Fully Automatic Welding Equipment For Industal Fan Volute

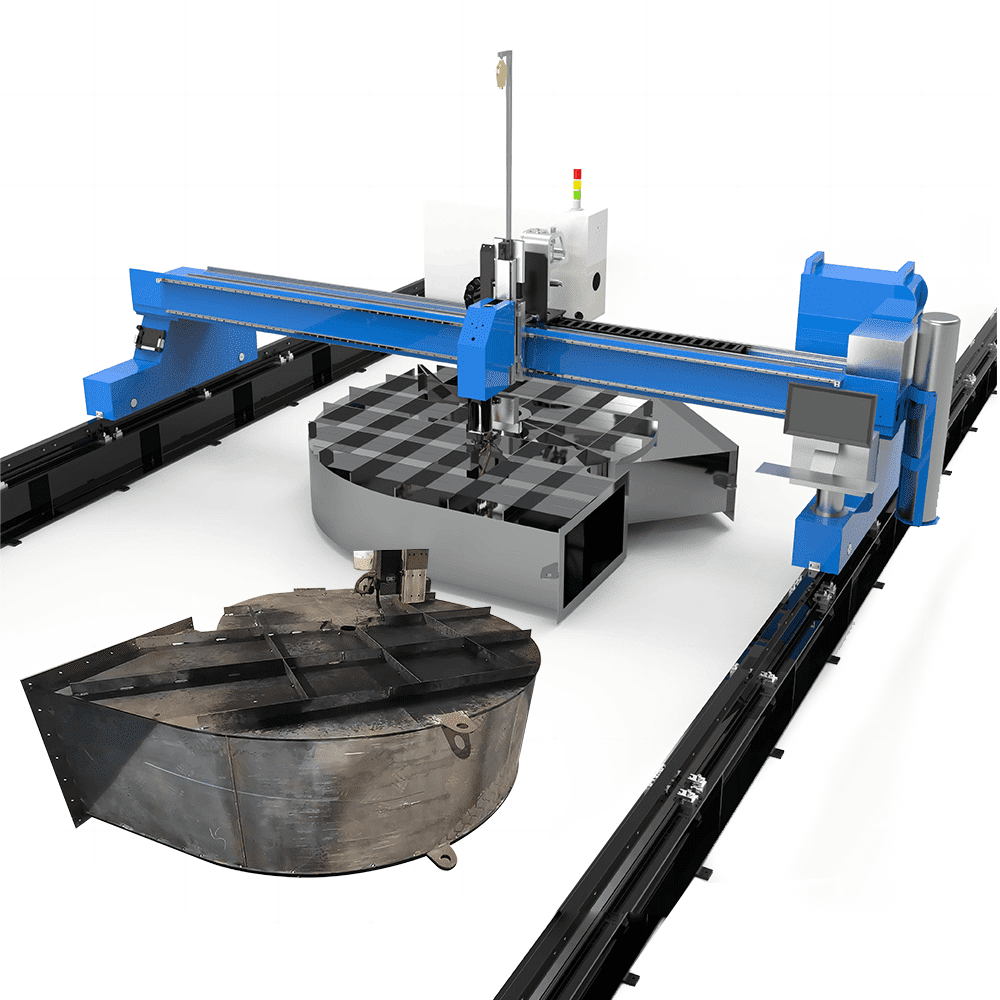

Overview of fan volute fully automatic welding machine

Gas Shielded Welding & Argon Arc Welding

(Vision AI corrects welding trajectory)

