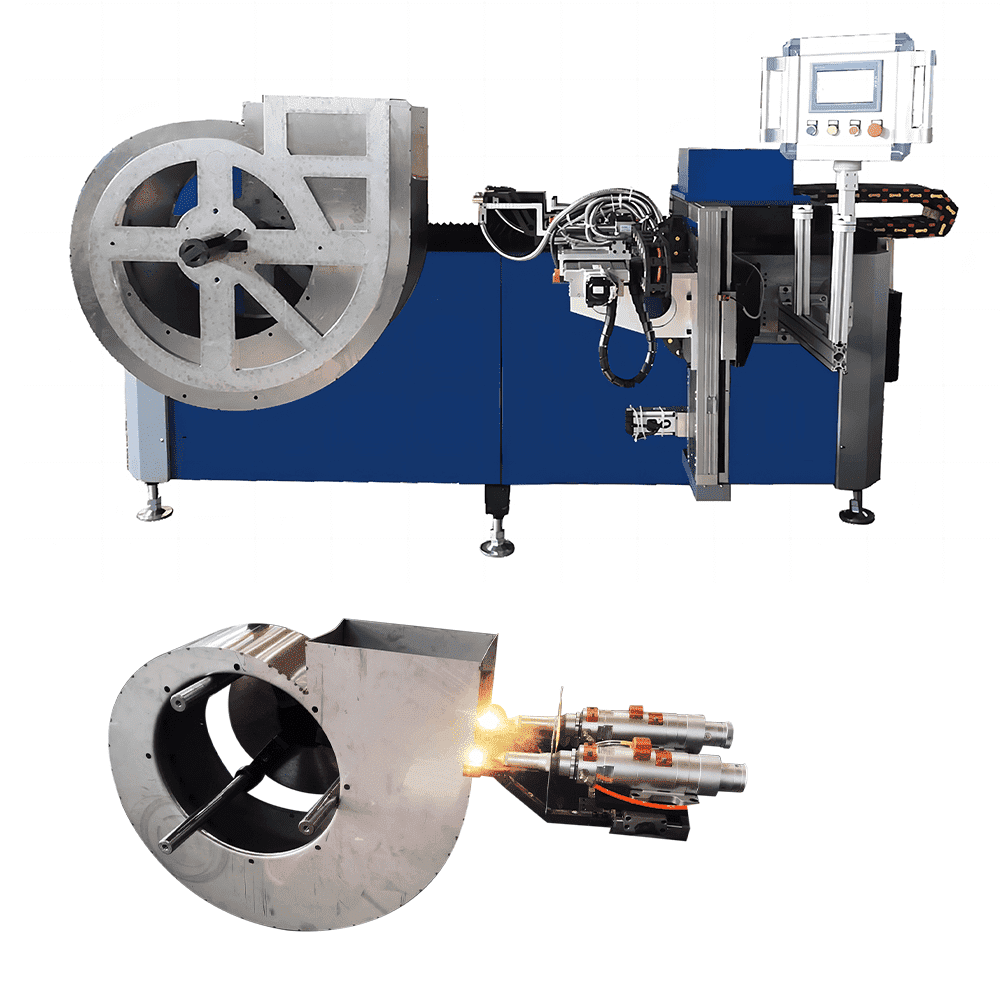

Double welding gun circumferential seam welding

①Put the cover into the fixture manually.

②After starting, the double-head mold automatically connects the cover and the cylinder after the cylinder is automatically fed in;

③The welding gun automatically comes down to spot weld in the pre-reserved hole.

④After the spot welding is completed, the cover fixture automatically retreats, exposing the spot weld, and automatically starts welding.

⑤After the welding is completed, the alternating feeding mechanism sends the workpiece to the receiving platform.

⑥Different molds need to be replaced for workpieces of different diameters. Alternating feeding platform

Discharging platform for cylindrical circumferential seam welding

①Accept the stainless steel container workpieces after the double gun circumferential seam welding.

②Store the welded workpieces to facilitate the transportation of the next stainless steel cylindrical tank body polishing process, etc.

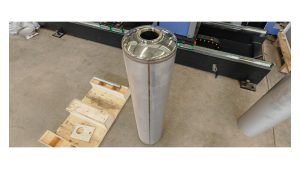

Stainless Steel Water Tank Double Head Ring And Seam Welding Effect.

