Meeting Diverse Industry Needs with Custom Spun Metal Solutions by ALTRON

Metal spinning, an age-old technique, finds its modern revival in the industrial landscape, offering versatile solutions to meet a spectrum of needs. ALTRON, a pioneering name in the field, spearheads this domain, offering an array of spun metal solutions. From single roller to double roller and Expansion CNC spun metal, each technique carries its own significance, catering to diverse industrial requirements. This blog delves into the nuances of spun metal manufacturing, exploring its applications and the role of ALTRON in meeting industrial demands.

Single Roller Spun Metal: Precision Unveiled

Precision Engineering: At the heart of single roller spun metal lies precision engineering. By employing a single roller, metal sheets are formed seamlessly into desired shapes, ensuring precision and accuracy in every product. This technique finds its application in various industries where intricate designs and shapes are required, such as aerospace, automotive, and architectural sectors.

Versatility in Applications: Under the canopy of single roller spun metal, a myriad of applications flourishes. From manufacturing aerospace components like engine casings and missile parts to crafting intricate automotive parts like hubcaps and wheel rims, the versatility of this technique knows no bounds. Moreover, architectural marvels like customized light fixtures and decorative elements also owe their finesse to single roller spun metal.

Enhanced Efficiency: One of the primary appeals of single roller spun metal is its efficiency. With minimal setup requirements and quick turnaround times, manufacturers can meet tight deadlines without compromising on quality. This efficiency makes it a preferred choice across industries where agility and precision are paramount.

