CNC Metal Spinning Machine -Single Roller AC1400

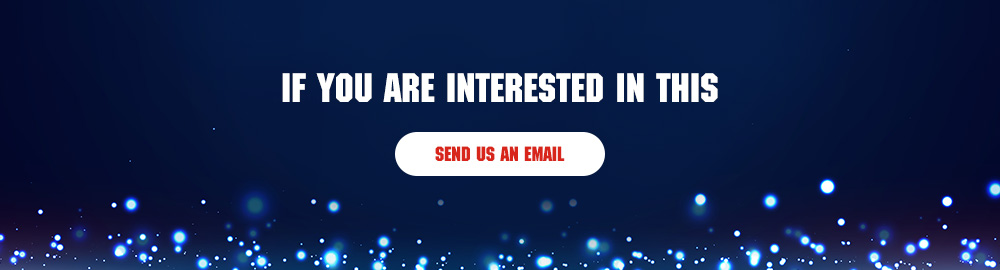

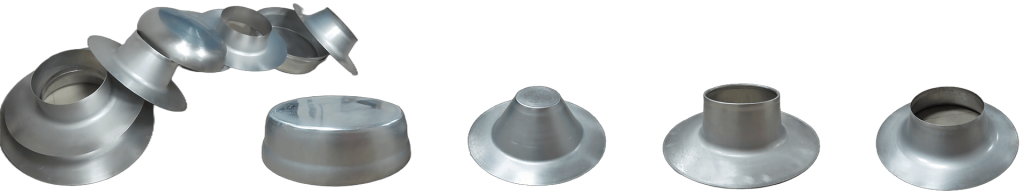

Metal Spinning For Ventilation And Industrial fans

|

Machine Name |

Single Wheel CNC Metal Spinning Machine |

|

Model |

AC1400:(diameter max Ф1400;aluminum-Max 8mm; carbon steel-Max 5mm) |

|

Application Industry |

(Aerospace, Aviation Weapons, Medical, Furniture, Lighting, Building, Fire, Musical Instruments, Automotive Parts, Pressure Vessel, Ventilation) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

Single Roller CNC Metal Spinning Machine-AC1400 Introduction:

