CNC Metal Spinning Machine -Single Roller AC1000

Metal Spinning For Milk Cans and Medicine Cans

|

Machine Name |

Single Wheel CNC Metal Spinning Machine |

|

Model |

AC1000:(diameter max Ф1050;aluminum-Max 8mm; carbon steel-Max 4.0mm) |

|

Application Industry: |

(Aerospace, Aviation Weapons, Medical, Furniture, Lighting, Building, Fire, Musical Instruments, Crafts, Automotive Parts, Pressure Vessel, Milk Cans and Medicine Cans ) |

|

Technical Service |

Complete the test in the early stage; provide online and offline training in the later stage, and complete the turnkey project. |

|

Technical Guidance |

Online 24 hours a day/ 7*24 Pre-sales technical service |

|

Project Progress |

30-120 days |

|

Relevant Files |

ALTRON_AUTO Catalog-Industrial Blower Machinery Turnkey Project |

- ADAVANTAGES

- PARAMETERS

- CUSTOMER TESTIMONIALS

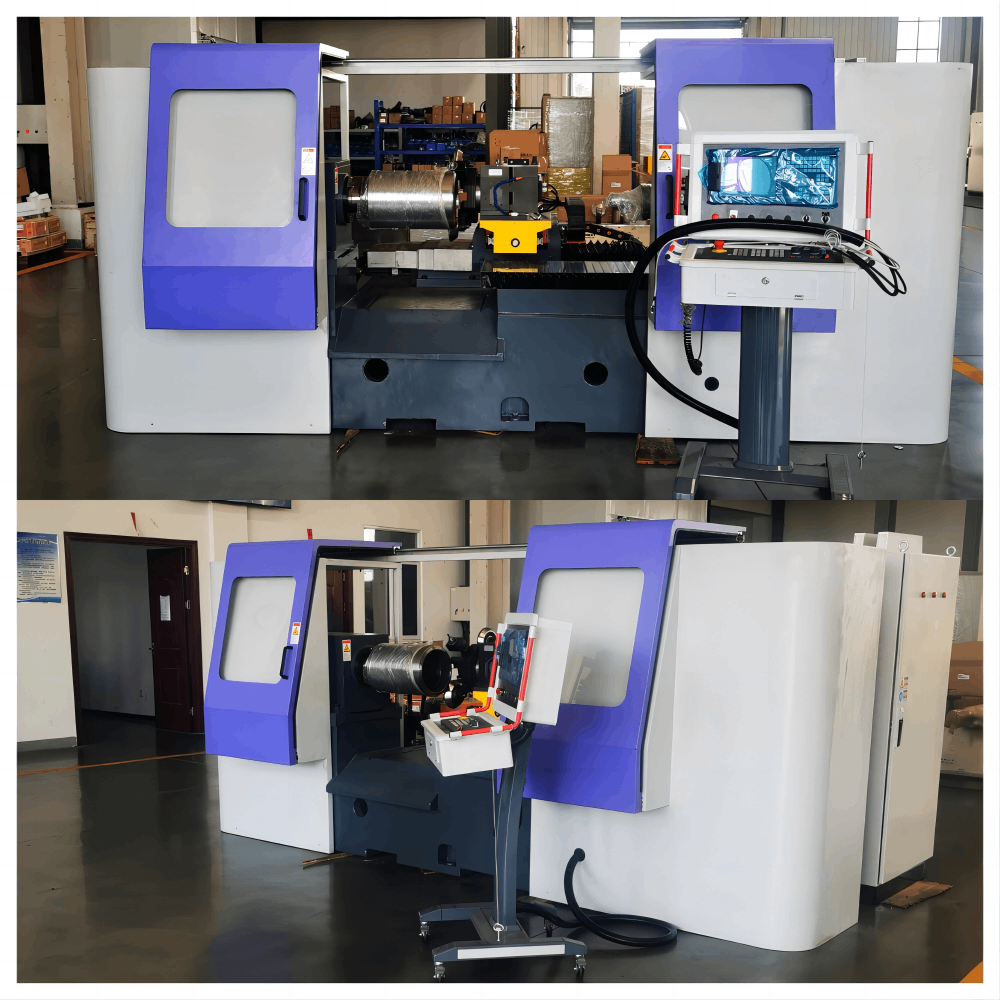

Single Roller CNC Metal Spinning Machine-AC1000 Introduction:

Altron’s CNC Metal Spinning For Milk Cans & Medicine cans is a very successful market application case, especially in countries with developed animal husbandry such as South Africa and Turkey. The machine has brought huge benefits to milk can manufacturers.- Metal Spinning For Milk Cans.