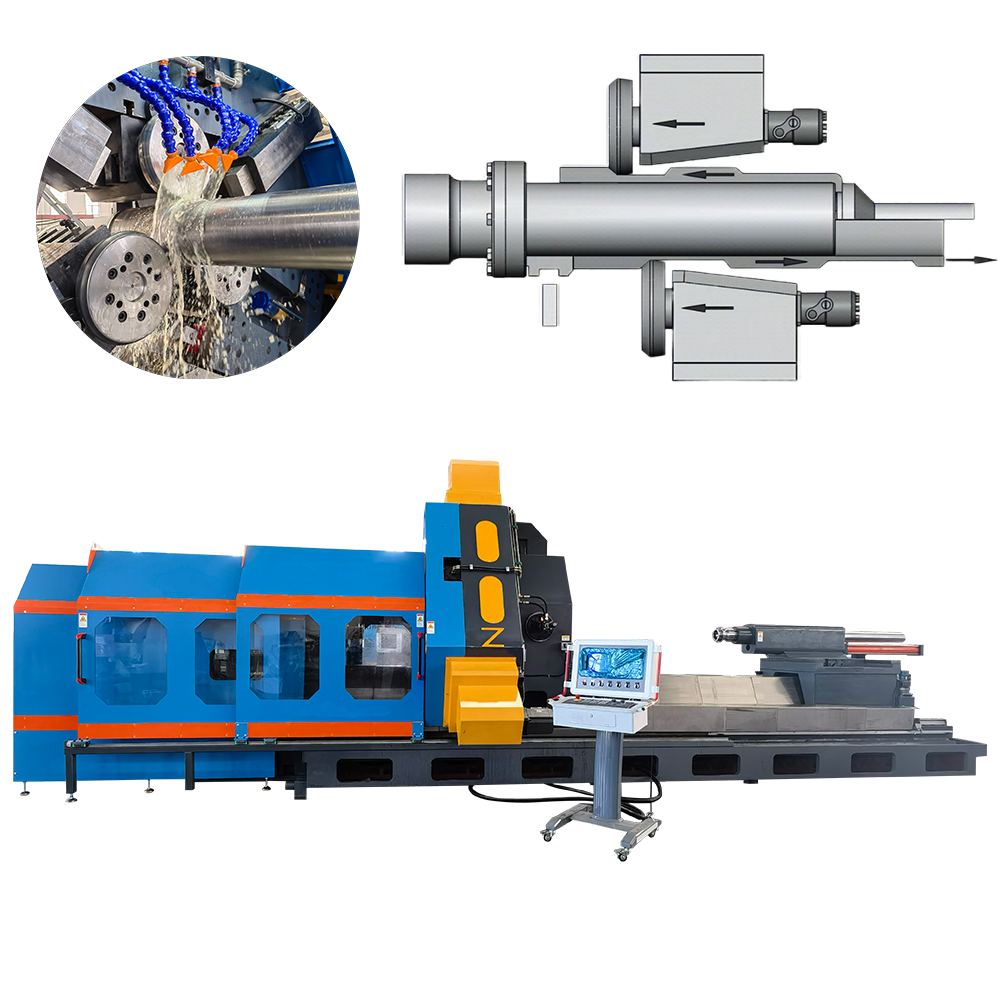

Double Roller Spun Metal: Strength in Simplicity

Dual Roller Dynamics: Double roller spun metal amplifies the capabilities of its single roller counterpart by introducing an additional roller into the equation. This tandem roller system enables the fabrication of larger and more complex metal components with enhanced structural integrity. The synchronized movement of rollers ensures uniform shaping and consistent results, making it ideal for high-volume production runs.

Strengthening Structural Integrity: In industries where durability and strength are non-negotiable, double roller spun metal emerges as a game-changer. Components subjected to high stress and load-bearing requirements, such as industrial machinery parts and pressure vessels, benefit from the superior structural integrity imparted by this technique. The seamless integration of multiple rollers elevates the quality standards, ensuring longevity and reliability in the final products.

Optimized Production Processes: Despite its advanced capabilities, double roller spun metal maintains a user-friendly approach to production. ALTRON’s expertise in this domain streamlines the manufacturing process, from design conceptualization to final product realization. By harnessing the power of automation and precision engineering, ALTRON empowers industries to optimize their production processes and achieve unparalleled efficiency.

