ALTRON's Robot Welding Equipment For Centrifugal Blower Impeller

The difference between automatic impeller welding and traditional manual welding

Auto Welding Advantages:

1 High production efficiency, saving labor costs;

2 Welding quality is high and no grinding is required;

3 Laser vision automatic scanning weld seam, strong adaptability;

4 Open system allows new products to be imported continuously and flexibly set welding parameters;

5 According to the process requirements, the welding mode of the equipment can be flexible adjusted so that no deformation occurs during the welding process;

6 One-time investment reduced production costs;

Easy to operate and change materials;

7 Fully automatic intelligent welding, greatly improving the image of enterprises.

Manual Welding Disdvantages:

1 Inefficiency, need a lot of manpower;

2 Poor welding quality and poor aesthetics;

3 Manual factors are complex and the quality is difficult to control;

4 Skilled welders are difficult to recruit and costly to employ;

5 Operating labor intensive, low customer acceptance;

6 Influencing corporate image;

7 Difficult to form scale effect;

8 Low degree of automation.

Comparison between automatic welding impeller and manual welding impeller

Auto Welding Effect:

Manual Welding Effect:

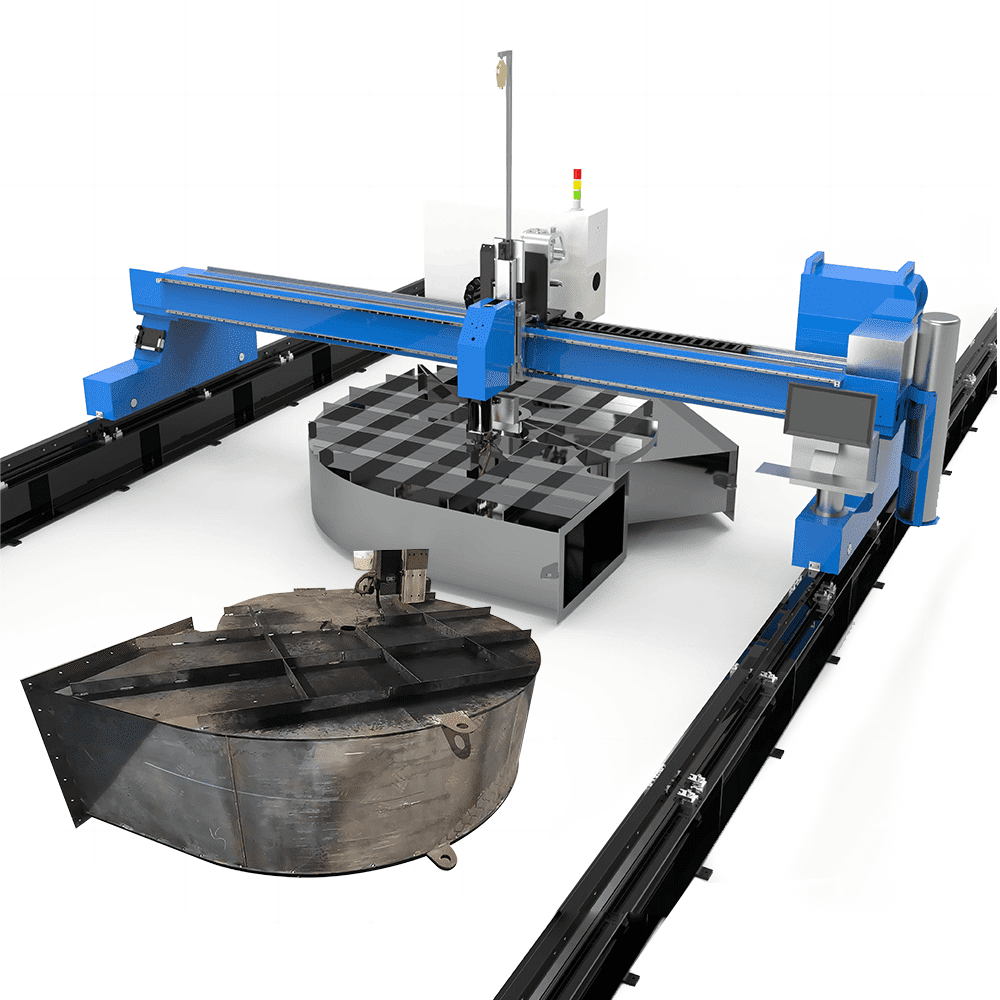

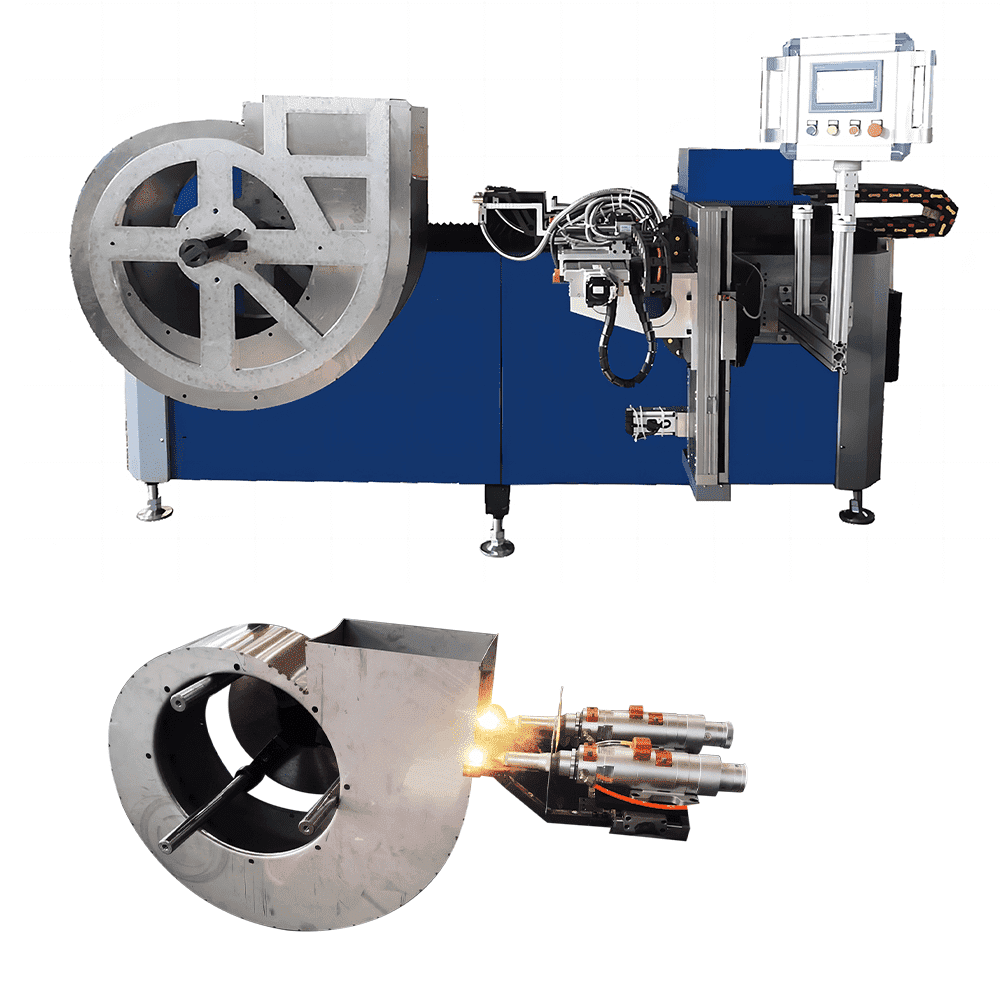

Welding-industrial fan impeller

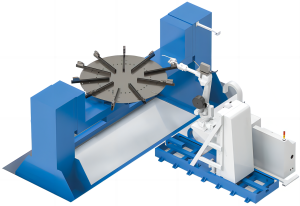

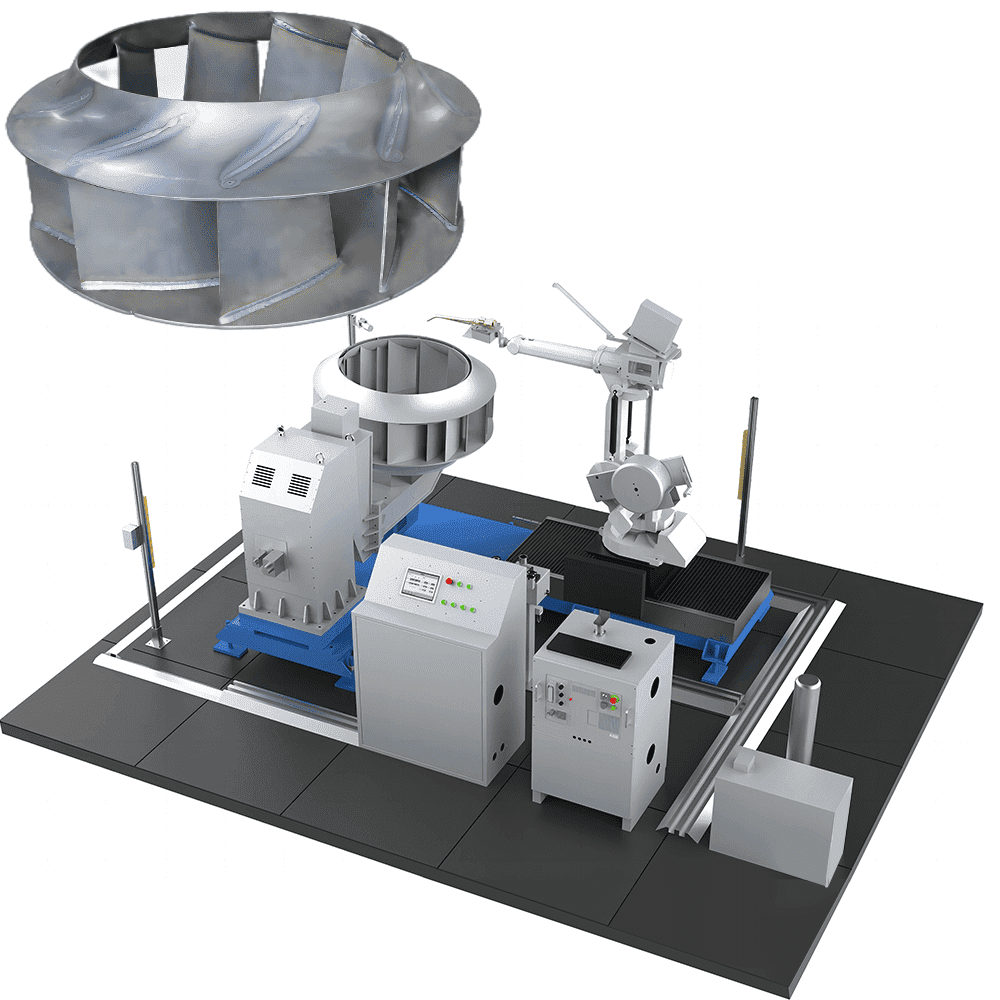

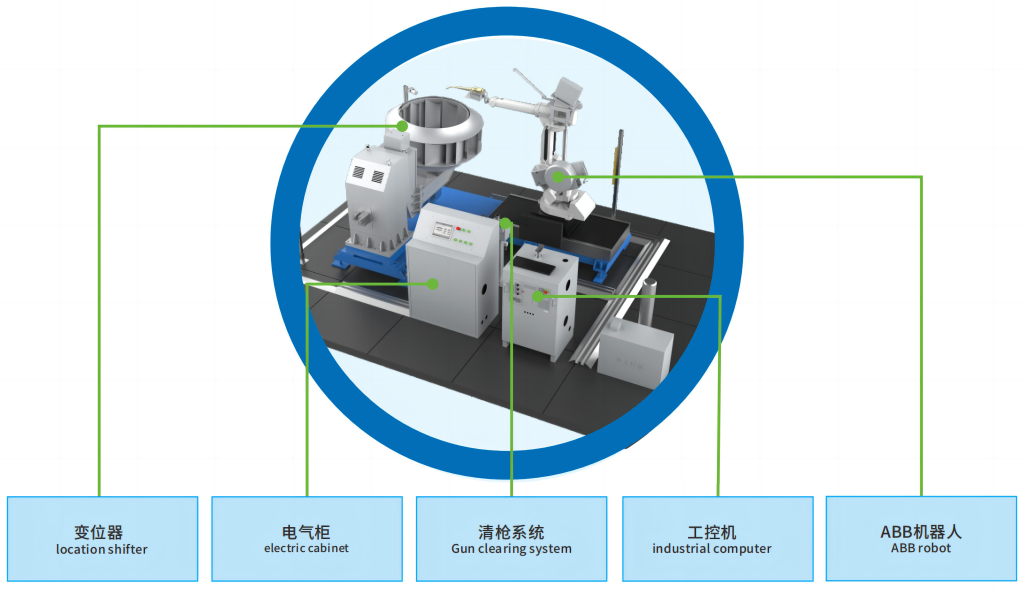

Equipment Composition

ABB robot/KUKA robot (optional) + positioner + industrial computer + electrical cabinet + cleaning welding gun system (optional) + welding machine + light curtain

Parameters Of Vision Guided Fan Impeller Welding Machine