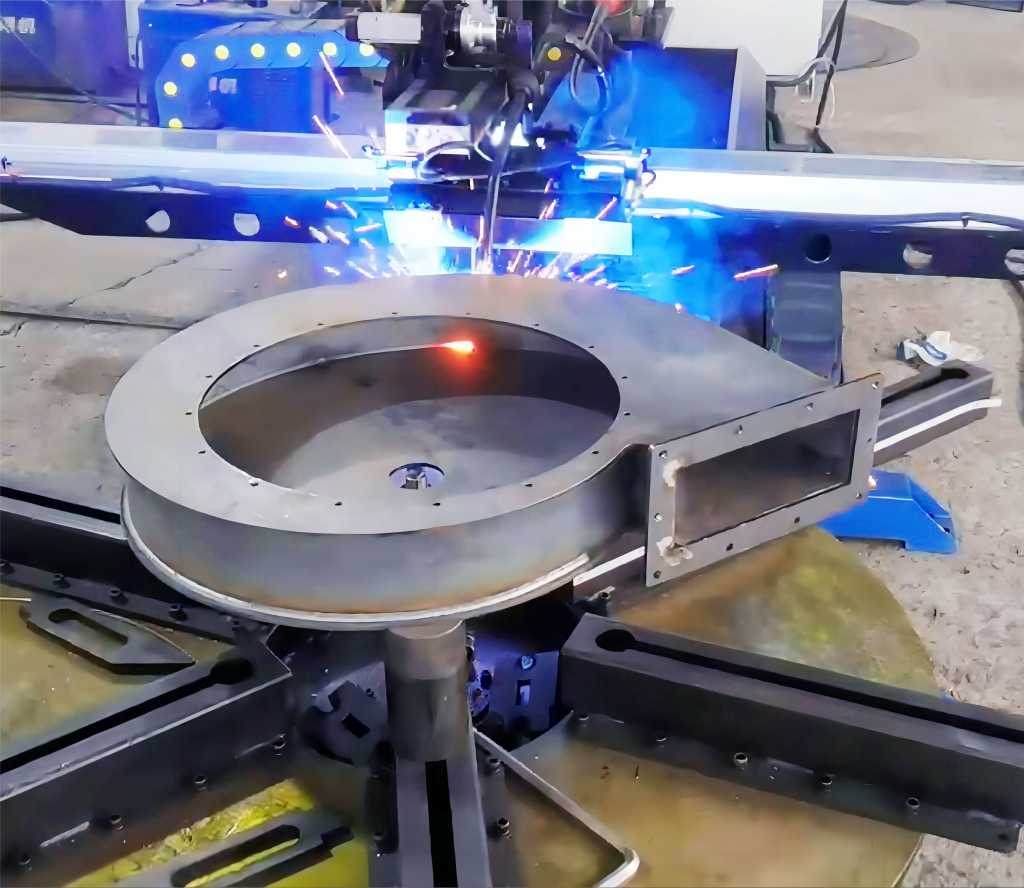

When welding stainless steel and carbon steel industrial fans volutes, their diameters are usually relatively large. During the spot welding and splicing assembly process by workers, the consistency of the industrial fan volute is not too high. Use this industrial fan volute automatic welding equipment It can automatically correct the weld trajectory. It does not require a complicated and high-precision positioning device. It only needs to place the fan volute that needs to be welded on the working platform, which greatly saves the automation problem of difficult manual positioning. This is ALTRON unique AI technology.

Before the machine is welded, the industrial camera and ranging laser will scan and identify the welding position of the industrial fan volute. AI will automatically calculate the best trajectory and let the welding gun follow the automatically identified trajectory for welding, allowing individuals to perform multiple operations at the same time. Fully Automatic Welding Equipment For Fan Volute.

Welding effect comparison: machine vs manual

Industrial Fans volute welding vodeos

Fully Automatic Welding Equipment For Fan Volute

| Item | HWK11V2 | HWK10V2.5 |

| Machine Dimension (L*W*H) | 5600*3100*1700mm | 6500*3600*1700mm |

| Machine Mass | 1.6 T | 2.3 T |

| Radius Of Volute | 100-1500 mm | 800-2000 mm |

| Load | 1 T | 2 T |

| Power Supply | Equipment: AC220V; Welding M/C: AC380V | Equipment: AC220V; Welding M/C: AC380V |

| Power Motor (not include welder) | 7 KW | 9 KW |

|  |  |

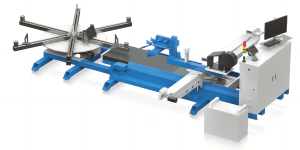

Overview of fan volute fully automatic welding machine

Introducing our Fully Automatic Welding Machine for Fan Volute, a state-of-the-art solution designed to revolutionize the manufacturing process of fan volutes. This cutting-edge machine combines advanced technology, precision engineering, and automation to deliver exceptional welding performance and unparalleled efficiency.

With its fully automated operation, this machine eliminates the need for manual intervention, resulting in increased productivity and reduced labor costs. It is specifically engineered to address the unique welding challenges posed by fan volutes, ensuring seamless and high-quality welds every time.

Equipped with a sophisticated vision system, the machine intelligently detects and tracks the weld seam, even in the presence of complex and irregular shapes. This ensures precise and accurate welding, regardless of variations in the volute design. The vision system, along with laser technology, enables real-time seam-finding, enhancing the machine’s intelligence and user-friendliness.