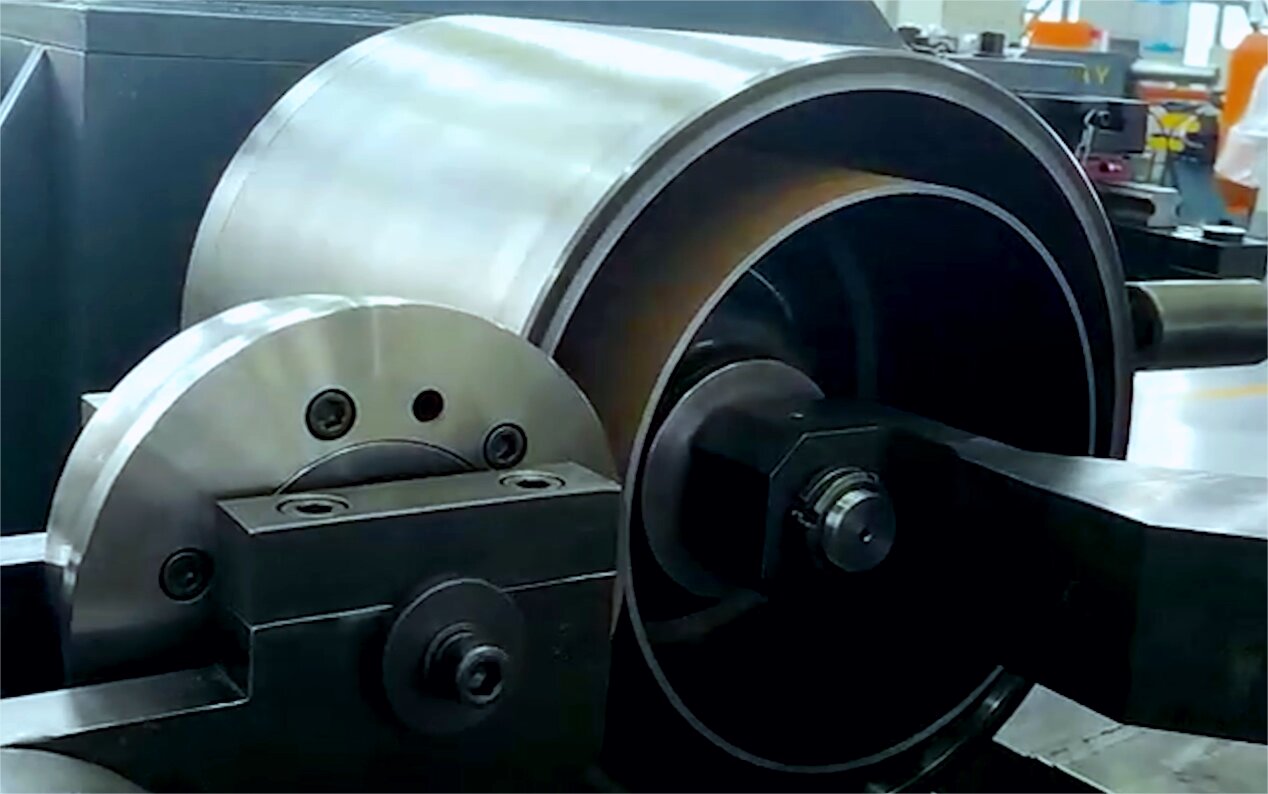

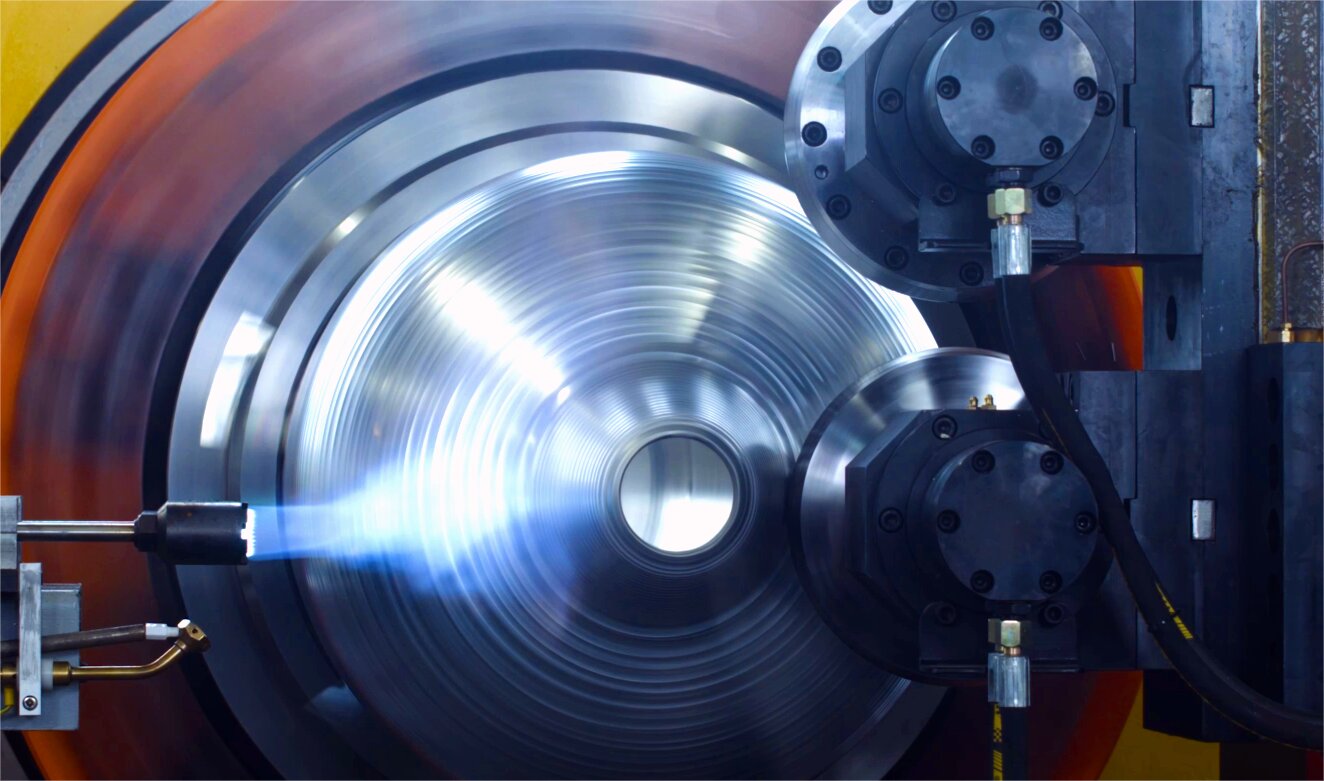

Expansion CNC Spun Metal: Pioneering Precision

Digital Precision: Expansion CNC spun metal marks the pinnacle of precision engineering in the metal spinning realm. Combining computer numerical control (CNC) technology with the art of metal spinning, this technique unlocks limitless possibilities in terms of design intricacy and dimensional accuracy. By programming intricate tool paths, ALTRON can create bespoke metal components tailored to the most exacting specifications.

Complex Geometry Mastery: In industries where geometric complexity reigns supreme, Expansion CNC spun metal reigns supreme. From intricate lampshades with elaborate patterns to specialized components for medical devices, the ability to manipulate metal sheets with unrivaled precision opens doors to innovative design solutions. ALTRON’s mastery in this domain enables industries to push the boundaries of what’s possible, unleashing creativity without compromising on quality or efficiency.

Future-Proof Manufacturing: As industries evolve and demand for customized solutions continues to rise, Expansion CNC spun metal emerges as a future-proof manufacturing technique. Its seamless integration with digital design tools and automation technologies ensures scalability and adaptability to changing market dynamics. By investing in this cutting-edge technology, industries can stay ahead of the curve and drive innovation in their respective domains.

Multi-Roller Powerful Spun Metal: Shaping Possibilities

Advanced Spinning Dynamics: Multi-roller powerful spun metal represents a paradigm shift in metal shaping capabilities. By leveraging multiple rollers in tandem, this technique enables the fabrication of large and intricate metal components with unparalleled precision. The synchronized movement of rollers ensures uniform shaping and consistency, empowering industries with the versatility to tackle complex projects with ease.

Enhanced Structural Integrity: At the core of multi-roller powerful spun metal lies its ability to impart enhanced structural integrity to the fabricated components. Industries grappling with demanding applications, such as aerospace and automotive sectors, rely on this technique to craft components that can withstand rigorous operational conditions. Whether it’s engine housings for aircraft or chassis components for high-performance vehicles, the robustness of multi-roller spun metal ensures reliability and longevity.

Scalability and Efficiency: Despite its advanced capabilities, multi-roller powerful spun metal remains remarkably efficient and scalable. ALTRON’s streamlined manufacturing processes, coupled with state-of-the-art equipment, enable seamless integration of this technique into industrial production lines. From prototyping to mass production, ALTRON empowers industries to meet tight deadlines without compromising on quality or efficiency.