| Item | HYL03-0.1T | HYL01-0.5T | HYL02-1T | HYL04-2T | HFT01 | HFT02 |

| Machine Dimension (L*W*H) |

2000*2000*1800mm | 3500*2200*2000mm | 3700*2500*2100mm | 3700*2700*2100mm | 6000*7000*3000mm | 6000*7000*3000mm |

| Machine Mass | 1500 KGS | 3500 KGS | 5000 KGS | 6000 KGS | 9200 KGS | 10800 KGS |

| Dia. Of Impeller | 300-600 mm | 400-1260 mm | 400-1600 mm | 400-2000 mm | ≤3.8 M | ≤3.8 M |

| Height. Of Impeller | ≤600 mm | ≤1000 mm | ≤1000 mm | ≤1000 mm | ≤2.4 M | ≤2.4 M |

| Load (With Tooling) | 100 KGS | 500 KGS | 1000 KGS | 2000 KGS | 5000 KGS | 8000 KGS |

| Power Supply | Equipment: AC220V; Welding M/C: AC380V |

Equipment: AC220V; Welding M/C: AC380V |

AC380V | AC380V | AC380V | AC380V |

|

|

|

||||

“Centrifugal Blower Impeller“-Welding

Industrial fan impellers play a pivotal role in various sectors, from ventilation systems to manufacturing processes, necessitating robust construction and precision welding techniques. Constructed from materials like stainless steel or aluminum, these impellers demand meticulous welding to ensure structural integrity and optimal performance.

Welding fan impellers involves a delicate balance of precision and durability. Utilizing TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding methods, welders meticulously join the impeller blades to the hub, ensuring uniformity and strength. The choice of welding technique depends on the material composition and desired attributes of the final product.

The process begins with careful preparation, ensuring surfaces are clean and free from contaminants to guarantee a strong weld. Skilled welders meticulously navigate the intricate geometry of the impeller blades, employing specialized fixtures and jigs to maintain alignment and achieve consistent weld beads.