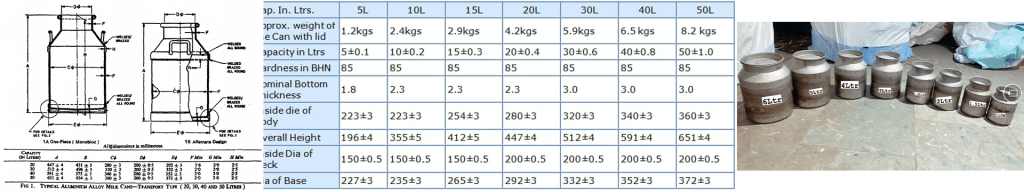

AC1000 CNC spinning machine is upgraded from the standard CNC spinning machine, with the addition of a hydraulic rotary cylinder. For thin-walled milk cans and medicine cans, it can spin round materials with a diameter of less than 1050mm; 40L milk cans and medicines, diameter: 340mm; height 590mm (The increase in the stroke length of the milk can machine is mainly to improve the production efficiency and quality of the CNC metal spinning machine);

The machine is equipped with Siemens mid-to-high-end system 828D, and free CNC spinning software is provided, making the spinning process and technology simpler!

Altron’s Single Roller CNC Metal Spinning Machine can spin a variety of metal materials and is suitable for Aerospace, aviation weapons, medical, furniture, lighting, construction, firefighting, musical instruments, handicrafts, auto parts, pressure vessels, milk cans, Medicine Cans, etc.

Working Video Of Spinning Machine

CNC Metal Spinning Process Flowchart And Case Studies:

Case Of Milk Cans

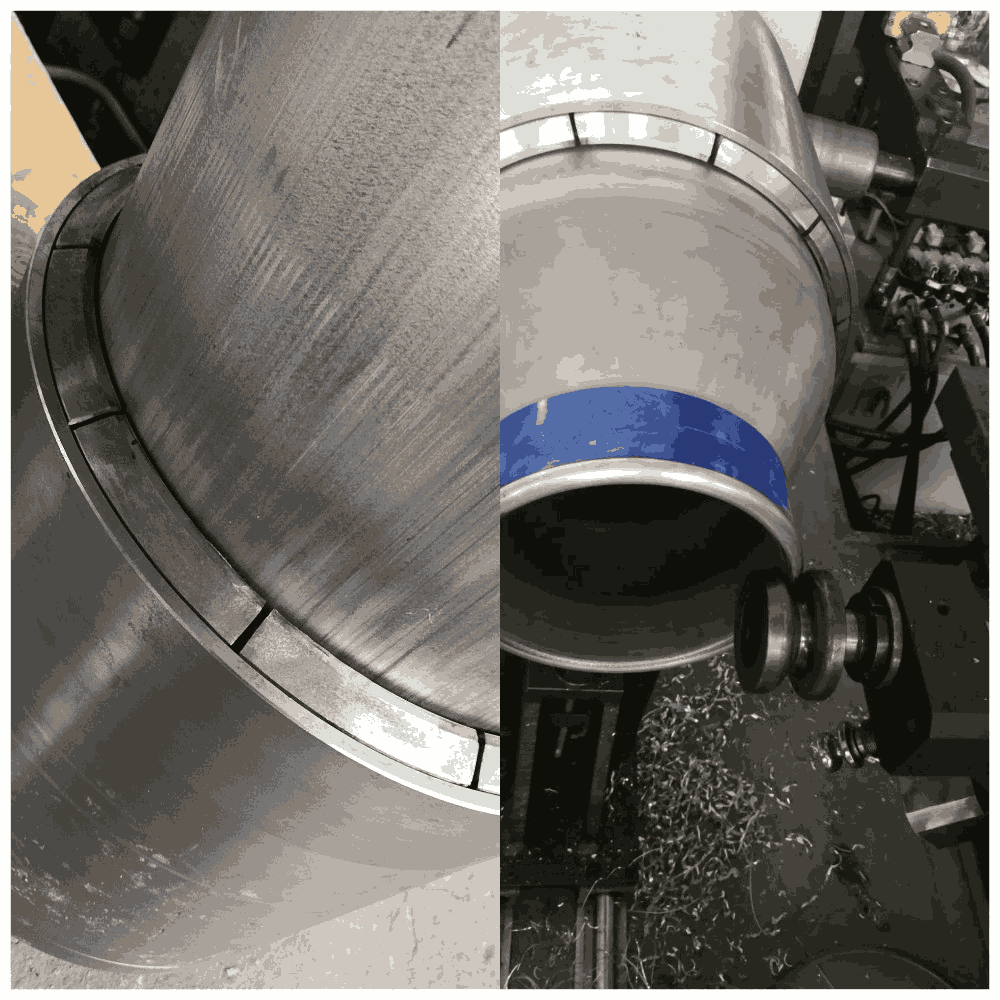

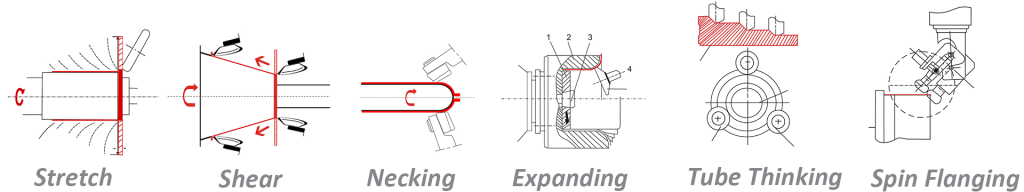

The spinning process of milk cans and medicine cans mainly uses two metal spinning processes: Stretch metal spinning and Neaking metal spinning.

1. Metal Spinning Case Of Milk Cans:

- The factory produces milk cans in many sizes and models, but in small quantities, and is in the development market;

- The milk can factory of the trader-turned-manufacturer can produce samples in a short period of time;

- The production of small batches of customized milk can orders;

- The development mold cost is low, the development cycle is short, and the size contour can be changed at will;

- The shape of the neck part is controlled by the CNC program, and no complex mold is required;

- The material at the bottom of the barrel is thicker, which has higher strength for the milk cans;

- The body of the milk can can be thinned to save costs;

