Exploring Spun Metal: The Precision and Versatility of CNC Spinning Machines

Spun metal, a process as old as metalworking itself, has evolved significantly with the advent of CNC spinning machines. These advanced tools have revolutionized how industries shape and form metal, offering unmatched precision and efficiency. This blog delves into the intricacies of CNC spun metal machines, their applications across various sectors, and the specialized needs they fulfill.

What is CNC spun metal machine?

CNC spun metal machines are specialized equipment used for metal spinning, a technique where a metal disc or tube is rotated at high speed and formed into a desired shape using CNC (Computer Numerical Control) programming. Unlike traditional methods that require manual skill, CNC spinning machines automate and streamline the process, ensuring consistent results and intricate designs. ALTRON stands at the forefront of manufacturing such machines, combining cutting-edge technology with decades of expertise in metalworking.

CNC spinning involves the use of best systems to create precise blueprints of the intended metal product. The machine then interprets these designs, using hydraulic or electrically driven rollers to shape the metal according to the programmed specifications. This method not only enhances accuracy but also reduces material waste, making it a preferred choice for industries that demand high-quality, customized metal components.

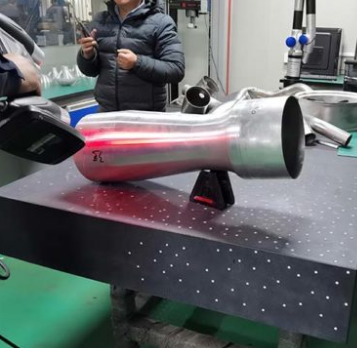

Introduce CNC Spinning Machine AC-D2500: ALTRON has carved a niche for itself in the realm of CNC metal spinning machines, known for their precision, reliability, and versatility. The AC-D2500 exemplifies ALTRON’s commitment to innovation in industrial spinning technology. This machine is tailored for handling a wide array of materials including stainless steel, carbon steel, aluminum alloy, and specialized alloys, making it indispensable for industries requiring robust and precise metal components.

ALTRON’s engineering prowess is evident in the design of the AC-D2500. Featuring a dual-channel symmetrical 45-degree inclined worktable, this machine enhances spinning thrust, ensuring high efficiency and accuracy in the production process. With a formidable total power of 195KW, the AC-D2500 stands out as a heavy-duty CNC spinning machine capable of meeting the most demanding manufacturing requirements.

How to use CNC spun metal machine?

Operating a CNC spun metal machine requires specialized training due to its complexity and the precision it demands. Operators start by loading the raw metal material—typically aluminum, stainless steel, or copper—onto the machine. They then input the CAD file containing the design parameters, adjusting settings such as rotational speed, roller pressure, and tooling path. Once the setup is complete, the machine spins the metal while the CNC system guides the rollers to gradually shape the material into the desired form.

Precision is paramount during operation, as even minor deviations can affect the final product’s integrity. Operators monitor the process closely, making adjustments as necessary to ensure dimensional accuracy and surface finish. Post-production, quality checks are conducted to verify compliance with specifications before the finished components are released for further assembly or application.

When to Use Spun Metal Technology

Spun metal technology is employed whenever there is a need for precision-formed metal components that exhibit superior strength, durability, and aesthetic appeal. Unlike traditional metalworking methods that may involve welding or casting, spun metal processes involve shaping a metal disc or tube by rotating it at high speeds and pressing it against a tool (mandrel or roller).

This method is particularly advantageous when manufacturing components that require seamless designs, high tolerances, and intricate geometries. Industries ranging from aerospace to fire protection utilize spun metal technology to achieve optimal performance and efficiency in their respective applications.

Which industry needs to use spun metal applications?

Industrial Fans: Optimizing Airflow and Efficiency

Industrial fans are critical for ventilation and air handling systems in various industrial settings, including manufacturing plants, warehouses, and commercial buildings. Spun metal technology plays a crucial role in manufacturing fan blades and housings that are designed for optimal airflow efficiency and minimal noise levels. CNC spinning machines allow for the production of aerodynamically optimized fan components, ensuring reliable performance and energy savings in HVAC systems. Manufacturers in this sector benefit from the precision and cost-effectiveness offered by spun metal processes to meet the demanding requirements of modern ventilation systems.

Aerospace and Defense: Meeting Rigorous Standards and Performance Demands

The aerospace and defense industries demand components that can withstand extreme conditions such as high temperatures, pressures, and mechanical stresses. Spun metal technology enables the production of lightweight yet durable components such as engine components, missile casings, and satellite dishes. These components must adhere to strict safety and performance standards, making CNC spinning an ideal choice due to its ability to produce complex shapes with high structural integrity. Aerospace manufacturers rely on spun metal applications to enhance aircraft performance, reduce weight, and ensure the reliability of critical systems and structures.