The challenge lies in achieving a weld that not only bonds the materials seamlessly but also endures the demanding operational conditions. Welders must factor in stress concentrations, thermal expansion, and dynamic forces that impellers undergo during operation, ensuring weld integrity under such conditions.

The Synergy of Automatic Welding Technology and Vision AI

In the realm of industrial machinery, welding serves as the backbone, providing strength and stability to structures that power our world. However, the conventional methods of welding, though effective, often demand extensive human intervention and meticulous precision.

Enter automatic welding technology coupled with Vision AI, revolutionizing this crucial industrial process by marrying the precision of machines with the intelligence of artificial vision systems.

Automatic welding technology has undergone a remarkable evolution over the years, transforming the landscape of industrial manufacturing. Traditionally, welding processes necessitated manual oversight, relying on skilled welders to ensure accuracy, consistency, and quality.

However, this approach came with inherent challenges – human limitations in precision, susceptibility to fatigue, and the possibility of human error.

Automatic welding trend

The advent of automatic welding technology heralded a new era by introducing mechanization into the welding process. This technology incorporates advanced machinery equipped with programmed instructions to perform welding tasks autonomously.

It brings forth a myriad of benefits, including increased efficiency, higher precision, reduced labor costs, and enhanced safety.

One of the pivotal elements elevating automatic welding technology to unprecedented levels of efficiency and accuracy is Vision AI.

Vision AI leverages sophisticated algorithms and machine learning models to enable machines to perceive and comprehend their surroundings with a level of acuity akin to human vision.

Through Vision AI, automatic welding systems gain the ability to ‘see’ and make real-time, data-driven decisions during the welding process. These systems utilize high-resolution cameras and sensors to capture and analyze intricate details of the welding environment.

By interpreting this visual information, they can precisely identify weld joints, seam positions, material irregularities, and deviations from specified parameters.

Diversification of automatic welding

The amalgamation of automatic welding technology and Vision AI offers a multitude of advantages that significantly augment industrial manufacturing processes.

The precision and accuracy achieved through Vision AI ensure consistent weld quality, mitigating defects and enhancing structural integrity.

Moreover, the ability to adapt in real-time to variations in materials or environmental conditions fosters unparalleled flexibility in production lines.

Furthermore, Vision AI-equipped automatic welding systems optimize operational efficiency by reducing setup times and minimizing material waste.

These systems can swiftly adapt to diverse welding tasks, accommodating variations in weld joint configurations, thicknesses, and materials, thereby streamlining the manufacturing workflow.

An integral facet of Vision AI in welding technology lies in its contribution to predictive maintenance. By continuously monitoring and analyzing welding parameters and performance metrics, these systems can anticipate potential equipment failures or deviations before they occur.

This proactive approach allows for timely maintenance, preventing costly downtime and ensuring the longevity of welding machinery.

The utilization of Vision AI in automatic welding technology also champions safety in industrial settings. These systems are adept at detecting hazards such as gas leaks, overheating, or deviations in welding arcs, promptly alerting operators and mitigating potential risks.

This proactive approach significantly enhances workplace safety standards, reducing accidents and ensuring a secure working environment for personnel.

As with any technological advancement, the integration of Vision AI in automatic welding technology presents its own set of challenges.

The complexity of the algorithms and the need for extensive training data for machine learning models require significant investments in research and development.

Moreover, ensuring the seamless integration of Vision AI systems with existing welding machinery demands careful planning and expertise.

Summary of the field of welding

In conclusion, the fusion of automatic welding technology and Vision AI marks a watershed moment in the realm of industrial manufacturing.

The synergy between these technologies not only enhances the precision and efficiency of welding processes but also revolutionizes safety standards and predictive maintenance practices.

As advancements in AI continue to evolve, the potential for further optimizing welding technology remains vast, promising a future where machines and AI work harmoniously to propel industrial innovation to unprecedented heights.