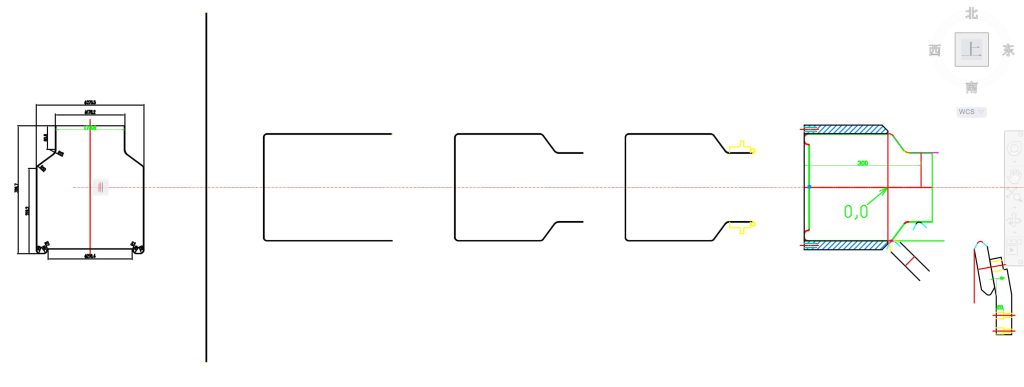

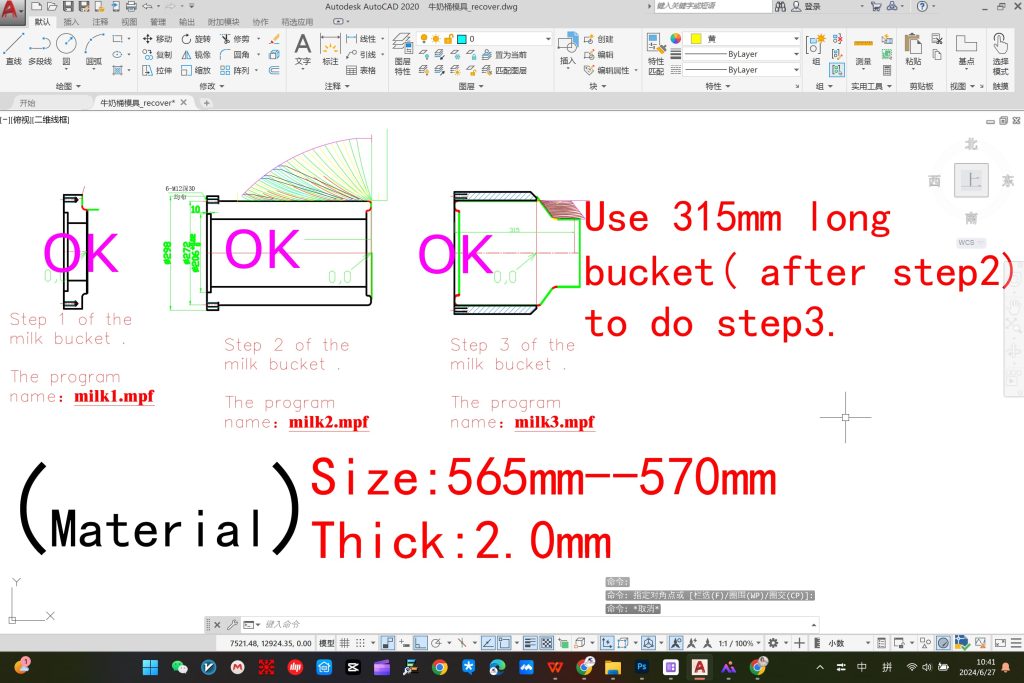

Process: Completed in two processes on the spinning machine.

2. Case of deep drawing + Neaking metal spinning

- The factory mass produces milk cans, with a large number of them, in the mass production stage, and has a fixed sales market;

- The investment cost of deep drawing molds is high, but the output and efficiency are greatly improved;

- The hydraulic machine for deep drawing needs to be specially customized. For example, the height of 40L milk cans is about 600, and the third deep drawing requires a hydraulic press with a working platform of more than 1800mm;

Process: multiple deep drawing & one spinning necking process

3. Case Of Deep Drawing + Tube Thinking Metal Spinning + Neaking Metal Spinning

- Neaking Metal Spinning

- The number of production orders is medium;

- Do not want to invest in high deep drawing mold costs;

- Take a compromise between the above two production efficiency and capacity issues;

