Welding Machines for Ventiladores Fans

In the realm of fan manufacturing, the significance of Welding Machines for Ventiladores Fans cannot be overstated. These powerful tools play a pivotal role in shaping the structure and functionality of ventiladores fans, ensuring durability and optimal performance. This comprehensive guide delves into the technical intricacies of welding machines tailored for ventiladores fans, shedding light on the critical processes and innovations that define this niche.

Understanding Welding Machines for Ventiladores Fans

Before delving into the world of Welding Machines for Ventiladores Fans, it’s imperative to establish a foundational understanding of ventiladores fans. These devices, designed to provide airflow and cooling in various settings, come in diverse forms – from ceiling fans to industrial-grade exhaust fans. The core purpose remains consistent: circulating air to maintain comfort and regulate temperature.

The Welding Connection

1. Types of Welding Processes

1.1. Resistance Spot Welding

A prevalent technique in fan manufacturing, resistance spot welding involves joining metal components by passing an electric current through them. The heat generated melts the metal, creating a strong bond. This process is ideal for components requiring precise, localized welds, ensuring the integrity of the fan’s structure.

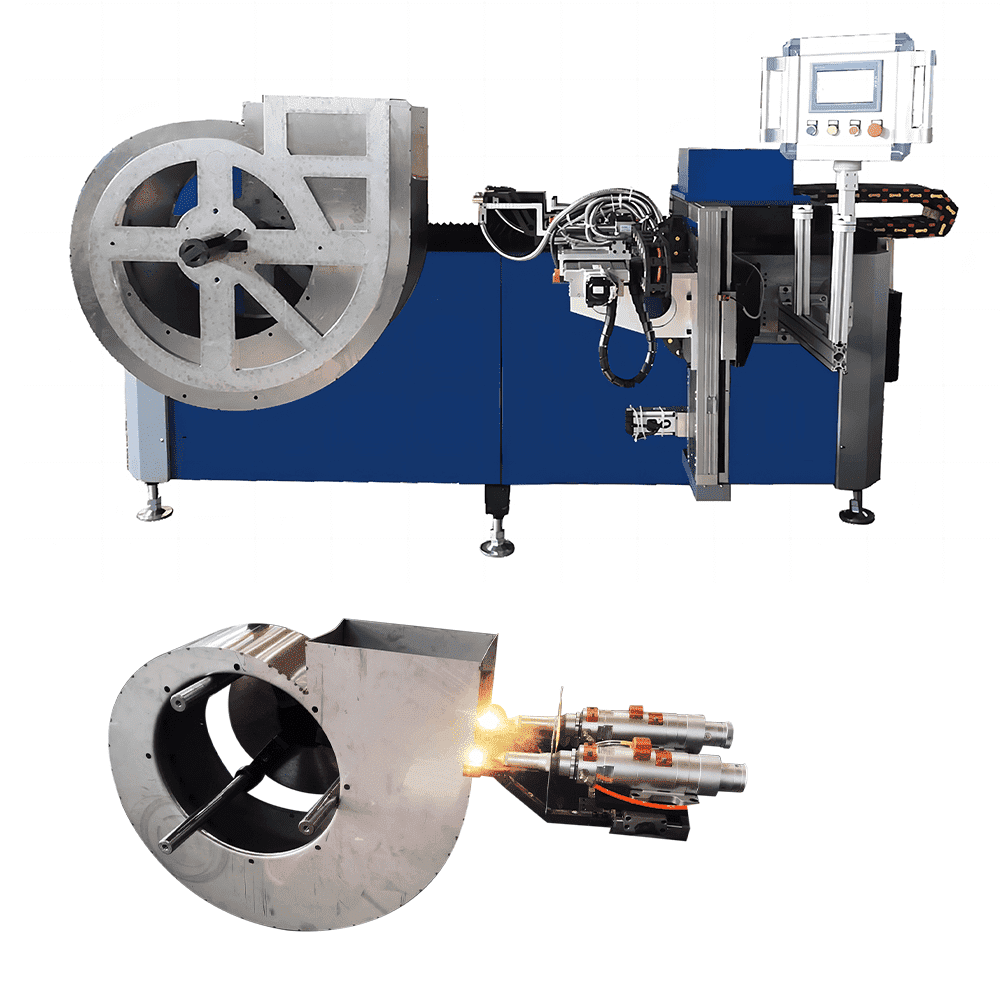

1.2. Gas Metal Arc Welding (GMAW)

GMAW, commonly known as MIG welding, employs a consumable wire electrode to create an electric arc, melting and fusing metal components together. This method offers versatility, making it suitable for both thin and thick materials. Fan manufacturers often leverage GMAW for welding components with varying thicknesses, ensuring uniform strength throughout the structure.

