Small CNC Metal Spinning Machine for Sale! Unlock New Possibilities

When it comes to precision metal spinning, one size certainly doesn’t fit all. ALTRON, a leading manufacturer in the field, understands this principle implicitly. Their Small CNC Metal Spinning Machine for Sale is not just tools but solutions meticulously crafted to cater to the nuanced needs of various industries. Whether it’s aerospace, automotive, or household appliance manufacturing, ALTRON’s machines are engineered to meet the specific requirements of each sector, ensuring optimal performance and unparalleled results.

High Precision Spinning: Customization for Industry Demands

1.1 Tailoring Precision: Aerospace Industry

In the aerospace industry, where precision is paramount and tolerances are razor-thin, ALTRON’s CNC metal spinning machines shine. These machines are equipped with advanced controls and programming capabilities that allow for the creation of complex geometries with utmost accuracy. Whether it’s forming intricate engine components or crafting lightweight yet durable aircraft parts, ALTRON’s tailored solutions empower aerospace manufacturers to push the boundaries of innovation.

1.2 Optimizing Efficiency: Automotive Sector

In the automotive sector, where production volumes are high and lead times are tight, efficiency is the name of the game. ALTRON’s CNC machines are designed with this in mind. By integrating features such as rapid tool changeovers and automated material handling systems, these machines streamline workflows and minimize downtime, allowing automotive manufacturers to meet demand without compromising on quality or cost-effectiveness.

1.3 Sophisticated Designs: Household Appliance Manufacturing

In the realm of household appliance manufacturing, aesthetics are just as important as functionality. ALTRON’s CNC metal spinning machines enable manufacturers to create sleek and sophisticated designs that captivate consumers’ attention. From stainless steel kitchenware to decorative lighting fixtures, these machines offer unparalleled flexibility and precision, ensuring that every finished product meets the highest standards of quality and craftsmanship.

Global Market Insight

2.1 Staying Ahead: Market Analysis

In today’s rapidly changing global market, staying ahead of the competition is crucial. ALTRON’s comprehensive market analysis allows them to anticipate industry trends and customer demands, ensuring that their machines are always equipped with the latest technologies and functionalities. Whether it’s integrating IoT capabilities for real-time monitoring or adopting advanced materials for improved performance, ALTRON remains at the forefront of innovation, empowering manufacturers to stay ahead of the curve.

2.2 Adapting to Industry Shifts

As industries evolve and markets shift, ALTRON remains agile and ready to adapt to changing needs and requirements. Whether it’s the emergence of new materials, the adoption of sustainable manufacturing practices, or the increasing demand for customization, ALTRON’s commitment to innovation and flexibility ensures that its machines are always primed to meet the evolving demands of the global market.

2.3 Expanding Global Reach

With a strong presence in markets around the world, ALTRON is well-positioned to serve customers wherever they may be. From established manufacturing hubs in North America and Europe to emerging markets in Asia and beyond, ALTRON’s global network of sales and service professionals ensures that customers receive the support they need, wherever their operations may take them.

Small CNC Metal Spinning Machine for Sale: Precision Engineering

3.1 Engineering Excellence

At the heart of ALTRON’s Small CNC Metal Spinning Machine for Sale lies a commitment to engineering excellence. From the selection of high-quality materials to the precision machining of critical components, every aspect of these machines is meticulously designed and rigorously tested to ensure optimal performance and reliability. Whether it’s achieving tight tolerances, minimizing vibration, or maximizing throughput, ALTRON’s machines are engineered to deliver unmatched precision in every spin.

3.2 Unrivaled Accuracy

In metal spinning, accuracy is non-negotiable. ALTRON’s CNC machines are designed to deliver precise, repeatable results with every rotation. By leveraging advanced servo motors, precision ball screws, and state-of-the-art control systems, these machines offer unrivaled accuracy and consistency across a wide range of applications and materials. Whether it’s aluminum, stainless steel, or titanium, ALTRON’s machines ensure that every spun part meets the strictest quality standards.

3.3 Continuous Improvement

ALTRON is committed to continuous improvement, constantly seeking ways to enhance the performance and capabilities of their machines. Whether it’s refining machining algorithms for smoother tool paths, optimizing cooling systems for faster cycle times, or introducing new features for greater versatility, ALTRON’s dedication to innovation ensures that their machines remain at the forefront of the industry, delivering superior results today and tomorrow.