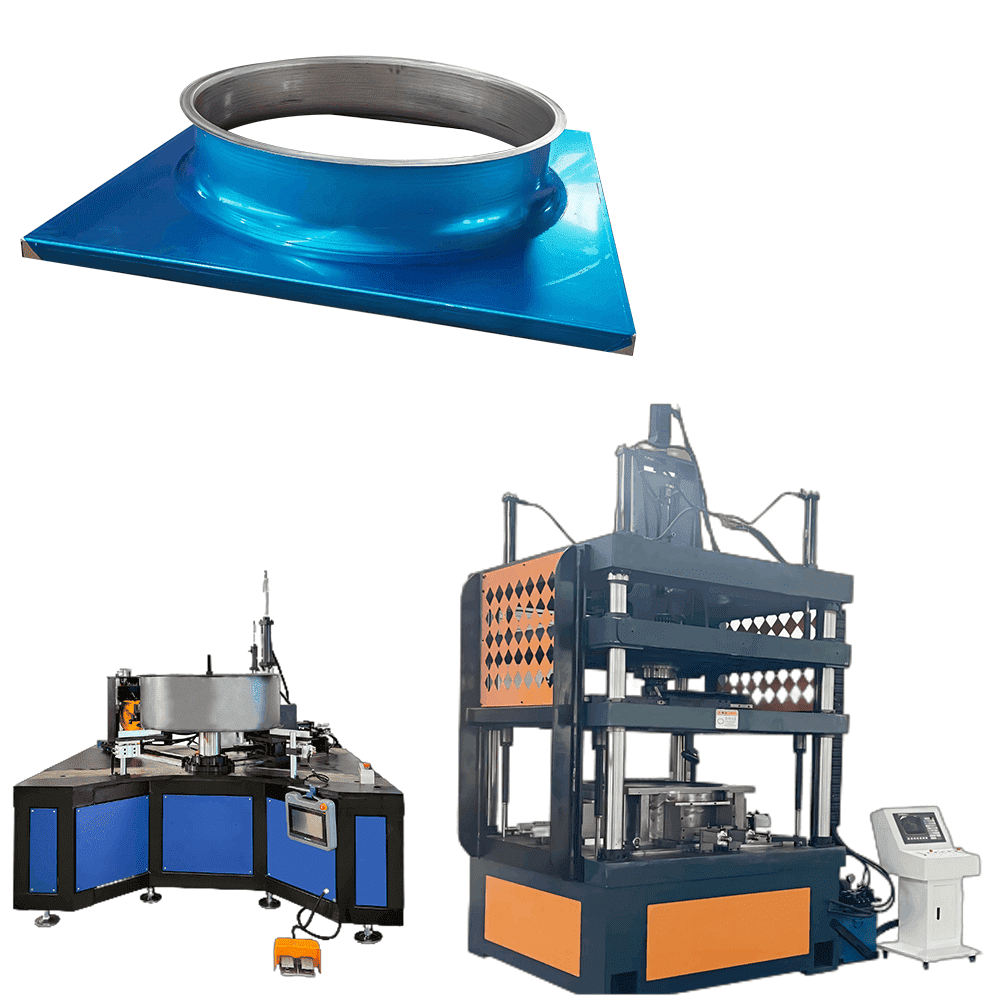

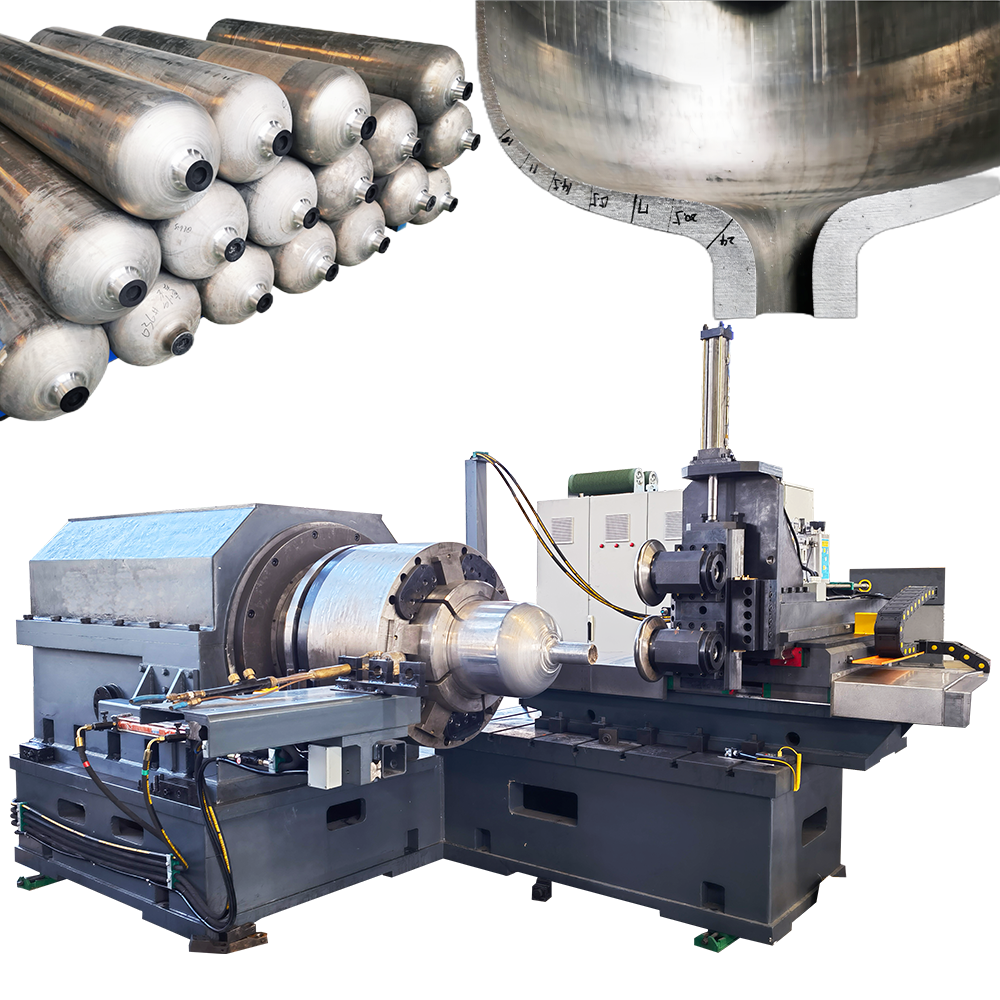

Altron single-roller CNC metal spinning machine can spin a variety of metal materials, suitable for aerospace, aviation weapons, medical, furniture, lighting, construction, fire protection, musical instruments, handicrafts, auto parts, pressure vessels, industrial fans and ventilation industries, etc.

Single-roller CNC metal spinning-AC1400 is a spinning machine that can spin 1400mm diameter raw materials. The machine uses Siemens CNC 828D system and will provide Altron CNC spinning programming software for free to simplify the difficulty of engineers to operate the machine; this model of CNC spinning machine is widely used in industrial fans and ventilation industries.

The spindle can be equipped with a servo spindle motor to achieve precise indexing function of the main line, and add a punching mechanism to complete the processing of flange mounting holes on the CNC spinning machine, saving a separate process.