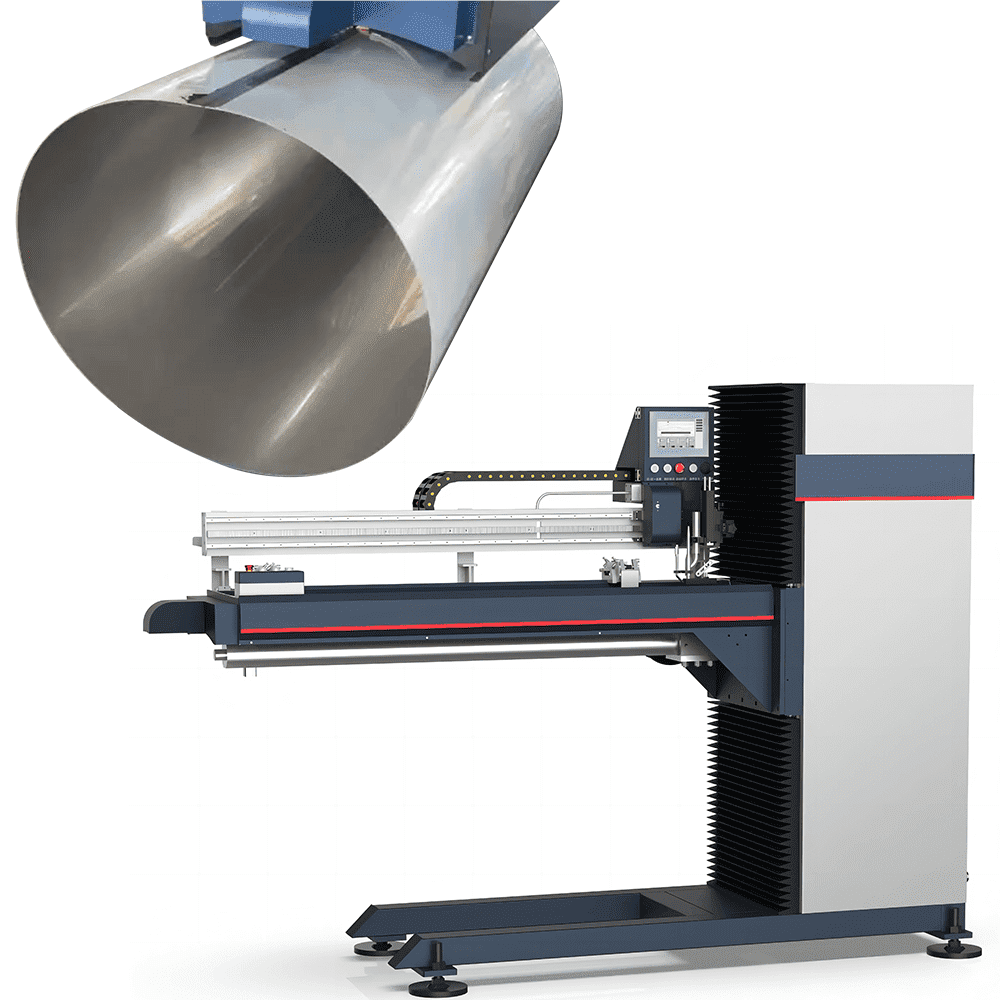

1.3. Laser Welding

Innovative and precise, laser welding utilizes a concentrated beam of light to melt and fuse metal components. This method is particularly advantageous for intricate fan designs, offering minimal heat-affected zones and high precision. As technology advances, laser welding is becoming increasingly popular in the production of high-performance ventiladores fans.

2. Key Considerations in Welding Ventiladores Fans

2.1. Material Compatibility

Choosing the right welding process involves considering the materials used in fan components. Common materials include aluminum, steel, and various alloys. Welding machines must accommodate these materials, ensuring a seamless fusion without compromising structural integrity.

2.2. Joint Design and Strength

The joint design plays a crucial role in determining the strength and durability of a welded connection. Ventiladores fans often require specific joint configurations to withstand the dynamic forces encountered during operation. Welding machines must be adept at executing these designs, creating robust connections that can endure the rigors of fan usage.

