Applications, Success Stories, & Future Trends in Sheet Metal Spinning

As we celebrate the first anniversary of the groundbreaking it technology, it’s fitting to delve into the intricacies and significance of this process. Sheet metal spinning, a technique that has evolved over the years, has become a linchpin in various industries, offering unparalleled versatility and precision.

Section 1: Basics of Sheet Metal Spinning

1.1 Definition and Process

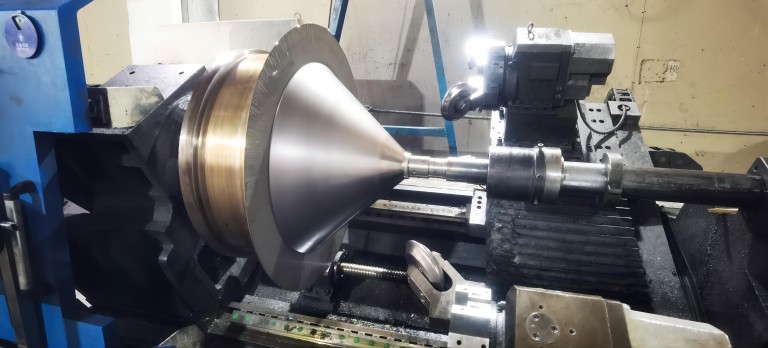

Sheet metal spinning, also known as metal spinning or spin forming, is a metalworking process that involves the rotation of a metal disc or tube on a lathe while forces are applied to shape it into a desired form. This method is particularly adept at producing seamless, symmetrical, and complex shapes, making it an invaluable tool in manufacturing.

1.2 Key Components Involved

The primary components in sheet metal spinning include the lathe machine, the metal blank, and specialized tooling. The lathe machine facilitates the rotation of the metal, while tooling, such as molds and mandrels, shapes and forms the material.

1.3 Materials Used

Sheet metal spinning accommodates a variety of materials, ranging from aluminum and stainless steel to copper and brass. Each material presents unique challenges and considerations, influencing factors such as tooling design, machine settings, and overall process parameters.

Section 2: Tools and Equipment — Best Sheet Metal Spinning in ALTRON

2.1 Lathe Machines

ALTRON, a leading sheet metal spinning machine manufacturer, has played a pivotal role in advancing lathe machine technology. These machines are crucial in achieving precise and consistent results. Different projects may require specific types of lathes, such as manual lathes for smaller-scale productions and CNC lathes for more intricate designs.

2.2 Tooling

The tools used in sheet metal spinning significantly impact the final product. ALTRON’s cutting-edge tooling solutions contribute to the efficiency and quality of the spinning process. Understanding the interplay between various tools and their effects on the material is essential for achieving the desired outcome.

Section 3: Techniques and Best Practices — Best Sheet Metal Spinning in ALTRON

3.1 Basic Techniques

The sheet metal spinning process involves several steps, from preparing the metal blank to refining the final shape. Challenges such as thinning of the material or wrinkles can be overcome with proper technique and expertise. ALTRON’s machines are designed to streamline these processes, ensuring smoother and more reliable outcomes.

What sets the ALTRON series apart is not just its raw power but the incorporation of cutting-edge technology. The machine employs a top-of-the-line SIEMENS control system, seamlessly paired with advanced programming software V4.2. This powerful combination allows for precise control and customization, enabling the seamless integration of double-wheel spinning functionality into your production process.

3.2 Advanced Techniques

For those seeking intricate designs and complex shapes, advanced it techniques come into play. These may include multi-pass spinning, where the metal undergoes multiple passes to achieve the desired form. Achieving precision in sheet metal spinning requires a combination of cutting-edge technology and skilled craftsmanship.

The user-friendly interface ensures ease of operation, making the ALTRON series accessible even to those new to sheet metal spinning. Meanwhile, the comprehensive features of the software provide flexibility and efficiency in programming, ensuring that the machine adapts to the unique needs of each project.

3.3 Quality Control

Quality control is paramount in sheet metal spinning to meet industry standards. ALTRON’s machines incorporate advanced inspection methods to ensure the integrity of the final product. Rigorous testing and adherence to quality benchmarks guarantee that every spun metal piece meets or exceeds expectations.

The ALTRON series comes with a standard configuration that sets the bar high in the it industry. The SIEMENS CNC 828D, coupled with SIEMENS Servo Motor & Drive, ensures precise control and efficient operation. The asynchronous servo spindle motor adds to the machine’s reliability, making it a robust choice for demanding manufacturing processes.

Section 4: Status of Sheet Metal Spinning in Various Industries — Best Sheet Metal Spinning in ALTRON

The status of sheet metal spinning in different industries is marked by a notable surge in adoption. Manufacturers are increasingly recognizing the advantages of this technique over traditional methods. The ability to produce complex shapes, reduce material waste, and enhance structural integrity positions sheet metal spinning as an integral part of modern manufacturing processes.

However, this growing interest also brings forth challenges that demand innovative solutions. ALTRON, as a leading player in the sheet metal spinning machine manufacturing domain, has identified and addressed these challenges through continuous research and development.

