What is the working principle of CNC spinning machine?

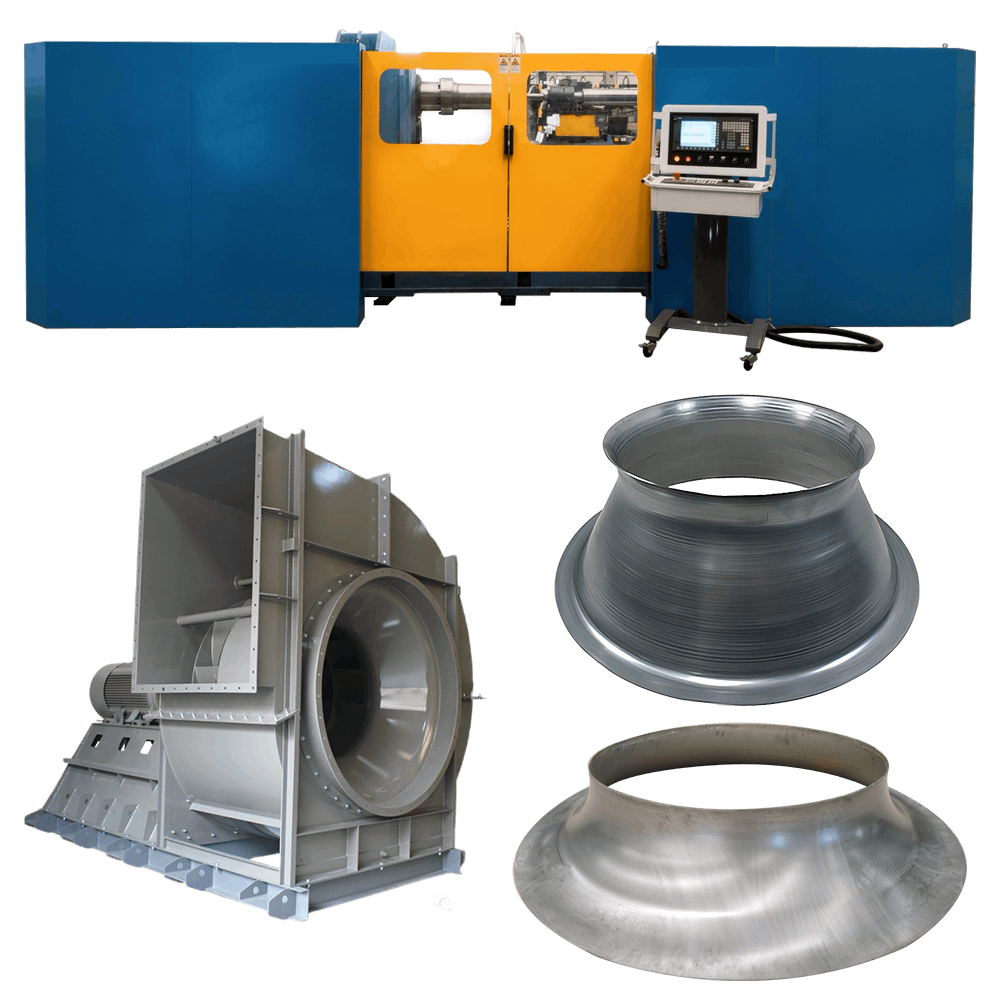

The working principle of CNC metal spinning is similar to pottery craft. The original shape is changed during the spinning process, which is called plastic deformation in metal processing!

CNC spinning has changed the traditional metal deep drawing and stamping processing technology; it greatly reduces the cost of metal forming!