Small Cnc Metal Spinning Machine For Sale: Enhanced Efficiency

4.1 Maximizing Productivity

In the fast-paced world of manufacturing, time is money. ALTRON’s Small CNC Metal Spinning Machine for Sale is designed for maximum efficiency, helping manufacturers reduce production time and increase throughput without sacrificing quality. Whether it’s optimizing tool paths for faster cycle times, implementing intelligent work holding solutions for quicker setups, or integrating robotic automation for unmanned operation, ALTRON’s machines empower manufacturers to do more with less, driving productivity and profitability to new heights.

4.2 Reducing Waste

Efficiency is not just about speed; it’s also about minimizing waste. ALTRON’s CNC machines are engineered to maximize material utilization, minimizing scrap and reducing overall production costs. Whether it’s nesting parts more efficiently to reduce material waste or implementing closed-loop feedback systems to optimize cutting parameters, ALTRON’s machines help manufacturers operate leaner and greener, driving sustainability and cost savings throughout the production process.

4.3 Streamlining Workflows

ALTRON’s Small CNC Metal Spinning Machine for Sale is designed with the user in mind, featuring intuitive interfaces and ergonomic designs that streamline workflows and minimize operator fatigue. Whether it’s programming complex parts with ease, monitoring machine performance in real-time, or accessing diagnostic tools for quick troubleshooting, ALTRON’s machines empower operators to work smarter, not harder, ensuring maximum uptime and productivity on the shop floor.

Small High-Precision Parts Spinning: Advanced Automation

5.1 Embracing the Future

Automation is the future of manufacturing, and ALTRON is at the forefront of this revolution. Their CNC metal spinning machines integrate cutting-edge automation features that streamline workflows, minimize manual intervention, and maximize productivity. Whether it’s robotic loaders for unmanned operation, vision systems for part inspection, or adaptive control algorithms for real-time process optimization, ALTRON’s machines leverage the power of automation to drive efficiency and innovation in the modern factory.

5.2 Unlocking Potential

By automating repetitive tasks and eliminating human error, ALTRON’s CNC machines free up operators to focus on more value-added activities, such as design optimization, process improvement, and quality assurance. This not only increases overall productivity but also empowers manufacturers to unleash their creative potential, pushing the boundaries of what’s possible and driving innovation across the entire supply chain.

5.3 Empowering the Workforce

Contrary to popular belief, automation doesn’t replace workers; it empowers them. ALTRON’s CNC metal spinning machines are designed to work seamlessly alongside human operators, augmenting their skills and enhancing their capabilities. By providing operators with the tools they need to succeed, from intuitive programming interfaces to advanced diagnostic capabilities, ALTRON’s machines empower the workforce of tomorrow, ensuring that they remain competitive in an increasingly automated world.

Military Spinning: Precision in Defense

6.1 Crafting Critical Components:

In military applications, precision is not just a preference but a necessity. ALTRON’s Small CNC Metal Spinning Machine caters to the demanding requirements of military spinning, enabling the fabrication of critical components such as missile powder covers with unparalleled accuracy.

6.2 Meeting Rigorous Standards:

With advanced CNC technology at its core, ALTRON’s machine ensures precise control over the spinning process, meeting the rigorous standards of military-grade applications. From shaping to finishing, every aspect is meticulously crafted to withstand the most demanding environments.

6.3 Enhancing National Security:

By facilitating the production of high-quality components for defense systems, ALTRON’s Small CNC Metal Spinning Machine plays a crucial role in enhancing national security. Its ability to deliver precision-crafted parts ensures the reliability and effectiveness of military equipment.

Missile Powder Cover Spinning: Precision in Every Detail

7.1 Ensuring Safety and Reliability:

The fabrication of missile powder covers requires the utmost precision to ensure safety and reliability in critical operations. ALTRON’s Small CNC Metal Spinning Machine excels in this aspect, providing precise control over the spinning process to create components that meet the highest quality standards.