The machine boasts advanced control systems, including servo control and PLC logic control, ensuring precise and consistent weld parameters. It offers customizable welding sequences and procedures, allowing flexibility in meeting specific production requirements.

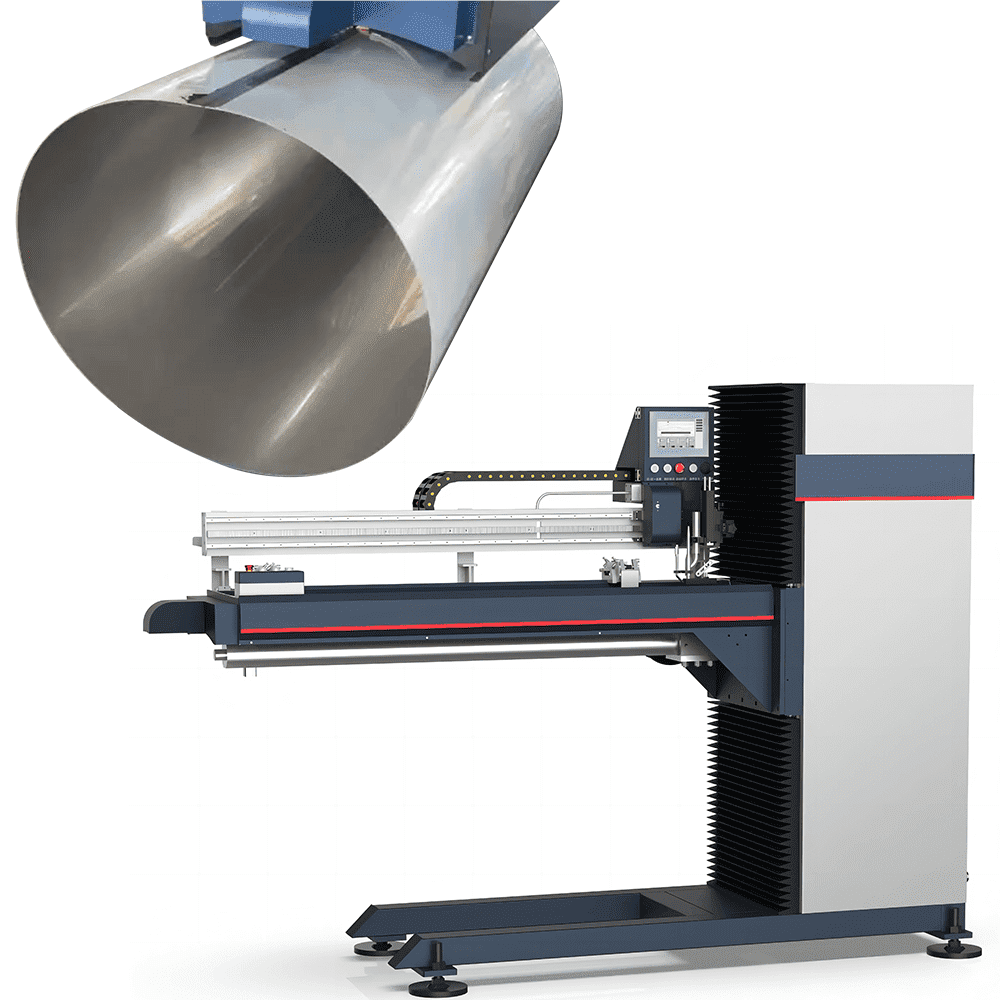

Laser welding

(Mechanical positioning profiling welding track)