Working Video Of Spinning Machine

Spinning Technology Solutions For The Ventilation Industry

Altron has extensive project experience in the ventilation industry. We have more than 300 domestic and foreign industrial fan and ventilation industry manufacturers who purchase Altron’s CNC metal spinning machines and CNC flanging machines to manufacture fan parts for them, thereby improving the product quality and performance of industrial fans, especially in the ventilation industry! During the COVID-19 period from 2019 to 2023, ventilation equipment and air purifiers are a very hot industry.

The following shows you the details of Altron’s services in the ventilation industry:

Service process after receiving metal spinning technical consultation:

- Altron Joby will analyze the customer’s information as soon as possible;

- Contact the customer to further understand the customer’s actual needs and technical points;

- When there are many technical points in the problem, assemble an online meeting;

- Solving pre-sales problems is the standard of our service;

- Determine the technical solution and explain the details of the solution to the customer;

- Achieve cooperation and solve technical problems!

- At the beginning of the project, we have a clear equipment production plan and machine testing and inspection process;

- Arrange customer engineers to conduct technical training on the machine, or our engineers go to the factory for training;

- The equipment must be 100% tested in the Altron factory before it is shipped out of the factory!

- The factory will have electronic and paper installation instructions for the metal CNC spinning machine.

Technical spinning machine production tasks:

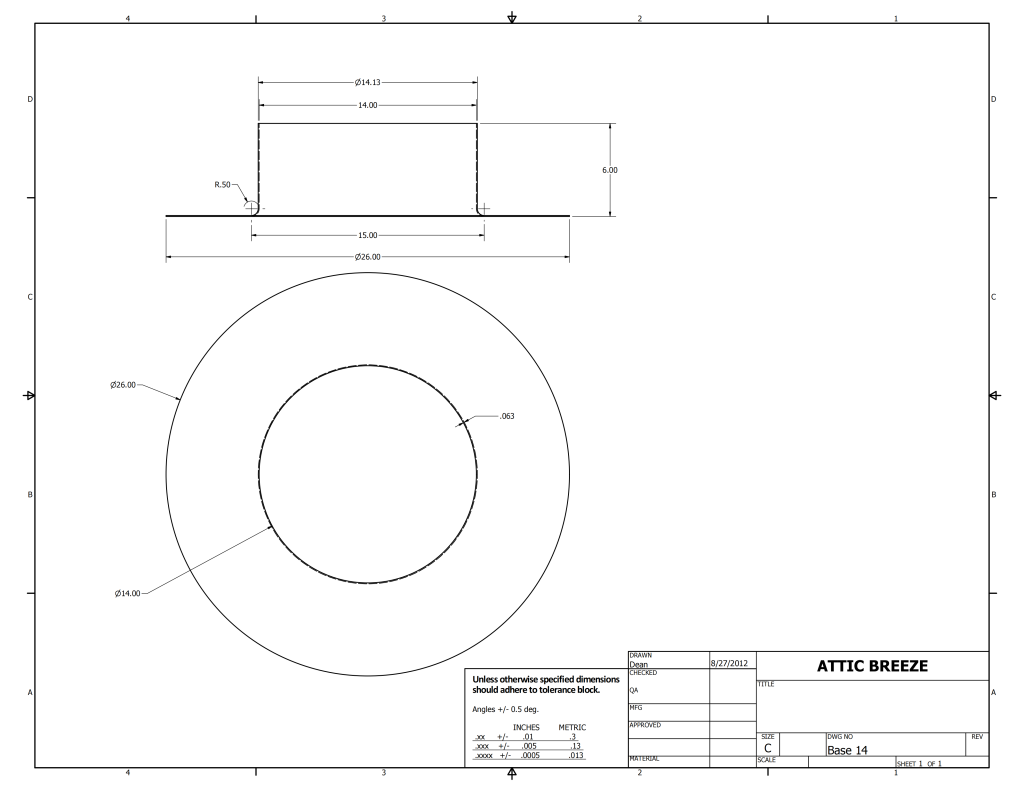

This is an AC1400 that has completed testing and training and is sent to the ventilation factory in the United States: ATTIC BREEZE,

Preparation of metal spinning mold:

- Rough turning and milling of the mold,

- Heat treatment, hardness treatment of the spinning mold,

- Fine turning of the installation position: to ensure the accuracy of repeated installation of the spinning mold,

- Install the mold on the CNC spinning machine to perform fine turning of the surface contour to ensure the runout accuracy of the mold.