Precision in Action: Welding Machine Features

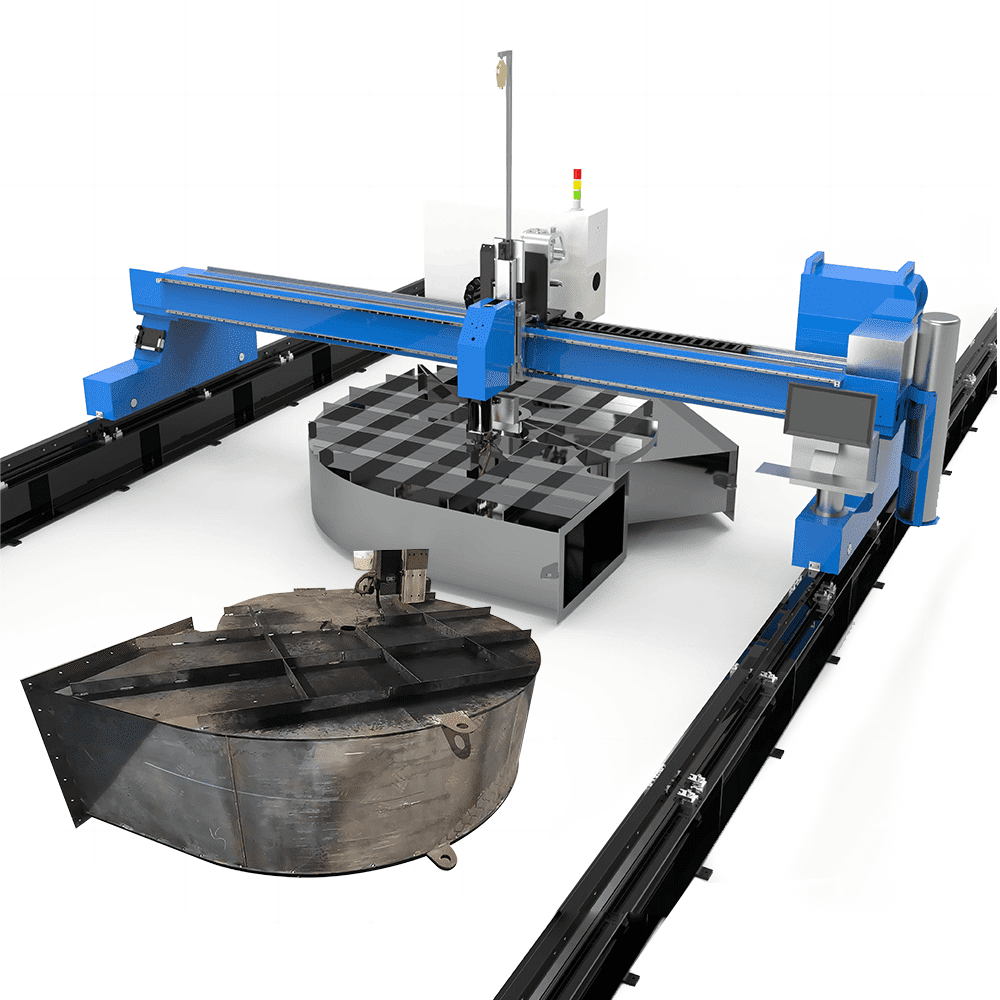

1. Automated Welding Systems

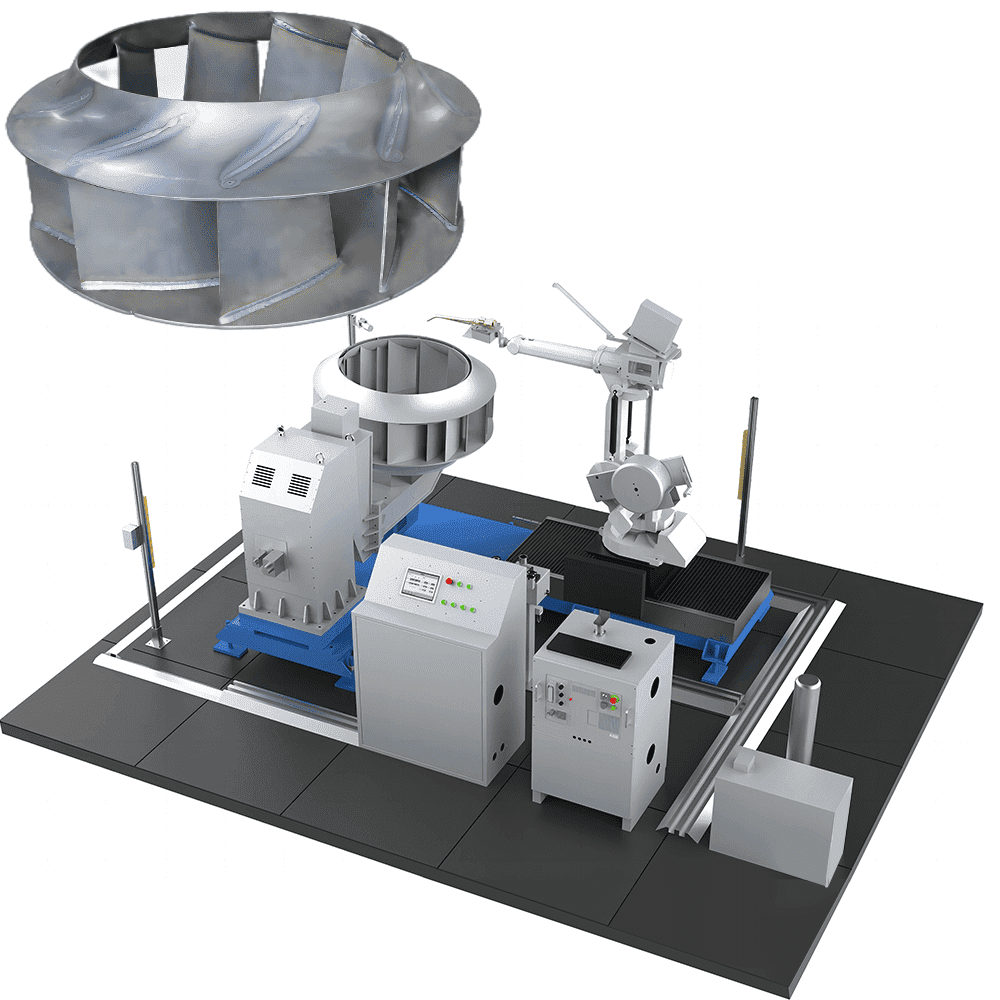

1.1. Robotics Integration

In modern fan manufacturing, automated welding systems featuring robotic arms have become instrumental. These systems offer unparalleled precision and efficiency, ensuring consistent weld quality across a large volume of ventiladores fans. The ability to program robotic welding arms enhances flexibility, enabling manufacturers to adapt to diverse fan designs and production requirements.

1.2. Computer Numerical Control (CNC) Technology

CNC technology enhances the accuracy and repeatability of welding processes. By programming specific welding parameters into the system, manufacturers can achieve precise welds. This technology is particularly beneficial in high-volume production settings, where maintaining uniform quality is paramount.

2. Advanced Welding Power Sources

2.1. Inverter Technology

Inverter-based welding machines have gained prominence in fan manufacturing due to their efficiency and energy savings. These machines convert input power into a stable output, ensuring a consistent welding arc. This not only improves weld quality but also reduces energy consumption, contributing to sustainable and cost-effective fan production.

2.2. Pulsed Welding

Pulsed welding technology delivers controlled pulses of current during the welding process. This feature is advantageous for welding thin materials commonly found in ventiladores fans. Pulsed welding minimizes heat input, preventing warping and distortion while maintaining the strength of the welded joint.

Quality Assurance in Welding machines Ventiladores Fans

1. Non-Destructive Testing (NDT)

1.1. Ultrasonic Testing

Ultrasonic testing involves the use of high-frequency sound waves to detect internal defects in welded joints. This non-destructive method ensures the integrity of welds without compromising the structure of ventiladores fans. Manufacturers employ ultrasonic testing to identify potential issues early in the production process, maintaining stringent quality standards.