Preparation before metal spinning

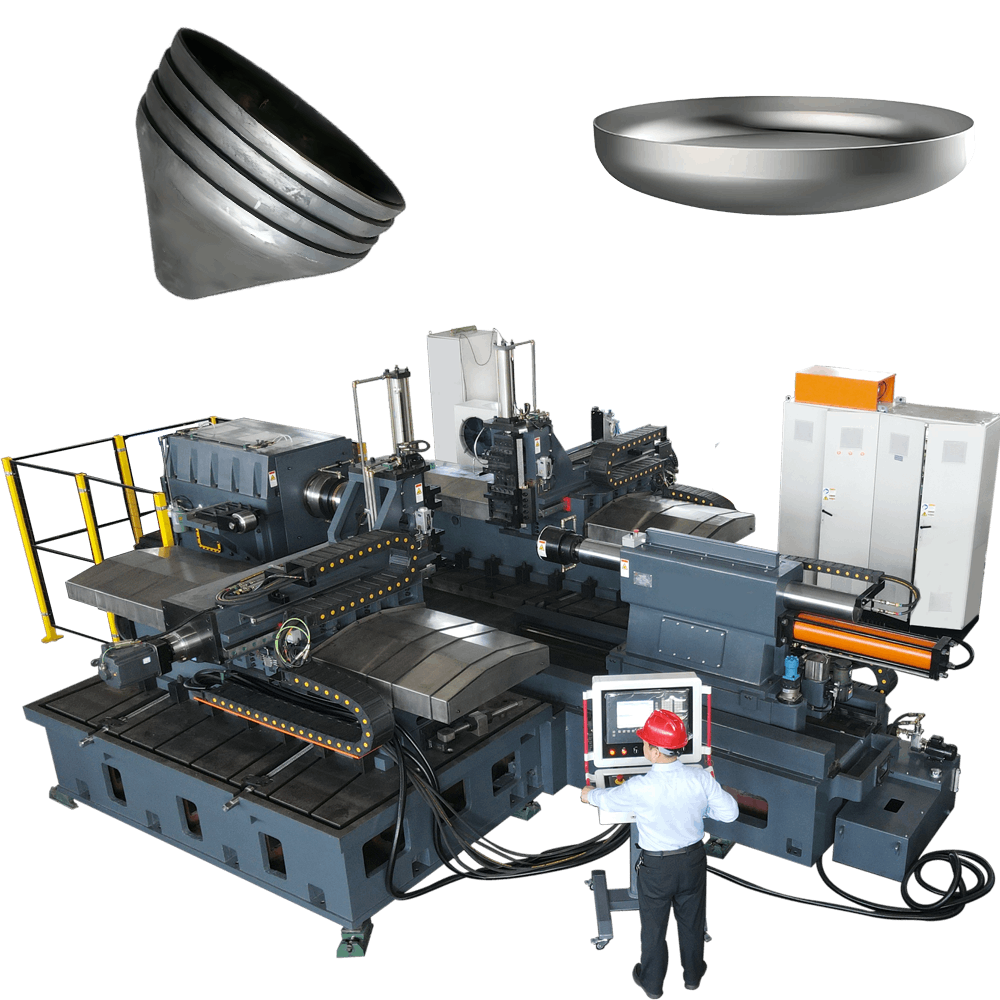

Metal spinning material selection

Metals such as aluminum, stainless steel and copper are commonly used materials. Different materials have unique properties that will affect the spinning process. The thickness and ductility of the metal are relative to each other!

Selection of metal spinning workpieces

Elements of different shapes, sizes, and materials need to be included in the selection of spinning rollers; the direct, contour, and R data of the spinning roller! You must choose the right spinning roller to have a perfect metal forming process!

