What is a Robotic Welding System? Precision & Efficiency

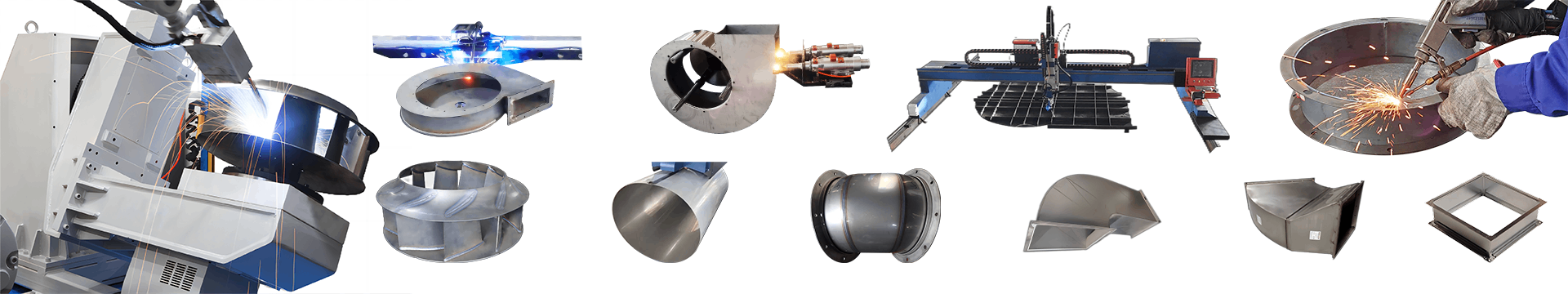

The welding industry has been transformed by technological advancements. One innovation that has revolutionized this field is the robotic welding system. This blog post will discuss what robotic welding systems are, how they work, and the leading manufacturer of these machines—ALTRON.

Understanding Robotic Welding Systems: What is a Robotic Welding System?

A robotic welding system refers to the integration of industrial robots into the welding process. These systems employ programmable machines, guided by computer software, to perform welding operations with precision and efficiency. The robots are equipped with articulated arms, welding torches, and sensors, allowing them to handle complex welding tasks autonomously.

Applications of Robotic Welding Systems: What is a Robotic Welding System?

1. Automotive Industry:

The automotive industry is one of the primary beneficiaries of robotic welding systems. These systems play a crucial role in assembling vehicle components, ensuring consistent and high-quality welds in chassis, body frames, exhaust systems, and more. By automating the welding process, manufacturers can achieve faster production cycles, reduce human error, and maintain uniformity in welding quality. ALTRON’s robotic welding systems offer the flexibility to adapt to various vehicle models and enable seamless integration into assembly lines, making them an ideal choice for automotive manufacturers.

2. Heavy Machinery:

The manufacturing of heavy machinery, including construction equipment, agricultural machinery, and mining vehicles, often involves large-scale welding operations. Robotic welding systems excel in handling heavy workpieces and performing repetitive welding tasks with high efficiency. ALTRON’s solutions offer the ability to program complex welding patterns and adapt to different workpiece sizes, enabling manufacturers to streamline their production processes and achieve consistent weld quality on a large scale.

3. Consumer Goods:

Robotic welding systems find applications in the production of various consumer goods, including appliances, furniture, and metal fixtures. These systems ensure precise and aesthetically pleasing welds, enhancing the overall quality and durability of the products. By automating the welding process, manufacturers can increase production speed and reduce costs associated with manual labor. ALTRON’s robotic welding systems provide a high level of customization, allowing manufacturers to meet specific product requirements while maintaining efficient production lines.

Functionality of Robotic Welding Systems: What is a Robotic Welding System?

Robotic welding systems operate through a series of sequential steps, which can be summarized as follows:

- Programming:Skilled operators or engineers input the necessary welding parameters, including joint designs, material specifications, and welding paths, into the system’s software.

- Positioning: The workpiece to be welded is placed in the designated position, either manually or with the assistance of automated fixtures. The robot’s sensors and cameras assist in identifying the precise location and orientation of the workpiece.

- Welding Execution:Once the workpiece is properly positioned, the robot initiates the welding process. It moves along the predetermined path, accurately depositing weld beads and controlling parameters such as arc length, travel speed, and heat input.

- Quality Assurance:Robotic welding systems incorporate advanced sensors to monitor the welding process in real-time. These sensors detect any deviations from the set parameters, ensuring consistent quality and minimizing defects.

Key Components: What is a Robotic Welding System?

1. Robot Arm and End Effector:

The robot arm in a robotic welding system serves as the primary tool for executing welding operations. It is designed to move along multiple axes, providing the necessary flexibility to reach diverse workpieces. Attached to the robot arm, the end effector holds the welding torch securely and controls its movements. It is crucial for the end effector to be adaptable to various welding techniques and able to accommodate different types and sizes of welding torches.

2. Power Source:

A high-quality power source is a fundamental component of a robotic welding system. It supplies the necessary energy and controls the welding parameters, such as voltage, current, and wire feed speed. ALTRON’s robotic welding systems are equipped with advanced power sources that ensure stable and precise control over the welding process, resulting in superior weld quality and reduced defects.

3. Control Unit:

The control unit serves as the brain of the robotic welding system. It communicates with the robot arm, power source, and other components, ensuring seamless coordination and synchronization. The control unit also houses the programming interface, allowing operators to create and modify welding programs, define welding parameters, and monitor the system’s performance.

Benefits of Robotic Welding Systems: What is a Robotic Welding System?

The adoption of robotic welding systems offers numerous advantages for manufacturers:

- Enhanced Productivity:Robots can work continuously, without the need for breaks or rest, resulting in higher productivity and faster completion of welding tasks. They can also perform complex welds with greater accuracy and consistency.

- Improved Safety:By replacing human workers in hazardous welding environments, robotic systems significantly reduce the risk of accidents, such as exposure to fumes, sparks, or electric shocks. This enhances overall workplace safety.

- Cost Efficiency:Although the initial investment in a robotic welding system may be significant, the long-term cost savings are considerable. The systems reduce labor costs, minimize rework and scrap, and optimize material usage.

ALTRON: A Leading Manufacturer in Robotic Welding Systems:

When it comes to cutting-edge robotic welding systems, ALTRON stands at the forefront. With a rich history in industrial automation, ALTRON has established itself as a renowned provider of advanced welding solutions. Their robotic welding systems combine state-of-the-art technology with precision engineering, enabling manufacturers to achieve exceptional welding results.

ALTRON’s systems offer a range of features, including:

- Flexibility:ALTRON’s robotic welding systems are adaptable to various welding applications, accommodating different materials, joint types, and geometries.

- Integration:ALTRON seamlessly integrates its systems with existing manufacturing processes, providing comprehensive automation solutions.

- Reliability:With a focus on robust design and rigorous testing, ALTRON ensures the reliability and longevity of its robotic welding systems, minimizing downtime and maximizing productivity.

Conclusion:

ALTRON robotic welding system represents a transformative solution for manufacturers seeking enhanced productivity, safety, and cost efficiency in their welding processes. ALTRON’s expertise and innovation in this field have positioned them as a leading manufacturer of robotic welding systems, offering state-of-the-art solutions to meet the evolving needs of the industry. Embracing the power of robotics in welding opens up a world of possibilities, where precision, speed, and quality converge to revolutionize manufacturing practices.