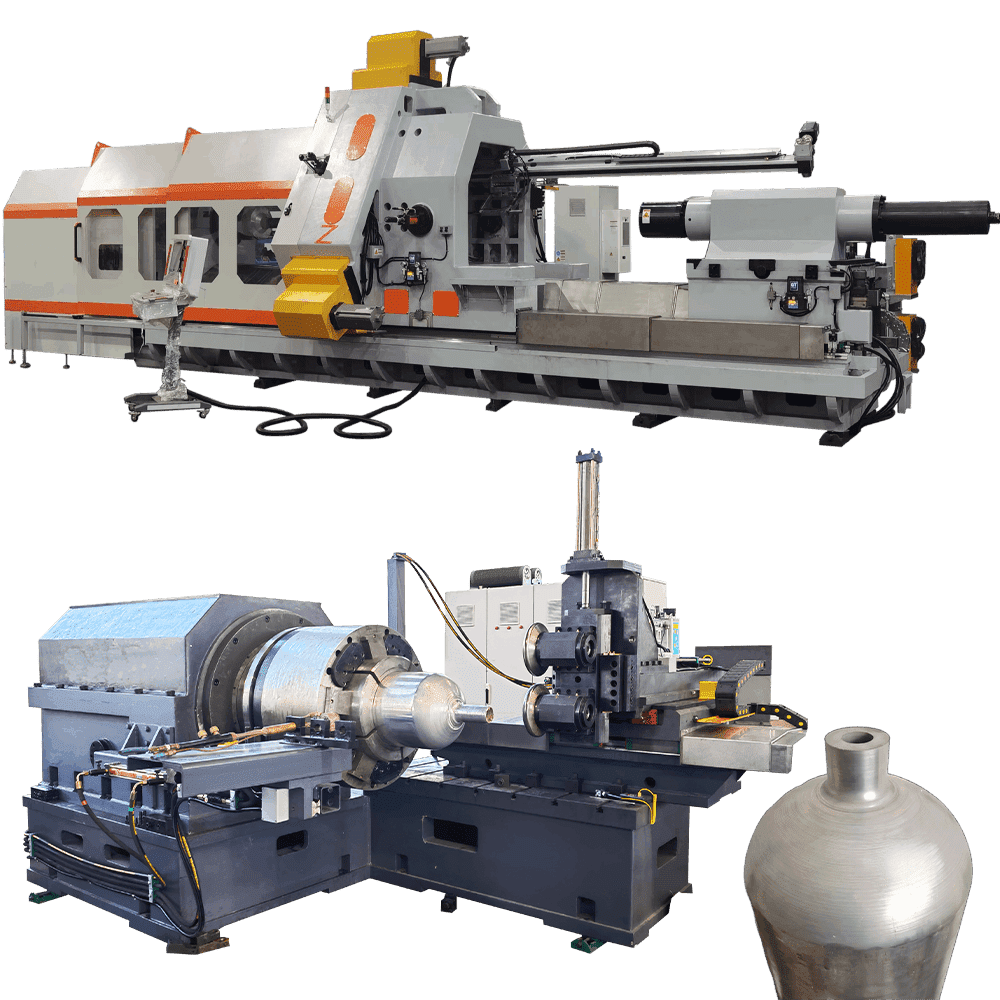

High-Pressure Gas Cylinder Spun Metal: Safeguarding Reliability

Critical Safety Standards: In industries where safety is paramount, such as the manufacturing of high-pressure gas cylinders, the choice of fabrication technique is crucial. High-pressure gas cylinder spun metal techniques ensure compliance with stringent safety standards while maintaining optimal performance. ALTRON’s expertise in this domain ensures that every cylinder manufactured meets regulatory requirements and exceeds industry expectations in terms of reliability and durability.

Precision Engineering for Critical Applications: The fabrication of high-pressure gas cylinders demands precision engineering to ensure leak-proof seals and structural integrity. ALTRON’s mastery of spun metal techniques, combined with rigorous quality control measures, ensures that each cylinder meets the highest standards of performance and safety. Whether it’s for industrial gases, medical applications, or aerospace propulsion systems, ALTRON’s high-pressure gas cylinder spun metal solutions offer peace of mind to industries operating in critical sectors.

Customized Solutions for Varied Needs: ALTRON understands that one size does not fit all when it comes to high-pressure gas cylinders. That’s why its spun metal solutions are customizable to meet the unique needs of different industries and applications. Whether it’s varying cylinder sizes, materials, or valve configurations, ALTRON collaborates closely with clients to deliver bespoke solutions that align with their specific requirements.

Spun Metal Samples: Pioneering Innovation

Prototyping for Perfection: The journey from concept to reality often begins with prototyping, and spun metal samples play a pivotal role in this process. ALTRON’s expertise in producing high-quality spun metal samples enables industries to validate designs, test functionality, and iterate quickly to achieve perfection. Whether it’s a new automotive component or a cutting-edge aerospace prototype, ALTRON’s spun metal samples pave the way for innovation and advancement.

Accelerating Time-to-Market: In today’s fast-paced industrial landscape, speed is of the essence. ALTRON’s rapid prototyping capabilities ensure that clients can accelerate their time-to-market without compromising on quality. By leveraging advanced spinning techniques and materials, ALTRON delivers spun metal samples that not only meet but exceed expectations, enabling industries to stay ahead of the curve and capitalize on emerging opportunities.