Machinery and Hardware: Customization and Durability

In the machinery and hardware sectors, spun metal technology offers unparalleled flexibility and customization capabilities. Manufacturers use CNC spinning machines to produce a wide range of components, including gears, bearings, shafts, and specialized housings. The ability to work with various metals such as aluminum, stainless steel, and copper allows for the creation of durable and precision-engineered parts tailored to specific equipment requirements. CNC spinning processes enhance the durability, functionality, and cost-effectiveness of machinery and hardware components across industries such as automotive, agriculture, and precision engineering.

Construction and Fire Protection: Enhancing Structural Integrity and Safety

In construction and fire protection applications, spun metal technology contributes to both the structural integrity and safety of buildings and fire suppression systems. Architects and engineers utilize spun metal components for structural elements such as columns, beams, and cladding panels due to their ability to create seamless and aesthetically pleasing designs. Spun metal also plays a crucial role in fire protection systems by manufacturing components like fire extinguisher casings, sprinkler heads, and ductwork. These components are engineered to withstand high temperatures and corrosive environments, ensuring reliable performance during fire emergencies and enhancing overall building safety.

Who provides CNC spun metal solutions?

In the realm of CNC spun metal solutions, ALTRON emerges as a key player, particularly renowned in Asia for its engineering prowess and innovative manufacturing capabilities. Established with a focus on technological innovation and sustainable development, ALTRON integrates research and development, manufacturing, sales, and service within its operations. This holistic approach ensures that customers receive tailored solutions for their metal forming needs, including metal spinning, stamping, stretching, polishing, and automatic welding.

ALTRON’s commitment to excellence is underscored by its dedicated team of engineers and technicians who specialize in metal forming technologies. This team not only focuses on delivering turnkey projects but also engages in continuous research to enhance product quality and technological innovation. This proactive stance has positioned ALTRON as a leader in CNC spinning technology both domestically and internationally, fostering collaborations with global partners and contributing to advancements in the field.

Why choose Altron’s CNC Supun metal machiane?

Choosing ALTRON’s CNC spun metal machines offers several distinct advantages rooted in their technological superiority and customer-centric approach. ALTRON’s machines are equipped with state-of-the-art CNC controls and precision engineering, ensuring unparalleled accuracy and efficiency in metal spinning processes. This capability is crucial for industries requiring high-performance components such as industrial fans, aerospace parts, and specialized machinery.

Moreover, ALTRON’s machines are designed to optimize production workflows, reduce material waste, and enhance overall manufacturing efficiency. By focusing on comprehensive solutions and customization options, ALTRON caters to the specific requirements of industrial fan manufacturers and other sectors where precision metal components are essential. This dedication to meeting customer needs has earned ALTRON a reputation for reliability and excellence in the industry.

ALTRON’s Impact on the Industrial Fan Automation Sector

Within the industrial fan automation sector, ALTRON has made significant strides by providing integrated production line solutions. Industrial fans play a critical role in various applications, including HVAC systems, ventilation, and industrial processes. ALTRON’s CNC spun metal technology enables the production of fan blades, housings, and other components with optimized aerodynamics and structural integrity. This not only improves fan performance but also contributes to energy efficiency and noise reduction in industrial environments.

Since 2018, ALTRON has intensified its focus on industrial fan services, investing heavily in technological research and development. This strategic initiative aims to expand market presence and solidify ALTRON’s position as a preferred supplier of automated production solutions for industrial fans. By leveraging advanced technologies such as automatic welding and metal forming production lines, ALTRON enhances manufacturing capabilities and supports the evolving needs of industrial fan manufacturers nationwide.

ALTRON’s Commitment to Innovation and Sustainability

Central to ALTRON’s operations is its commitment to innovation and sustainability. The company’s new factory, scheduled for completion in 2024, reflects its ongoing investment in expanding production capacity and integrating eco-friendly practices. ALTRON’s innovative culture is nurtured through continuous academic exchanges and collaborations on CNC spinning technology, ensuring that its machines remain at the forefront of industry standards.

Furthermore, ALTRON places a strong emphasis on customer service and satisfaction. By maintaining long-term technical communication with over 120 industrial fan manufacturers, ALTRON not only understands market demands but also provides tailored solutions to enhance production quality and efficiency. This customer-centric approach has earned ALTRON a loyal clientele and positioned it as a trusted partner in the industrial manufacturing sector. You can find contact information for ALTRON, including details on how to get in touch with them, at their website: https://www.auto-altron.com/contact.

Conclusion

CNC spun metal machines represent a pinnacle of modern manufacturing technology, offering unparalleled precision and versatility across diverse industries. From enhancing the efficiency of industrial fans to meeting the rigorous demands of aerospace and defense, these machines play a vital role in shaping the future of metalworking. As industries continue to evolve, CNC spinning remains indispensable for creating customized, high-performance metal components that drive innovation and progress in global markets.