1.2. X-ray Inspection

X-ray inspection provides a comprehensive view of the internal structure of welded joints. This technique is invaluable in detecting hidden flaws or imperfections that may compromise the performance of ventiladores fans. By implementing X-ray inspection as part of quality assurance protocols, manufacturers can confidently deliver fans that meet or exceed industry standards.

Future Trends in Welding Technology for Ventiladores Fans

1. Industry 4.0 Integration

1.1. Smart Welding Systems

The integration of Industry 4.0 principles in fan manufacturing heralds the era of smart welding systems. These interconnected systems leverage data analytics, real-time monitoring, and machine learning to optimize welding processes. Smart welding machines can adapt to varying production conditions, ensuring unparalleled efficiency and adaptability in the fabrication of ventiladores fans.

2. Additive Manufacturing in Fan Production

2.1. 3D Printing for Prototyping

Additive manufacturing, specifically 3D printing, is revolutionizing prototyping in fan development. Manufacturers can quickly produce intricate prototypes of fan components, allowing for rapid design iterations and improvements. While 3D printing is not a replacement for traditional welding processes, it complements welding by expediting the product development cycle.

Welding machine for ventiladores fans Conclusion

In the realm of ventiladores fans welding machines stand as the unsung heroes, shaping the structural integrity and performance of these essential devices. From traditional resistance spot welding to cutting-edge laser welding technologies, the evolution of welding processes continues to redefine the landscape of fan manufacturing. As we look to the future, the integration of automation, advanced power sources, and smart welding systems promises a new era of precision and efficiency in welding machines tailored for ventiladores fans. Manufacturers embracing these innovations will undoubtedly lead the way in delivering fans that not only meet but exceed the expectations of a dynamic and ever-evolving market.