7.2 Optimizing Performance:

By leveraging CNC technology, ALTRON’s machine optimizes the performance of missile powder covers, enhancing their aerodynamic properties and ensuring optimal functionality. This precision-engineered approach contributes to the overall effectiveness of missile systems.

7.3 Adapting to Evolving Threats:

In an ever-changing landscape of defense technology, ALTRON’s Small CNC Metal Spinning Machine offers flexibility and adaptability to meet evolving threats. Its ability to quickly produce customized components enables defense agencies to stay ahead of emerging challenges.

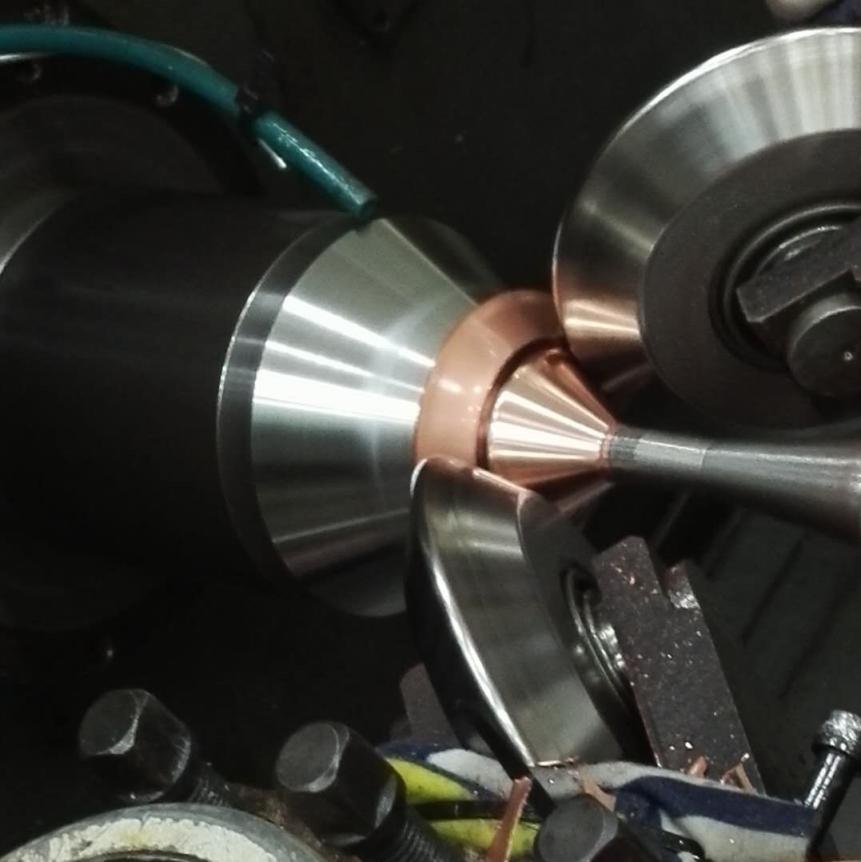

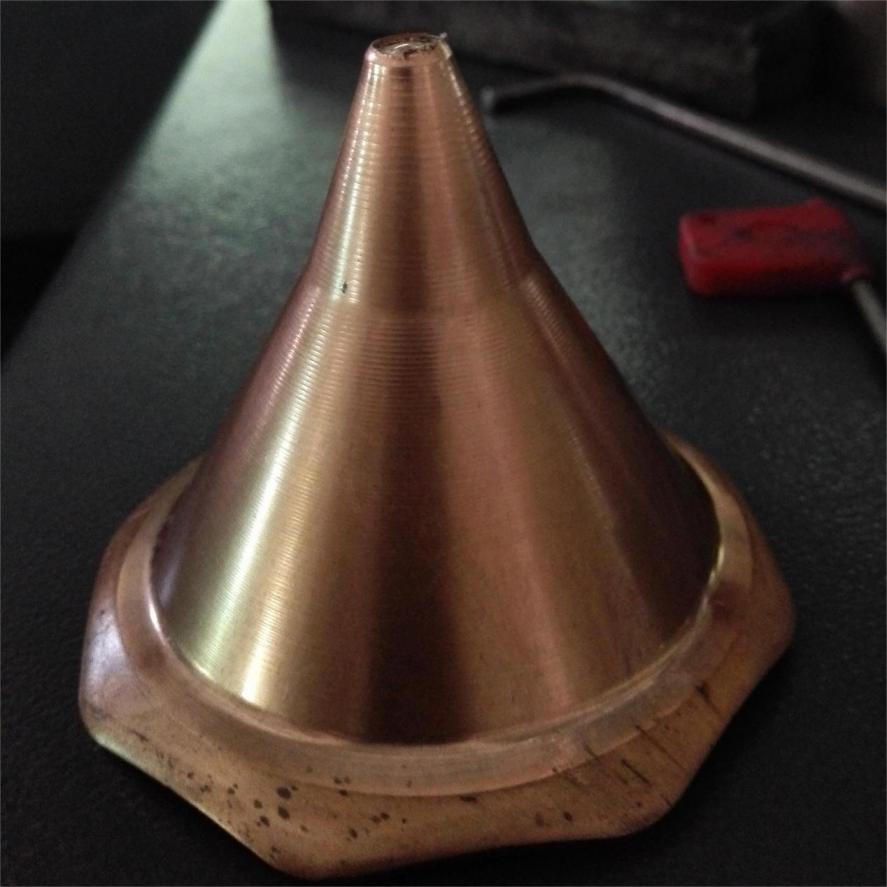

Copper CNC Metal Spinning: Shaping the Future of Electronics

8.1 Precision in Electronic Components:

From heat sinks to connectors, copper components play a crucial role in electronic devices. ALTRON’s Small CNC Metal Spinning Machine empowers manufacturers to craft these components with precision, ensuring optimal performance and reliability.

8.2 Meeting Industry Standards:

With meticulous attention to detail, ALTRON’s machine meets the strict quality standards of the electronics industry. Each copper component is crafted to exact specifications, guaranteeing compatibility and functionality in various electronic applications.

8.3 Driving Innovation:

By enabling the production of precision-crafted copper components, ALTRON’s Small CNC Metal Spinning Machine drives innovation in the electronics sector. Its ability to create complex shapes and geometries expands the possibilities for designers and engineers, leading to the development of advanced electronic devices.