Collaborative Approach to Innovation: ALTRON’s commitment to innovation extends beyond its manufacturing capabilities to fostering collaborative partnerships with clients. By understanding their unique challenges and objectives, ALTRON collaborates closely to develop spun metal samples that address specific needs and drive innovation. Whether it’s refining existing designs or exploring new possibilities, ALTRON’s collaborative approach ensures that clients have a trusted partner every step of the way.

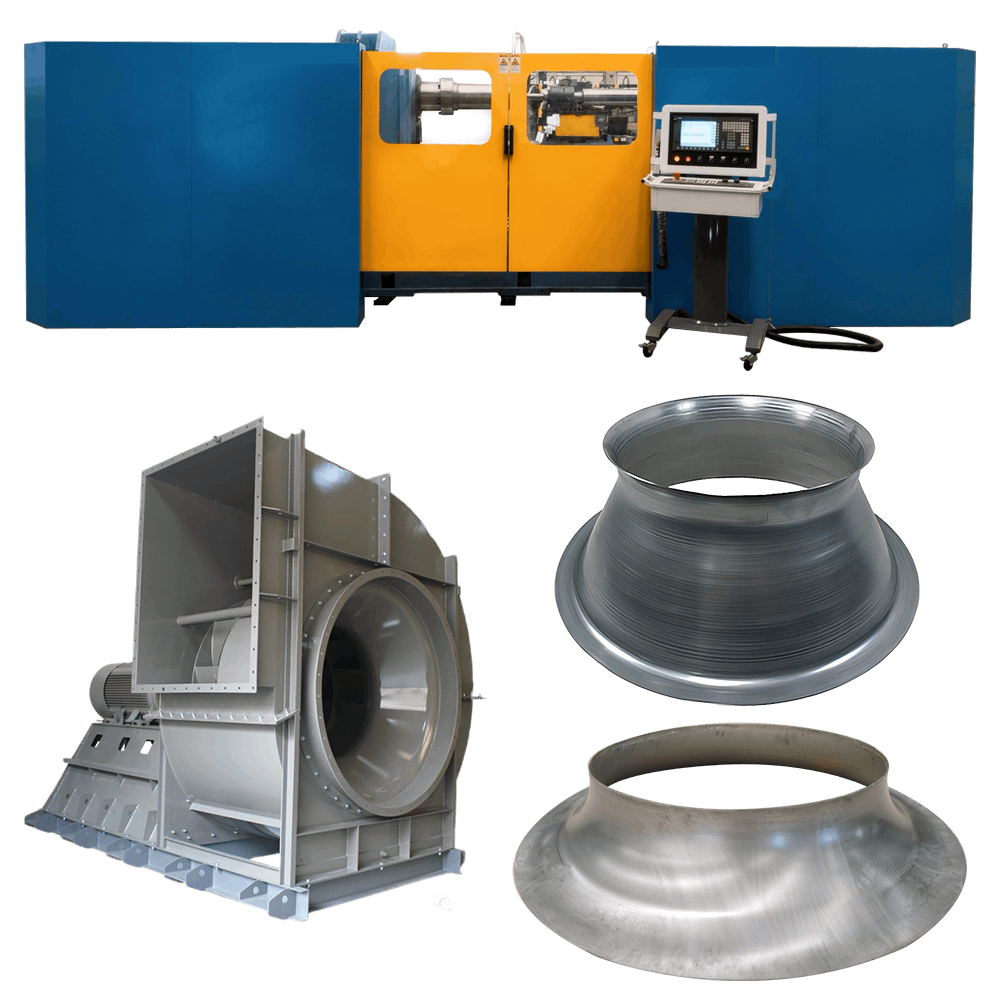

Industrial Fan Welding & Forming: Optimizing Airflow Efficiency

Enhanced Airflow Design: In industries relying on industrial fans for ventilation, cooling, or material handling, optimizing airflow efficiency is crucial for productivity and safety. ALTRON’s custom spun metal solutions for industrial fan welding and forming are designed to meet these needs. By leveraging precision welding techniques and advanced forming processes, ALTRON ensures that every fan component is engineered for optimal performance, durability, and efficiency.