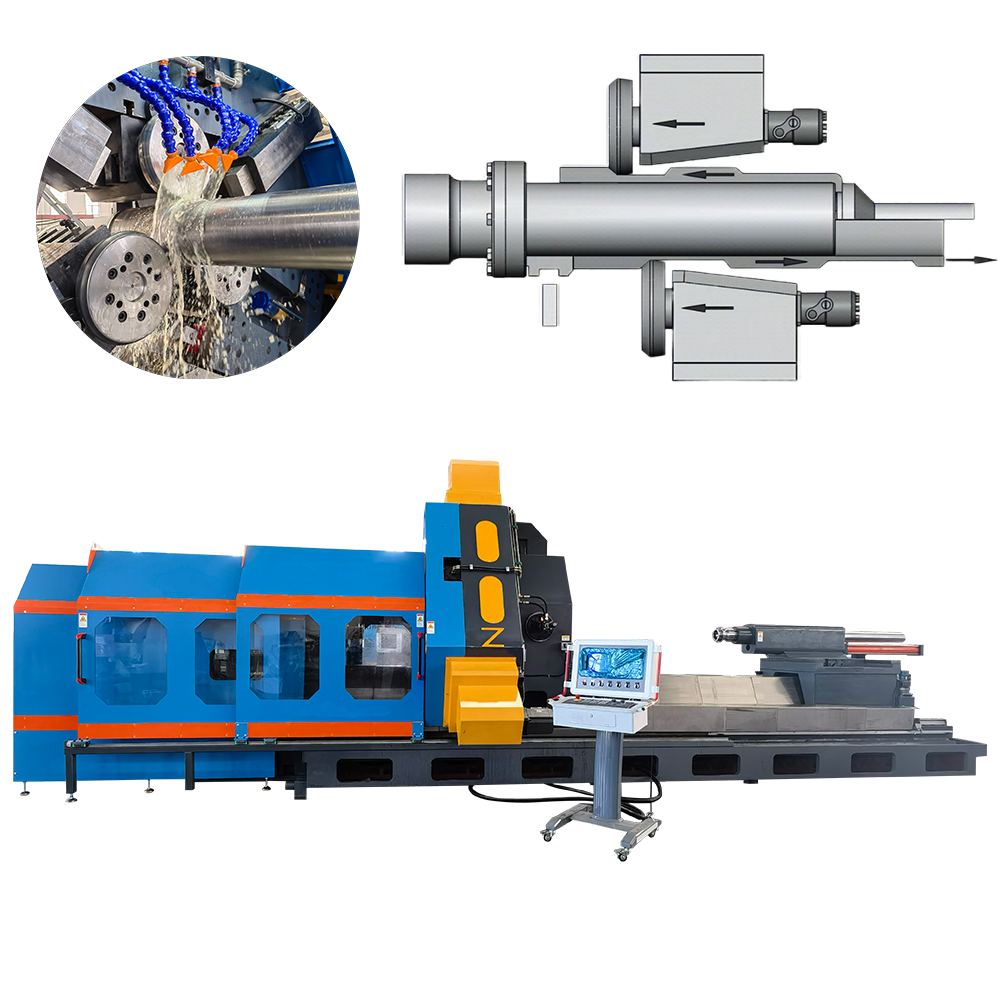

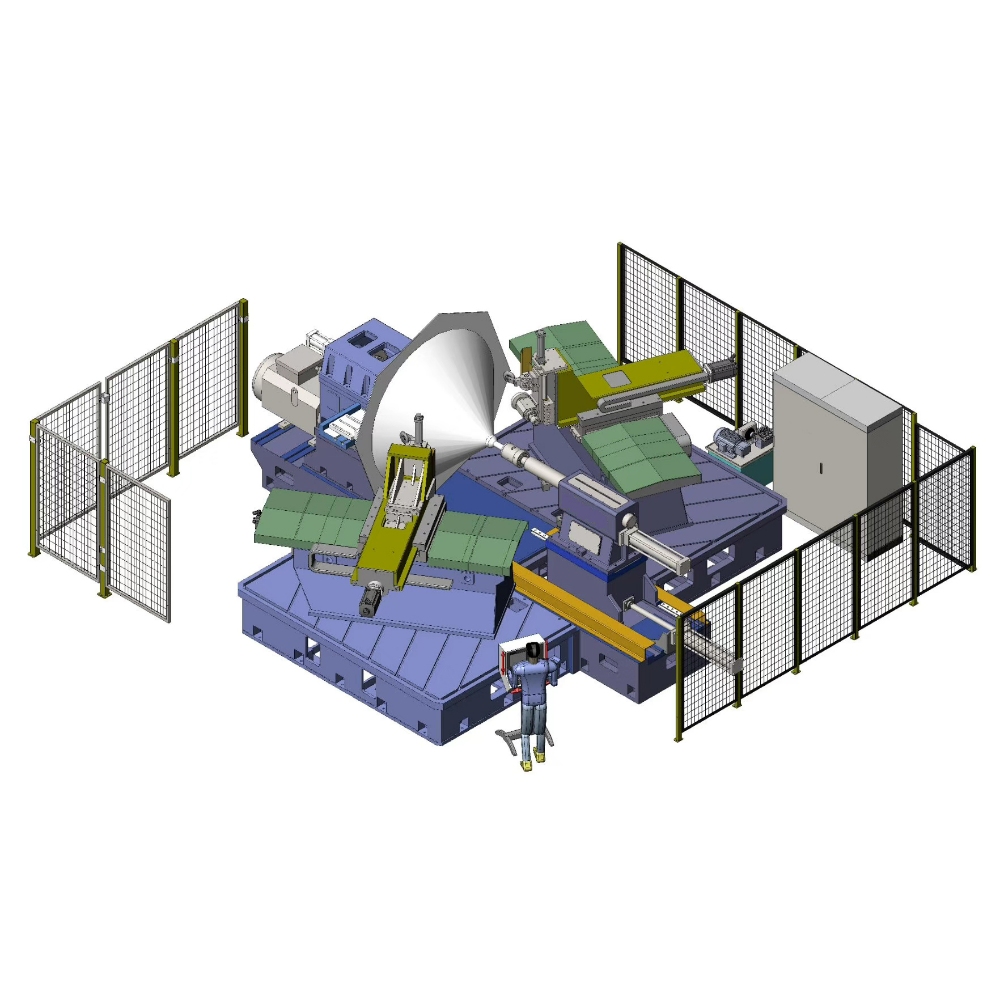

CNC metal spinning machine settings

The coordinate setting of the CNC spinning machine, the machine must accurately calibrate the machine tool coordinate value or the absolute coordinate value! To ensure the accuracy of metal spinning process, the runout of spinning roller and mold installed on the machine and the mold contour accuracy must be guaranteed. The finishing of the mold can also be completed by the spinning machine, so that the runout of repeated installation of the mold is better.

CNC metal spinning machine programming

Programming is the core of the technology, and the entire forming process is determined by forming.

CNC metal spinning programming steps: draw a trajectory diagram, set different speeds S and feed speeds F, export the program code by automatic programming software, and use computer software to simulate the spinning motion trajectory!