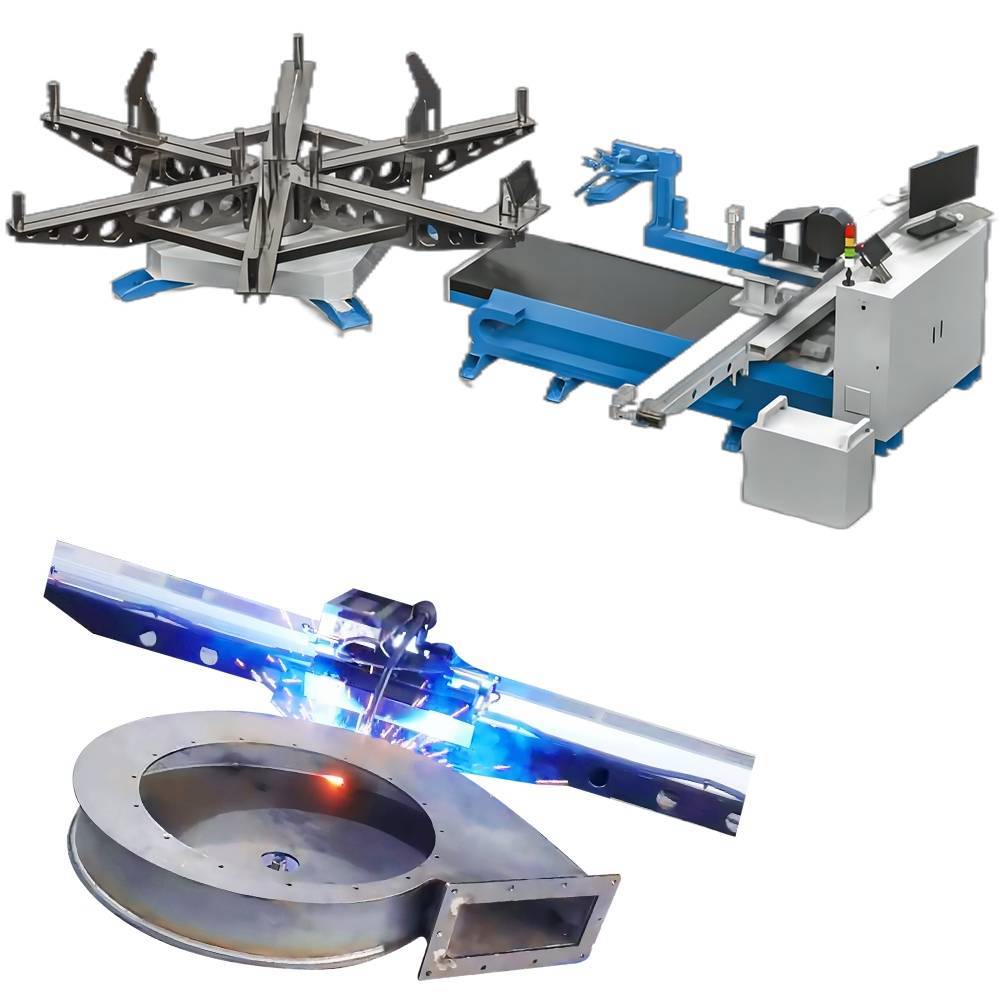

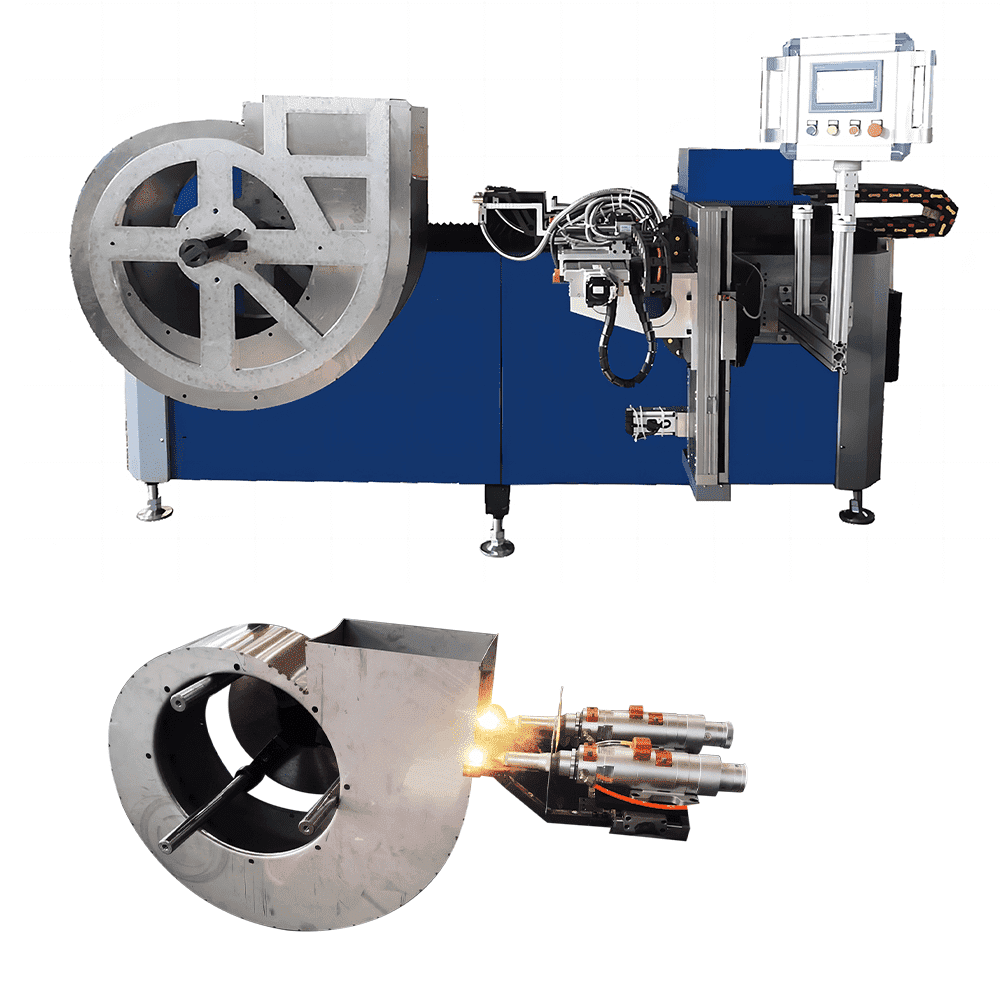

Semi Auto Vertical Welding Machine For Fan Volute Primary Features:

The welding process can be initiated through a parametric programming-free human-machine interface by inputting the maximum and minimum radius, as well as the length and width of the straight edge. Mechanical profiling ensures stability and reliability, allowing real-time correction of weld seam deviations to achieve optimal welding results. Lifting-assisted positioning eliminates the need for manual labor, as the lifting table securely holds the workpiece and allows easy loading and unloading by loosening the fixture.

Semi Auto Vertical Welding Machine For Fan VoluteTechnical Parameters:

Automatic welding without programming, enabling automatic welding of volute workpieces without manual intervention.

Manual switching function available for manual control adjustments when required.

System controls crucial parameters like welding speed, with fault alarms and prompts for manual intervention in case of equipment failure.

Simultaneous welding on both upper and lower sides of the workpiece, eliminating the need to flip the workpiece.

Fan casing should be wrapped for convenient copying and positioning, with a minimum hemming size specified.

At least one side of the fan casing must be flat, featuring a round hole in the center for positioning and clamping.

Suitable for circular flange workpieces and similar components within the welding technical requirements.

Volute thickness should be a minimum of 1.5mm.

Workpiece materials: carbon steel, stainless steel.

Equipment supports a minimum welding diameter of 300mm, maximum welding diameter of 1300mm, and a distance of 64-500mm between upper and lower welds.

Equipment Structure:

Base Platform: Provides installation and positioning of each device component, ensuring stability and preventing excessive shaking during welding.