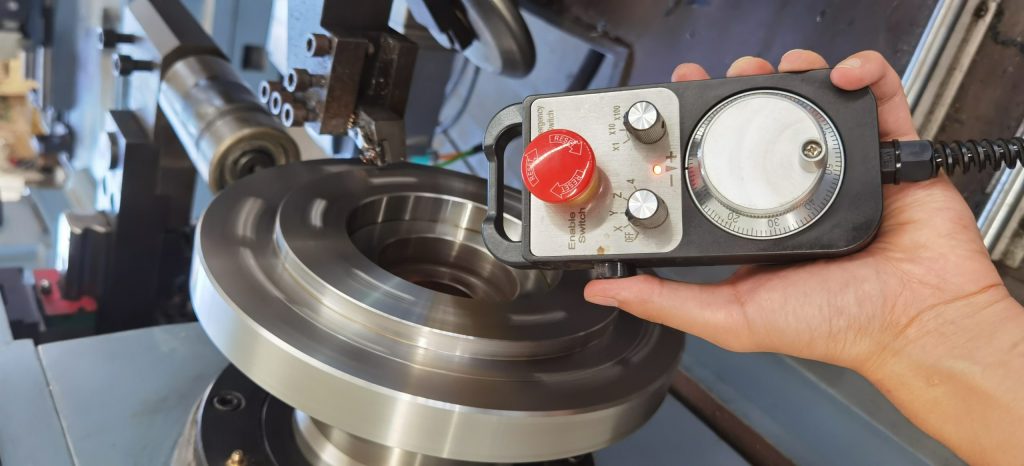

Metal spinning process debugging and testing:

|

|

|

|

|

|

This is an online training course for a Mexican manufacturer of ventilation refraction lamps. Due to special reasons, face-to-face training and technical guidance were not possible!

The customer was very smart. In the early stage, he recorded videos and pictures of the test and completed the installation, mechanical, electrical, and horizontal work of the CNC spinning machine. During the period, it took only 5-6 days to complete the spinning commissioning of multiple parts in the project plan.

Later, Altron assisted the customer in developing new metal spinning products and new spinning processes, allowing customers to use Altron’s spinning machines more smoothly.

Key factors for learning CNC spinning machines:

- The customer has CNC lathe operation inspection,

- CAD software skills,

- Manual Manual spinning technology,

Combining these 3 main factors, the use of the machine becomes simple. Altron’s CNC metal spinning software only needs to draw the contour line of the spinning trajectory, and the software will automatically generate the G code program of the CNC spinning machine. The program automatically generates the spindle speed, feed speed, and fast return to dry run speed; the CNC spinning program only needs a little detection, and it can be transferred to the CNC metal spinning machine to start working, which can be transmitted via USB or data network.

Since the coordinates of program production are established on the machine tool coordinate system, the numerical coordinates will not change unless the spinning wheel or turning tool is replaced. This ensures that the daily production of the machine can call the old program and can be produced immediately without re-debugging; stable data and higher production portability!

Regular After-Sales Consultation:

Altron will proactively contact and consult customers at specified intervals to ensure that Altron’s CNC spinning machines are in normal and stable production at the manufacturer’s factory; when engineers go to surrounding cities or countries, they will contact customers immediately to inform them of their itinerary and ask whether they need to visit and solve problems.

Altron’s Factory Video

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| AC-800 | 800 | 400 | 600 | 40 | 20 | 18.5 | 50-1000 | 5 / 3 / 2 |

| AC-1000 | 1050 | 450 | 650 | 40 | 20 | 22 | 50-1000 | 6 / 4 / 3 |

| AC-1200 | 1250 | 480 | 800 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| AC-1400 | 1450 | 650 | 800 | 70 | 50 | 37 | 50-500 | 10 / 6 / 4.5 |

| AC-1600 | 1650 | 680 | 800 | 80 | 50 | 37 | 50-500 | 10 / 6 / 4.5 |

| AC-2000 | 2000 | 750 | 1250 | 140 | 100 | 55 | 20-400 | 14 / 10 / 7 |

| AC-2500 | 2500 | 800 | 1750 | 200 | 140 | 90 | 20-300 | 14 / 10 / 7 |

| AC-3000 | 3000 | 900 | 2000 | 200 | 160 | 115 | 10-250 | 14 / 10 / 7 |

Machine Configuration Parameters

Technical index

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The AC1400 has exceeded our expectations in terms of efficiency and versatility. Its user-friendly interface and adjustable tooling options have made component shaping a breeze. We are thrilled with the exceptional results we have achieved

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Thanks to the AC1400, we have been able to streamline our metal spinning operations. Its robust construction and comprehensive safety features ensure a secure working environment, while its maintenance-friendly design has reduced our downtime. An excellent investment for our manufacturing facility

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The AC1400 Single Wheel CNC Spinning Machine has transformed our metal spinning process. Its precise control and repeatability have allowed us to achieve exceptional results with ease. Highly recommended

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We are extremely impressed with the performance of the AC1400 machine. It offers outstanding stability and accuracy, resulting in flawless shaping of cylindrical components. Our productivity and product quality have significantly improved.