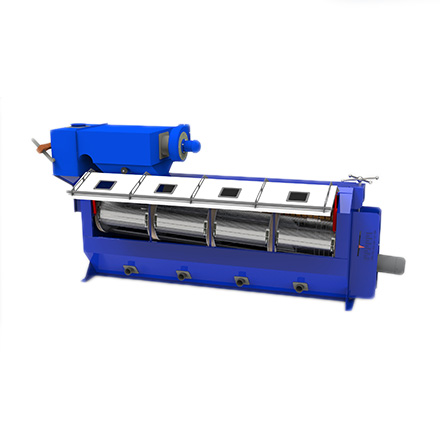

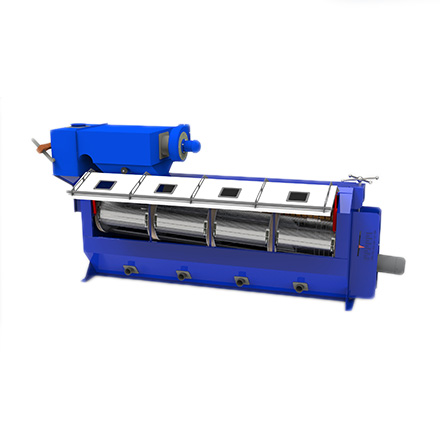

Servo 4 Roller Rounding Machine

Servo rolling machine for environmentally friendly air duct

|

Machine Name |

Servo Four-Roller Rounding Machine |

|

Model |

AC-W12SK-1300 |

|

Application Industry |

Environmentally friendly ventilation, the roundness of the cylinder of grain machinery |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/Engineer Video Online Conference To Solve Pre-Sales Problems. |