Process: single stretching + 2 spinning processes

CNC metal spinning for milk cans solution

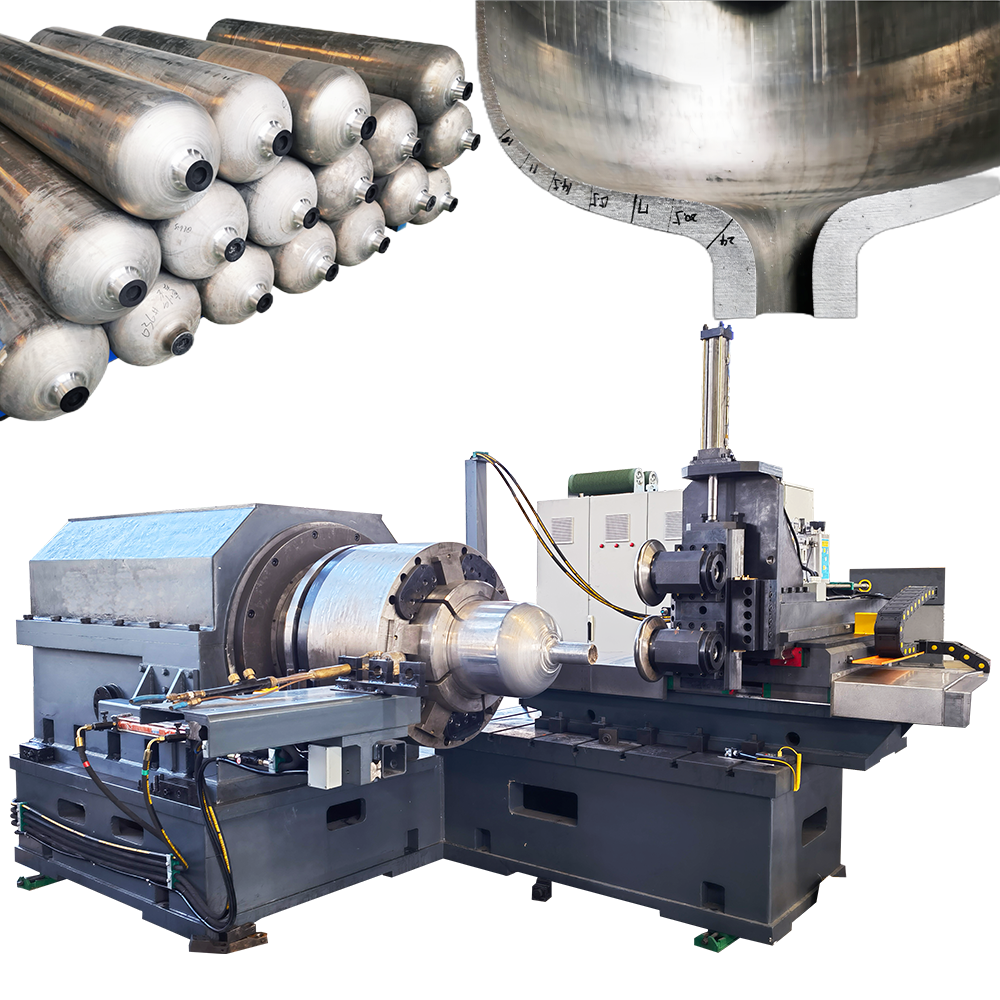

Altron’s CNC metal spinning machine is used to make milk, from the disc to the whole process of forming milk cans. The metal aluminum disc is cut by laser; the disc is formed into a barrel embryo by CNC spinning; the mold is replaced or another machine with a hydraulic rotary cylinder is used for extreme necking and beading of the mouth edge. Other processes include manual polishing and brushing, cleaning and degreasing; anodizing; drying, and finally packaging the finished milk cans.

