Training & Installation

When the project machine or production line reaches the shipping standard and passes the continuous working test, Altron will invite the customer engineer to the factory for training! Including mechanical maintenance, electrical testing, equipment operation and product debugging!

In another case, if the customer cannot come to the Altron factory for training, Altron’s engineers will be sent to the customer’s factory for installation and training. Usually, we will send engineers to the site for installation and debugging of production lines or larger equipment!

Factory receives the machine and prepares

Altron provides an English manual for each single machine or production line; before Altron sends the machine, it will inform the customer of the specific installation requirements, such as air compressor gas, voltage and power, foundation installation requirements and other detailed information!

Ensure that the customer can install the machine as soon as possible after receiving it!

Random accessories and machine information

- Electronic user manual,

- Electronic English manual,

- Circuit diagram for daily testing,

- Basic mechanical drawings,

- System program and product program backup USB disk(CNC machine),

Equipment delivered to customer factory

Due to the long transportation time and cycle, please check whether the machine is intact as soon as it arrives. If you find any problems, please take photos and record them as soon as possible, and contact Altron in time!

Altron has video and photo records in all delivery links! If there are major problems, you should contact the local insurance company as soon as possible!

Mechanical Installation

All steps and technical requirements must be strictly followed in the instruction manual or installation video! Avoid sending mechanical parts damaged! Altron will mark special parts! Make mechanical installation easy!

Electricity, gas and oil installation and commissioning

Follow and add according to the actual machine requirements. There will also be relevant instructions in the instructions. If you encounter any problems, please contact Altron in time!

When all the supporting facilities of the machine are completed and powered on for the first time, the phase sequence of the power supply must be checked to avoid short circuit of the motor! Check the rotation direction of the motor, and cut off the power and adjust it in time if any abnormality is found!

After the equipment is installed, it enters the debugging stage

If customers have received operation training at Altron’s factory, we will not send engineers for guidance. If there are any problems that cannot be solved, please contact us as soon as possible. Altron continues to provide services!

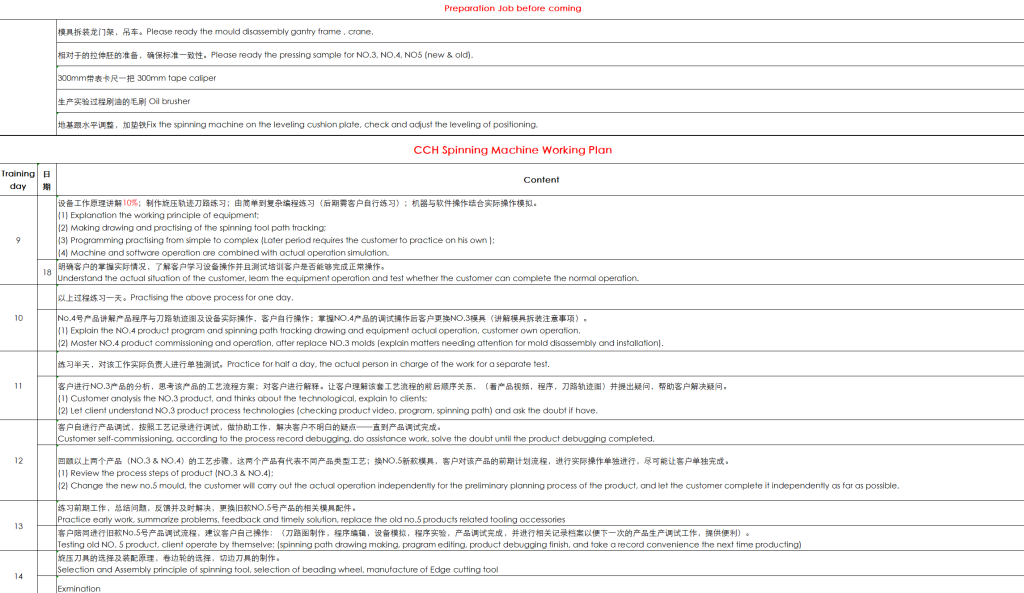

Altron arrives at the customer’s agreed location at the time specified by the customer! Engineers will develop training plans and record the training process based on the actual situation!

When the training is coming to an end, Altron will develop an assessment based on the project situation and require factory managers to review it! Summarize the entire learning and training process! Solve problems in a timely manner to prevent problems from being left in the actual production process!

Online training:

If we are forced to choose video training if we encounter some force majeure! Due to time differences, our progress will be very slow and we do not recommend remote training under normal circumstances. This consumes a lot of manpower and time.

After the situation stabilizes, we will arrange on-site training services as soon as possible. We must ensure that our equipment can continue to operate and produce in the customer’s factory and create value for the customer.

This kind of situation is relatively rare. Generally, it will occur in relatively confidential projects. Customers do not want the relevant core technology to flow into the market!

Altron will squeeze the corresponding machine to record the video and organize it into English letters, so that customers can understand how to operate the machine more easily! It is feasible for single machines or simpler projects!

Production lines or larger machines cannot be operated in this way. Problems are very likely to occur. Face-to-face training is required to master every link and step!

Training content:

Theoretical knowledge of the machine, explanation of the performance parameters of the equipment, operation of the equipment, use of software, inspection and maintenance of basic electrical appliances, maintenance and maintenance of machinery and lubrication, personal experience teaching by engineers, etc.

AI welding robot for centrifugal fan impellers trained in Korea

Axial fan cylinder curling, welding production line test

Roll & Tunnel Seam Welding Test

CNC Spinning Machine Programming Tutorial

For more related videos, please follow Altron’s Youtube channel

Altron Manufactures And Provides Forming and Welding Solutions For:

- CNC Metal Spinning Machine,

- Multi-Roller Flow Forming Machine,

- Neck Spinning Machine,

- Internal Spinning Machine,

- Hub Spinning Machine,

- CNC Flanging Machine,

- Welding Robot, Rolling Machine,

- Seam Welding,

- Axial Flow Fan Production Line,

- Centrifugal Fan Impeller Welding,

- Centrifugal Fan Housing Welding,

- Air Duct Production Line,

- Spiral Duct Production Line,

- Rectangular Duct Production Line,

- Impeller Forming Production Line,

- Customized Industrial Fan Impeller,

- Laser Cutting Production Line,

- Laser Welding Solution, ect…