|

Project Progress |

30-120 days |

|

Relevant Files |

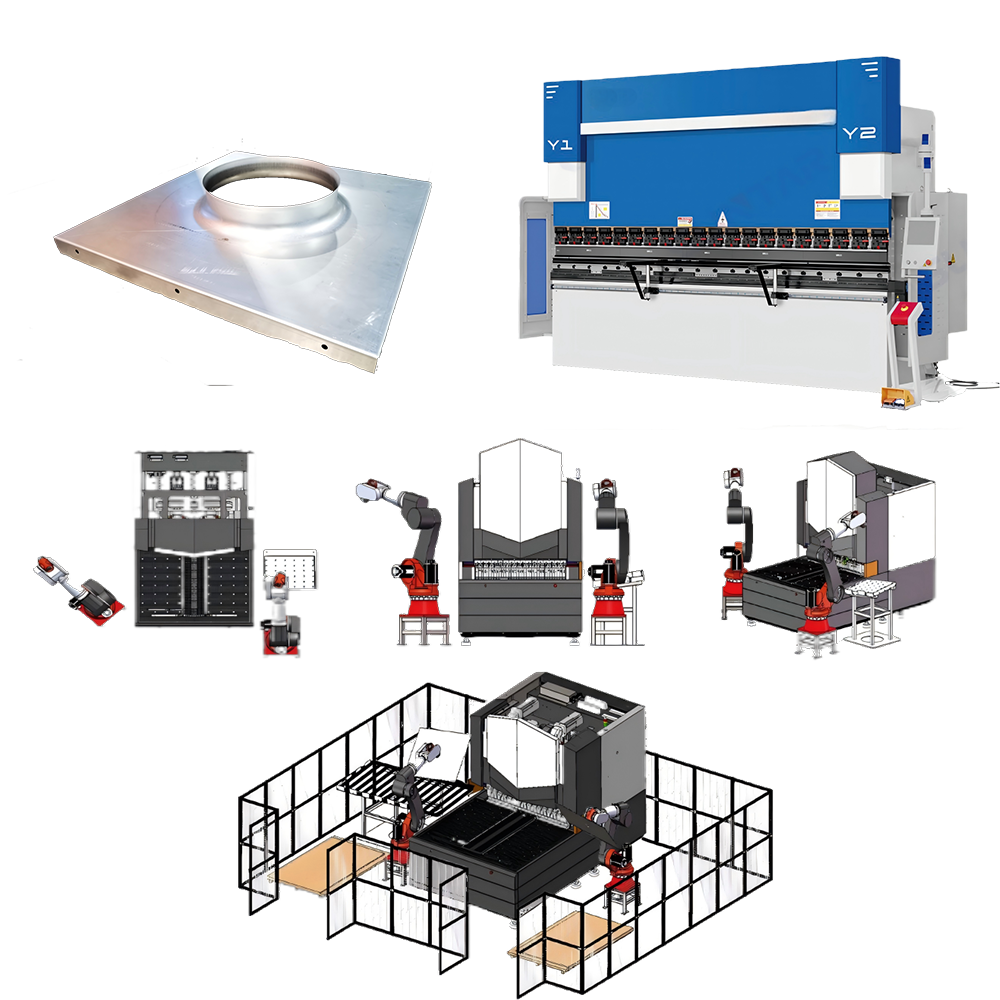

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

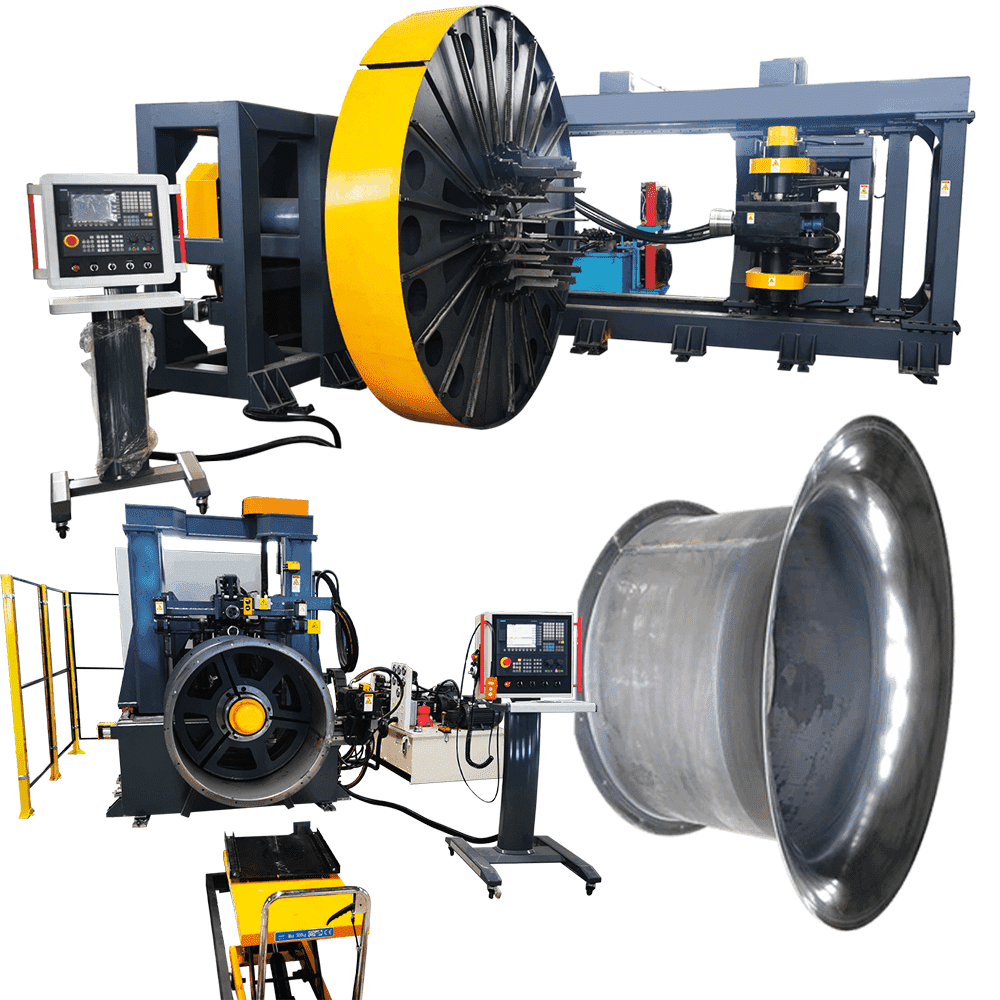

Axial Fans A-Z Project:

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

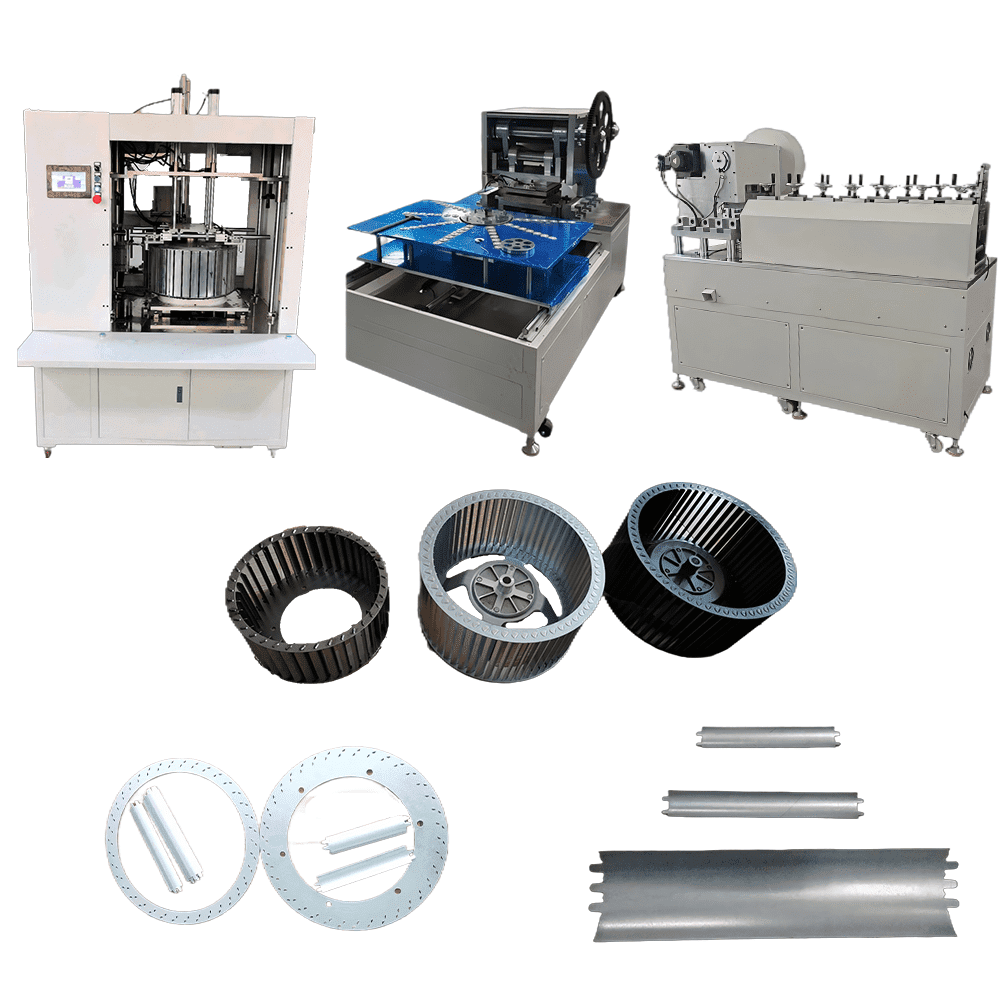

The Servo Four-Roller Rounding Machine is a precision-engineered piece of equipment designed for efficient and accurate rounding of metal sheets and plates. With its advanced servo control technology and robust construction, this machine offers superior performance and reliability.

The machine features four precision-aligned rollers that work in synchronization to provide smooth and consistent rounding of the metal material. The servo control system ensures precise and controlled movements, allowing for high-quality and uniform results.

One of the key advantages of the Servo Four-Roller Rounding Machine is its versatility. It can handle various types of metal sheets, including steel, aluminum, stainless steel, and more. This flexibility makes it suitable for a wide range of applications across industries such as metal fabrication, automotive, aerospace, and construction.

Applications:

The Servo Four-Roller Rounding Machine finds applications in various industries and processes that involve rounding of metal sheets and plates. Some of its common applications include:

-

Metal Fabrication: The machine is widely used in metal fabrication processes, such as the production of tanks, cylinders, pipes, and cones. It ensures precise and uniform rounding of metal sheets, resulting in high-quality fabricated components.

-

Automotive Industry: In the automotive sector, the machine is utilized for rounding metal sheets used in the production of automotive body parts, chassis components, and exhaust systems. It contributes to the manufacturing of accurately rounded and smoothly finished parts.

-

Aerospace Industry: The machine is suitable for the aerospace industry, where precision and quality are of utmost importance. It is used for rounding metal sheets used in the production of aircraft parts, including fuselages, wings, and structural components.

-

Construction and Architecture: The machine plays a crucial role in the construction and architectural sectors for rounding metal sheets used in building facades, decorative elements, and structural components. It helps achieve the desired curvature and aesthetics in metal fabrication.

Primary qualities:

Our full-servo CNC four-roller rolling machine excels in several primary qualities, including:

-

Linear Displacement of Side Rollers: The machine incorporates linear displacement technology for its side rollers, which ensures a superior pre-bending effect. This feature enables precise control over the bending process, resulting in high-quality finished products.

-

Servo Control for Active Rollers: Both the active rollers and compression rollers of our machine are controlled by servo motors. This servo-driven system offers enhanced accuracy and flexibility in controlling the rolling process, contributing to consistent and reliable performance.

-

Synchronization and Precision: Our machine is designed with excellent synchronization capabilities, ensuring the coordinated movement of all rollers. This synchronization, combined with the precision provided by the servo control, guarantees consistent and accurate rolling results. The fast response speed of the machine further enhances its efficiency and productivity.

Product Finished Effect

Configuration

Mainly used for environmental protection air ducts, grain machinery cylinders rolled.

| Material Thickness |

cold plate 0.5~1.5mm stainless steel 0.5~1.0mm |

| Max. Sheet | 1250mm |

| Material | cold plate, stainless steel |

| Rolling Speed | about 10M/min |

| Total Power | 4.2KW |

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

I am extremely pleased with the performance of the equipment and the support provided by the company. I highly recommend this welding system to others in need of efficient and reliable welding solutions.

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

The efficiency of the equipment has exceeded my expectations. It has significantly reduced labor costs and improved productivity in our welding processes. T

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The quality of the welds produced by the machine is excellent, and I no longer have to worry about inconsistencies or uncertainties that were common with manual work. This has increased the acceptance of our products among our customers.

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

I am extremely pleased with the performance of the equipment and the support provided by the company. I highly recommend this welding system to others in need of efficient and reliable welding solutions.