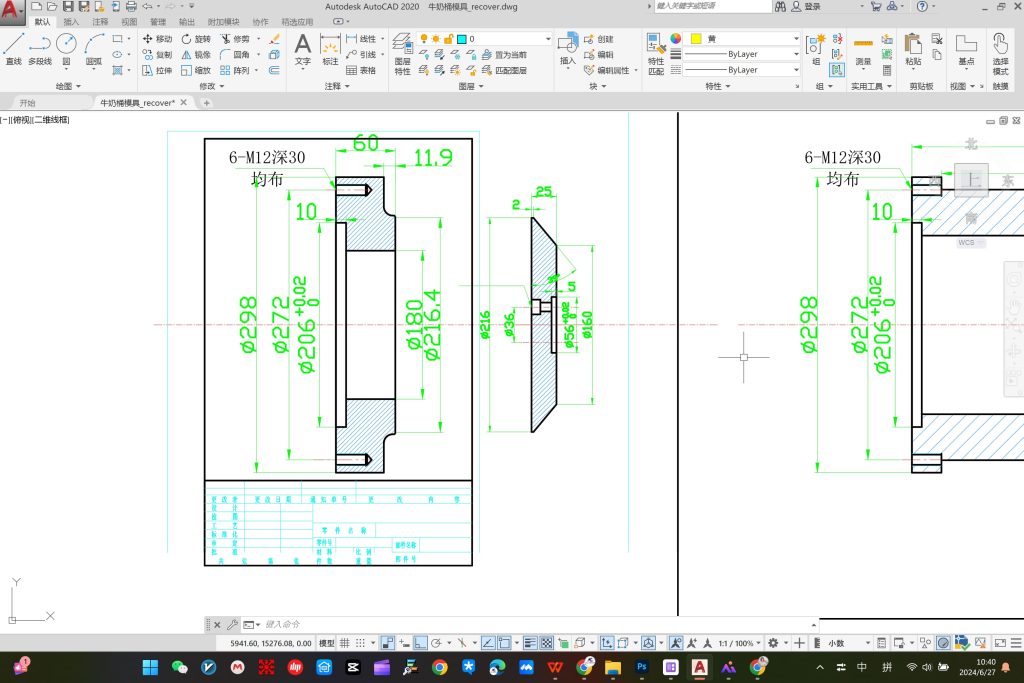

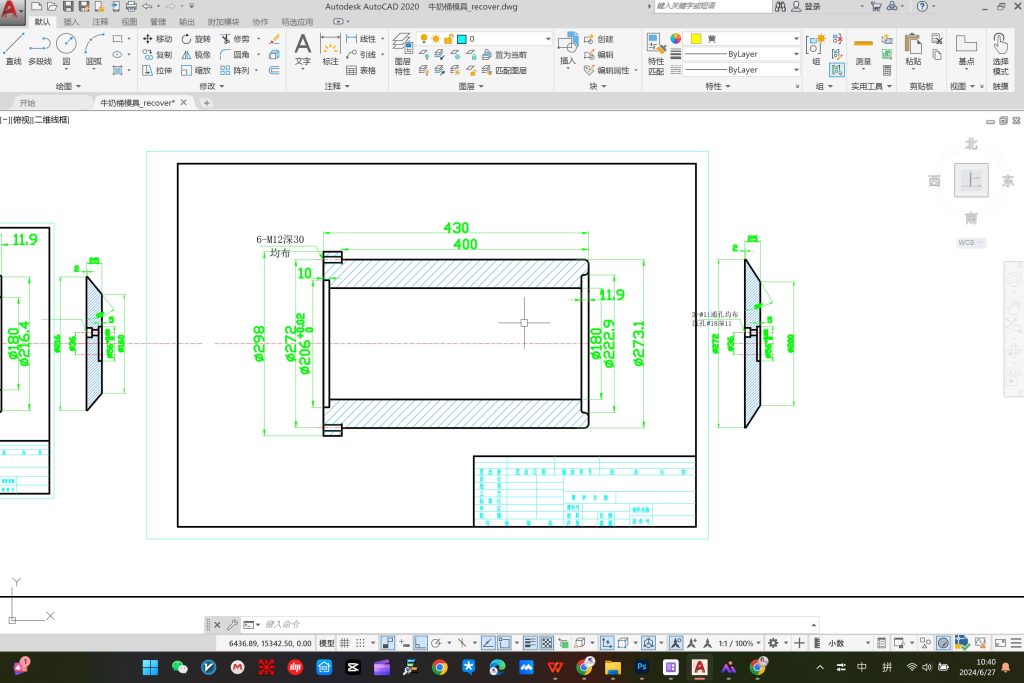

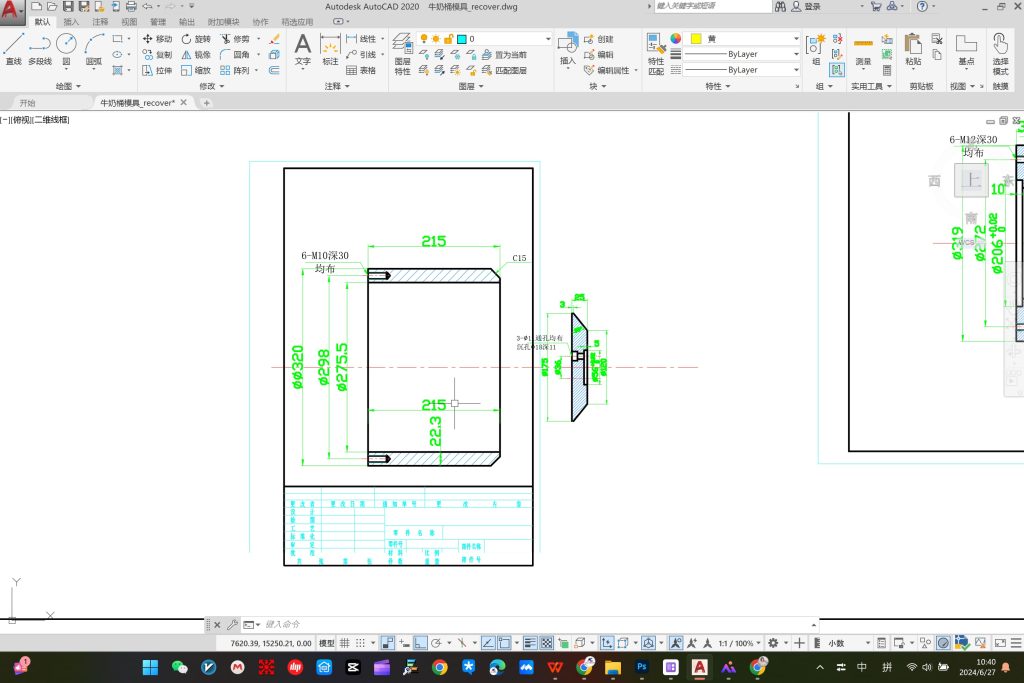

CNC metal spinning mold for milk cans

CNC Metal Spinning Milk Cans Process and Spinning Technology

For any questions related to CNC spinning technology, please consult Joby online.

If you are engaged in the production and manufacturing of milk cans, or sell milk cans in the form of trade and are ready to invest in your own production factory, I can provide you with a complete production plan and automated machinery for your milk cans and medicine cans.

Altron’s Factory Video

Configuration

Standard Configuration

- SIEMENS CNC 828D

- SIEMENS Servo Motor & Drive

- Asynchronous Servo Spindle Motor

- APEX Servo Reducer

- High Strength Ductile Iron Sliding Table

- Blanks Center Assembly

- Back Roller Assembly

- CNC Tool Turret

- Hydraulic Station & Air Cooling System

- Air Unload Assembly

- Self-developed Spinning System

- Control System Remote Maintenance

Select Configuration

- Spindle Spinning Cylinder

- Trimming Tool Assembly

- Air Conditioner for Hydraulic Station

- Hot Spinning Parts Under 700℃

- Teach In & Play Back System

| Model No. |

Max. Material Dia. (mm) |

Radial Stroke (mm) |

Axial Stroke (mm) |

Roller Thrust (KN) |

Tailstock Force (KN) |

Spindle Power (KN) |

Spindle Speed (RPM) |

Material Thickness AL./carbon steel/SUS (mm) |

| AC-800 | 800 | 400 | 600 | 40 | 20 | 18.5 | 50-1000 | 5 / 3 / 2 |

| AC-1000 | 1050 | 450 | 650 | 40 | 20 | 22 | 50-1000 | 6 / 4 / 3 |

| AC-1200 | 1250 | 480 | 800 | 60 | 50 | 30 | 50-800 | 8 / 5 / 4 |