Customized Fan Designs: Industrial applications often require custom fan designs to accommodate specific airflow requirements, space constraints, and operational conditions. ALTRON collaborates closely with clients to develop bespoke fan designs tailored to their unique needs. Whether it’s a high-capacity centrifugal fan for HVAC systems or a specialized axial fan for industrial processes, ALTRON’s custom services enable industries to achieve optimal airflow management and energy efficiency.

Durability and Reliability: Industrial fan components are subjected to harsh operating conditions, including high temperatures, corrosive environments, and heavy loads. ALTRON’s expertise in spun metal fabrication ensures that fan components exhibit exceptional durability and reliability, even in the most demanding industrial settings. By selecting materials with superior mechanical properties and corrosion resistance, ALTRON’s custom spun metal solutions offer longevity and performance under adverse conditions.

Fan Spinning Case: Precision Engineering for Critical Applications

Precision Engineering for Critical Applications: Fan spinning cases play a vital role in housing and protecting industrial fan components, such as motors, bearings, and impellers. ALTRON’s custom spun metal solutions for fan spinning cases are engineered with precision to meet the stringent requirements of critical applications. From dimensional accuracy to structural integrity, every aspect of the fan spinning case is meticulously crafted to ensure optimal performance and reliability.

Customization for Specific Requirements: Industries often require fan spinning cases that are tailored to their specific needs in terms of size, shape, and functionality. ALTRON’s custom services enable clients to customize fan spinning cases according to their unique requirements. Whether it’s a compact enclosure for portable fans or a robust housing for industrial blowers, ALTRON collaborates closely with clients to deliver solutions that meet their exact specifications.

Seamless Integration and Compatibility: Fan spinning cases must seamlessly integrate with other fan components and auxiliary systems to ensure smooth operation and performance. ALTRON’s expertise in spun metal fabrication ensures that fan spinning cases are designed and manufactured to meet strict dimensional tolerances and compatibility requirements. By ensuring proper fit and alignment, ALTRON’s custom solutions minimize installation time and optimize system performance.

CNC Metal Spinning Product Application: Precision and Versatility

Advanced CNC Metal Spinning: CNC metal spinning represents a cutting-edge technology that offers unparalleled precision and versatility in metal forming. ALTRON’s custom CNC metal spinning product applications leverage this technology to meet the diverse needs of various industries. From complex geometries to high-volume production runs, ALTRON’s CNC metal spinning capabilities enable the fabrication of components with exceptional accuracy and repeatability.

Versatility in Applications: The versatility of CNC metal spinning makes it suitable for a wide range of applications across industries. Whether it’s manufacturing automotive components, aerospace parts, or medical device enclosures, ALTRON’s custom CNC metal spinning solutions excel in producing high-quality, precision-engineered components. By leveraging advanced CNC programming and tooling, ALTRON adapts to the unique requirements of each application, delivering solutions that meet or exceed industry standards.

Efficiency and Cost-Effectiveness: CNC metal spinning offers significant advantages in terms of production efficiency and cost-effectiveness. With its ability to produce complex shapes and intricate details in a single operation, CNC metal spinning reduces the need for secondary machining processes, saving time and reducing production costs. ALTRON’s expertise in CNC metal spinning optimization further enhances efficiency, enabling industries to meet tight deadlines and budget constraints without compromising on quality.

In Conclusion: ALTRON – The Vanguard of Spun Metal Solutions

ALTRON’s unwavering commitment to excellence and innovation has cemented its position as a vanguard in the realm of spun metal manufacturing. From single roller to double roller and Expansion CNC spun metal, each technique represents a testament to ALTRON’s prowess in meeting diverse industrial needs. By harnessing the power of precision engineering, advanced technologies, and a relentless pursuit of perfection, ALTRON continues to redefine the possibilities of spun metal, empowering industries to reach new heights of success.