Section 5: Applications of Sheet Metal Spinning — Best Sheet Metal Spinning in ALTRON

As we take in technological advancements, it’s imperative to highlight the role of it in reshaping various industries. The art of molding metal sheets into complex and intricate shapes has found its sweet spot in manufacturing, aerospace, automotive, and more. Among the pioneers in this transformative field is ALTRON, a leading sheet metal spinning machine manufacturer, providing custom solutions that redefine possibilities for diverse industries.

The ALTRON series double-wheel spinning machine boasts exceptional accuracy and ensures flawless surface quality. Its intelligently designed symmetrical spinning force and pressure distribution provide outstanding shock protection for the spindle, enhancing durability and reliability. This heavy-duty machine is not just robust but also versatile, making it ideal for manufacturing long and slender goods, as well as cone-shaped products.

Moreover, the machine is well-equipped to process thinning and lengthening barrel blanks, making it the go-to solution for creating seamless thin tubes. Its capabilities extend further to include the hardening treatment of workpieces, significantly expanding its range of applications and usefulness in various industries.

Section 6: Needs and Challenges in Sheet Metal Spinning

6.1 Precision and Efficiency

As industries demand more intricate and precise designs, the need for higher levels of precision and efficiency becomes paramount. Sheet metal spinning addresses this need by allowing manufacturers to create complex shapes with minimal material wastage. ALTRON’s machines are designed to meet and exceed these precision requirements, enabling manufacturers to achieve unparalleled accuracy in their products.

6.2 Material Compatibility

Diverse industries use an array of materials, each with its own set of challenges during the spinning process. ALTRON’s commitment to customization extends to material compatibility. Their machines are equipped to handle various metals, from aluminum to stainless steel, ensuring manufacturers can choose the right material for their specific applications without compromising on quality.

6.3 Speed and Volume

In a world where time is money, the speed of production becomes a critical factor. ALTRON’s sheet metal spinning machines are not only precise but also designed for efficiency. They empower manufacturers to meet tight deadlines without compromising on the quality of the end product. This addresses the challenge of balancing speed and volume in manufacturing processes.

Section 7: Case Studies — Best Sheet Metal Spinning in ALTRON

7.1 Success Stories

ALTRON’s it technology has been at the heart of numerous success stories. One notable case involves the production of bespoke automotive components for a leading car manufacturer, showcasing the precision and efficiency of ALTRON’s machines. Another success story involves the aerospace sector, where sheet metal spinning played a key role in crafting lightweight components for a satellite project, demonstrating the adaptability of the technology across diverse industries.

7.2 Lessons Learned

Examining these case studies reveals valuable lessons for manufacturers and engineers. The importance of machine reliability, precise tooling, and a deep understanding of material behavior surfaces as key takeaways. ALTRON’s commitment to continuous improvement aligns with the ever-evolving needs of industries relying on sheet metal spinning, showcasing the importance of staying abreast of technological advancements.

Section 8: Future Trends — Best Sheet Metal Spinning in ALTRON

8.1 Innovation in Sheet Metal Spinning

The future of it is marked by ongoing innovation. ALTRON leads the charge by integrating smart technologies into their machines, enhancing automation and data-driven precision. Emerging technologies such as artificial intelligence and machine learning promise to further optimize the spinning process, reducing production time and minimizing material waste.

8.2 Future Trends and Possibilities

The horizon of sheet metal spinning holds exciting possibilities. The integration of sustainable materials and eco-friendly practices is gaining traction, aligning with global efforts towards greener manufacturing. Furthermore, advancements in 3D printing technologies may intersect with sheet metal spinning, opening avenues for even more intricate and customized designs.

Section 9: ALTRON’s Custom Solutions: A Technological Marvel

As industries navigate the challenges and needs associated with sheet metal spinning, ALTRON stands out as a beacon of innovation. The company’s commitment to providing custom solutions sets them apart in the competitive landscape of it machine manufacturers.

9.1 Tailored Machine Designs

ALTRON understands that one size does not fit all. Different industries have unique requirements, and their machines are designed with this in mind. Whether it’s the aerospace sector’s demand for intricate and lightweight components or the automotive industry’s need for speed and efficiency, ALTRON’s machines are tailored to meet specific needs.

9.2 Advanced Control Systems

The heart of any it machine lies in its control systems. ALTRON takes pride in offering advanced control systems that not only enhance precision but also provide manufacturers with the flexibility to adapt to changing requirements. This ensures that their machines are not just tools but strategic assets in the manufacturing process.

9.3 Continuous Research and Development

ALTRON’s commitment to excellence is evident in its emphasis on research and development. The company consistently invests in staying ahead of the curve, anticipating industry trends, and incorporating cutting-edge technologies into their machines. This proactive approach ensures that ALTRON’s customers are equipped with the latest advancements in sheet metal spinning technology.

Conclusion

As we reflect on innovation in sheet metal spinning, it is clear that ALTRON has been a driving force in shaping the landscape of this transformative technology. From the basics of the spinning process to the advanced techniques and tools, it has come a long way in providing unmatched precision and versatility across industries. As we look ahead, the future promises even greater strides in the evolution of this indispensable manufacturing technique. Cheers to a year of shaping possibilities with sheet metal spinning!