| AC-1400 | 1450 | 650 | 800 | 70 | 50 | 37 | 50-500 | 10 / 6 / 4.5 |

| AC-1600 | 1650 | 680 | 800 | 80 | 50 | 37 | 50-500 | 10 / 6 / 4.5 |

| AC-2000 | 2000 | 750 | 1250 | 140 | 100 | 55 | 20-400 | 14 / 10 / 7 |

| AC-2500 | 2500 | 800 | 1750 | 200 | 140 | 90 | 20-300 | 14 / 10 / 7 |

| AC-3000 | 3000 | 900 | 2000 | 200 | 160 | 115 | 10-250 | 14 / 10 / 7 |

Machine Configuration Parameters

Technical index

Ball screw rod

-

Marcley

★★★★★Post a review on Aug 21, 2022 From Bolivia

The AC1000 has exceeded our expectations in terms of efficiency and versatility. Its user-friendly interface and adjustable tooling options have made component shaping a breeze. We are thrilled with the exceptional results we have achieved

-

Arthur Zonneveld

★★★★★Post a review on Fec 21, 2022 From Mauritius

Thanks to the AC1000, we have been able to streamline our metal spinning operations. Its robust construction and comprehensive safety features ensure a secure working environment, while its maintenance-friendly design has reduced our downtime. An excellent investment for our manufacturing facility

-

Nicolas Vazquez

★★★★★Post a review on jul 21, 2022 From Uruguay

The AC1000 Single Wheel CNC Spinning Machine has transformed our metal spinning process. Its precise control and repeatability have allowed us to achieve exceptional results with ease. Highly recommended

-

OSCAR URBANEJA

★★★★★Post a review on Oct 10, 2022 From Venezuela

We are extremely impressed with the performance of the AC1000 machine. It offers outstanding stability and accuracy, resulting in flawless shaping of cylindrical components. Our productivity and product quality have significantly improved.