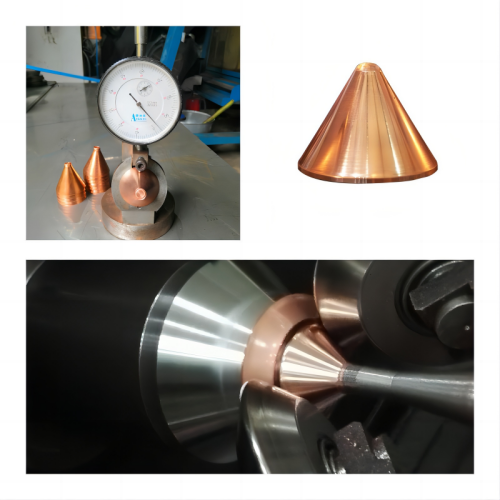

High-Precision Spinning Inspection Tools: Ensuring Quality Assurance

9.1 Critical Role in Quality Control:

Inspection tools play a vital role in ensuring the quality and reliability of manufactured components. ALTRON’s Small CNC Metal Spinning Machine facilitates the production of high-precision inspection tools, enabling manufacturers to conduct thorough quality assurance processes.

9.2 Enhancing Manufacturing Efficiency:

With precision-engineered inspection tools, manufacturers can identify and rectify defects early in the production process, minimizing wastage and optimizing manufacturing efficiency. ALTRON’s machine streamlines this crucial aspect of quality control, ensuring consistency and reliability in every batch of components.

9.3 Meeting Industry Regulations:

In regulated industries such as aerospace and automotive, adherence to stringent quality standards is non-negotiable. ALTRON’s Small CNC Metal Spinning Machine helps manufacturers meet and exceed these regulations by producing inspection tools with unmatched precision and accuracy.

Conclusion

In conclusion, ALTRON’s Small CNC Metal Spinning Machine for Sale represents the pinnacle of precision engineering, efficiency, and automation. With tailored solutions for diverse industries, comprehensive market insight, and a relentless commitment to innovation, ALTRON is revolutionizing the way metal spinning is done, empowering manufacturers to achieve new levels of productivity, quality, and competitiveness in today’s global market.