The working principle of spinning machine

Spinning machine is a plastic processing equipment used to perform metal spinning process to manufacture thin-walled hollow rotating parts. The scope of the workpiece is very wide, the small diameter is only a few millimeters, and the large diameter is close to 10m.

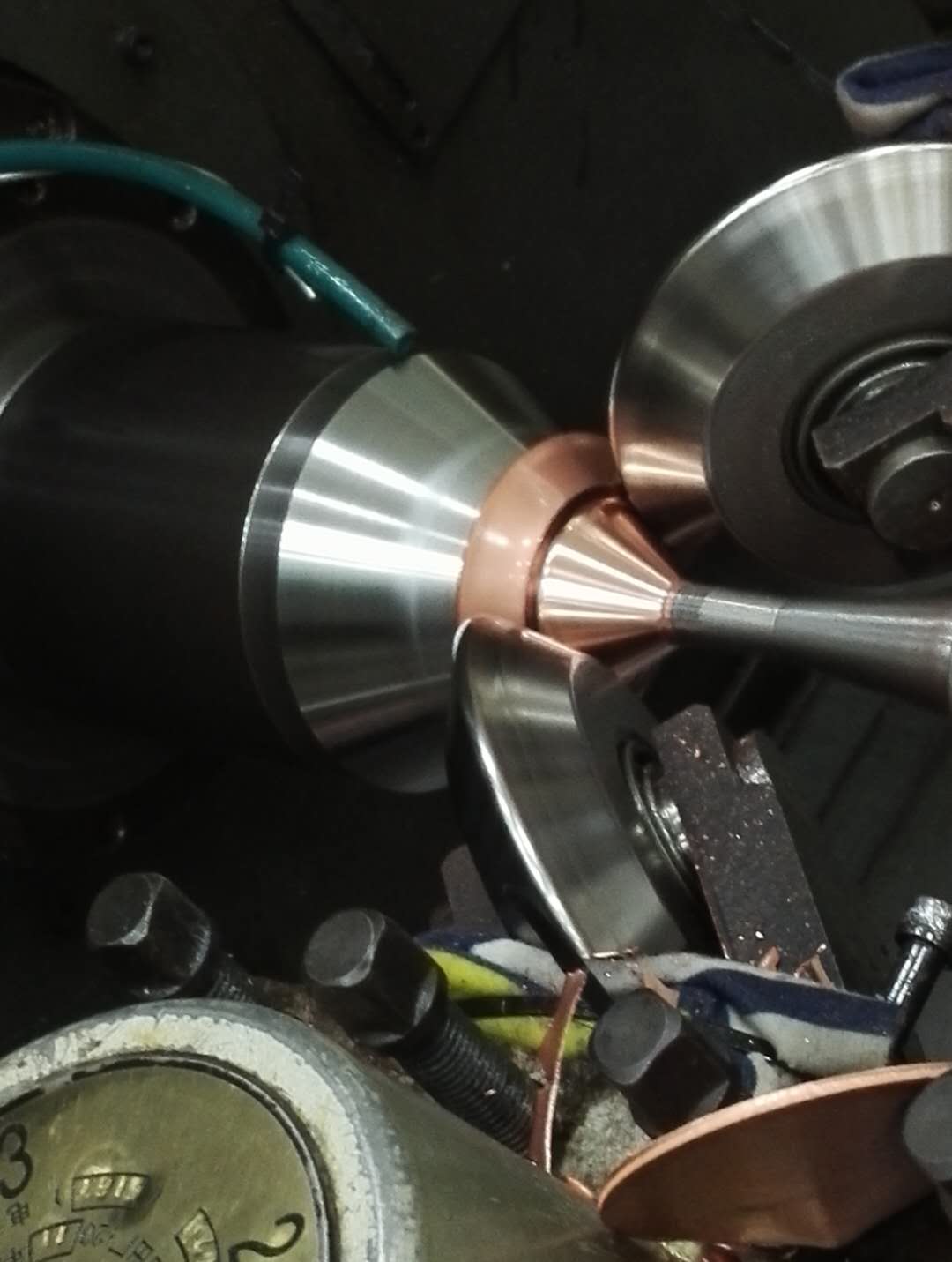

Metal Spinning machine usually consists of main components, such as main body, headstock, rotating shaft base and tailstock. In the metal spinning process, the blank (plate or ring) is clamped on the mold to make it rotate, and the spinning wheel is pressurized and pressurized, so that the blank is continuously deformed point by point and becomes a workpiece.

1. Working principle of scroll compressor

The scroll air compressor is composed of a combination of a moving scroll and a static scroll of the functional equation. In the process of suction, compression and exhaust, the fixed scroll is fixed on the frame, while the moving plate is driven by the eccentric shaft and controlled by the anti-rotation mechanism. It rotates around the center of the fixed disc base circle and rotates in a plane with a small radius. Air is drawn into the periphery of the static disk through the air filter element. With the rotation of the eccentric shaft, the gas is gradually compressed in several pairs of crescent-shaped compression chambers formed by the teeth of the moving disk and the static disk, and then continuously discharged from the axial hole in the static disk.