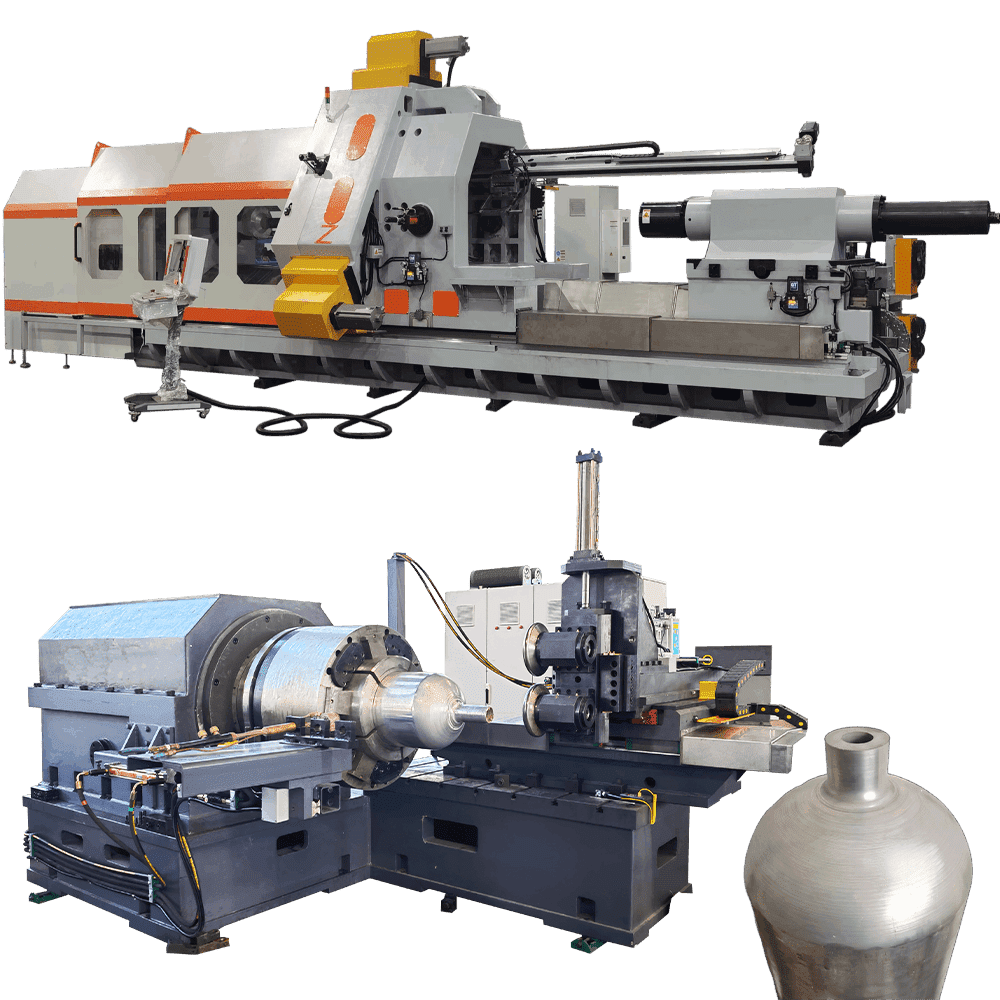

Before the metal spinning test, it must be simulated in the CNC metal spinning machine

CNC metal spinning test process

The metal blank is clamped on the mandrel, and the CNC program code is entered to let the tail head tighten the metal blank!

The CNCmetal spinning machine starts, starts running the spinning program, and the mandrel starts to rotate at high speed. The speed and feed speed are controlled by the programming instructions. When the speed mismatch is found, the magnification can be used to adjust.

CNC metal spinning detection and adjustment process

After the spinning program is completed, check the dimensional accuracy and surface texture of the parts! Adjust the gap between the spinning roller and the die, the proportion of the spinning speed, and the addition of auxiliary turning, beading and other functional instructions according to the actual situation! Achieve the ideal forming effect and a program that can be produced continuously.

Remove the metal parts from the mandrel after cooling, especially the process of heated spinning!

Report and record after metal spinning is completed

After completing the metal spinning forming, a complete archive record must be made, including the model of the machine, the name and archive of the program, the percentage of the speed and feed speed, the data of the raw material blank, etc.

This is to prepare for the next batch production! Able to quickly restore the spinning process and production status!

The core key of CNC metal spinning

Understand the performance and processing capacity range of CNC metal spinning machines, the parameters of different metal materials, the experience of adjusting and modifying the program of the metal forming process, etc.

The working principle and operation method of CNC metal spinning

Tool preparation, process selection and operation, technical requirements and quality inspection are the core points of CNC metal spinning, and each step must be treated with caution.

Proper training of engineers, selection of materials and tools, and quality and performance of machines are key elements for successful CNC metal spinning. Choosing Altron CNC Metal Spinning provides technical guarantee for metal forming.