The photo shows the longitudinal seam welded by laser, the circumferential seam welded by argon arc welding, and the pressure test of 8 MPa passed!

Rolling & Laser Welding Production Line Configuration List:

- Loading robot (3 meters)

- Feeding platform (2 meters)

- CNC hydraulic four-roller rolling machine

- Weld alignment mechanism

- Automatic discharging mechanism of rolling machine

- Automatic tunnel welding – 1.5KW laser welder X1

- Laser welder (1.5KW)

- Tunnel welding discharging mechanism

- Discharging platform

- Automatic feeding mechanism of girth welding

- Automatic girth welding – 1.5KW laser welder X2

- Head mold

- Automatic discharging mechanism of girth welding

- Discharging platform of girth welding

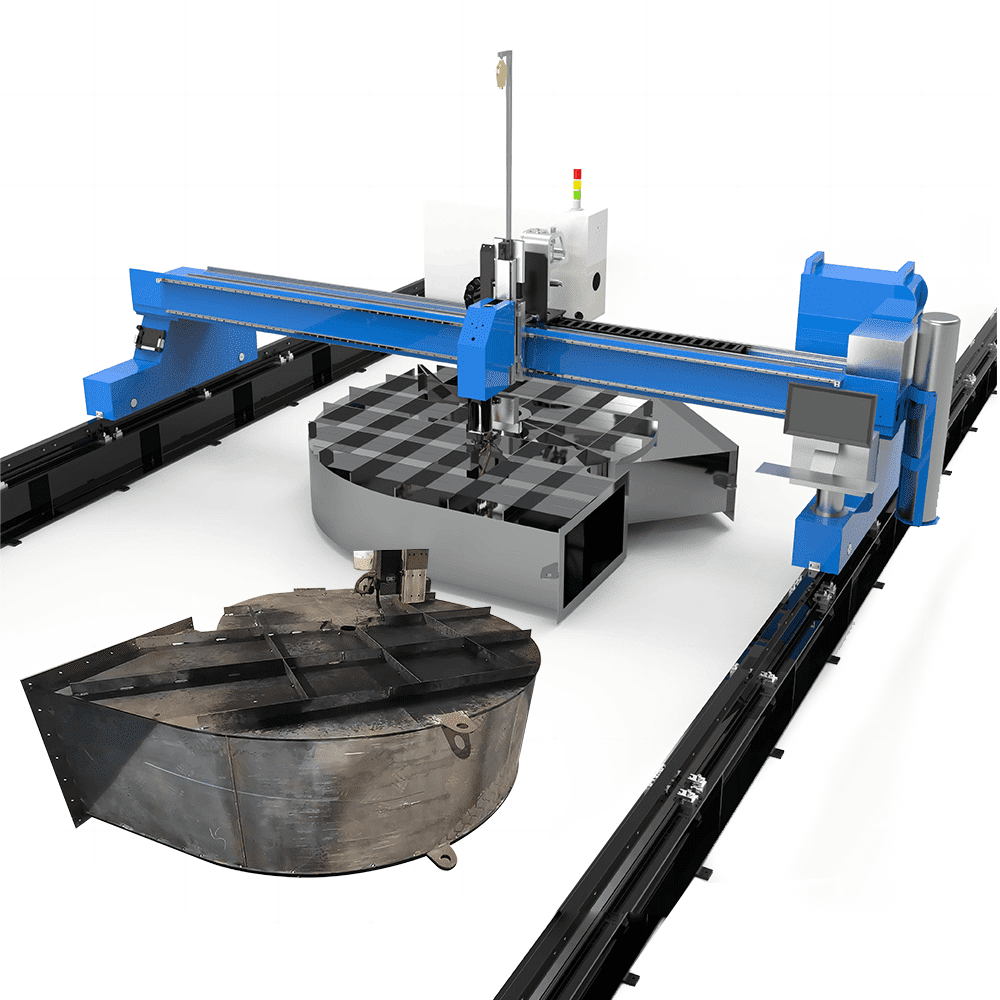

Rolling & Laser Welding Production Line Details

If you have the same tank container, please contact us. We have extensive experience in metal forming and welding and can provide customized automated production solutions for your products!

Showing detailed pictures of some customized production lines and details of the plan!