Mechanical Profiling Double-Gun Manipulator: Profiles the weld bead of the workpiece, accommodating deformations within a 50x50mm vertical plane centered on the welding point. Simultaneously welds upper and lower welds without the need for flipping or secondary positioning, significantly improving efficiency for large workpieces.

Rotating Bottom Bracket: Offers a flat surface for the workpiece to rest on and allows 360-degree rotation. Equipped with an outrigger top block, facilitating alignment of the workpiece’s bottom round hole.

Electric Control System: Includes a main control PLC, a user-friendly human-machine control interface, peripheral servo system, various sensors, and intelligent elements for efficient operation.

Vertical fan volute welding machine (laser welding optional)

The Vertical Fan Volute Welding Machine is a specialized equipment designed for efficient and precise welding of vertical fan volutes. It incorporates advanced features and technologies to ensure high-quality welds and streamline the welding process. The machine offers parametric programming-free operation through a user-friendly human-machine interface, allowing users to input the maximum and minimum radius as well as the length and width of the straight edge. With its stable mechanical profiling and real-time deviation correction capabilities, it guarantees optimal welding results. The lifting-assisted positioning feature eliminates the need for manual labor, as the lifting table securely holds the workpiece and facilitates easy loading and unloading by loosening the fixture.

Applications: Vertical Fan Volute Welding Machine

The Vertical Fan Welding Machine finds widespread application across various industries and sectors. One of its primary applications is in the HVAC (Heating, Ventilation, and Air Conditioning) industry. It is utilized for welding fan volutes used in HVAC systems, ensuring precise and reliable welds that meet the high-quality standards required for efficient airflow and optimal system performance.